Polygon box body molding bonding machine and box body molding method using the same

A technology of polygonal and bonding machines, which is applied in the direction of container manufacturing machinery, box making operations, and rigid/semi-rigid container manufacturing. The effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

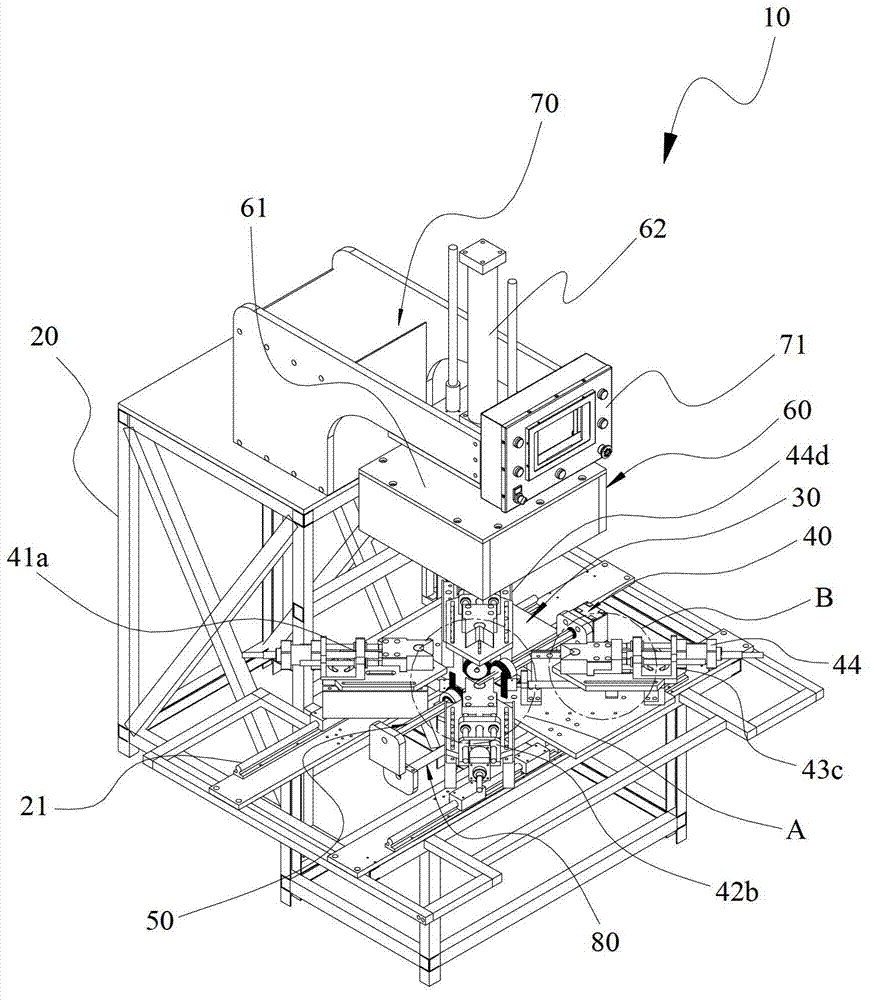

[0037] see figure 1 As shown, the present invention provides a polygonal box body forming and bonding machine 10, including a frame 20, a workbench 30, a box body fixture device 40, a synchronous feed mechanism 50, a glue drying device 60 and a control system 70, and the workbench 30 Installed on the frame 20, it is used to place the plate assembled into a polygonal box; the box clamp device 40 includes at least three chuck devices 41, and the at least three chuck devices 41 are arranged in equal parts along the circumference of the working area. platform 30 and it is telescopically clamped on the plate, so that the plate is clamped into a polygonal box structure, wherein the at least three chuck devices 41 are arranged on the workbench 30 at equal intervals along the circumference to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com