Preparation method of one-component oxime transparent silicone adhesive

A single-component, silicone adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of unsatisfactory appearance, insufficient shear force, increased energy consumption, etc. Reduced pass rate, reduced construction time, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

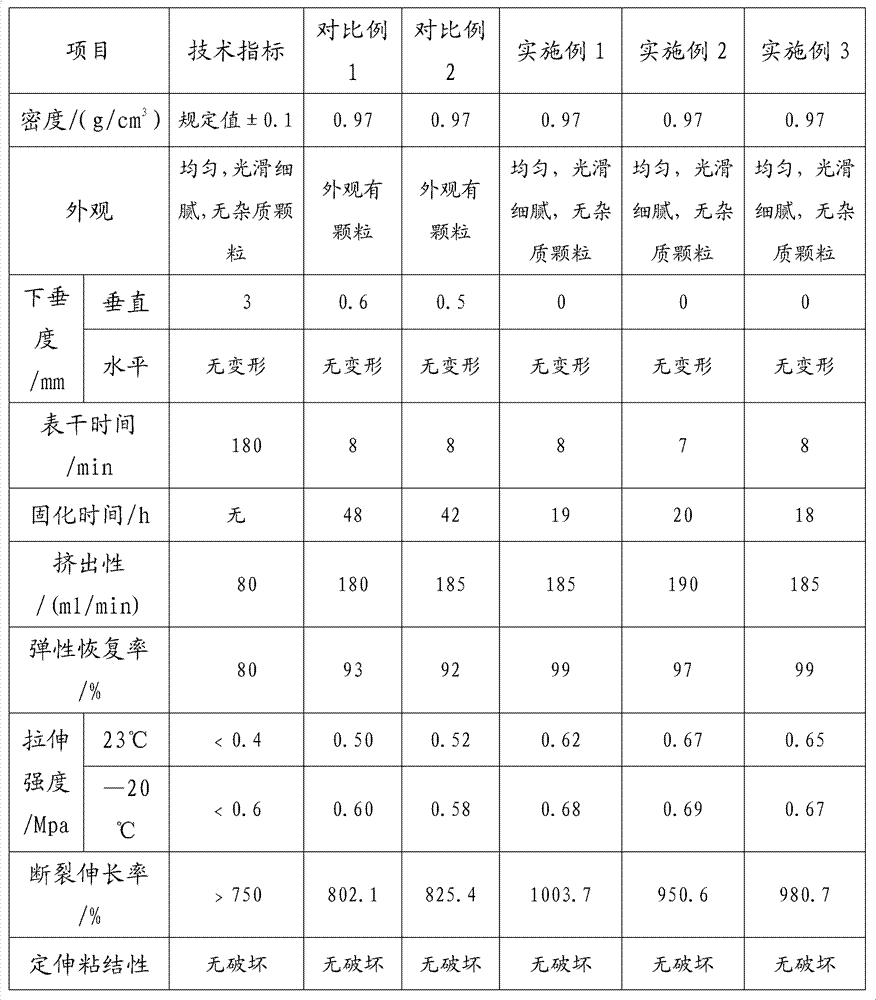

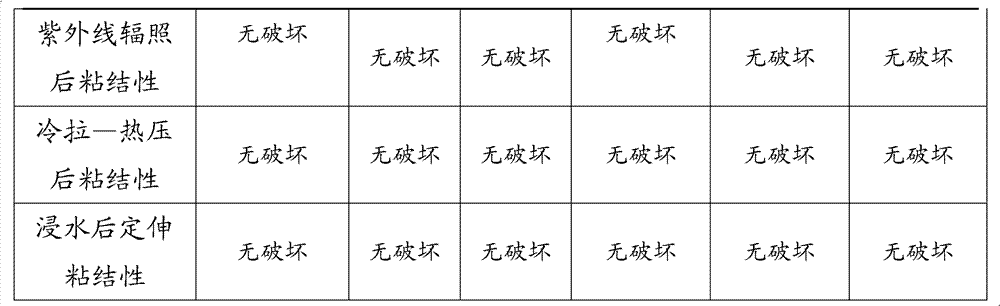

Examples

Embodiment 1

[0048] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0049] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 60 parts of white oil (accounting for 76.9% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 10°C, and vacuumize to -0.1MPa;

[0050] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum degree at -0.1MPa during the stirring process;

[0051] (3) Nitrogen was released to remove the vacuum, and 1.5 parts of γ-(2,3-glycidyloxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate were added, and stirred at a speed of 300 rpm for 10 minutes. Keep the vacuum at -0.1MPa; ...

Embodiment 2

[0055] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0056] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 50.4 parts of white oil (accounting for 80% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 20°C, and vacuumize to -0.09MPa;

[0057] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum at -0.09MPa during the stirring process;

[0058] (3) Nitrogen was released to remove the vacuum, and 1.5 parts of γ-(2,3-glycidyloxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate were added, and stirred at a speed of 300 rpm for 10 minutes. Keep the vacuum at -0.09MPa;

[...

Embodiment 3

[0062] A preparation method of a one-component ketoxime transparent silicone adhesive, comprising the following steps:

[0063] (1) Put 100 parts of 80000 centipoise α, ω-dihydroxy polydimethylsiloxane and 48 parts of white oil (accounting for 70% of the required amount of white oil) and 0.04 parts of color paste into the 1000L high-speed dispersion planet Mixer, stirring at a speed of 300 rpm for 10 minutes, while passing cooling water into the jacket of the planetary mixer, the temperature of the cooling water is 30°C, and vacuumize to -0.08MPa;

[0064] (2) Add 15 parts of cross-linking agent by blowing nitrogen to release the vacuum, stir at 300 rpm for 10 minutes, and keep the vacuum at -0.08MPa during the stirring process;

[0065] (3) Add 1.5 parts of γ-(2,3-glycidyloxypropoxy)propyltriethoxysilane and 0.15 parts of dibutyltin dilaurate to release the vacuum by blowing nitrogen gas, and stir at 300 rpm for 10 minutes. Keep the vacuum at -0.08MPa;

[0066] (4) Add 21 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com