Antistatic wear-resistant epoxy terrace coating

A technology for floor coatings and wear-resistant rings, applied in the direction of epoxy resin coatings, conductive coatings, polyurea/polyurethane coatings, etc., can solve problems such as easy generation of static electricity, product impact, construction ground quality or color differences, and achieve improvement Wear resistance and antistatic properties, improve film forming and aging resistance, and ensure the safety of human body and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

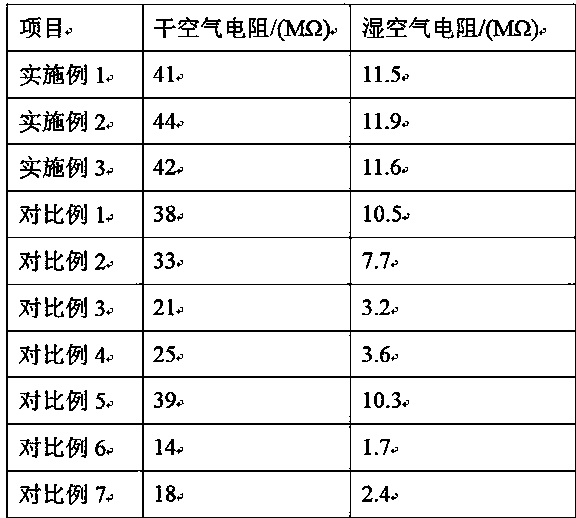

Examples

Embodiment 1

[0017] An antistatic wear-resistant epoxy floor coating, made of the following raw materials in parts by weight: water-based bisphenol A epoxy resin 56, water-based UV resin 42, modified water-based polyurethane 15, calcium lignosulfonate 11, mica powder 7, hydroxypropyl methylcellulose 3, fumed silicon dioxide 1.5, negative ion powder 0.6, nano silver 0.3, water 10.

[0018] The modified water-based polyurethane is to heat the water-based polyurethane to 60°C, add an acrylic emulsion of 6% by weight of the water-based polyurethane, adjust the vacuum degree to -47kPa, stir in vacuum at 66r / min for 20min, continue to increase the temperature to 110°C, and then Add 6% of water-based polyurethane nano-titanium dioxide dispersion and continue vacuum stirring for 35 minutes, which can improve the film-forming and aging resistance of water-based polyurethane, shorten the curing time of epoxy floor, reduce the accumulation of dust, and improve the durability of epoxy floor. Gloss, pr...

Embodiment 2

[0028] An antistatic wear-resistant epoxy floor coating, made of the following raw materials in parts by weight: water-based bisphenol A epoxy resin 57, water-based UV resin 43, modified water-based polyurethane 16, calcium lignosulfonate 12, mica powder 8, hydroxypropyl methylcellulose 3.5, fumed silica 1.6, negative ion powder 0.7, nano silver 0.4, water 10~12.

[0029] The modified water-based polyurethane is to heat the water-based polyurethane to 65°C, add an acrylic emulsion of 7% by weight of the water-based polyurethane, adjust the vacuum degree to -48kPa, stir in vacuum at 68r / min for 25min, continue to increase the temperature to 120°C, and then Adding 7% nano-titanium dioxide dispersion by weight of water-based polyurethane, and continuing vacuum stirring for 40 minutes, can improve the film-forming and aging resistance of water-based polyurethane, shorten the curing time of epoxy floor, reduce the accumulation of dust, and improve the durability of epoxy floor. Glo...

Embodiment 3

[0039] An antistatic wear-resistant epoxy floor coating, made of the following raw materials in parts by weight: water-based bisphenol A epoxy resin 58, water-based UV resin 44, modified water-based polyurethane 17, calcium lignosulfonate 13, mica powder 9, hydroxypropyl methylcellulose 4, fumed silica 1.7, anion powder 0.8, nano silver 0.5, water 12.

[0040] The modified water-based polyurethane is to heat the water-based polyurethane to 70°C, add an acrylic emulsion of 8% by weight of the water-based polyurethane, adjust the vacuum degree to -49kPa, stir in vacuum at 70r / min for 30min, continue to increase the temperature to 130°C, and then Adding 8% nano-titanium dioxide dispersion by weight of water-based polyurethane and continuing vacuum stirring for 45 minutes can improve the film-forming and aging resistance of water-based polyurethane, shorten the curing time of epoxy floor, reduce the accumulation of dust, and improve the durability of epoxy floor. Gloss, prolong th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com