High-definition colorful three-dimensional touch decorative color board and manufacturing method thereof

A color three-dimensional, color plate technology, applied in applications, coatings, inks, etc., can solve the problems of pattern distortion, high cost, and environmental pollution, and achieve the effects of less space, low cost, and high aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

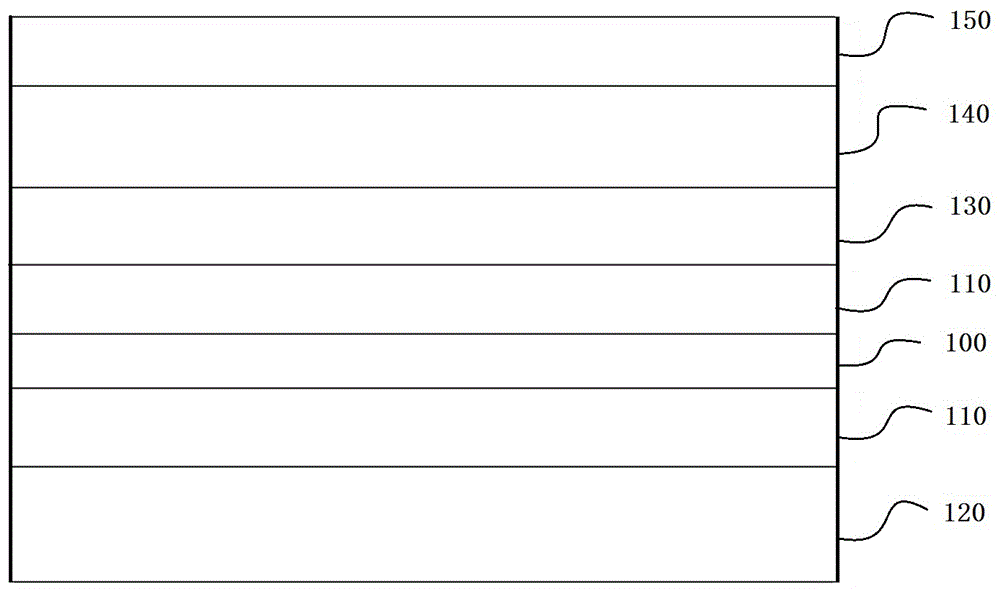

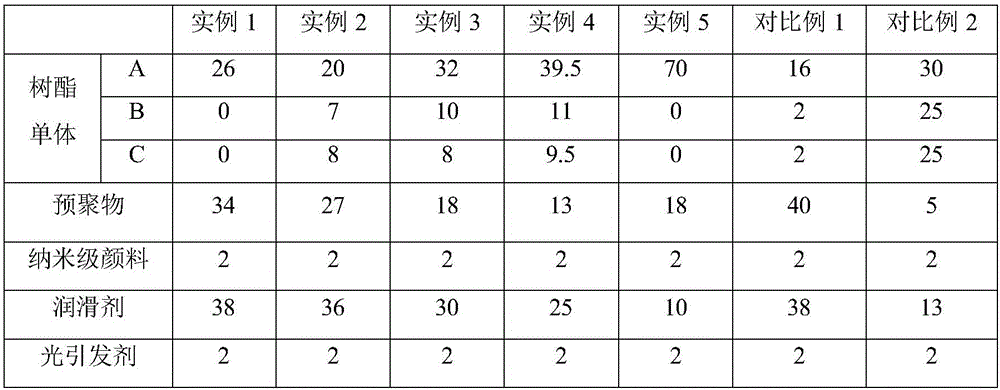

[0046] A high-definition color three-dimensional tactile decorative color plate includes a metal plate base layer 100, a pretreatment layer 110, a primer layer 130, a printing layer 140 and a protective film layer 150 sequentially connected from bottom to top. The formula of the ink that described printing layer adopts is as table 1, and described resin monomer can be polyester acrylate (A), epoxy acrylate (B) or neopentyl glycol polymethyloxyethylene diacrylic acid At least one of ester (C); the prepolymer is polyurethane acrylic acid prepolymer; the photoinitiator is benzaldehyde; the lubricant is cetyl alcohol polar wax. The ink formulations in Examples 1-5 were tested for performance, and the results are shown in Table 2.

[0047] The ink formula that table 1 embodiment 1-5 adopts

[0048]

[0049] The performance test result of ink formula in table 2 embodiment 1-5

[0050] Example 1 Example 2 Example 3 Example 4 Example 5 Comparative example 1 ...

Embodiment 6-10

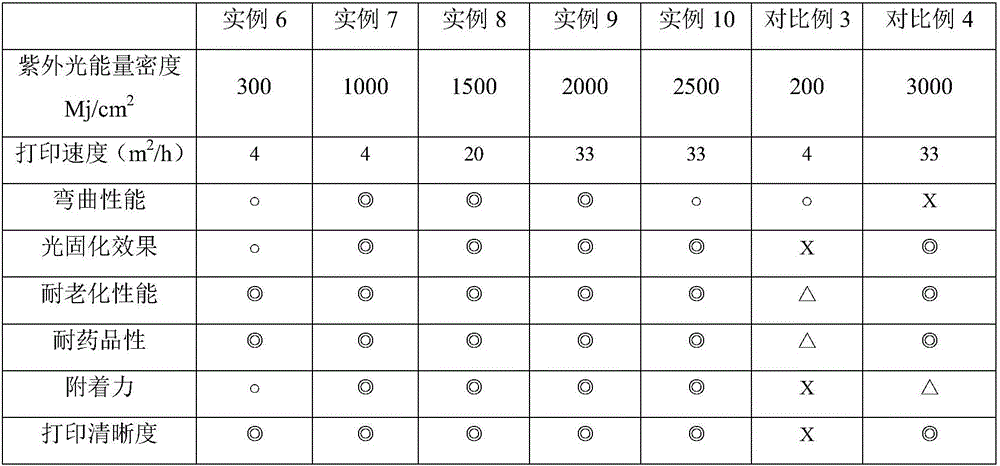

[0073] A high-definition color three-dimensional tactile decorative color plate, including a back paint layer 120, a pre-treatment layer 110, a metal plate base layer 100, a pre-treatment layer 110, a primer layer 130, a printing layer 140 and a protective film layer sequentially connected from bottom to top 150. The formula of the ink that described printing layer adopts is as example 3, and the formula of described primer layer is acrylic resin 40%, butoxy melamine resin 8%, pigment 30%, auxiliary agent 5%, solvent 17%, is weight percent . The printing speed of the printer is 4-33m 2 Under the conditions of different ultraviolet light energy densities, the performance test was carried out, and the results are shown in Table 3.

[0074] Performance test results under different UV energy densities and printing speeds in Examples 6-10 in Table 3

[0075]

[0076] Relative evaluation criteria: ◎Excellent, ○Good, △Normal, X Poor

[0077] Embodiment 6-10 and comparative exa...

Embodiment 11-12

[0079] A high-definition color three-dimensional tactile decorative color plate, including a back paint layer 120, a pre-treatment layer 110, a metal plate base layer 100, a pre-treatment layer 110, a primer layer 130, a printing layer 140 and a protective film layer sequentially connected from bottom to top 150. The formula of the ink that described printing layer adopts and the formula of primer layer are with embodiment 6-10, to mercury lamp (example 11), halogen lamp (example 12), LED lamp (comparative example 5) light source in same energy and printing The test was carried out under speed conditions, and the results are shown in Table 4.

[0080] Ink formula in table 4 example 11 and 12 is cured test result under different light sources

[0081]

[0082]

[0083] Relative evaluation criteria: ◎Excellent, ○Good, △Normal, X Poor

[0084] As can be seen from Table 4, both mercury lamps and halogen lamps can be used to cure the ink of this embodiment, and the curing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com