Method and device for testing accelerated degradation of friction moment of ball screw pair

A technology of accelerated degradation test and ball screw pair, applied in the direction of machine gear/transmission mechanism test, etc., to achieve the effect of convenient operation, reduced test cost, and shortened test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

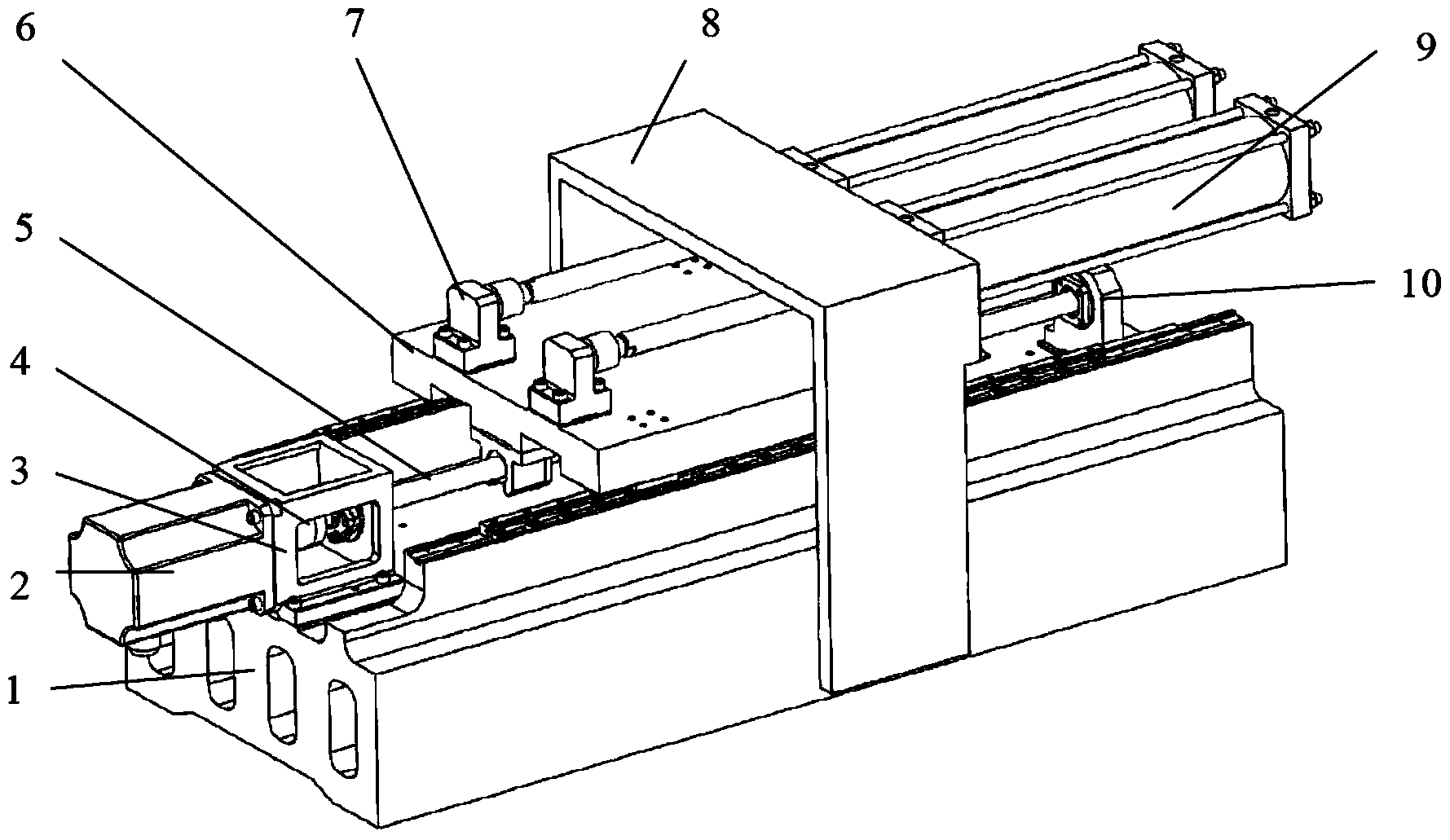

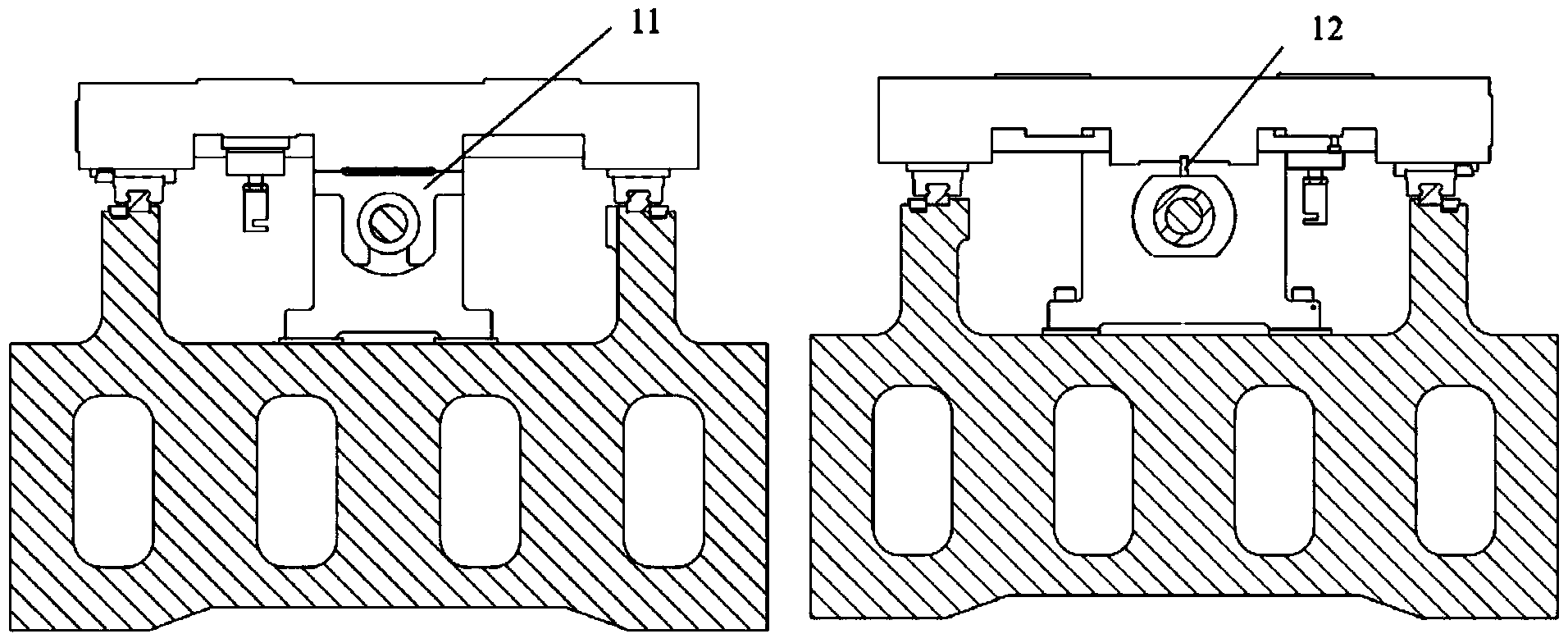

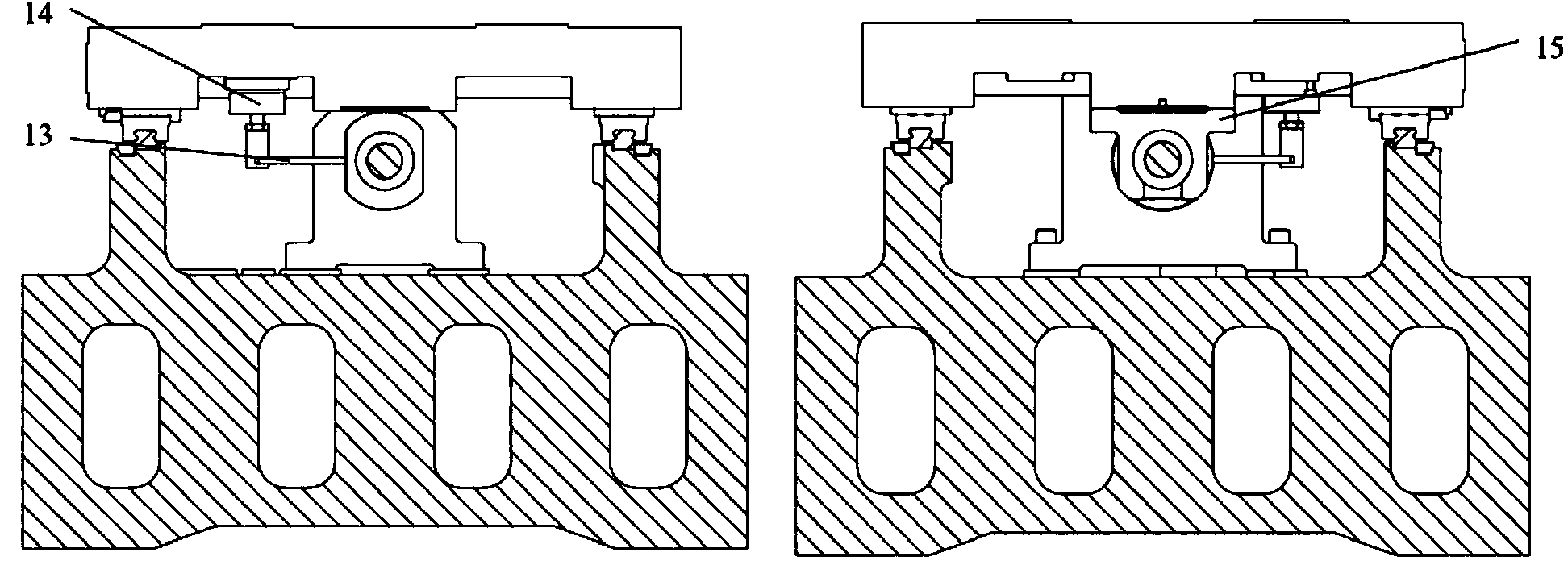

[0021] Device of the present invention and test method are described in conjunction with accompanying drawing, as figure 2 The figure shows that in the test state, the ball screw pair (5) drives the slide plate (6) to reciprocate through the main nut, the main nut seat is fastened on the slide plate (6), the auxiliary nut seat (15) is removed, and the auxiliary nut is The position rod (12) limits its rotation, and one end of the limit rod (12) is fastened on the secondary nut flange, and one end is stuck in the limit groove of the slide plate (6). The loading cylinder (9) is installed on the loading bracket (8) to load the slide plate (6), and the loading bracket (8) is fastened on the base (1).

[0022] Such as image 3 The figure shows that in the measurement state, the ball screw pair (5) drives the slide plate (6) to reciprocate through the auxiliary nut, the auxiliary nut seat (15) is fastened on the slide plate (6), and the main nut seat (11) is removed, the main nut s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com