Forming method of stress semiconductor groove

A semiconductor and channel technology, applied in the formation of strained semiconductor channels, can solve the problems of difficult to control etching depth, loss of strained Si coating, relaxation of strained Si coating, etc., to avoid loss of semiconductor layer and reduce processing Steps, Effects of Controlling Etching Depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] One or more aspects of embodiments of the invention are described below with reference to the drawings, wherein like reference numerals generally refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more aspects of the embodiments of the invention. It may be apparent, however, to one skilled in the art that one or more aspects of the embodiments of the invention may be practiced with a lesser degree of these specific details.

[0027] In addition, although a particular feature or aspect of an embodiment is disclosed in terms of only one of some implementations, such feature or aspect may be combined with other implementations that may be desirable and advantageous for any given or particular application. One or more other features or aspects of .

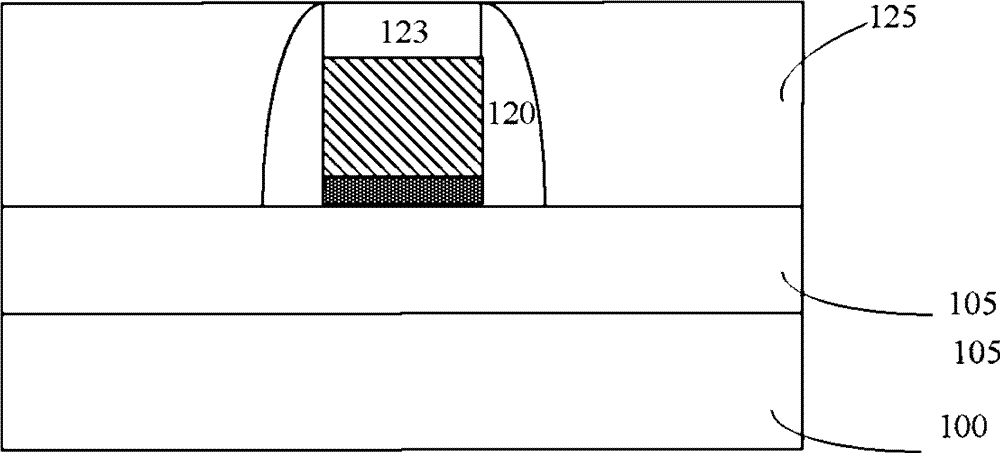

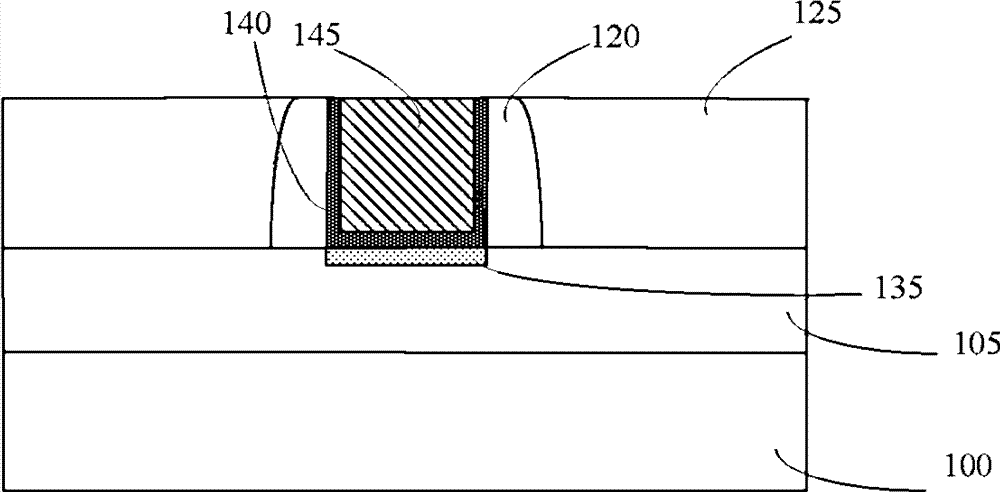

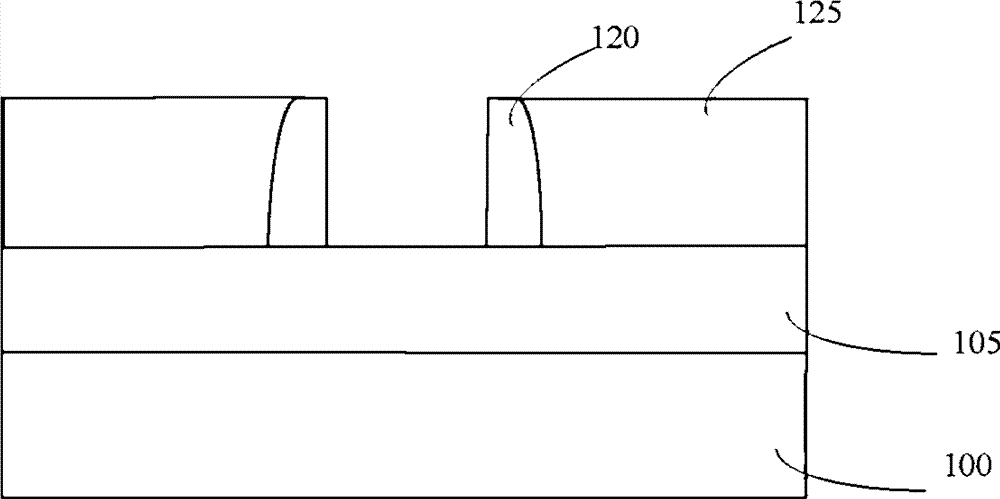

[0028] First, a relaxed layer 105 is formed on a substrate 100 (such as Si, silicon-on-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com