Method for preparing silicone sealant

A technology of silicone sealant and base glue, which is applied in the direction of chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of silicone sealants, etc., and achieve increased product stability, good economic benefits and social benefits. Benefits, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

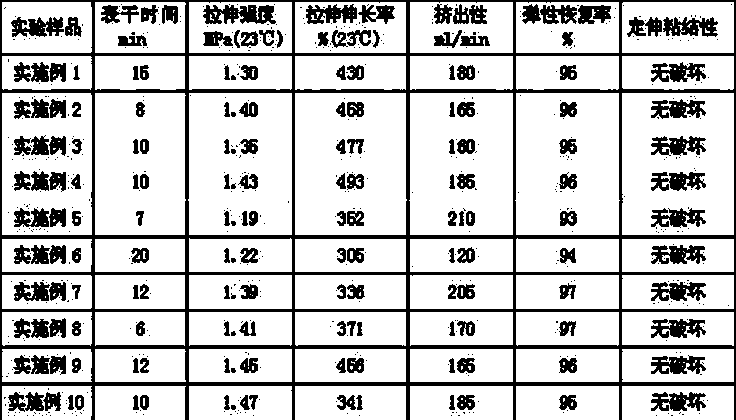

Examples

Embodiment 1

[0033] 100 parts of 50000cP α, ω-dihydroxypolydimethylsiloxane with a specific surface area of 35m 2 120 parts / g of active nano-calcium carbonate, 15 parts of heavy calcium and 4 parts of 8000cP dimethyl silicone oil are added to the vacuum kneader, the temperature of the material is controlled at 75 ° C, the vacuum is -0.1 MPa, and the heating is stopped after mixing for 3 hours. Inject nitrogen to release the vacuum, add 0.1 part of γ-aminopropyltriethoxysilane, and knead for 0.5h to make the base rubber; the base rubber is sealed and cooled to room temperature, then moved into a planetary mixer, and methyl tributylketoxime silane is added in turn 8 parts, 1 part of vinyl tributyl ketoxime silane, 0.5 parts of γ-aminopropyl triethoxysilane and 0.25 parts of γ-(2.3-glycidyloxy) propyl trimethoxysilane, dilauric acid di 0.1 part of butyl tin, vacuumize and stir with the rubber base for 60 minutes, and keep the vacuum at -0.1MPa.

Embodiment 2

[0035] 100 parts of 80000cP α, ω-dihydroxypolydimethylsiloxane with a specific surface area of 30m 2 115 parts / g of active nano-calcium carbonate, 13 parts of heavy calcium and 5 parts of 5000cP dimethyl silicone oil are added to the vacuum kneader, the temperature of the material is controlled at 80 ° C, the vacuum degree is -0.1 MPa, and the heating is stopped after mixing for 3 hours. Inject nitrogen to release the vacuum, add 0.1 part of γ-aminopropyltriethoxysilane, 0.05 part of γ-(2.3-glycidoxy)propyltrimethoxysilane, and mix for 0.5h to make base rubber; the base rubber is sealed After cooling to room temperature, move it into a planetary mixer, add 7 parts of methyl tributyl ketoxime silane, 1 part of vinyl tributyl ketoxime silane, and 0.08 part of dibutyltin dilaurate in turn, and stir with base glue for 60 minutes in a vacuum. The degree is maintained at -0.1MPa.

Embodiment 3

[0037] 100 parts of α, ω-dihydroxy polydimethylsiloxane with 100000cP and a specific surface area of 25m 2 105 parts / g of active nano-calcium carbonate, 11 parts of heavy calcium and 7 parts of 2000cP dimethyl silicone oil were added to the vacuum kneader, the temperature of the material was controlled at 130 ° C, the vacuum degree was -0.1 MPa, and the heating was stopped after mixing for 3 hours. Inject nitrogen to release the vacuum, add 1 part of composite dry silane, and knead for 0.5 hours to make the base rubber; after the base rubber is sealed and cooled to room temperature, move it into a planetary mixer, add 6 parts of methyl tributylketoxime silane, γ-aminopropyl 1.5 parts of base triethoxysilane, 0.12 parts of dibutyltin dilaurate, vacuum-stir with the base rubber for 60min, and keep the vacuum at -0.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com