In-mold film with 2D or 3D pattern

An inner film and pattern technology, which is applied in the field of in-mold films, can solve the problems of grating material or ink heat-melt deformation, pasting of patterns, failure to meet mass production and high quality, etc., to achieve outstanding recognition effect, meet refinement and sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features and advantages of the present invention will be described in detail below with reference to the accompanying drawings.

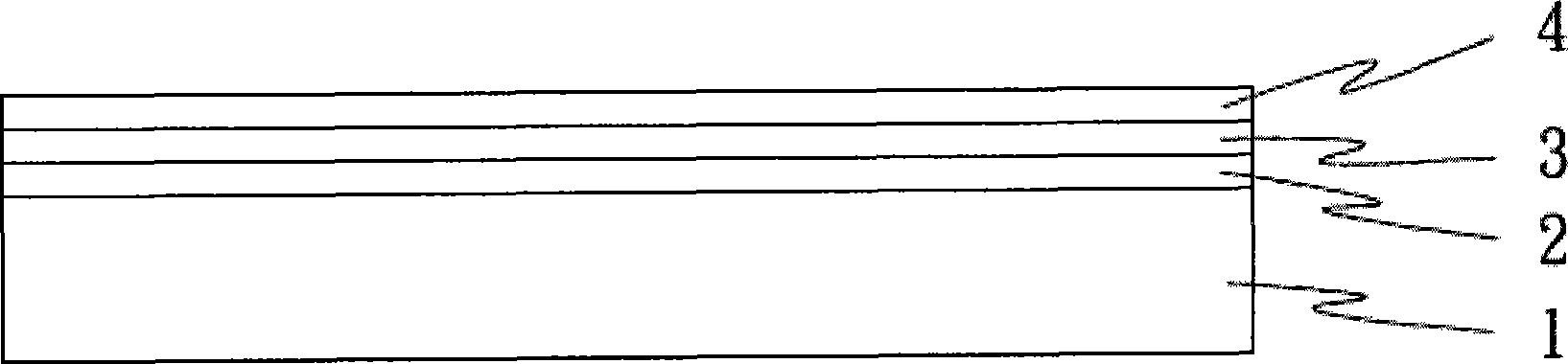

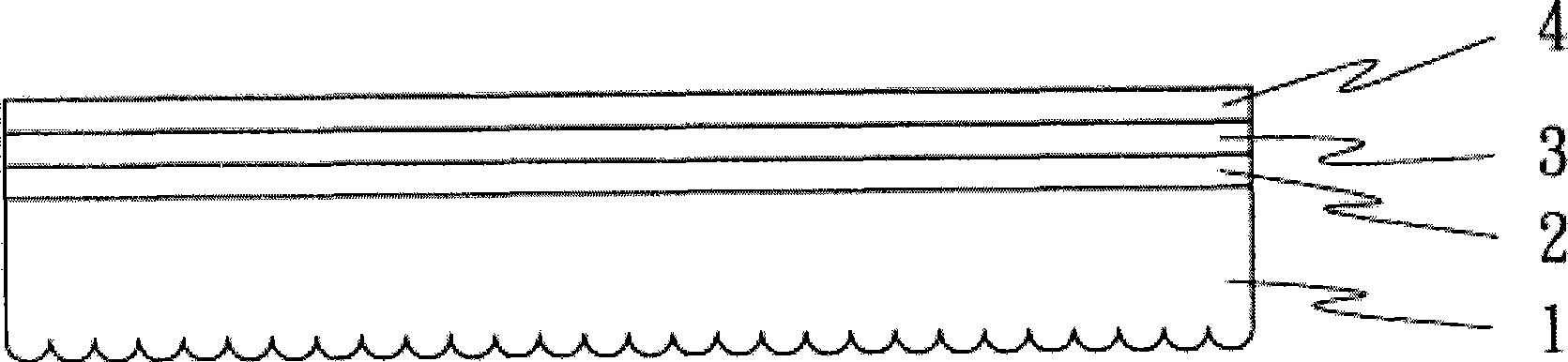

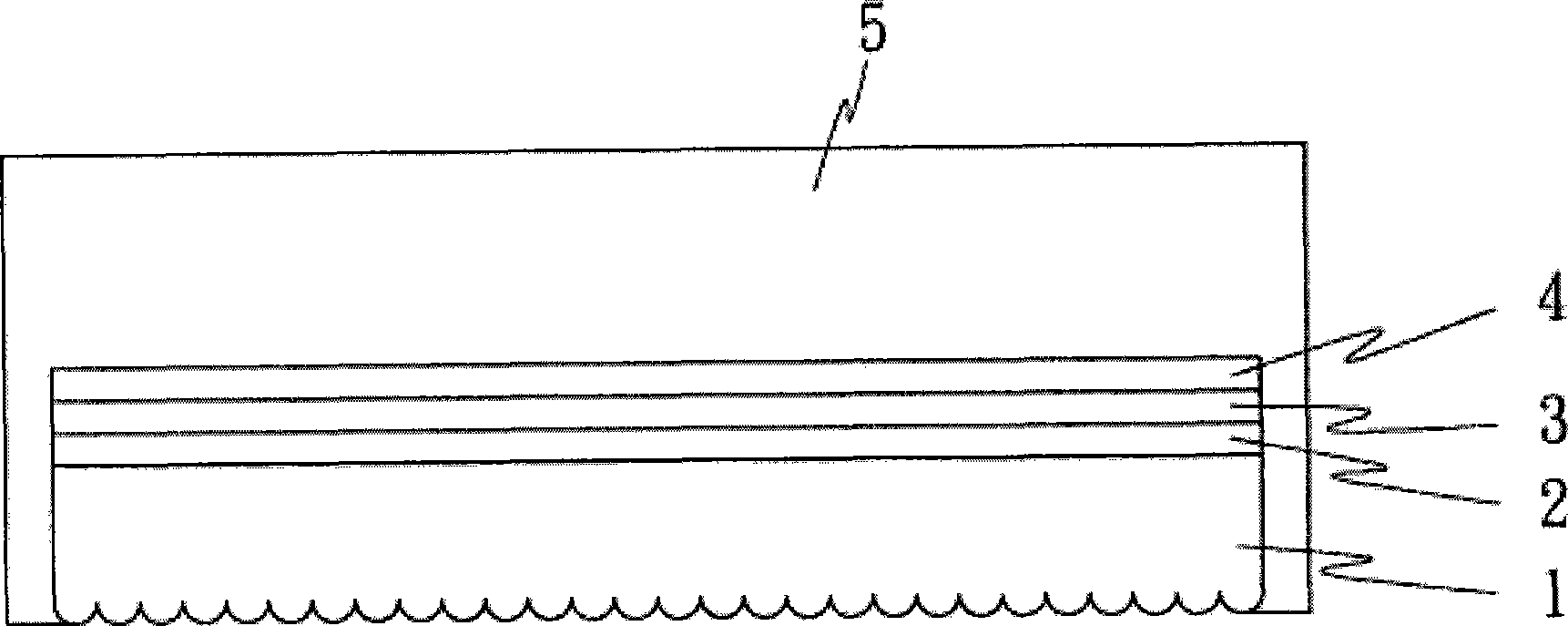

[0020] Such as figure 1 or figure 2 As shown, the in-mold film with 2D / 3D patterns provided by the present invention includes a substrate layer 1, a pattern layer 2, a protective layer 3 and an adhesive layer 4, wherein:

[0021] The substrate layer 1 is made of one or more composite materials in resin materials such as PET, PI, PP, PS, PU, PMMA, PC, PBT, ABS or Nylon, and the substrate layer 1 can be as a visual panel (such as figure 1 ) or a grating surface (such as figure 2 ), the use of a vision board is suitable for printing a mirrored 2D pattern, while the use of a grating board is suitable for printing a mirrored 3D pattern (the following embodiment diagrams are all illustrated with the implementation of the grating board).

[0022] The pattern layer 2 is made of one or more composite materials of resin materials such as PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com