Titanium dioxide/polyaniline photocatalyst with 3D pattern structure and preparation method of titanium dioxide/polyaniline photocatalyst

A titanium dioxide and polyaniline light technology, which is applied in the field of photocatalyst preparation, can solve the problems of complex operation, secondary pollution and high cost in the semiconductor compounding process, and achieve the effects of improving light energy conversion efficiency, saving energy and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

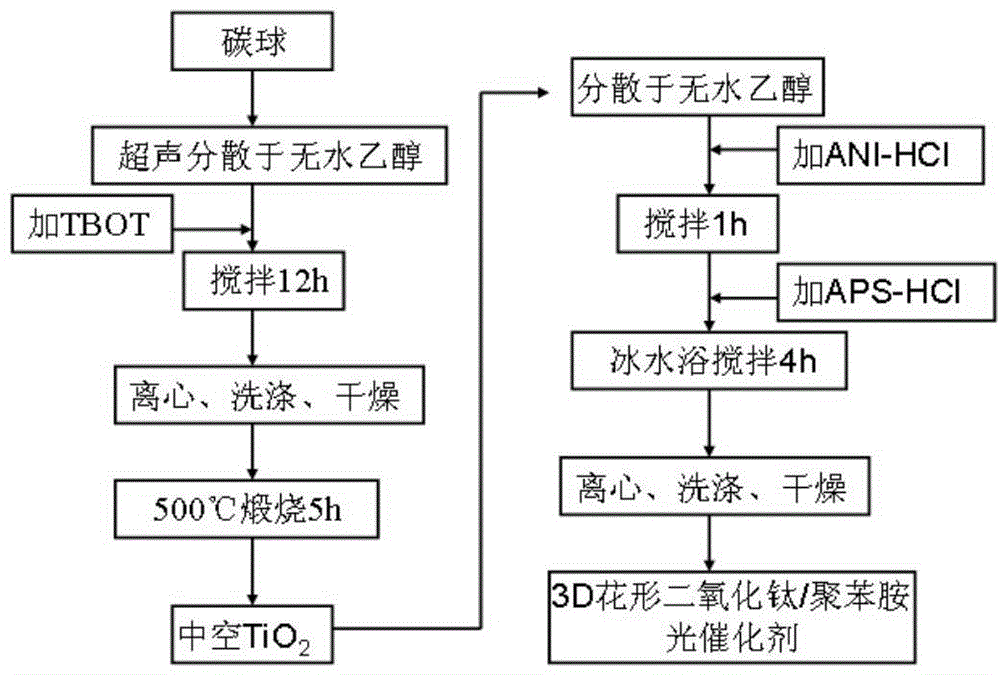

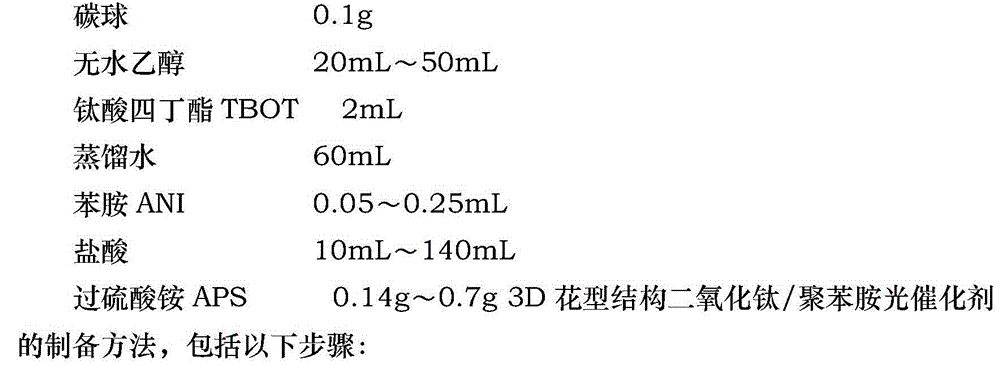

[0034] The preparation method of 3D flower structure titanium dioxide / polyaniline photocatalyst comprises the following steps:

[0035] A. Disperse under ultrasonic conditions for 30 minutes according to the dispersion ratio of carbon spheres 0.1gC / 50mL absolute ethanol to obtain A solution;

[0036] B. Add tetrabutyl tertanoate TBOT into solution A according to the mass ratio of 0.1gC / 2mLTBOT, and stir magnetically for 1 hour to obtain solution B;

[0037] C. According to the volume ratio of 50mL alcohol / 60mL water, add distilled water dropwise to B at a rate of 60 drops / min, then stir at room temperature for 12 hours to obtain C solution;

[0038] D. Centrifuge the C solution at a speed of 7000-7300r / min for 6 minutes, wash with distilled water and then ethanol, repeat the washing and separation for 3 times, and dry at 70°C-80°C for 12h to obtain brown powder D;

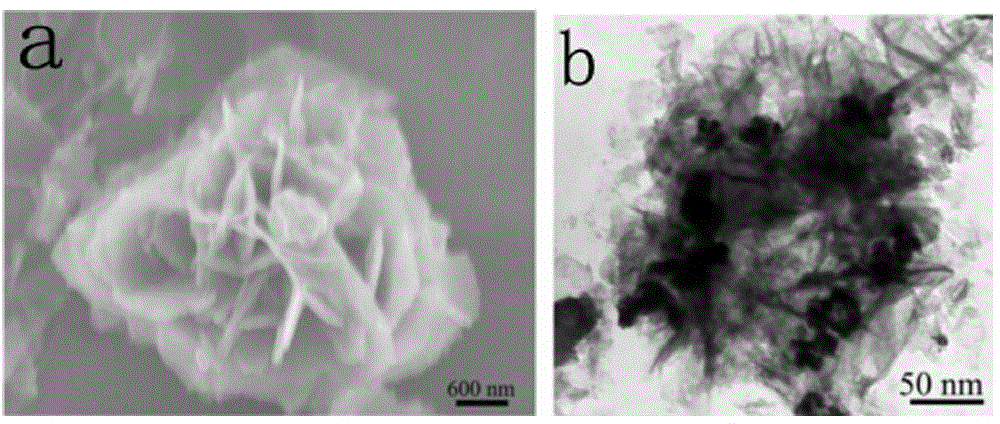

[0039] E. Calcining powder D at 500°C for 5 hours to obtain white hollow titanium dioxide nanoparticles HT-500;...

Embodiment 1

[0047] A. Take 0.1g of carbon spheres, disperse in 50mL of absolute ethanol solution, and disperse under ultrasonic conditions for 30min, to obtain A solution;

[0048] B. Take 2mL of tetrabutyl TBOT and add it into the A solution, and stir it magnetically for 1 hour to obtain the B solution;

[0049] C. Add 60 mL of distilled water dropwise to solution B at a rate of 60 drops / min, then stir at room temperature for 12 hours to obtain solution C;

[0050] D. Centrifuge the C solution at a speed of 7000r / min for 6min, wash and separate it three times with distilled water and ethanol, and dry it at 70°C to obtain a brown powder D;

[0051] E. Calcining powder D at 500°C for 5 hours to obtain white hollow titanium dioxide nanoparticles HT-500;

[0052] F. Weigh 0.05g HT-500 and disperse it in 20mL absolute ethanol, and disperse it under ultrasonic conditions for 30min to obtain solution E;

[0053] G. Measure 0.05mL ANI and disperse it into 10mL HCl (1mol / L), stir magnetically f...

Embodiment 2

[0060] A. Take 0.1g of carbon spheres, disperse in 50mL of absolute ethanol solution, and disperse under ultrasonic conditions for 30min, to obtain A solution;

[0061] B. Take 2mLTBOT and add it to the A solution, and stir it magnetically for 1 hour to obtain the B solution;

[0062] C. Add 60 mL of distilled water dropwise to solution B at a rate of 60 drops / min, then stir at room temperature for 12 hours to obtain solution C;

[0063] D. The C solution was centrifuged at a speed of 7100r / min for 6min, washed and separated with distilled water and ethanol repeatedly for 3 times, and dried at 75°C to obtain a brown powder D;

[0064] E. Calcining powder D at 500°C for 5 hours to obtain white hollow titanium dioxide nanoparticles HT-500;

[0065] F. Weigh 0.1g HT-500 and disperse in 40mL of absolute ethanol, and disperse under ultrasonic conditions for 30min to obtain solution E;

[0066] G. Measure 0.05mL ANI and disperse it into 10mL HCl (1mol / L), stir magnetically for 1h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com