Fracturing fluid recovery erosion-prevention sand-removal system and method

A fracturing fluid and anti-erosion technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as separator explosion, gas well drainage safety and environmental protection hazards, etc., and achieve the effect of eliminating erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

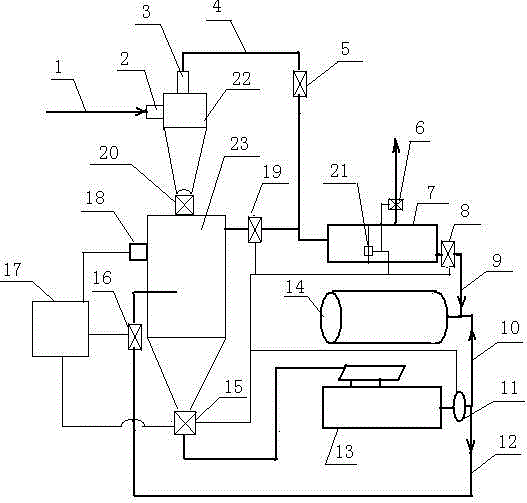

[0032] Such as figure 1 , one A fracturing fluid recovery anti-erosion sand removal system is characterized in that it includes at least one cyclone desander 22, and the desander fluid inlet 2 of the cyclone desander 22 is connected with a sand-containing fluid pipeline 1, so The gas-liquid outlet 3 at the top of the cyclone desander 22 is connected to a gas-liquid separator 7 through the gas-liquid pipeline 4, and the bottom outlet of the cyclone desander 22 is connected to a sand storage tank 23 through the cyclone sand discharge remote control valve 20 ;

[0033] The gas outlet of the gas-liquid separator 7 is provided with a natural gas outlet needle valve 6, and the liquid outlet of the gas-liquid separator 7 is connected to a fracturing fluid recovery tank 14 through the separator drain line 9;

[0034] The upper part of the sand storage tank 23 is connected to the inlet of the gas-liquid separator 7 through the pressure release switch 19, and the sand outlet at the bot...

Embodiment 2

[0040] On the basis of Example 1, the gas-liquid pipeline 4 is provided with a high-pressure needle valve 5, and the working pressure of the cyclone desander 22 is 35MPa; separation flow rate: liquid 1.5 cubic meters / min; gas 5×10 4 square / day; separation particle size: 20um; the rated pressure of the sand storage cylinder 23 is 35MPa. During the working process, open the wellhead tubing valve, close the high-pressure needle valve 5 at the same time, open the cyclone sand discharge remote control valve 20, and close the sand storage cylinder sand discharge remote control valve 15 through the PLC controller 17, and observe the inside of the well. The liquid flow rate of the flowback liquid entering the cyclone desander 22; when the liquid flow rate of the flowback liquid entering the cyclone desander 22 in the well is ≤ 1 cubic meter per minute, open the high-pressure needle valve 5 and pass through the cyclone desander 22. The gas-liquid mixture of the flowback liquid processe...

Embodiment 3

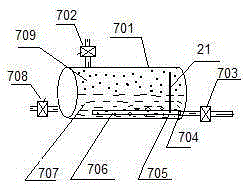

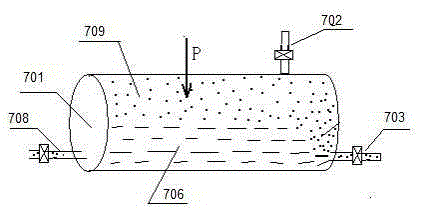

[0042] On the basis of embodiment 1 or 2, at present as image 3 The volumetric gas-liquid separator shown must be separated under a certain pressure condition, otherwise, the volume of the gas under normal pressure is too large, and the gas-liquid flow rate is too fast, and the gas-liquid flow rate cannot be reached in a volumetric separator of a certain volume. The gravity separation condition of the liquid; when the volumetric separator adopts a certain pressure for separation, the volume of the gas will shrink, which can greatly reduce the velocity of the fluid in the separator; if the pressure in the separator reaches 5MPa, the volume of the gas It is 1 / 50 of the normal pressure, and the flow rate of the fluid in the separator can also be changed in the range of 50 times less than the volume of the normal pressure according to the gas-liquid ratio, so as to achieve a better effect of gas-liquid separation;

[0043] But when there is pressure in the separator, when the sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com