Method for measuring particle diameter and concentration based on ultrasonic pulsation principle

A technology of particle size and principle, applied in particle and sedimentation analysis, measuring device, particle size analysis, etc., can solve problems such as attenuation of transmitted sound wave intensity, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

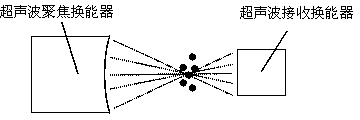

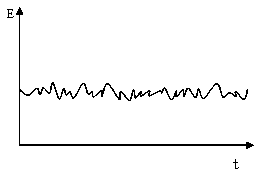

[0018] The method for measuring particle size and concentration based on the principle of ultrasonic pulsation in the present invention utilizes changes in ultrasonic pulsation signals to accurately measure particle concentration. The basic principle of ultrasonic signal pulsation method measurement, such as figure 1 As shown, using the incident ultrasonic E 0 , due to the scattering and absorption of the granular medium, its transmitted ultrasonic intensity E ( t ) will attenuate. When the ratio of the particle size to the diameter of the ultrasonic focused beam is controlled within the range of 0.1-20, the number and size of particles in the measurement area change with time, and the transmitted ultrasonic intensity E ( t ) also pulsates with time. The random pulsation of this ultrasonic signal is related to the size and number of particles in the ultrasonic focused beam measurement area at the moment of measurement. The transmitted ultrasonic intensity is measured E ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com