Oxide skin separation assembly and method

A technology for separating components and separation methods, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as the inability to eliminate solid particle erosion, and achieve the solution of solid particle erosion, avoid solid particle erosion, and avoid accumulation The effect of clogging or even pipe bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are for explanation rather than limitation of the present invention.

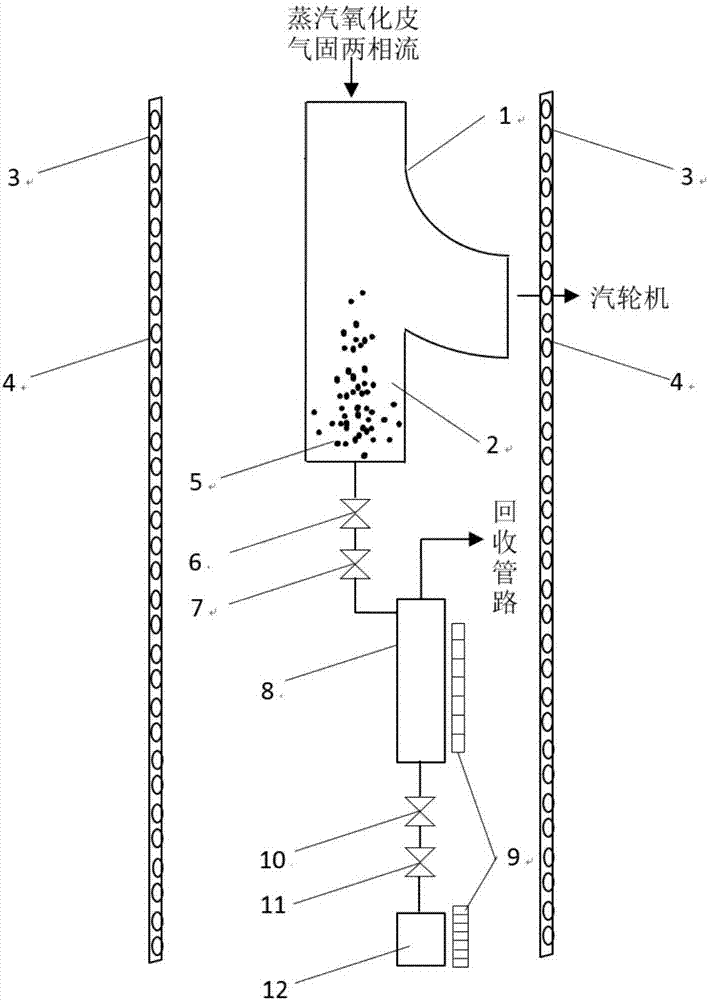

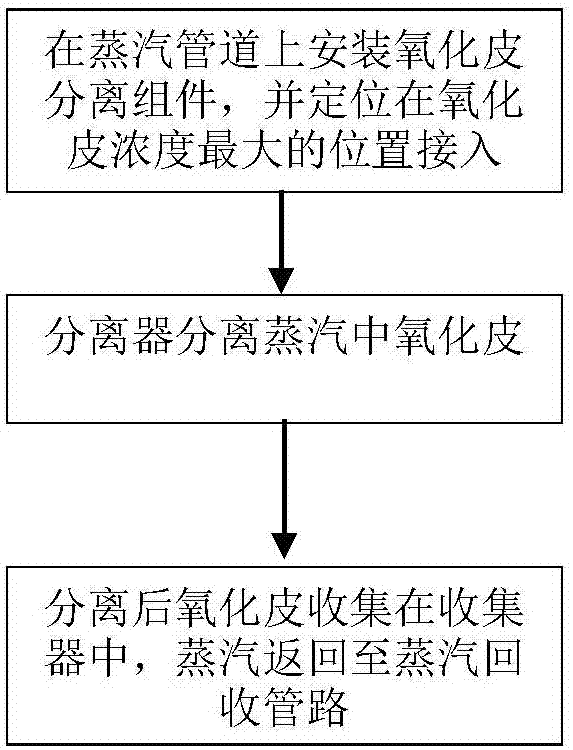

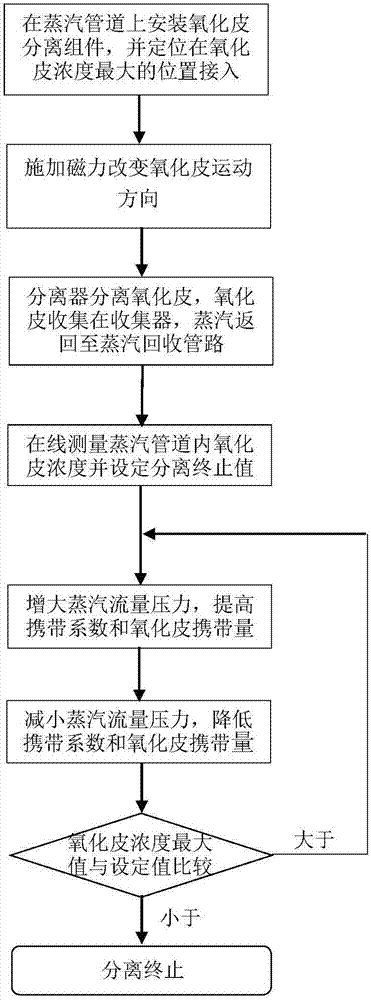

[0039] The present invention proposes an oxide scale separation assembly, which includes a separation device installed on a high-temperature and high-pressure steam pipeline 1. The separation device includes a sampling pipe 2, a separator 8 and a collector 12 arranged in sequence; the separator 8 is configured as a pressure pipe or container that uses magnetic force, centrifugal force or gravity to separate the oxide scale 5 in the steam. In order to avoid welding stress between different materials, the material of the sampling tube 2 is the same as that of the steam pipe 1. In order to make the magnetic force penetrate the separator 8 and the collector 12 and act on the oxide scale 5, the material of the separator 8 and the collector 12 is not magnetic Of austenitic stainless steel.

[0040] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com