3D pattern printing method

A printing method and pattern technology, applied in the printing field, can solve problems such as local production difficulties, high reject rate, and difficulty in folding and forming lenticular sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

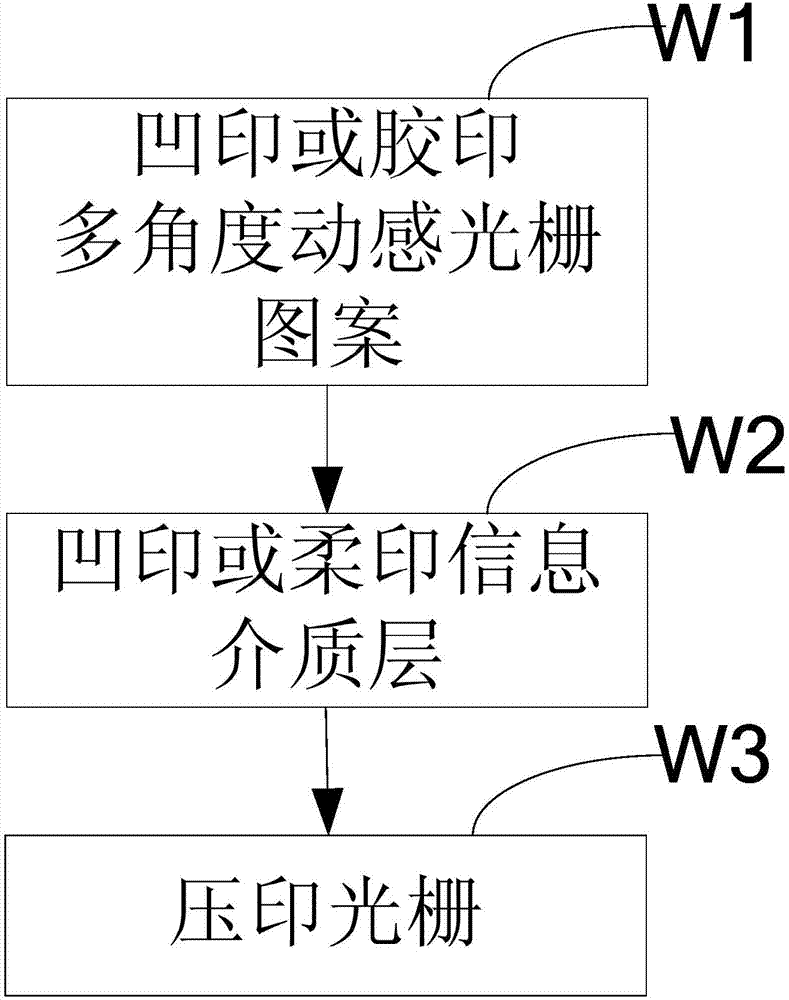

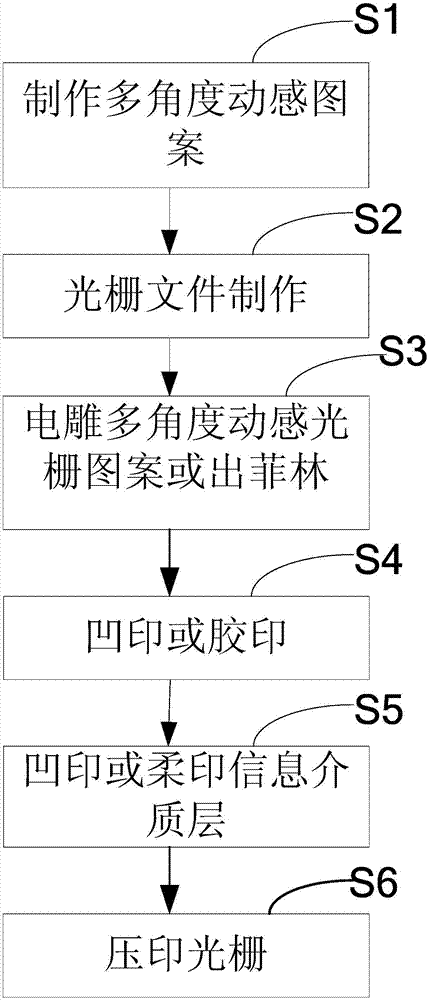

[0046] like figure 1 As shown, the invention discloses a printing method of a 3D pattern, comprising the following steps:

[0047] Step W1: making a multi-angle motion grating pattern;

[0048] Step W2: gravure printing or flexo printing the information medium layer;

[0049] Step W3: Embossing the grating.

[0050] In step W2, the information medium layer is printed on the surface of the printed matter, the curing degree of the information medium layer is controlled by controlling the energy of the ultraviolet lamp, and the hardness of the information medium layer is controlled by controlling the curing degree of the information medium layer.

[0051] In step W2, the drying degree of the information medium layer is 35-40%, specifically manifested as a surface conjunctiva, and the entity remains flexible and plastic.

[0052] In step W3, the following steps are included:

[0053] Q1. Before embossing, lay a layer of information medium on the full version or partially;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Engraving depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com