Large-caliber high-gradient optical mirror surface on-line measuring system

A technology of optical mirror surface and measurement system, which is applied in the field of optical mirror surface online detection system to achieve the effect of small light-emitting area, high brightness, and in-situ/on-line detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

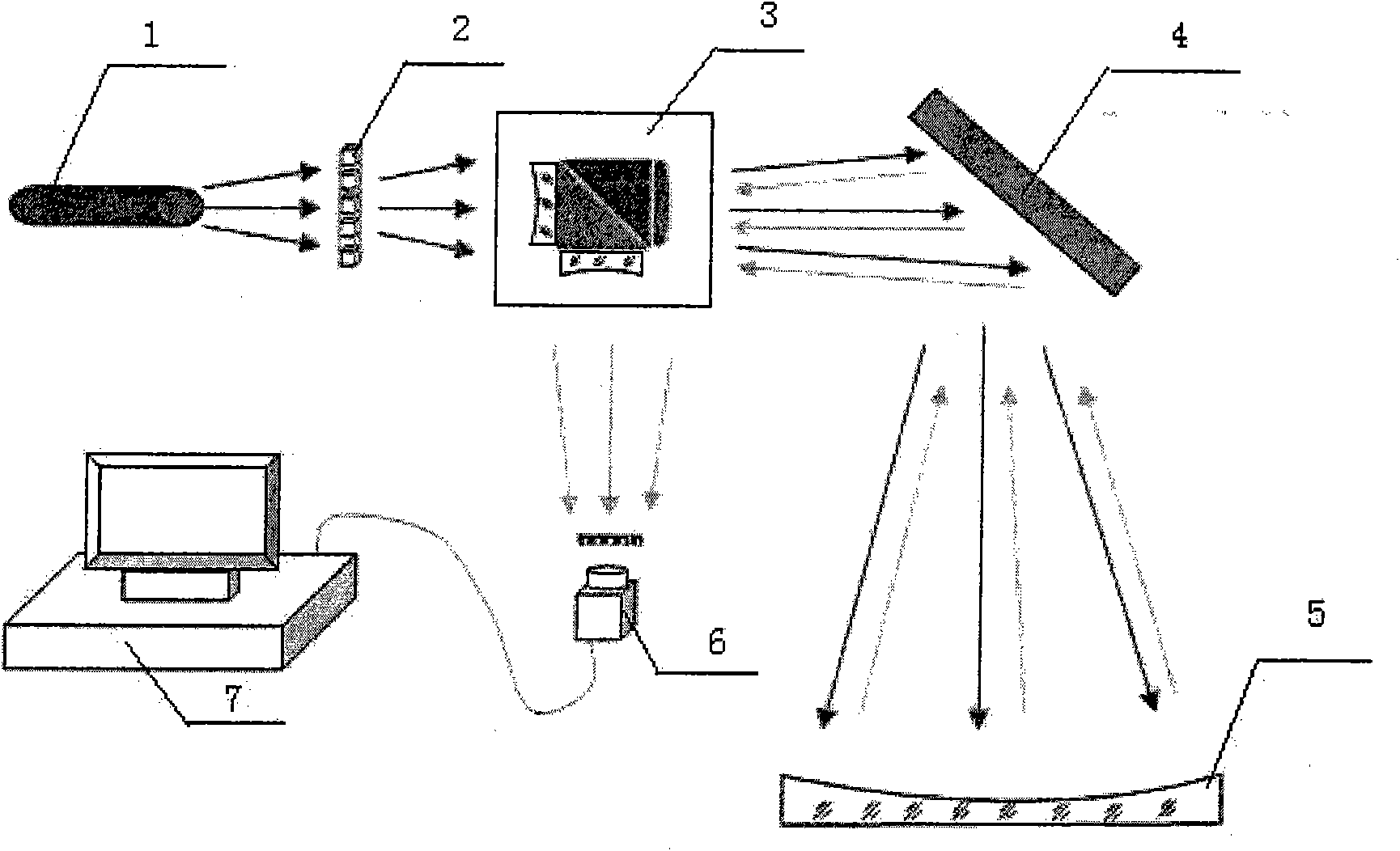

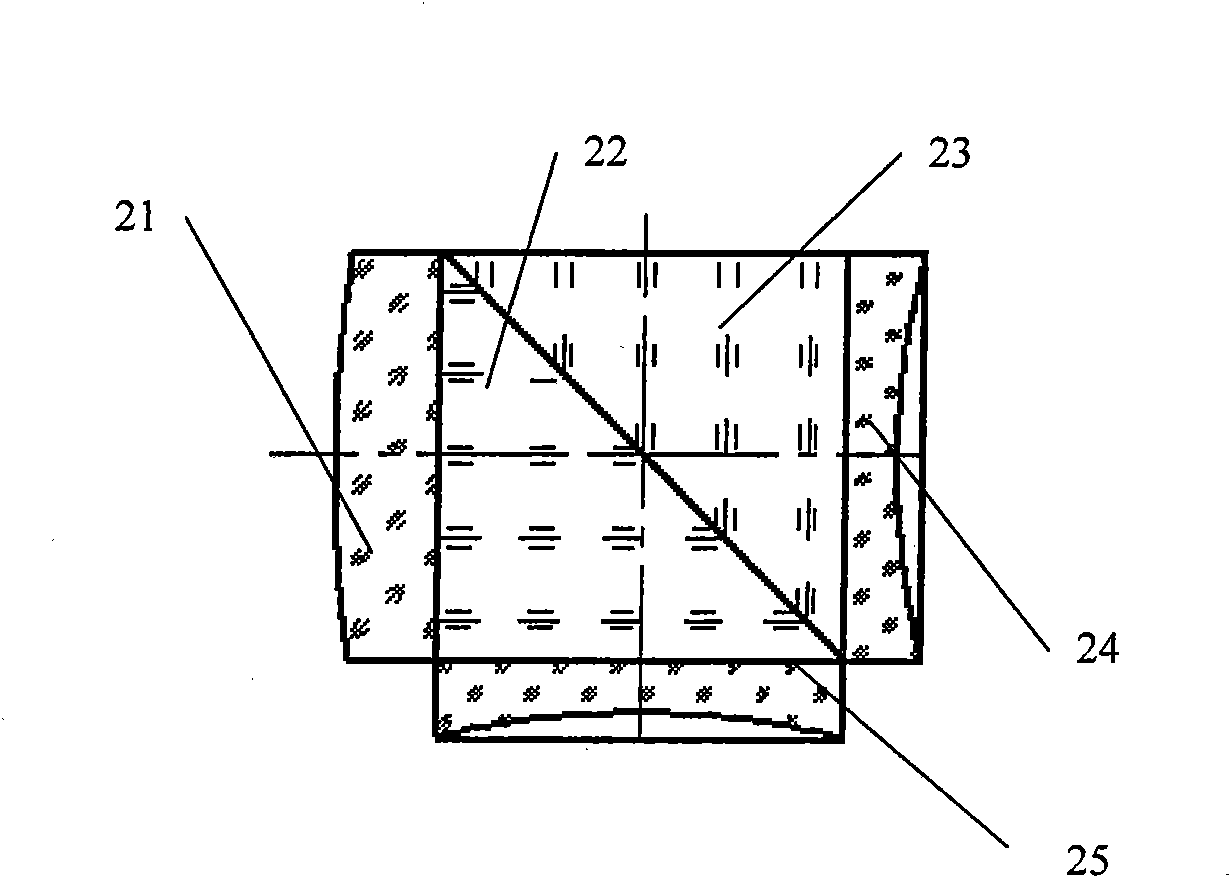

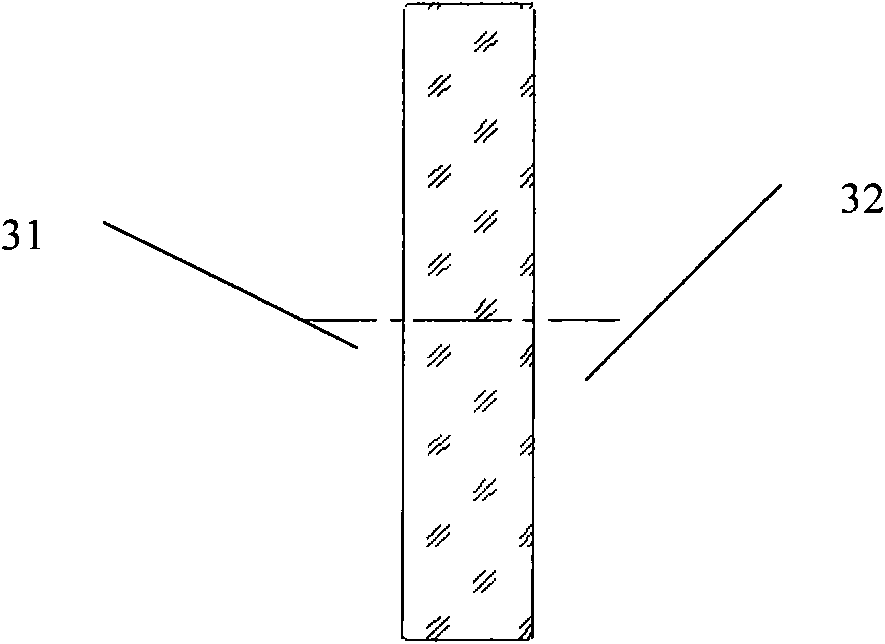

[0034] Such as figure 1 As shown, the present invention consists of a fiber optic light source 1, a replaceable measuring grating 2, a converging optical path spectroscopic system 3, a plane mirror 4, an optical mirror 5, a digital color CCD 6, and a computer information processing system 7. The fiber optic light source 1 adopts a large numerical aperture, That is, the fiber optic light source with a numerical aperture greater than 0.22, the plane reflector 4 adopts high precision, that is, the plane reflector whose surface PV value is less than one-tenth of the wavelength, and the optical mirror 5 adopts a large-diameter and high-steep optical mirror, that is, under normal circumstances , whose aperture is greater than 1000mm, and the relative aperture is greater than 1 / 2 of the optical mirror; the light emitted from the fiber optic light source 1 passes the shadow of the replaceable measuring grating 2 through the converging optical path splitting system 3, and is reflected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com