Patents

Literature

31 results about "Solid particle erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid particle erosion (SPE) is the loss of material that results from repeated impact of solid particles energized in a carrier fluid. This article reviews important SPE variables, their effects for different classes of materials, composites and coatings, and the mechanisms and theories proposed to explain SPE.

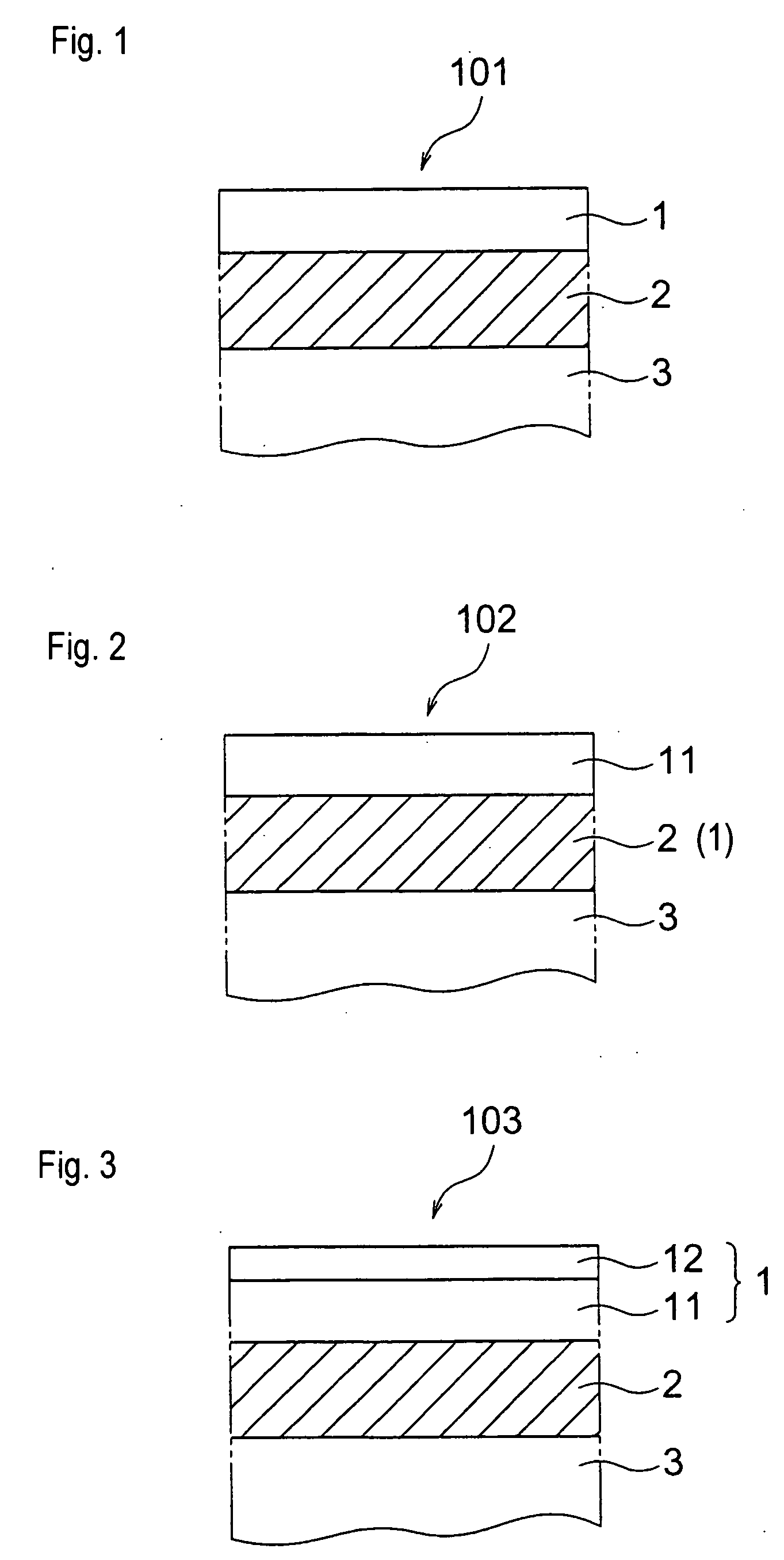

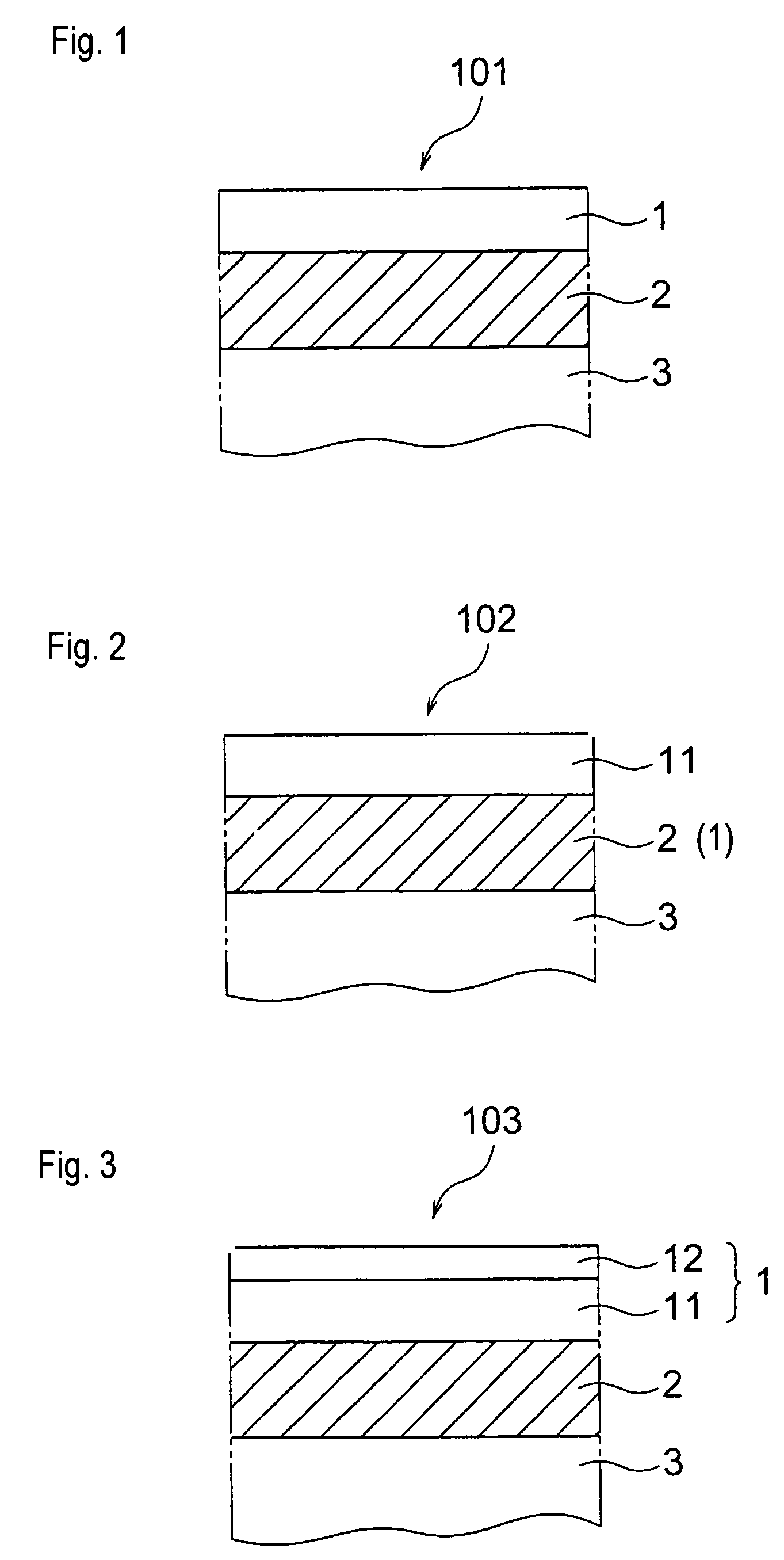

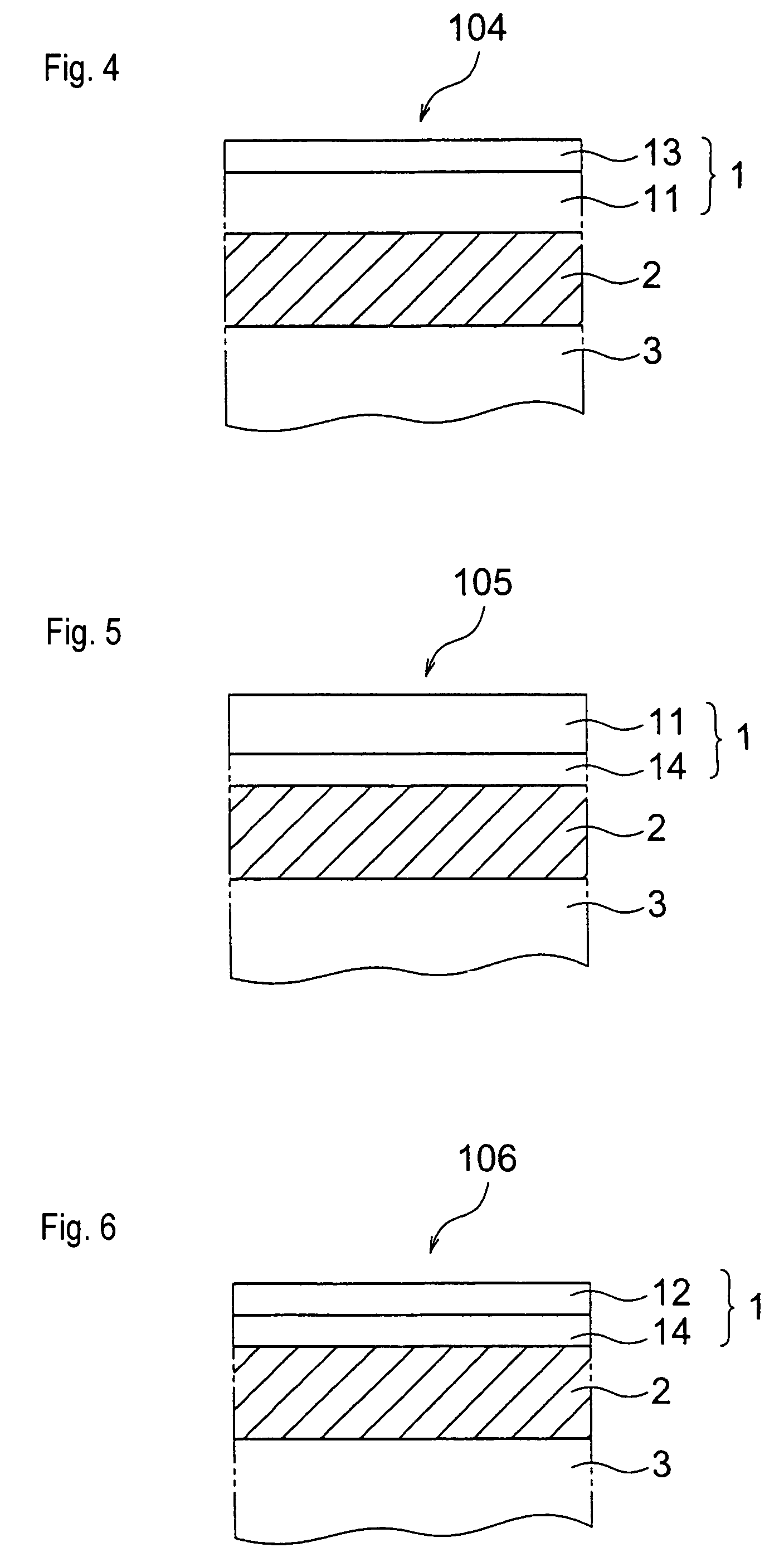

Solid Particle Erosion Resistant Surface Treated Coat and Rotating Machine Applied Therewith

ActiveUS20090123737A1Improve fatigue strengthHigh erosion resistance and oxidation resistance and fatigue strengthLiquid surface applicatorsPump componentsAxial compressorSolid particle

A solid particle erosion resistant surface treated coat is provided by which a solid, particle erosion resistance is largely enhanced and a rotating member is given with an oxidation resistance without deteriorating a fatigue strength. Also, a rotating machine, such as a steam turbine, axial compressor or the like, applied with this coat is provided. The solid particle erosion resistant surface treated coat comprises a nitrided hard layer formed on a surface of base material and a PVD (physical vapor deposition) hard layer of at least one layer formed on the nitrided hard layer by a PVD method. The nitrided hard layer has a thickness of at least 30 μm. The PVD hard layer has a total thickness of at least 10 μm. Deformation of the base material by collisions by solid particles is prevented and crack of the coat comprising the nitrided hard layer formed on the base material and the PVD hard layer formed on the nitrided hard layer is prevented. Thereby, the solid particle erosion resistance is secured, life of the solid particle erosion resistant surface treated coat can be elongated and the oxidation resistance and fatigue strength are enhanced.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

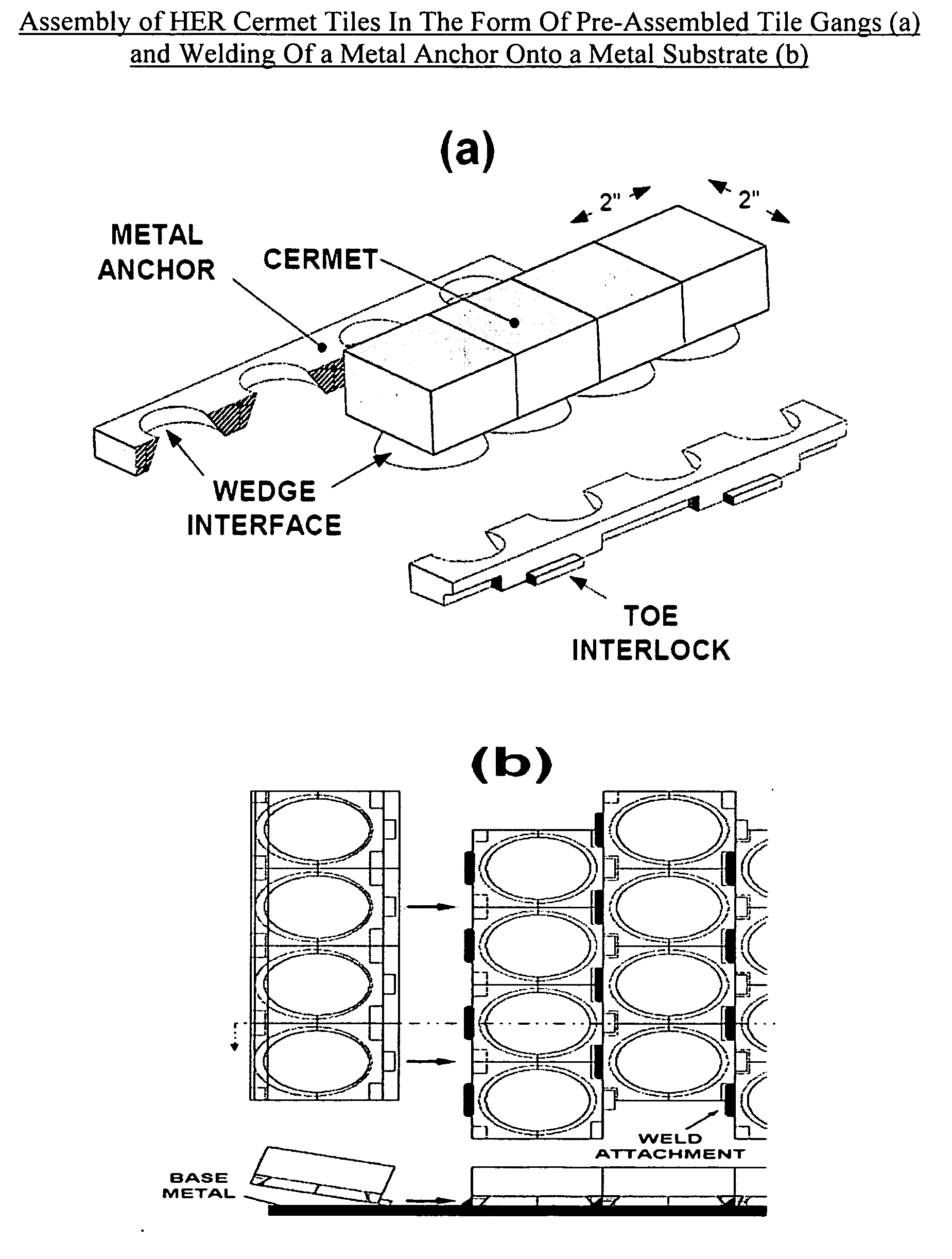

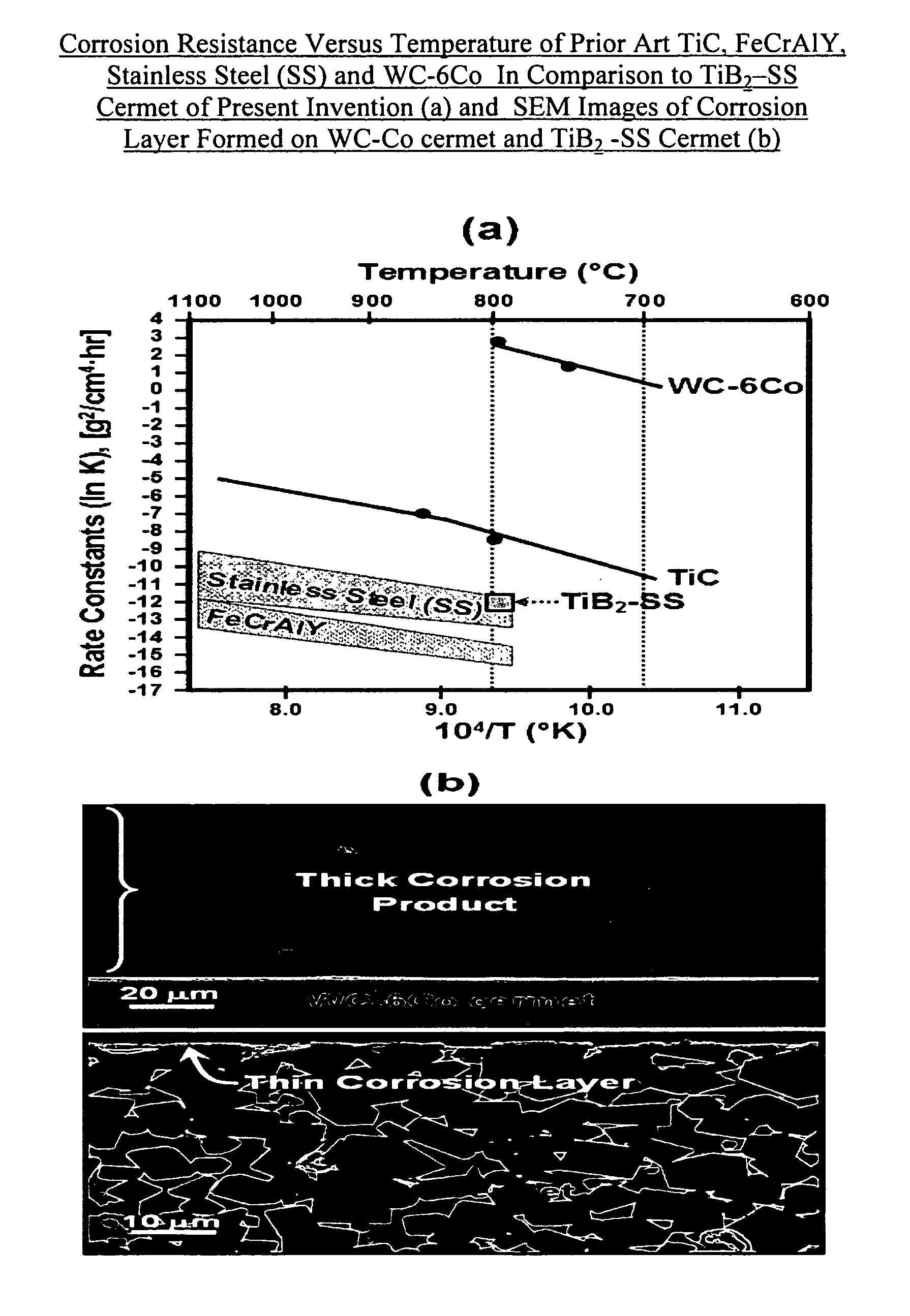

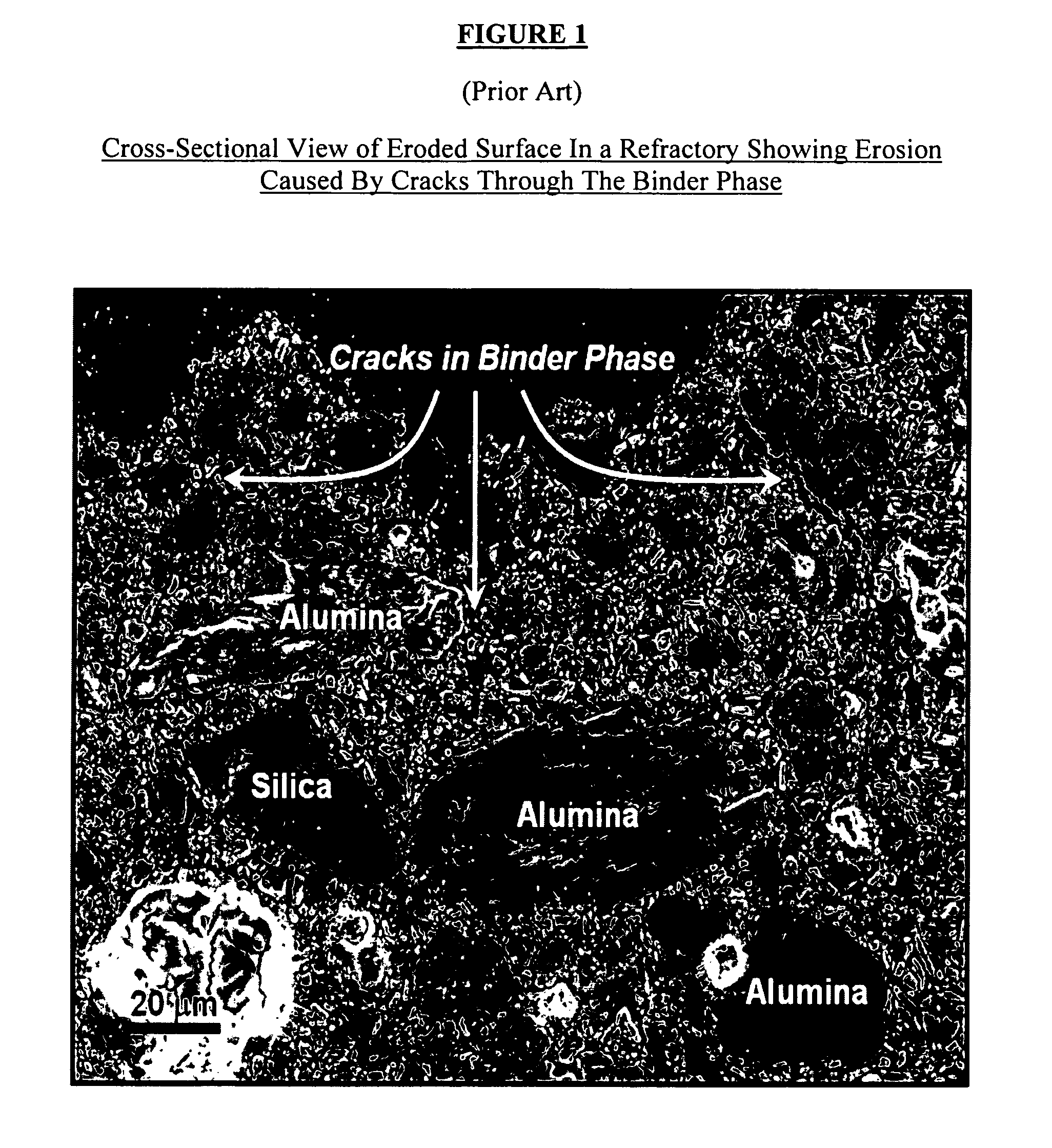

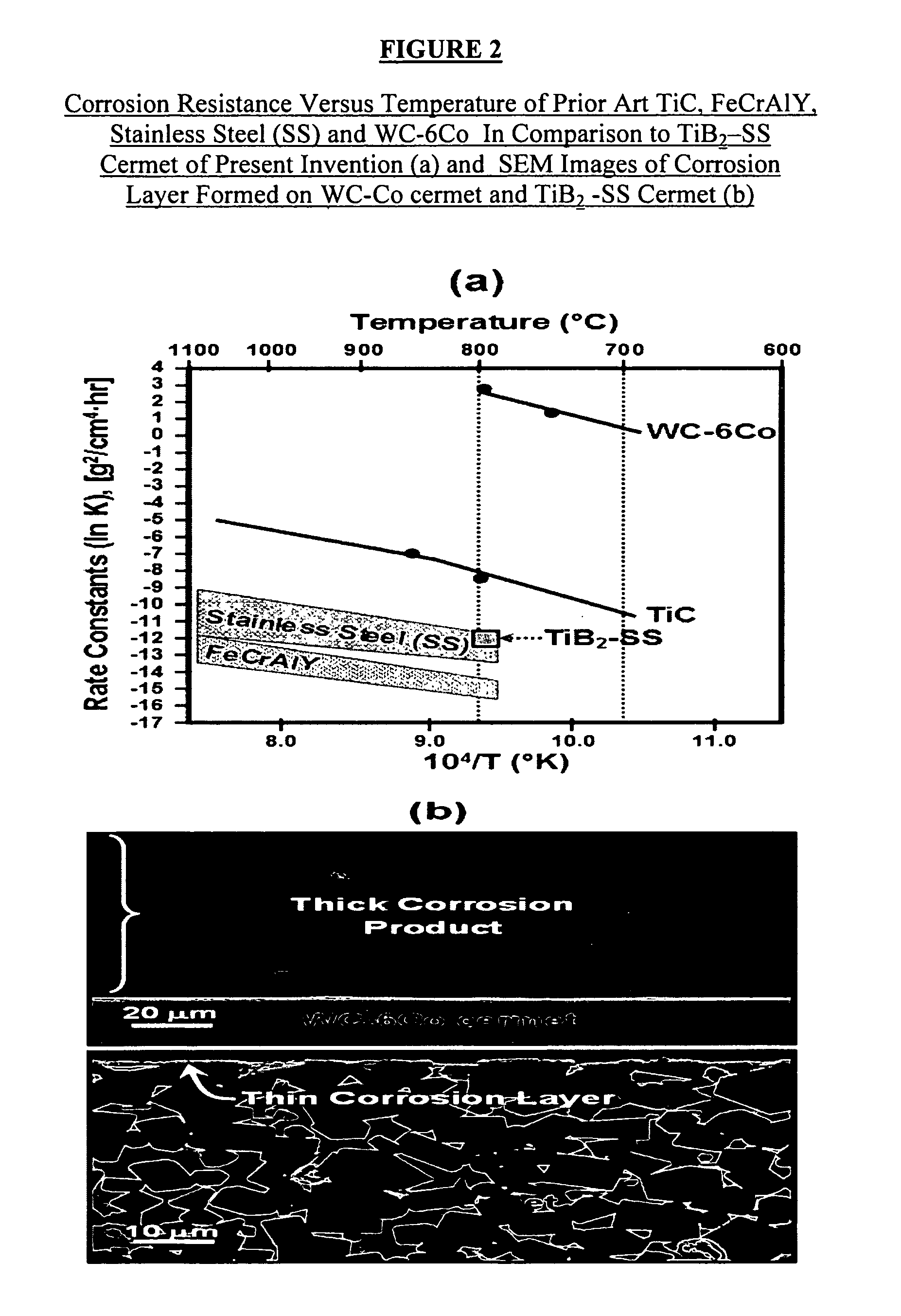

Erosion resistant cermet linings for oil & gas exploration, refining and petrochemical processing applications

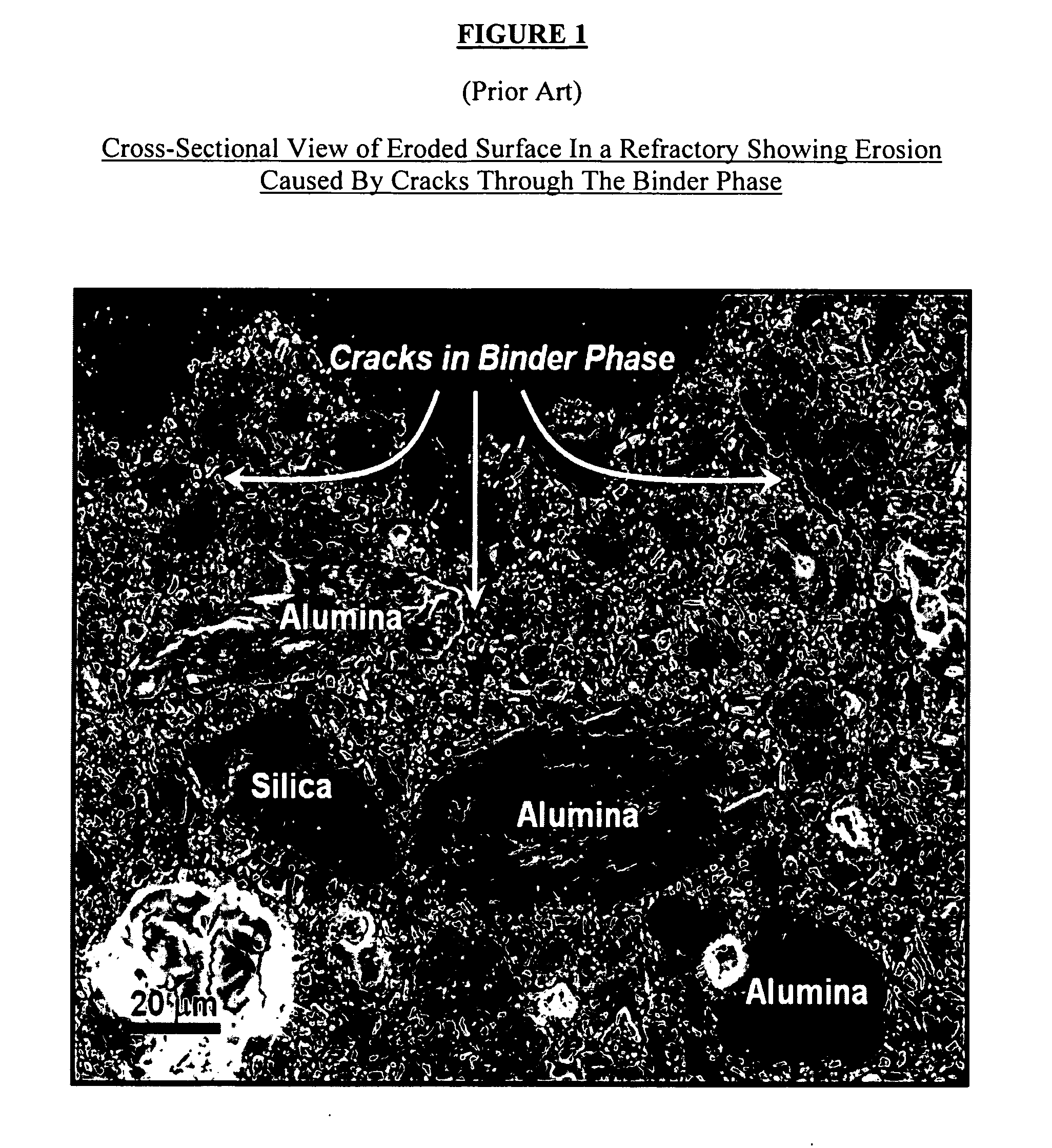

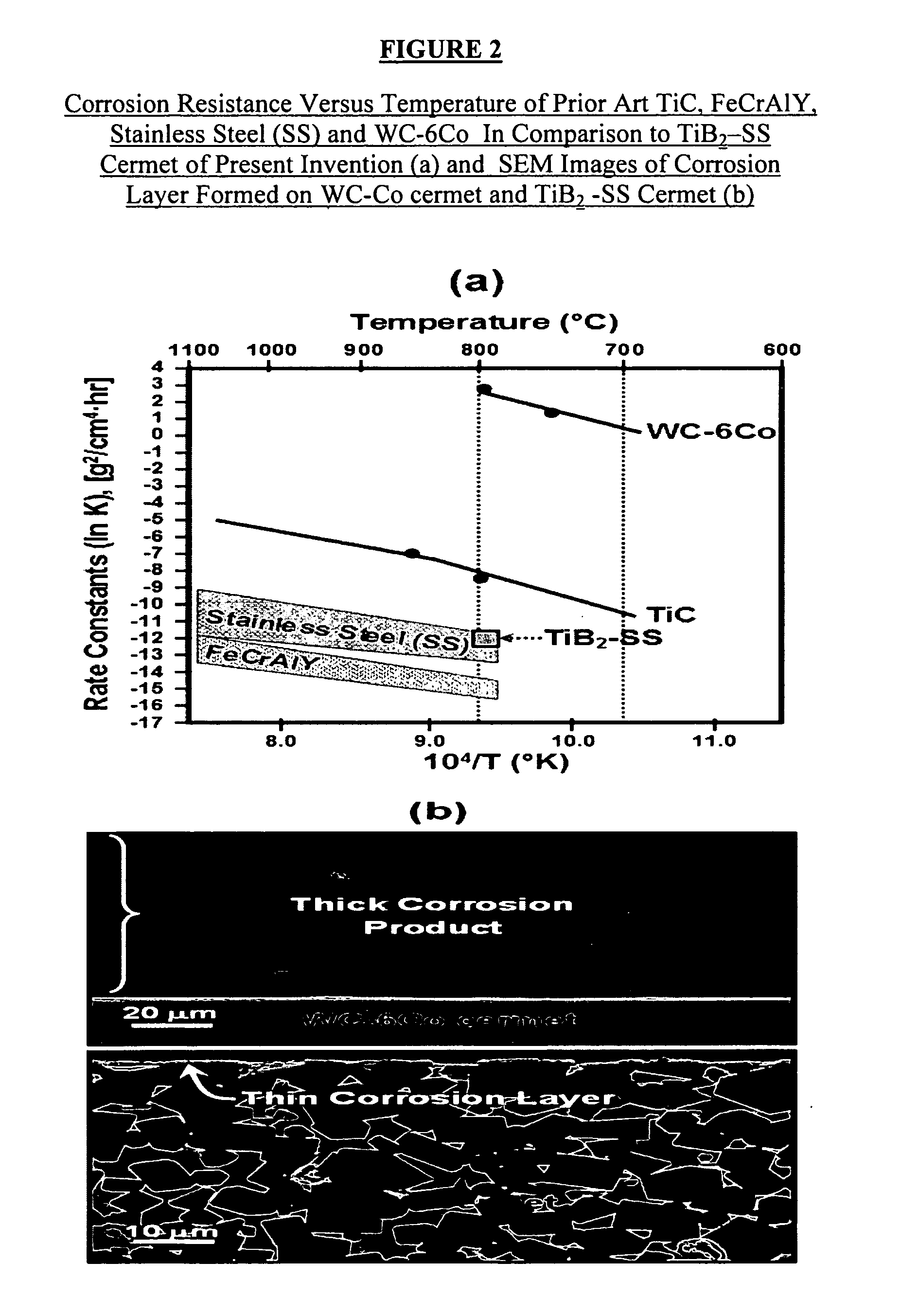

InactiveUS20080003125A1Outstanding hardnessImprove stabilitySolid state diffusion coatingFurnace typesParticulatesPetroleum

The present invention is directed to a method for protecting metal surfaces in oil & gas exploration and production, refinery and petrochemical process applications subject to solid particulate erosion at temperatures of up to 1000° C. The method includes the step of providing the metal surfaces in such applications with a hot erosion resistant cermet lining or insert, wherein the cermet lining or insert includes a) about 30 to about 95 vol % of a ceramic phase, and b) a metal binder phase, wherein the cermet lining or insert has a HEAT erosion resistance index of at least 5.0 and a K1C fracture toughness of at least 7.0 MPa-m 1 / 2. The metal surfaces may also be provided with a hot erosion resistant cermet coating having a HEAT erosion resistance index of at least 5.0. Advantages provided by the method include, inter alia, outstanding high temperature erosion and corrosion resistance in combination with outstanding fracture toughness, as well as outstanding thermal expansion compatibility to the base metal of process units. The method finds particular application for protecting process vessels, transfer lines and process piping, heat exchangers, cyclones, slide valve gates and guides, feed nozzles, aeration nozzles, thermo wells, valve bodies, internal risers, deflection shields, sand screen, and oil sand mining equipment.

Owner:EXXON RES & ENG CO

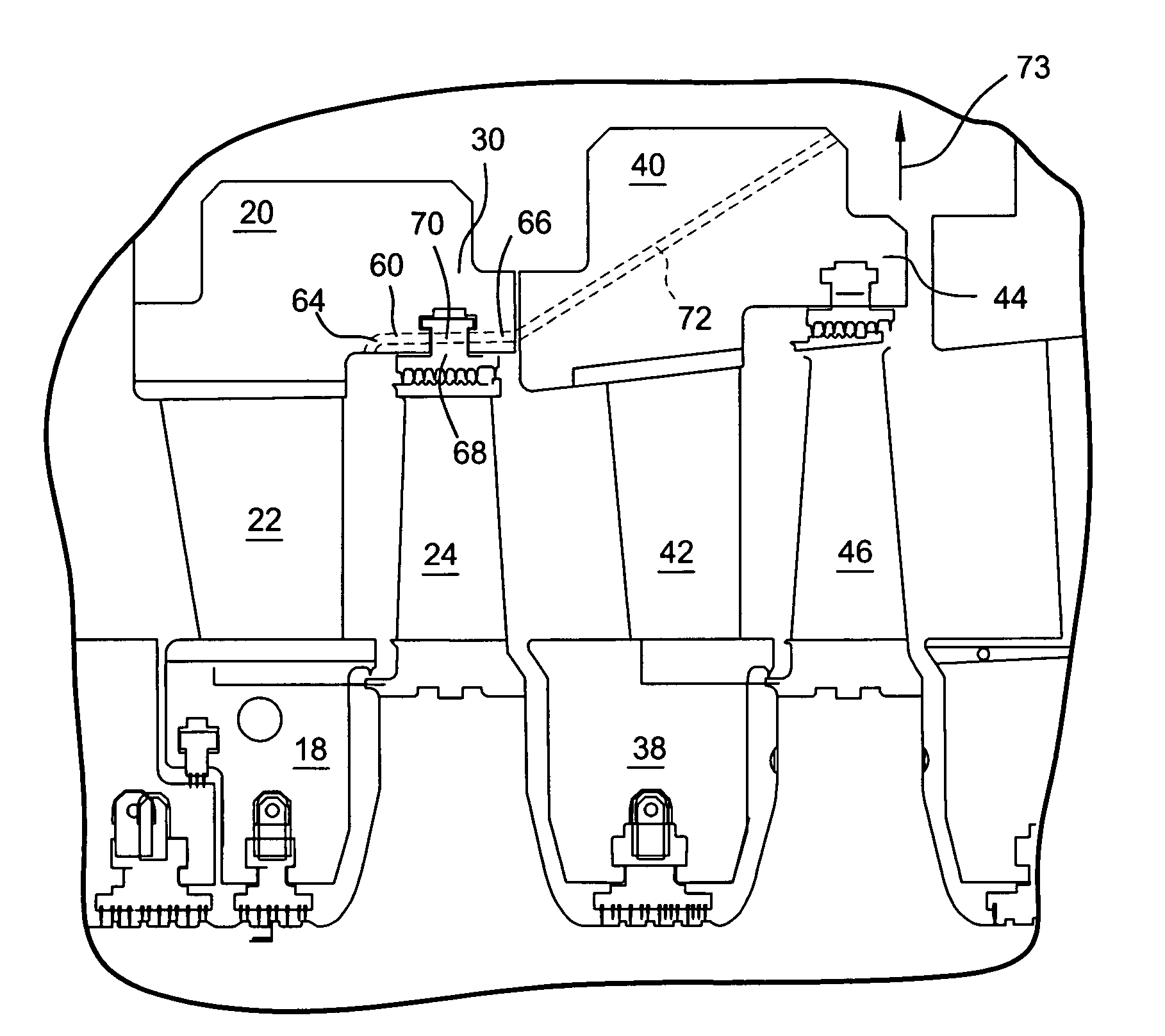

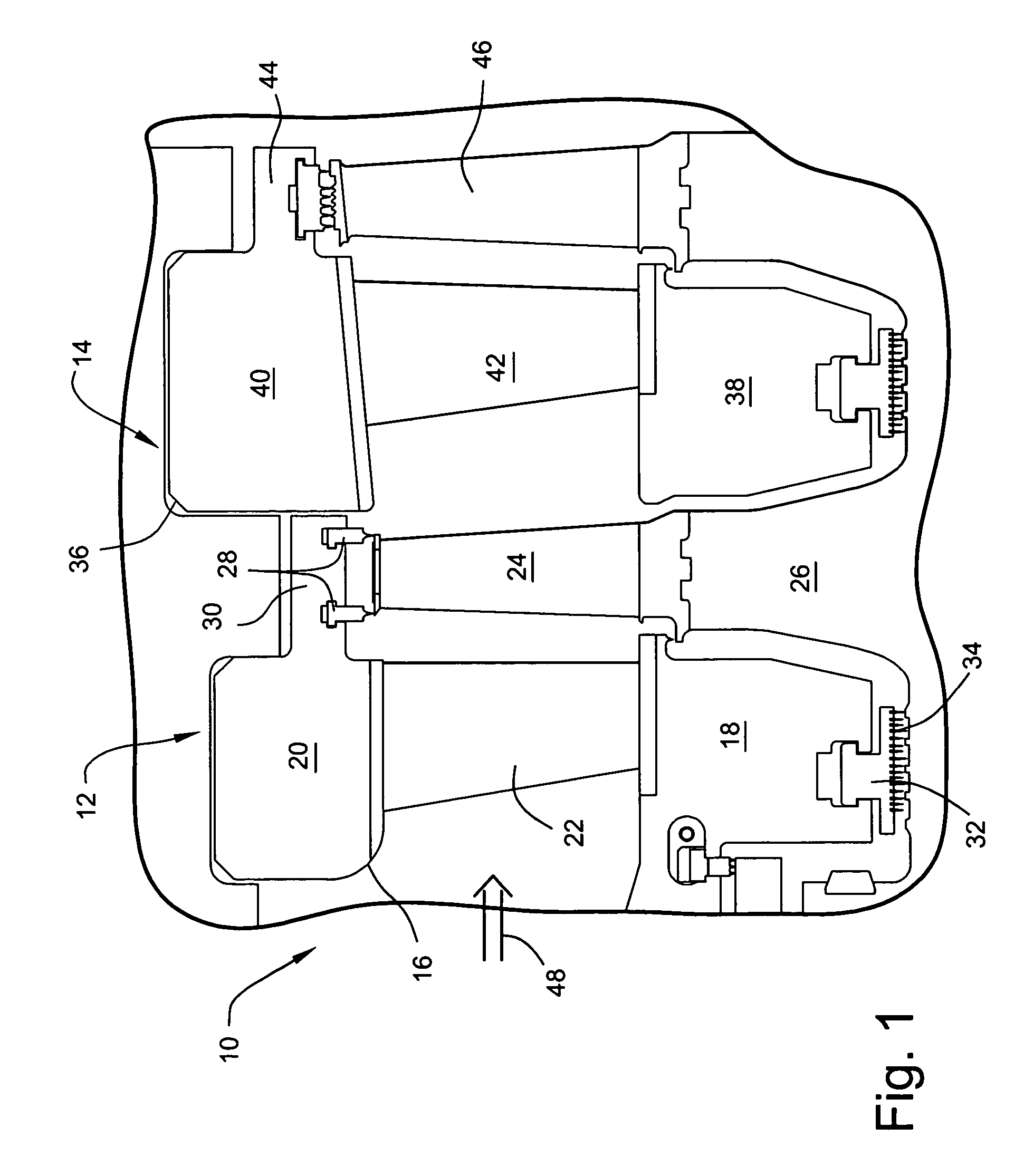

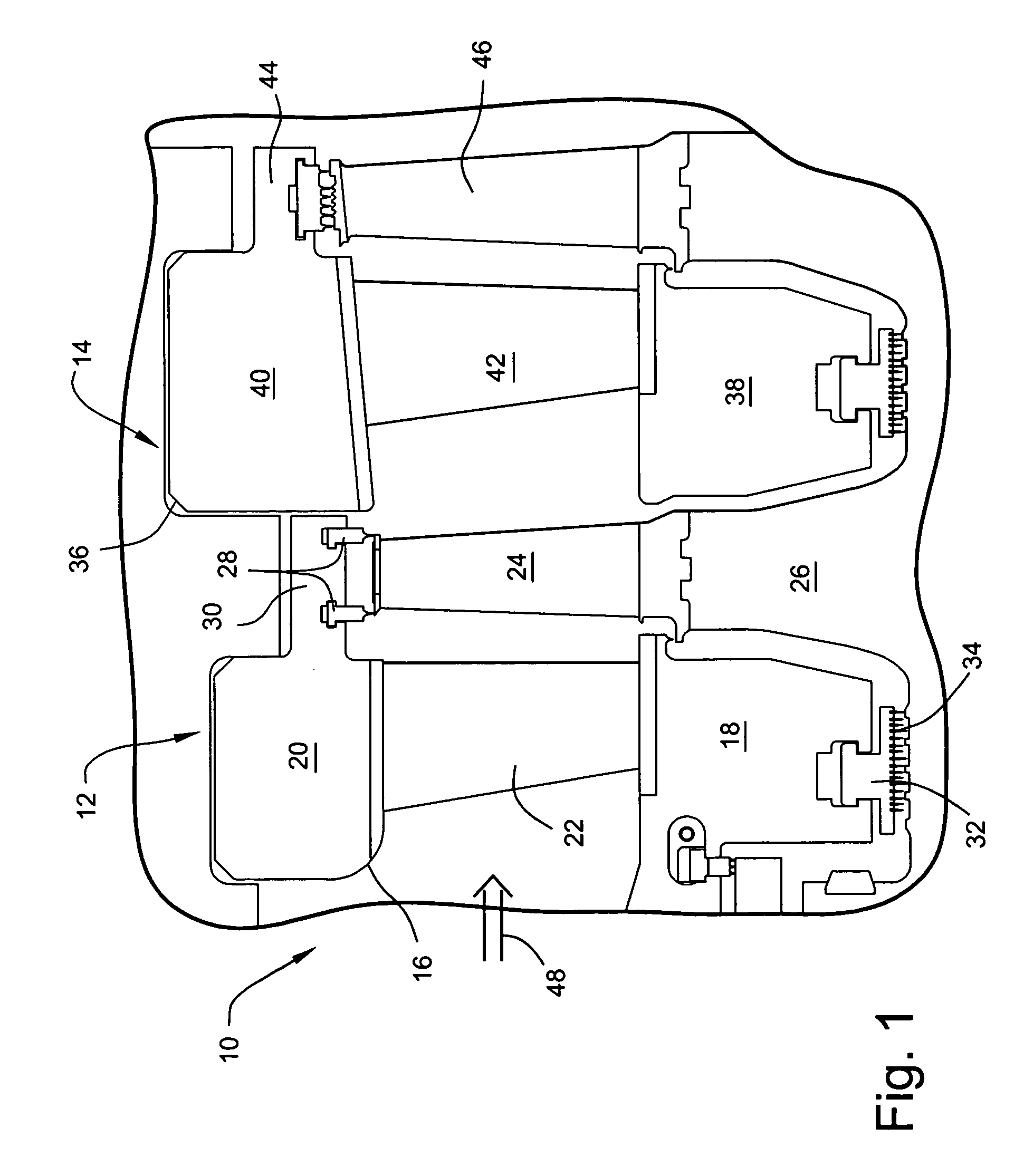

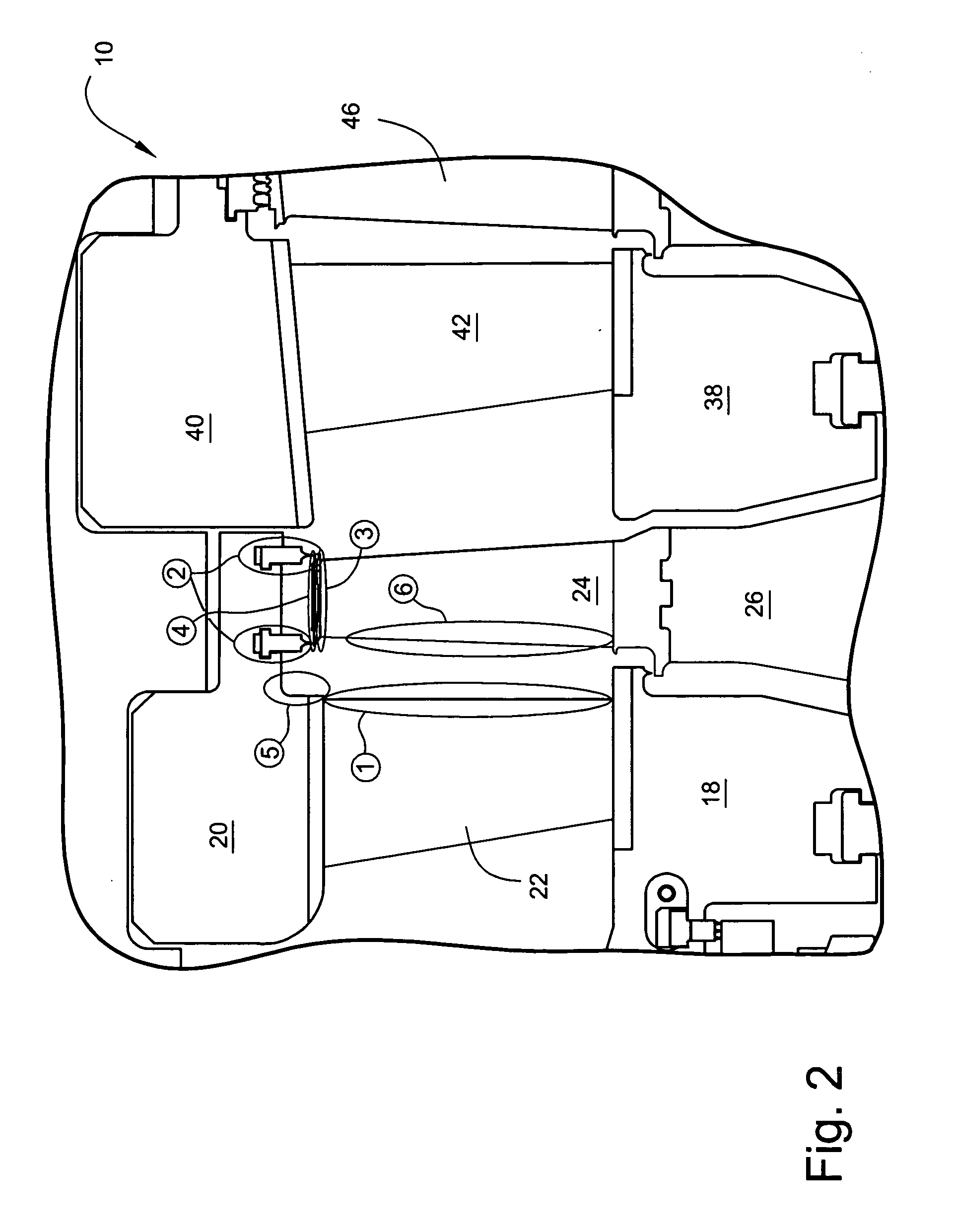

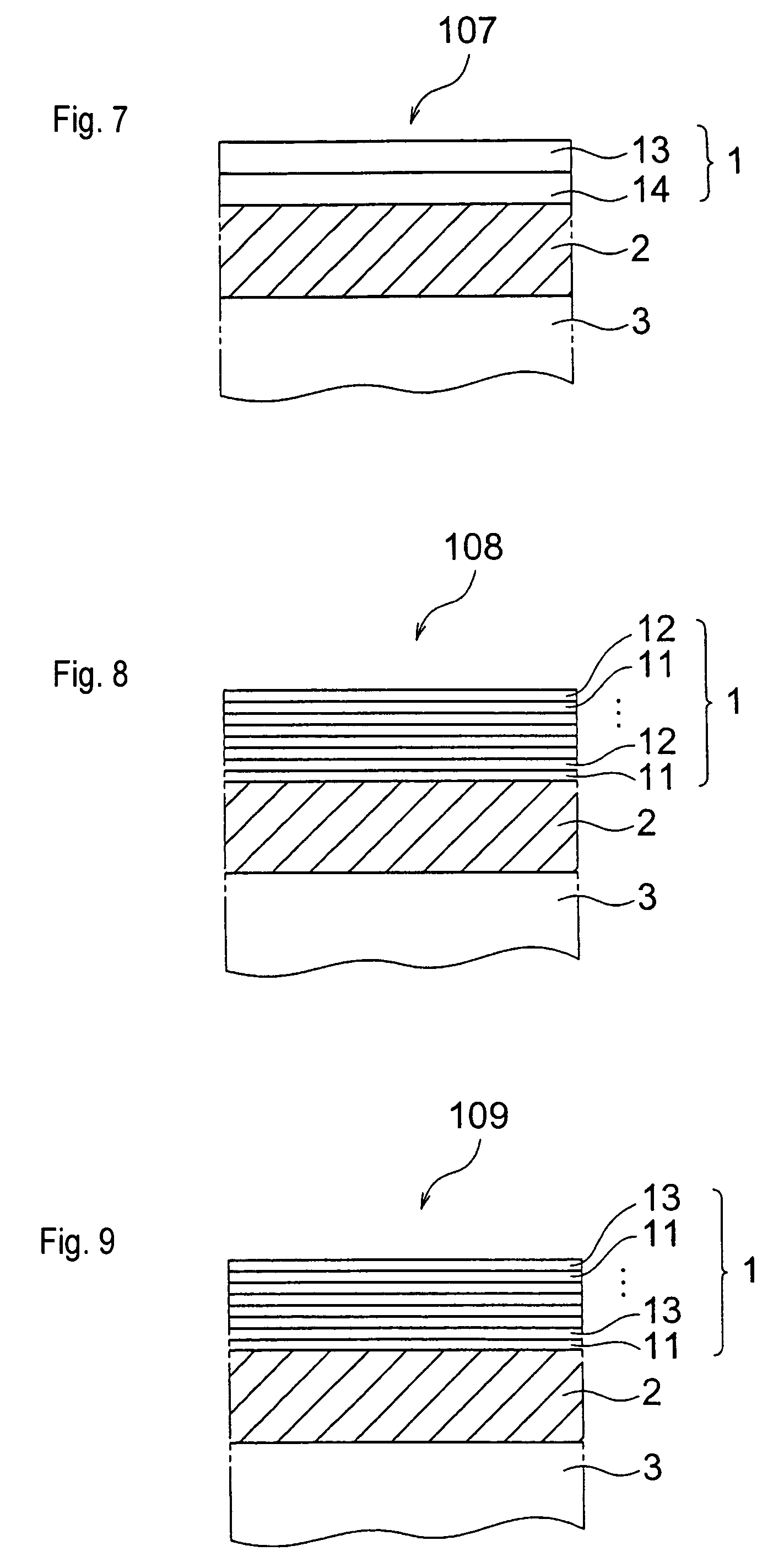

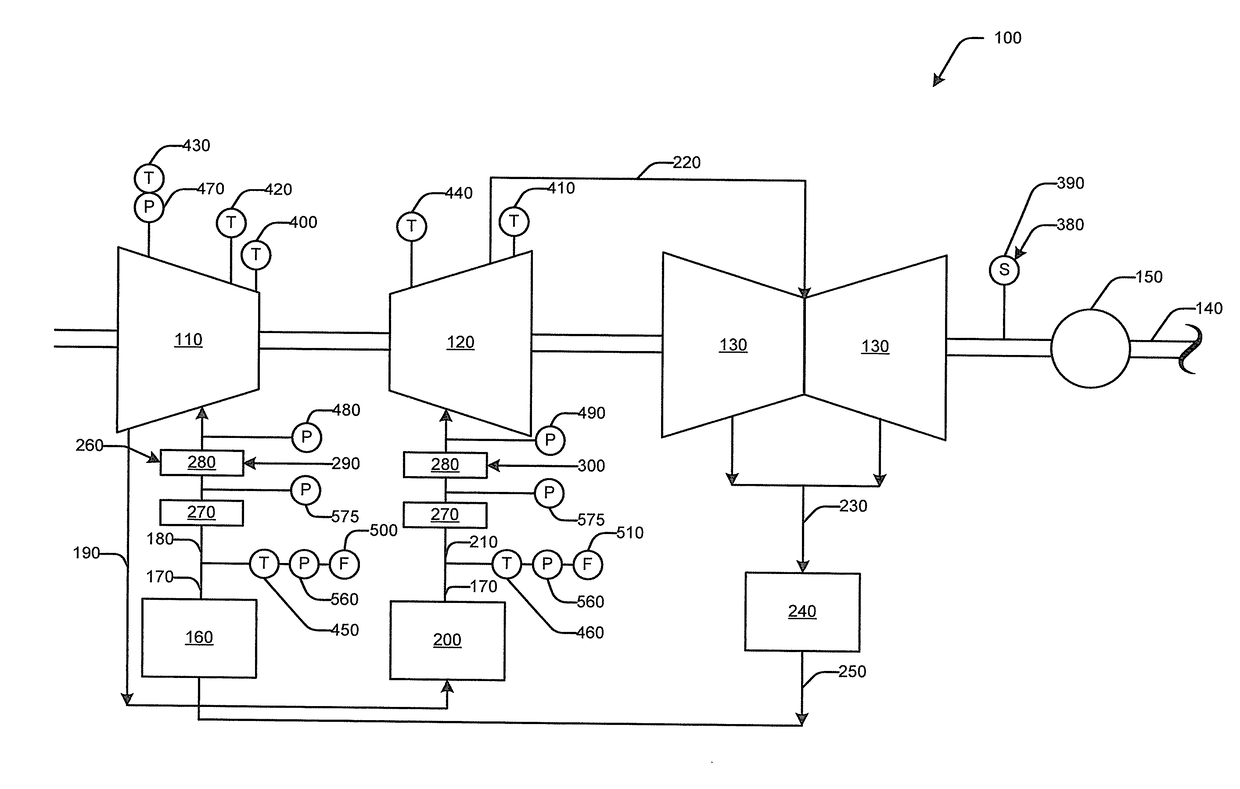

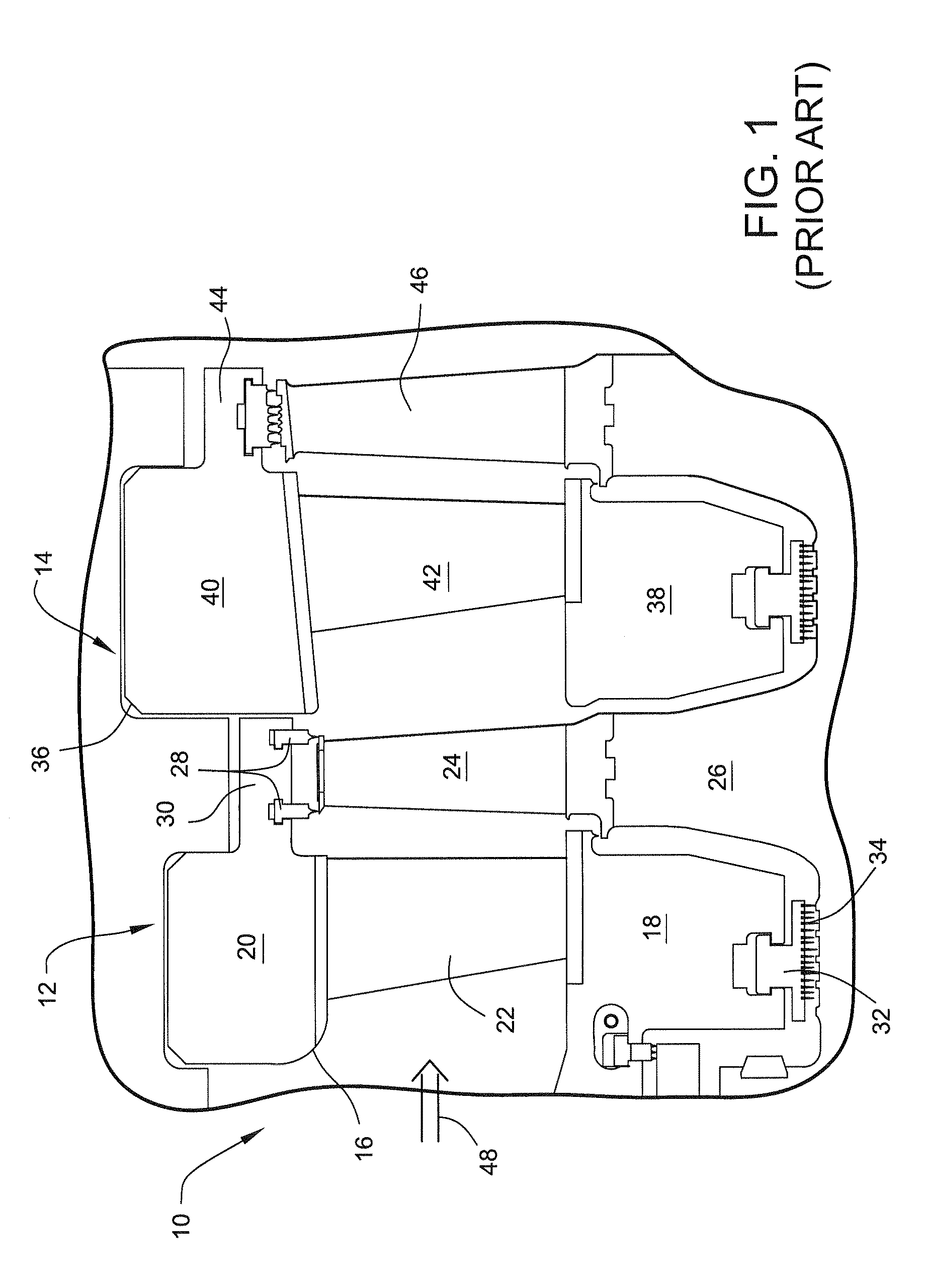

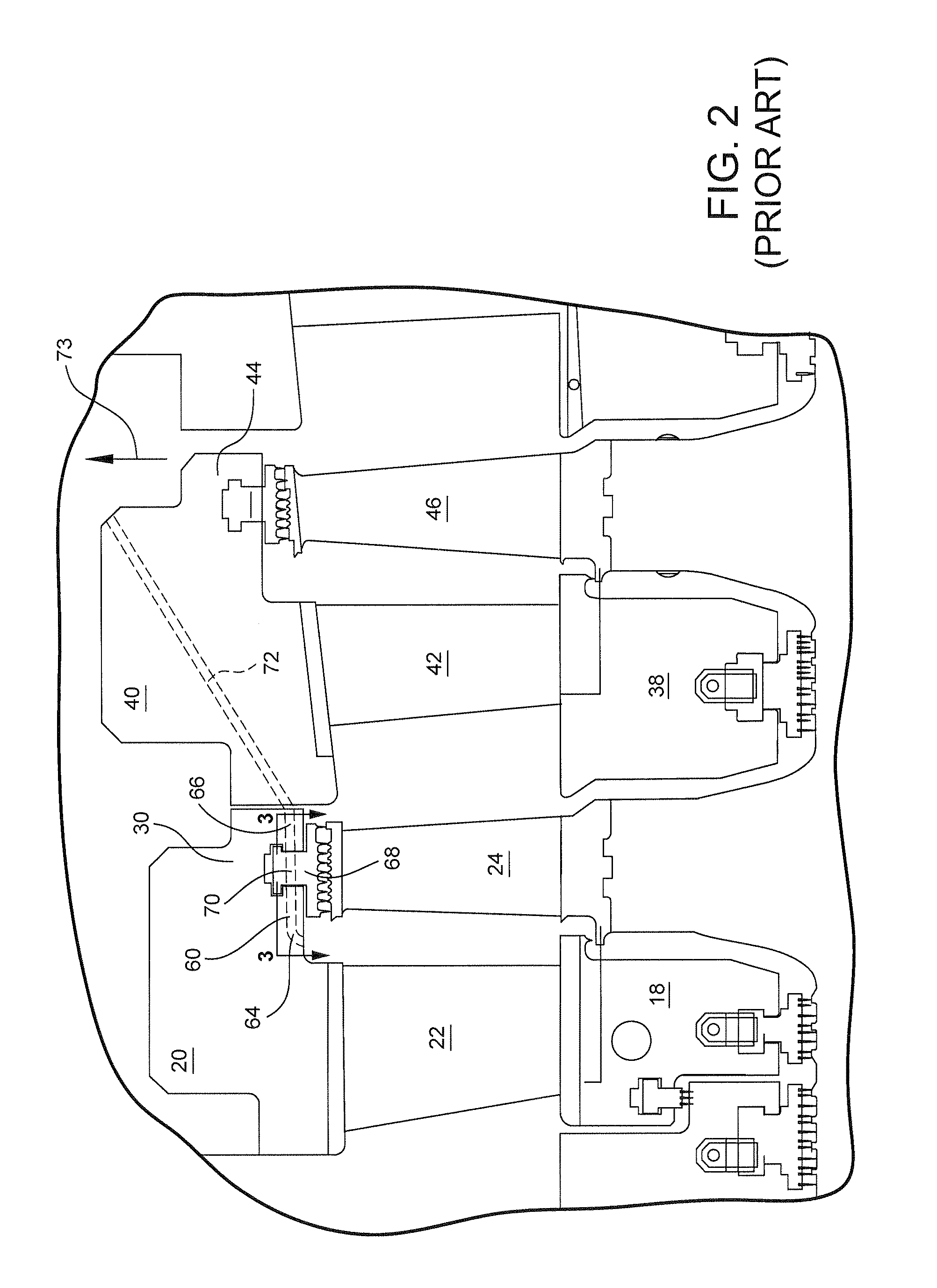

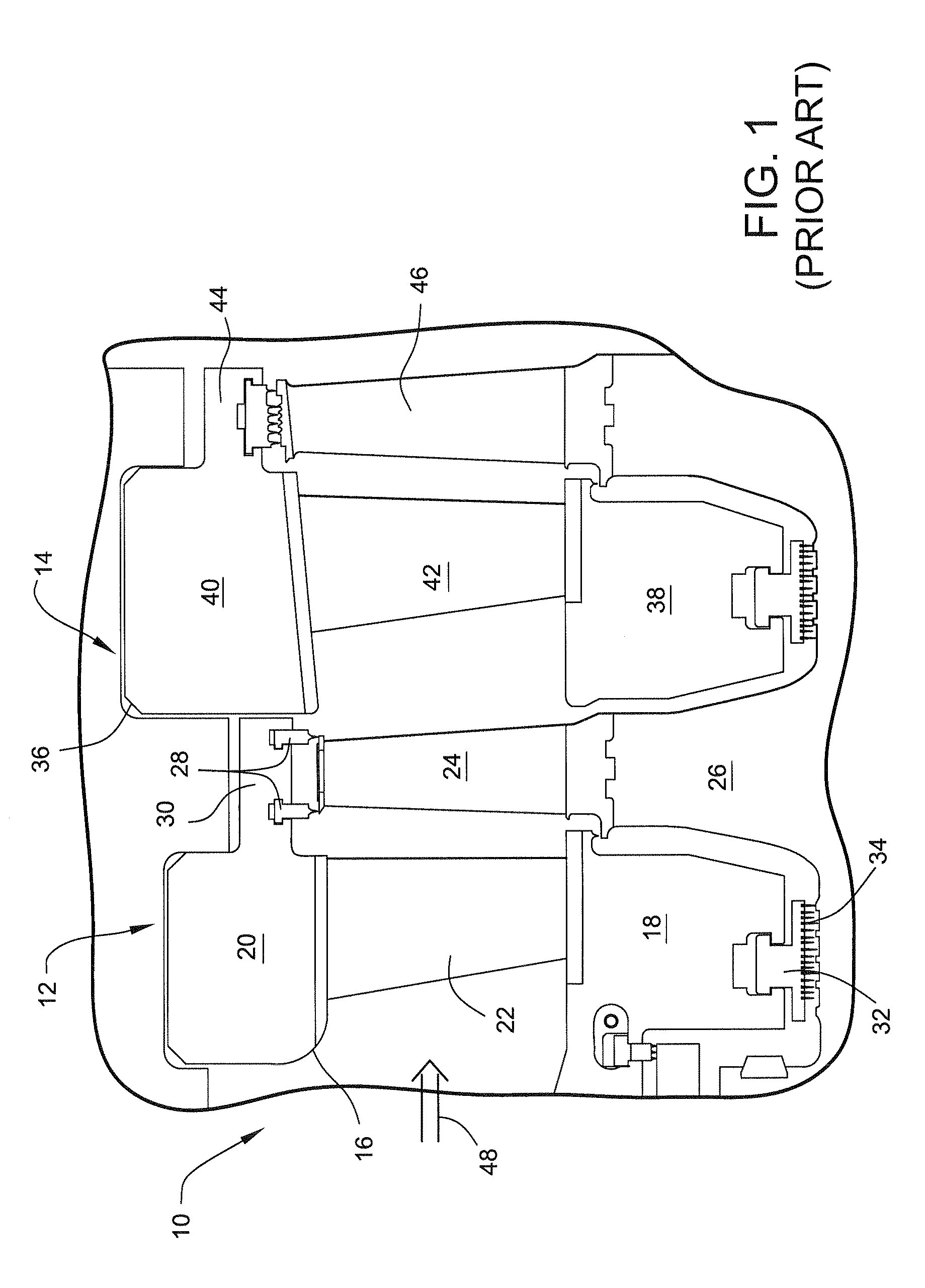

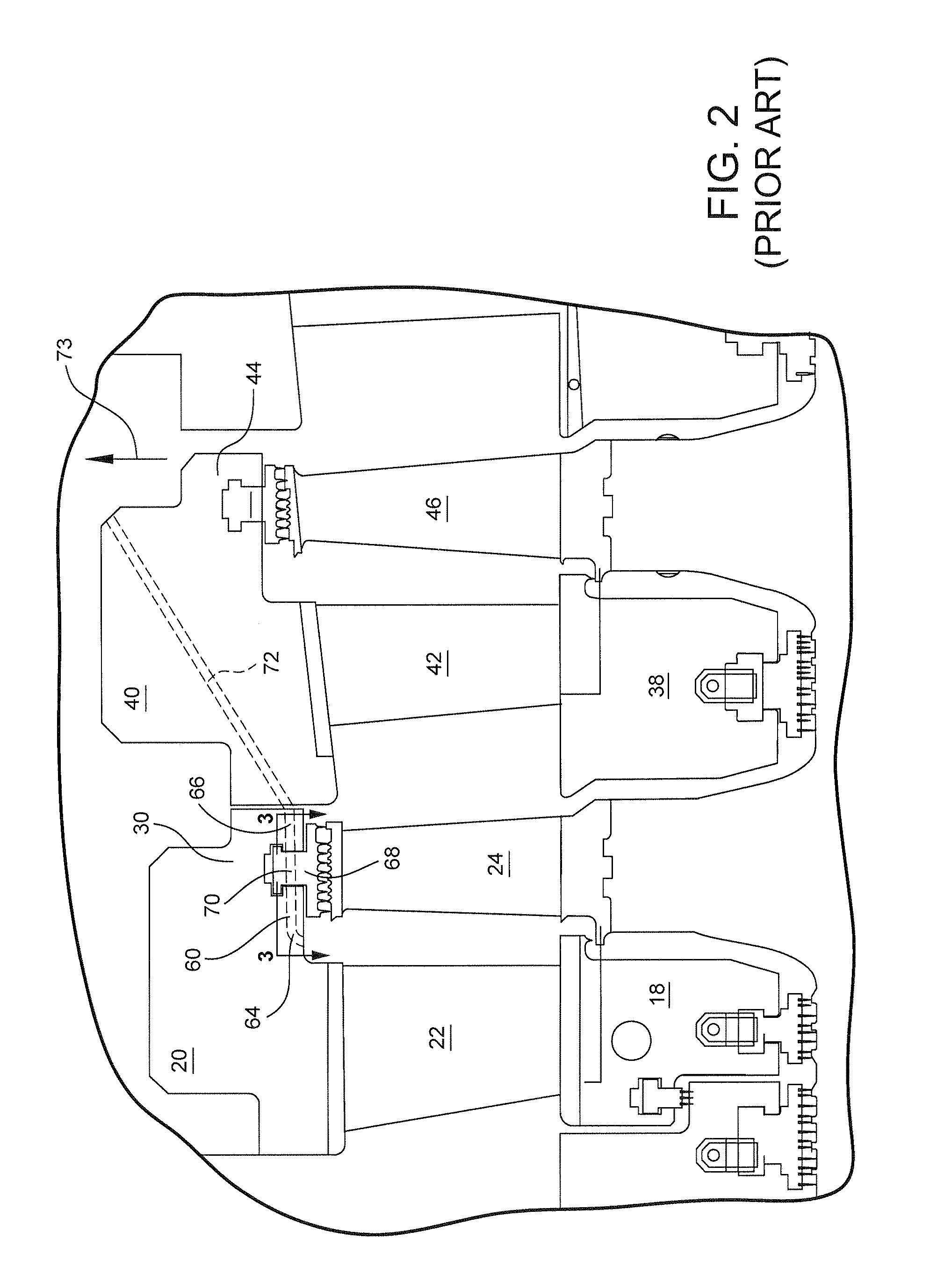

Apparatus and methods for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through holes in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The hole through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The hole in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices are thereby minimized.

Owner:GE INFRASTRUCTURE TECH INT LLC

Apparatus and methods for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through holes in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The hole through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The hole in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices are thereby minimized.

Owner:GENERAL ELECTRIC CO

Erosion resistant cermet linings for oil and gas exploration, refining and petrochemical processing applications

The present invention is directed to a method for protecting metal surfaces in oil & gas exploration and production, refinery and petrochemical process applications subject to solid particulate erosion at temperatures of up to 1000° C. The method includes the step of providing the metal surfaces in such applications with a hot erosion resistant cermet lining or insert, wherein the cermet lining or insert includes a) about 30 to about 95 vol % of a ceramic phase, and b) a metal binder phase, wherein the cermet lining or insert has a HEAT erosion resistance index of at least 5.0 and a K1C fracture toughness of at least 7.0 MPa-m1 / 2. The metal surfaces may also be provided with a hot erosion resistant cermet coating having a HEAT erosion resistance index of at least 5.0. Advantages provided by the method include, inter alia, outstanding high temperature erosion and corrosion resistance in combination with outstanding fracture toughness, as well as outstanding thermal expansion compatibility to the base metal of process units. The method finds particular application for protecting process vessels, transfer lines and process piping, heat exchangers, cyclones, slide valve gates and guides, feed nozzles, aeration nozzles, thermo wells, valve bodies, internal risers, deflection shields, sand screen, and oil sand mining equipment.

Owner:EXXON RES & ENG CO

Turbine jet nozzle static and moving blade preventing solid microparticle from etching and its heat treatment method

InactiveCN1554856AImproved resistance to solid particle erosionImprove erosion abilityBlade accessoriesStatorsHardnessMicroparticle

The static and moving blade used in supercritical and super-supercritical jet are made of 12%Cr heat resistant martensite steel and have the surface first boronizing treated with granular single phase boronizing agent to form one layer of single phase Fe2B structure combined firmly with the substrate and then tempering treated. The boronized layer has hardness as high as 1200-1600 HV, much higher than that of nitridated layer, and stable high temperature hardness. The present invention can meet the requirement of preventing solid particle erosion of supercritical and super-supercritical jet.

Owner:DONGFANG TURBINE CO LTD

Chloridization corrosion resistant double-layer structure alloy coating for heating surface of garbage incinerator and preparation method

The invention discloses a chloridization corrosion resistant double-layer structure alloy coating for a heating surface of a garbage incinerator. The double-layer structure comprises a chloridizationcorrosion resistant bottom layer and a solid particle erosion resistant surface layer, wherein the chloridization corrosion resistant bottom layer comprises components in percentage by mass as follows: 20%-23% of Cr, 8%-10% of Mo, 3.15%-4.15% of Nb, 5% of Fe, 1% of Co, 0.5% of Mn, 0.5% of Si, 0.4% of Al, 0.4% of Ti and the balance of Ni and inevitable impurities; the solid particle erosion resistant surface layer comprises components in percentage by mass as follows: 80% of NiCr and 20% of Cr3C2; the chloridization corrosion resistant bottom layer in the double-layer structure coating is prepared with an activated combustion HVAF (high velocity air fuel) spraying process; the solid particle erosion resistant surface layer in the double-layer structure coating is prepared with an HVOF (highvelocity oxygen fuel) spraying process. The problems of pipe wall thinning and pipe explosion caused by the fact that the heating surface of the garbage incinerator is easily corroded by high-temperature chloride and eroded by solid particles are solved, and the service life and the maintenance cycle of pipes on the heating surface of the garbage incinerator are prolonged greatly.

Owner:XIAN THERMAL POWER RES INST CO LTD

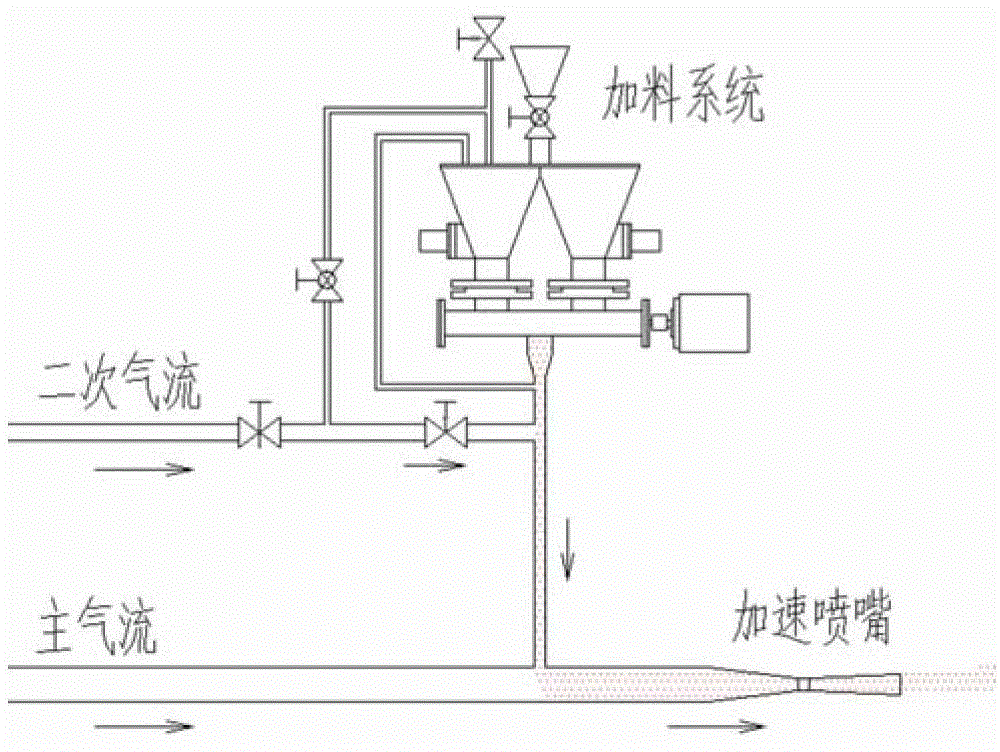

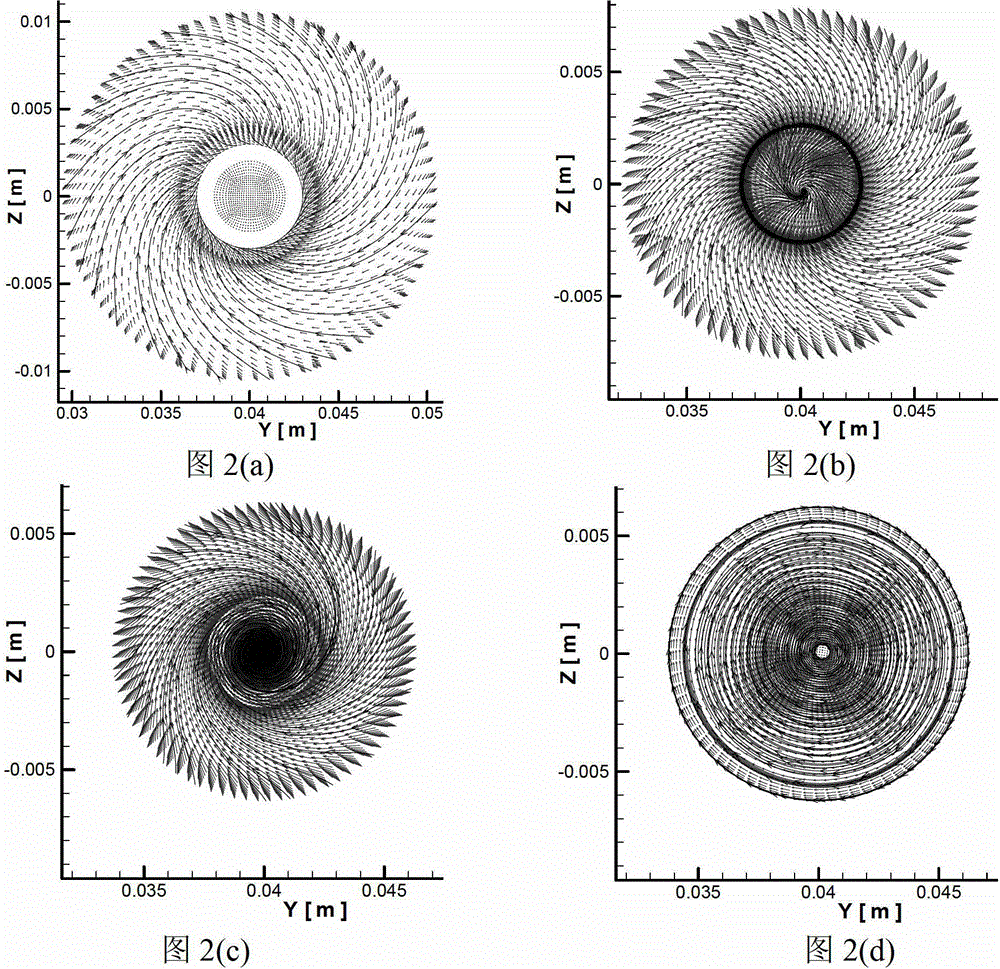

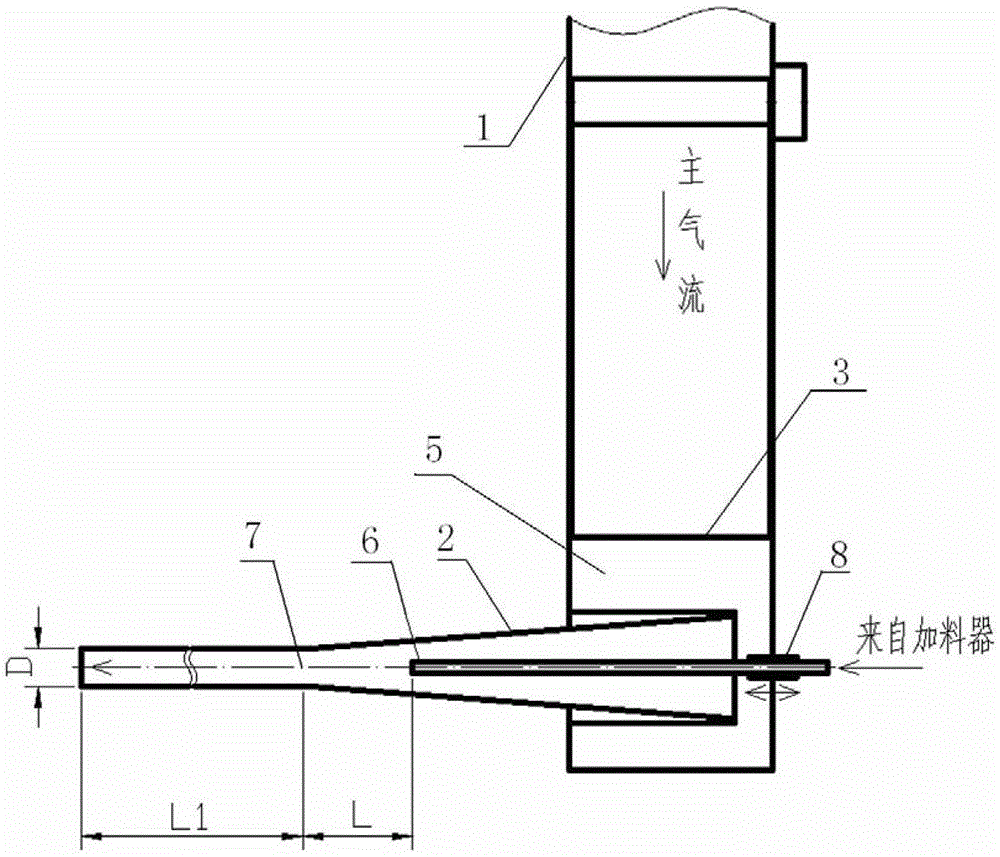

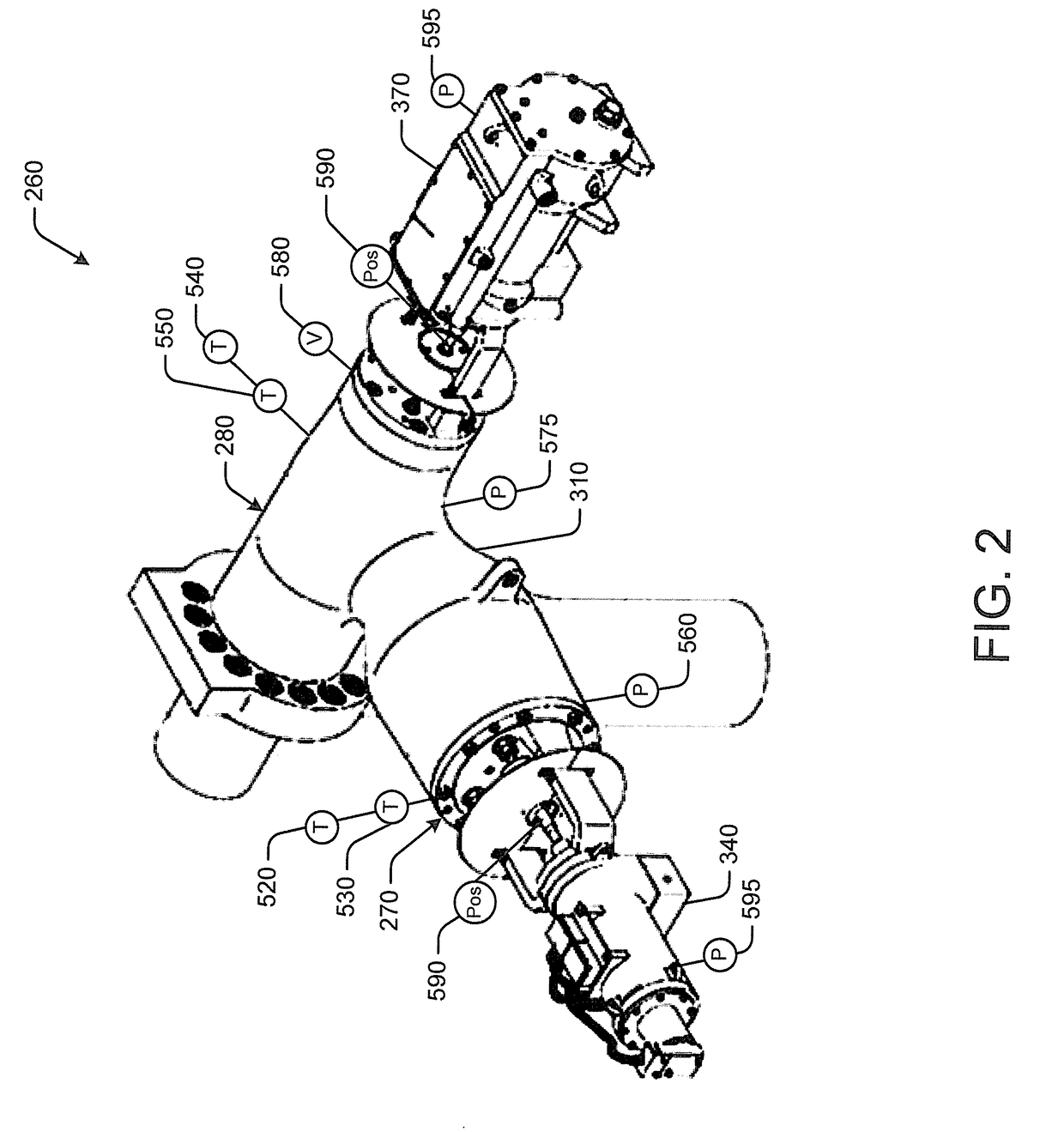

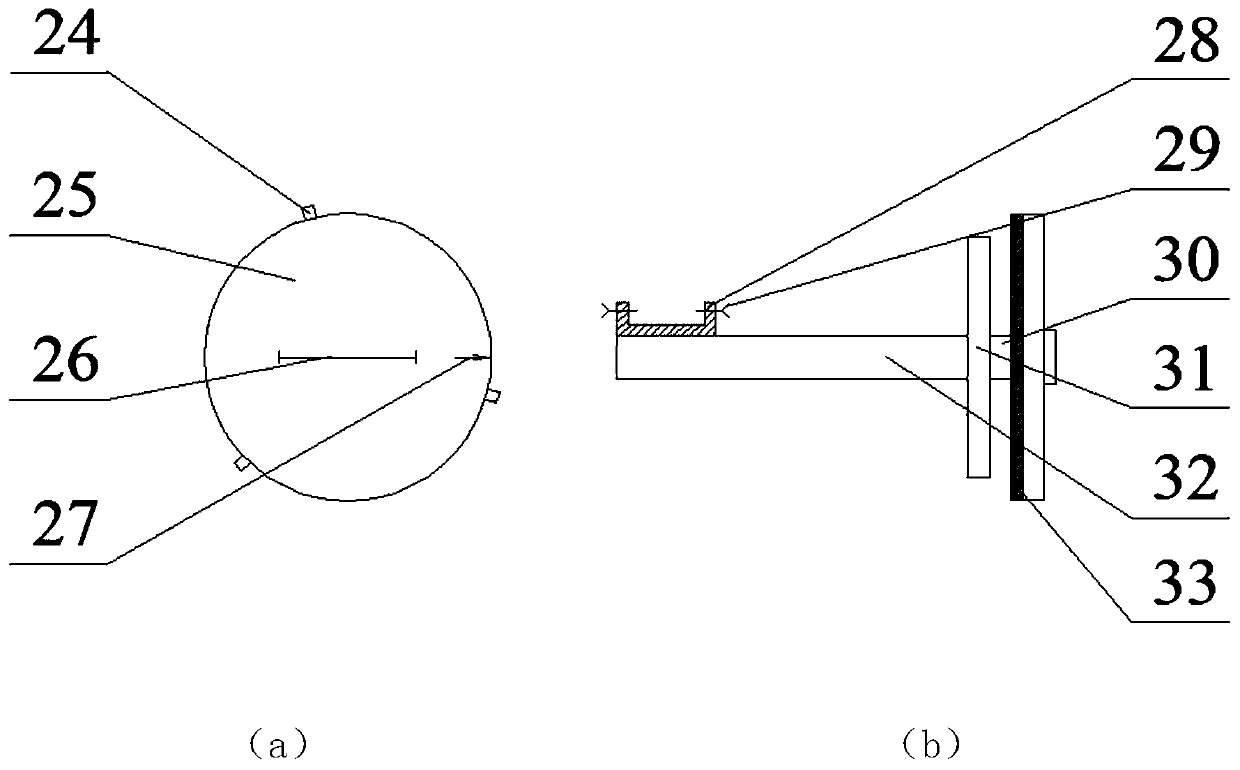

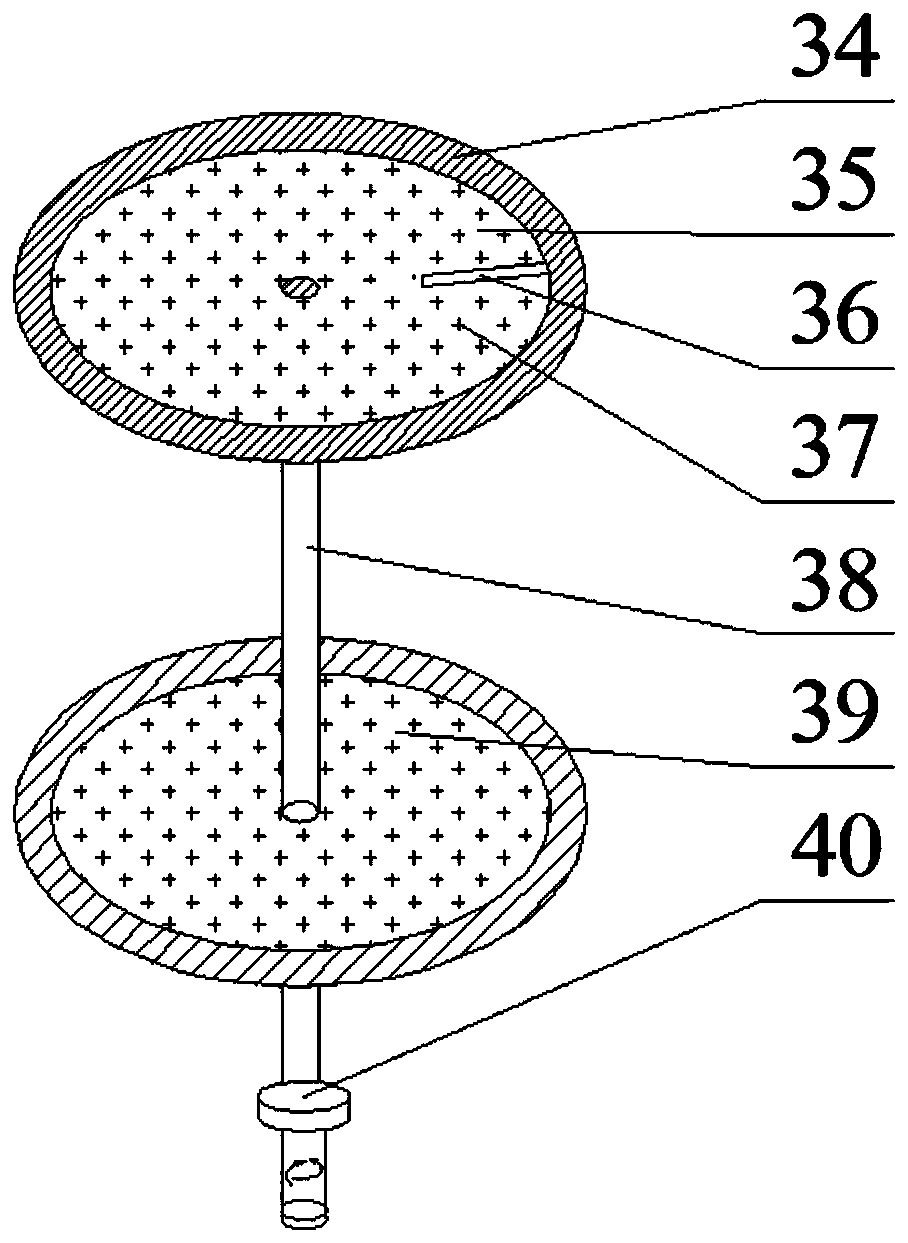

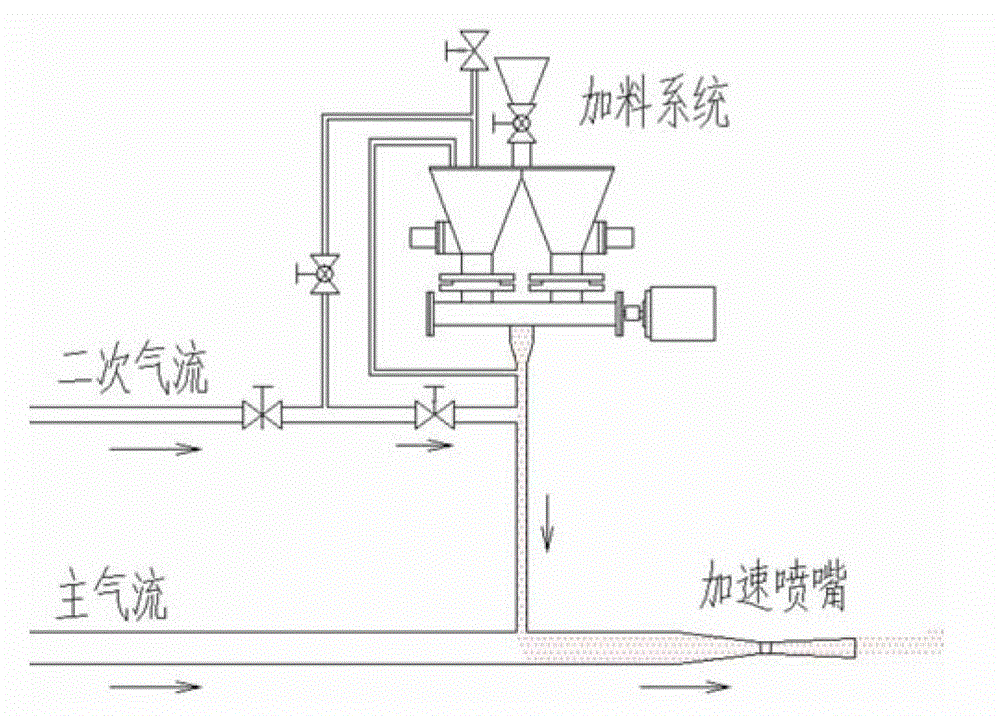

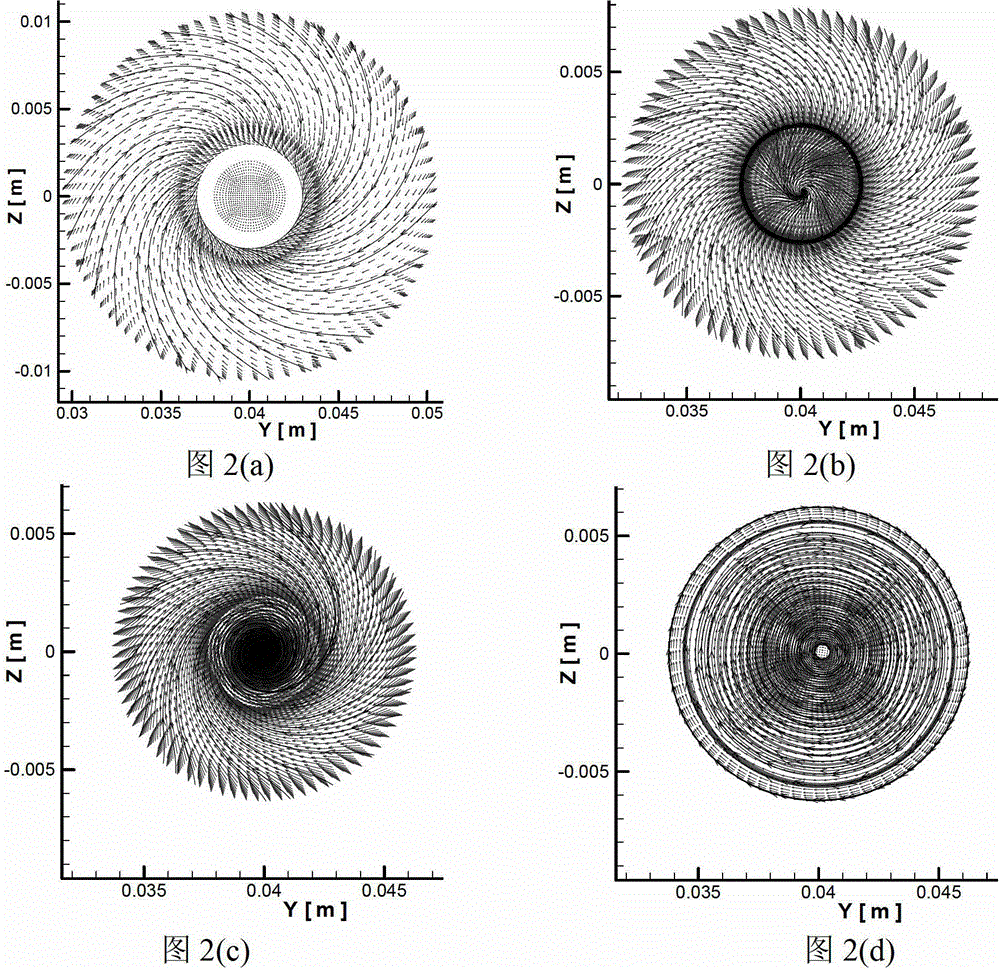

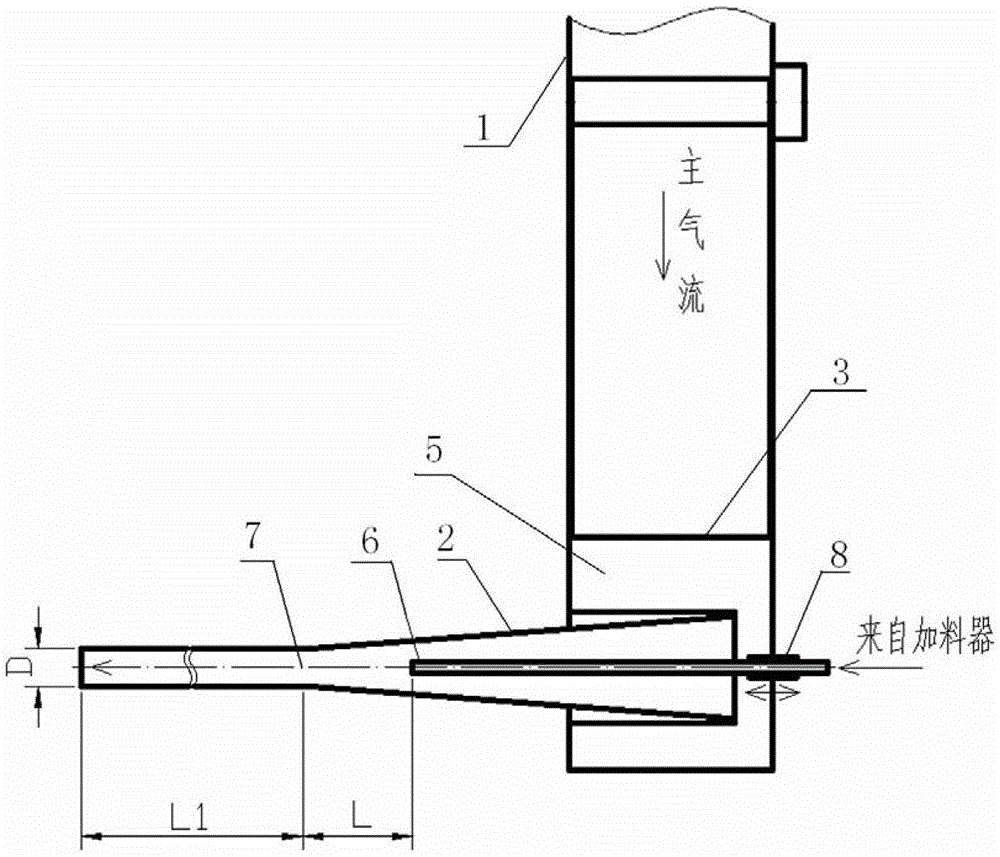

Solid particle pre-whirl mixing pneumatic acceleration device and method

InactiveCN102744173AStable spatial distributionImprove uniformityLiquid spraying apparatusCycloneThermal spraying

The invention discloses a solid particle pre-whirl mixing pneumatic acceleration device and method. An acceleration nozzle is of a contraction-straight pipe type or scaling type; the primary air flow generates moderate rotational flow before entering the acceleration nozzle through a specially-designed cyclone or a similar device; the solid particles are directly sprayed to the front part of the nozzle throat in an air flow carrying mode; the solid particles sprayed from a thin pipe are accelerated along the flow direction while generating radial diffusion under the dragging of the rotating air flow; the rotation kinetic energy of the air flow can be gradually dissipated under the mutual effect between the wall surface and the solid particles; the space distribution of the particles is dissipated along with the rotational flow and tends to be stable; and finally, a uniform high-speed air-solid two-phase jet flow is formed. The device and method disclosed by the invention can be used for improving the uniformity of the space distribution of the particles and the speed consistency of the particles, and are of great significance in improving the technology quality of the industrial production of a material thermal spraying technology, sand blasting and the like and improving the test precision of the scientific research field of solid particle erosion acceleration test and the like.

Owner:XI AN JIAOTONG UNIV

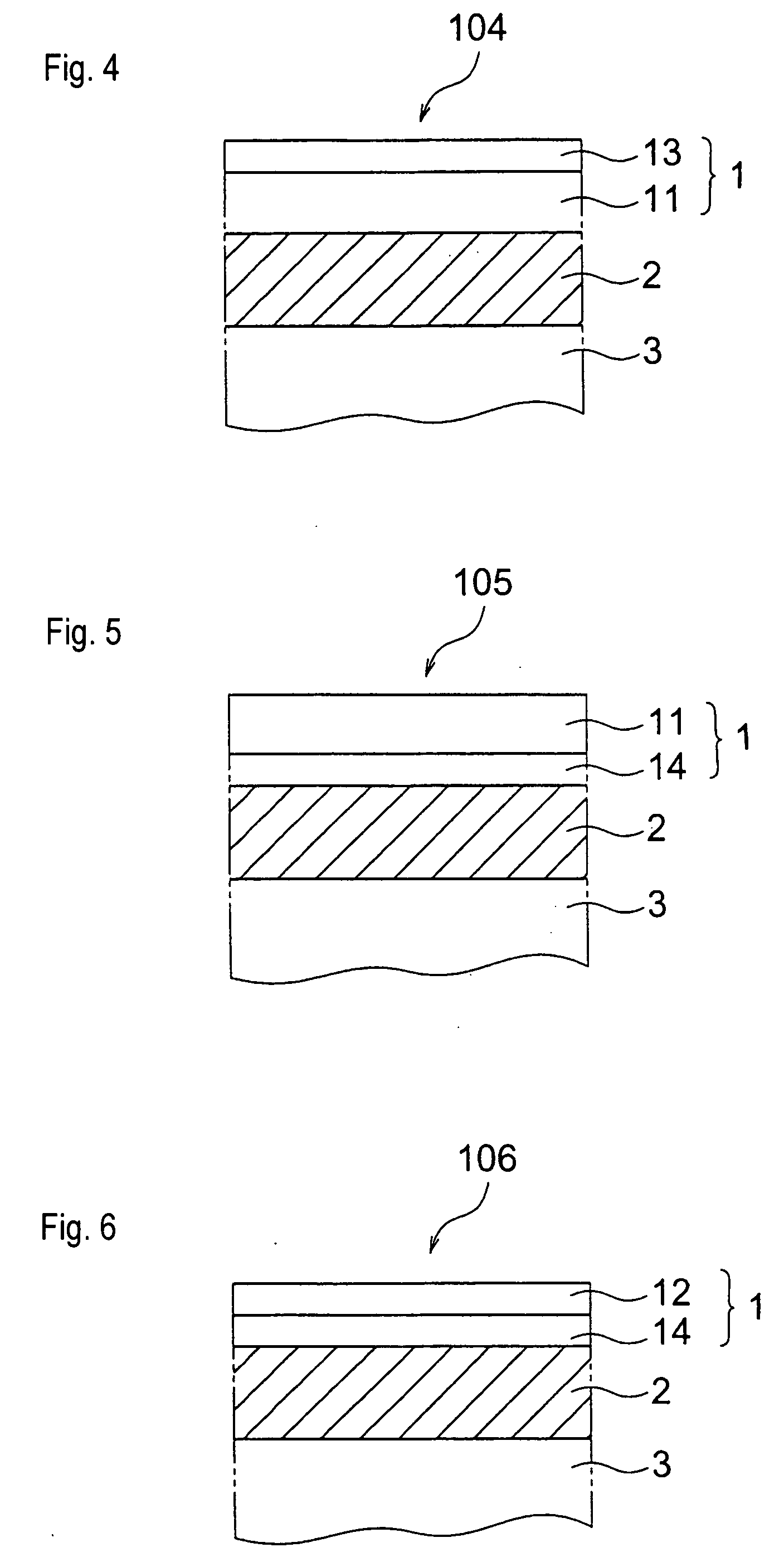

Solid particle erosion resistant surface treated coating and rotating machine applied therewith

ActiveUS7998581B2Reduce fatigue strengthImprove corrosion resistanceLiquid surface applicatorsPump componentsSolid particleUltimate tensile strength

A solid particle erosion resistant surface treated coating has a solid particle erosion resistance that is largely enhanced and a rotating member having the coating gains oxidation resistance without deteriorating a fatigue strength. Also, a rotating machine can have this coating applied thereto. The solid particle erosion resistant surface treated coating has a nitrided hard layer formed on a surface of a base material and a PVD (physical vapor deposition) hard layer of at least one layer formed on the nitrided hard layer by a PVD method. Deformation of the base material by collisions by solid particles is prevented and cracking of the coating is prevented. Thereby, the solid particle erosion resistance is secured, life of the solid particle erosion resistant surface treated coating can be increased and oxidation resistance and fatigue strength are enhanced.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

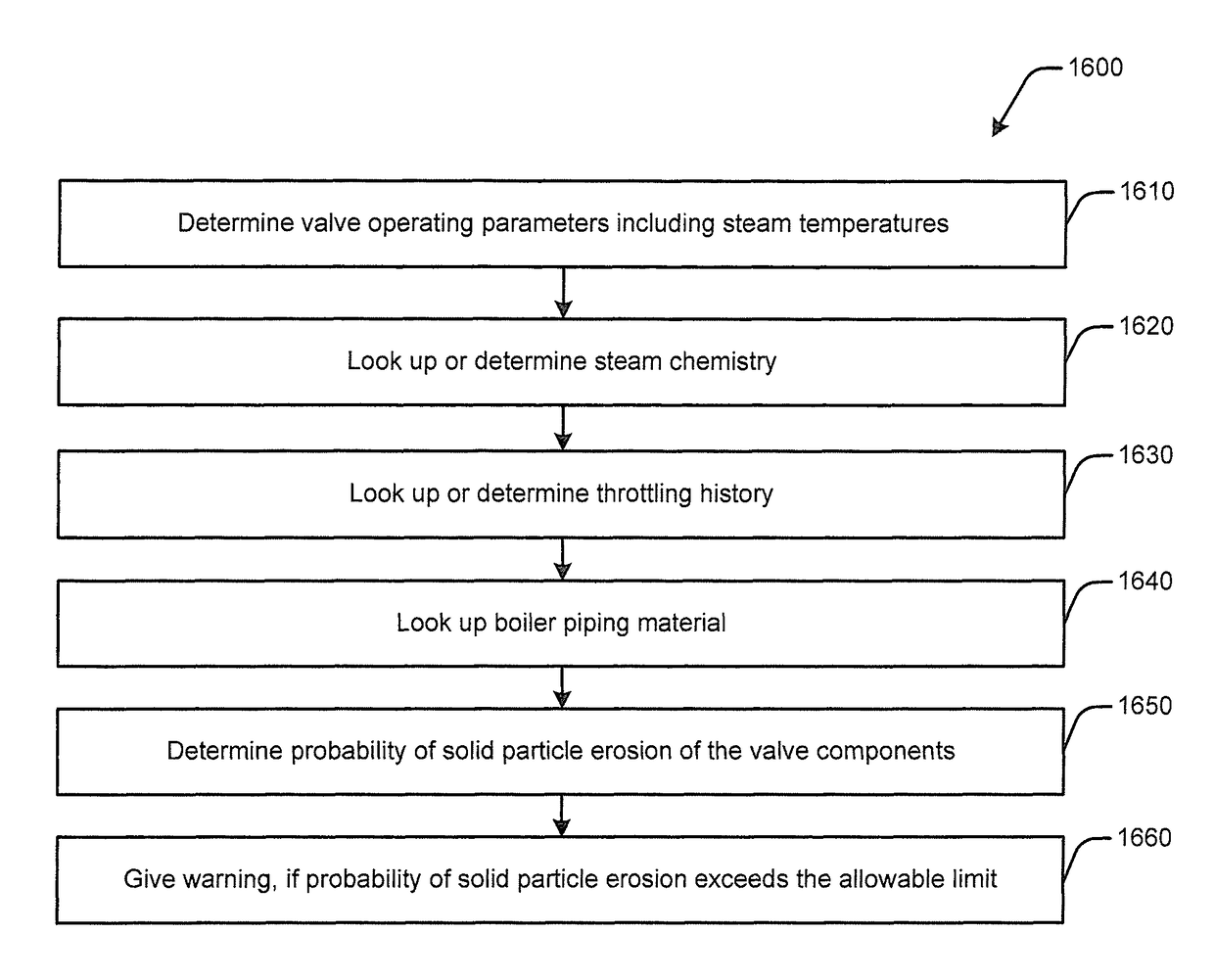

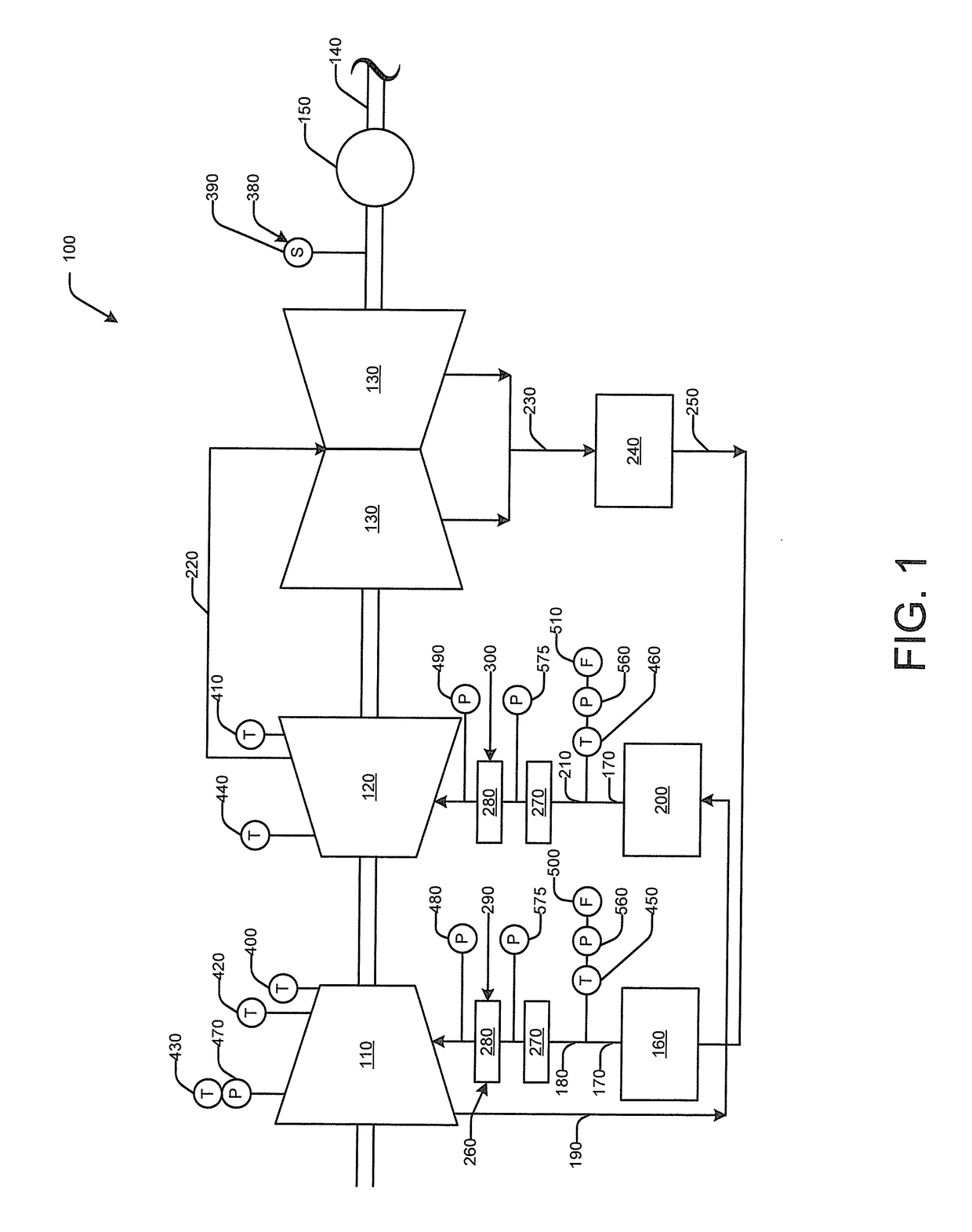

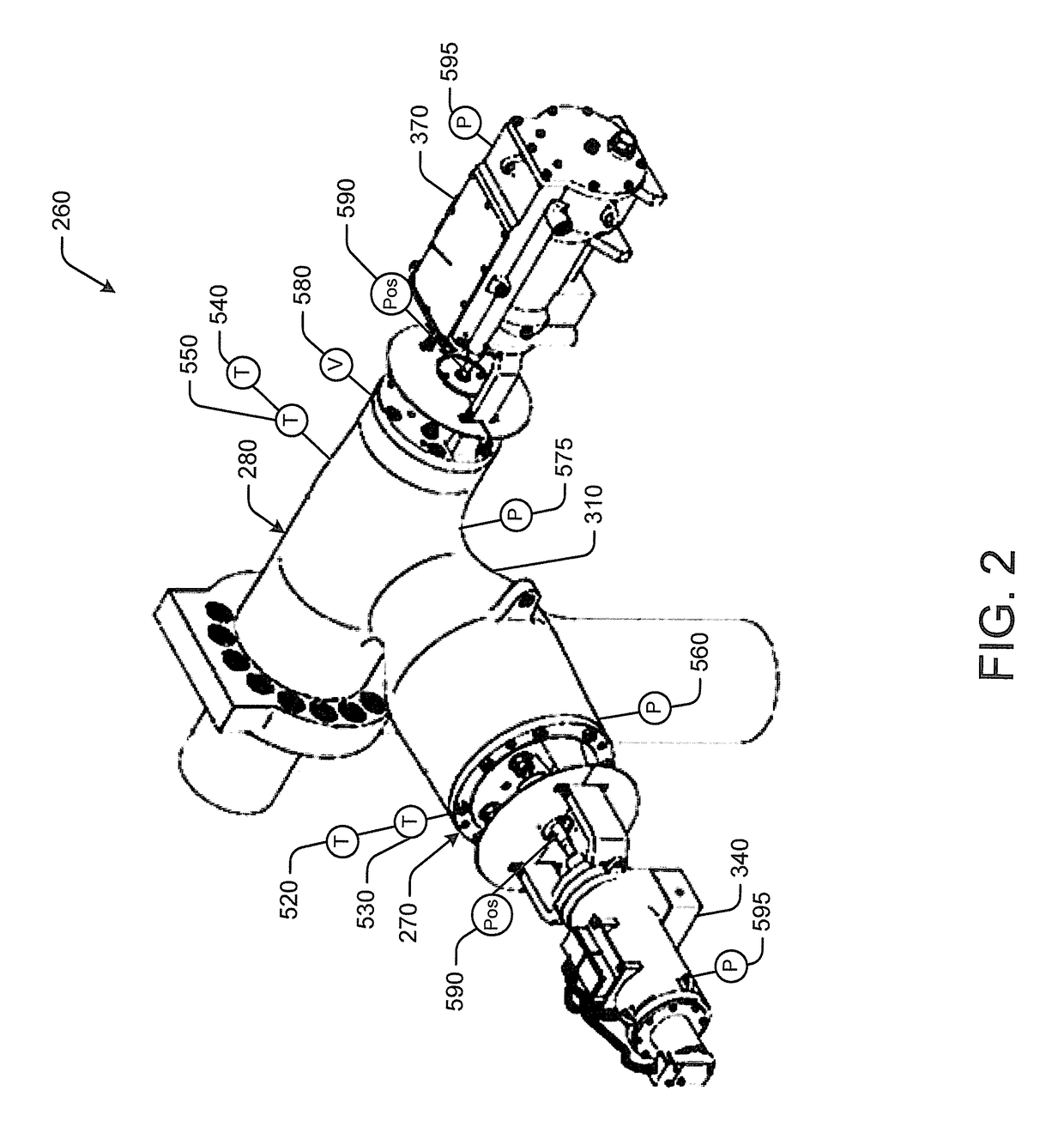

Solid Particle Erosion Indicator Module For A Valve And Actuator Monitoring System

InactiveUS20180058254A1Programme controlGas-turbine engine testingChemical compositionSteam pressure

The present application provides a method of evaluating valve conditions in a turbine by a data acquisition system. The method may include the steps of receiving a number of operating parameters from a number of sensors, wherein the operating parameters may include steam temperatures determined over time and steam pressure, determining a steam chemistry, a throttling history, and a piping material, determining a probability of valve erosion based upon the steam temperatures determined over time, the steam chemistry, the throttling history, and the piping material, and altering one or more of the operating parameters and / or initiating repair procedures based upon the determined probability.

Owner:GENERAL ELECTRIC TECH GMBH

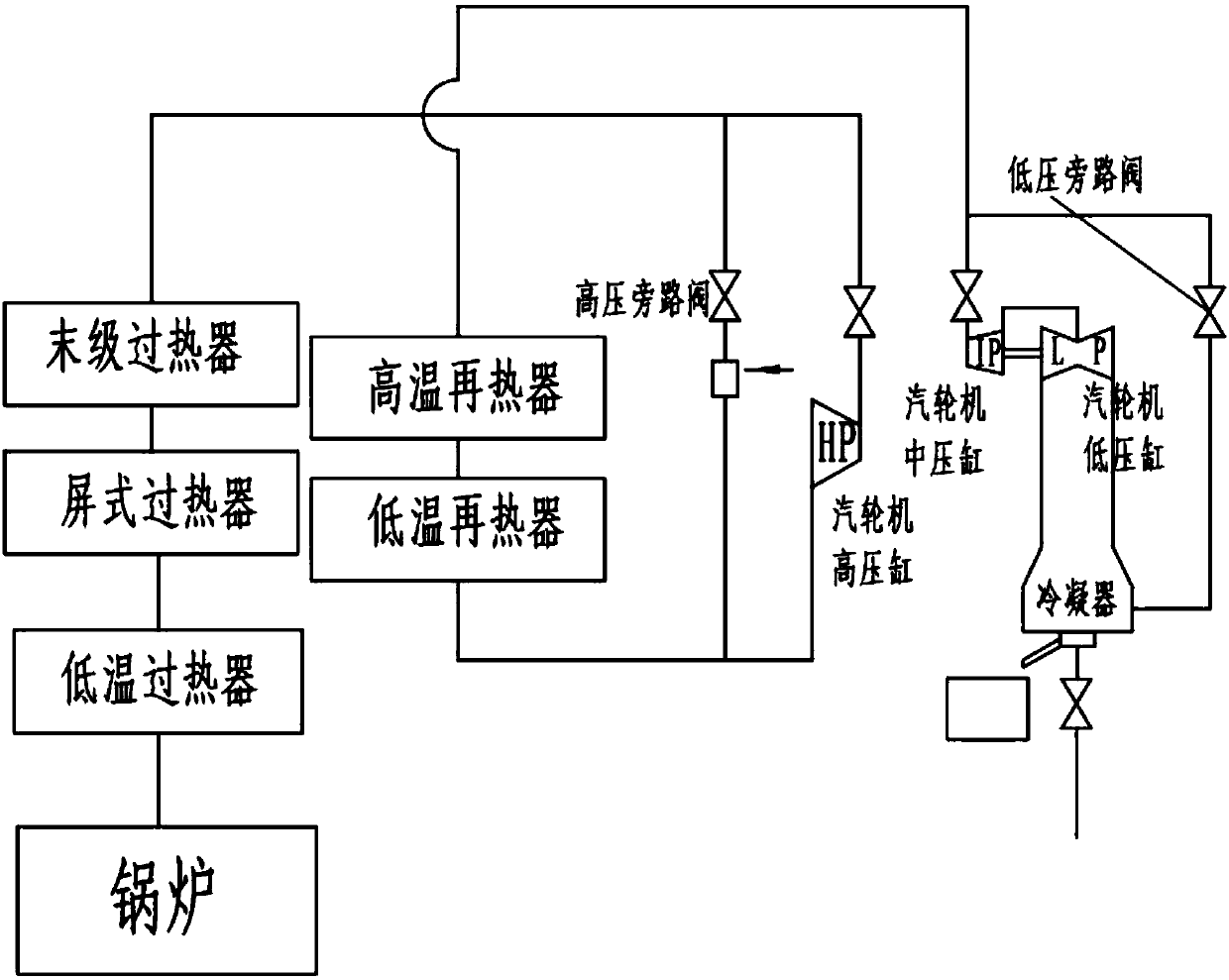

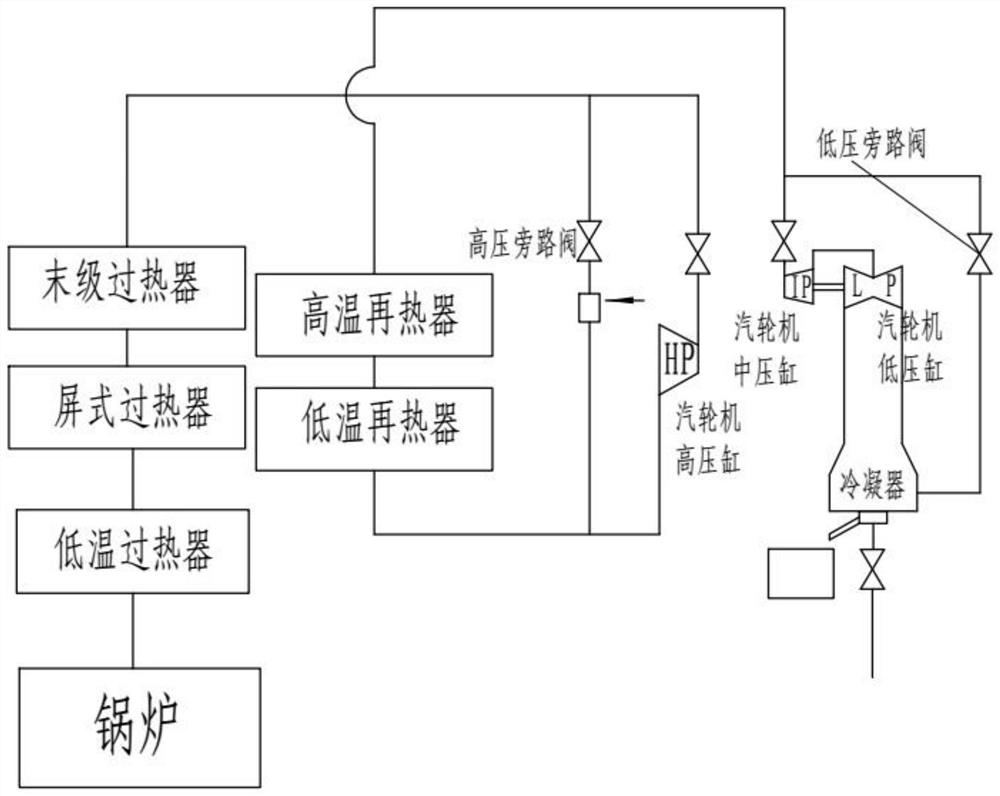

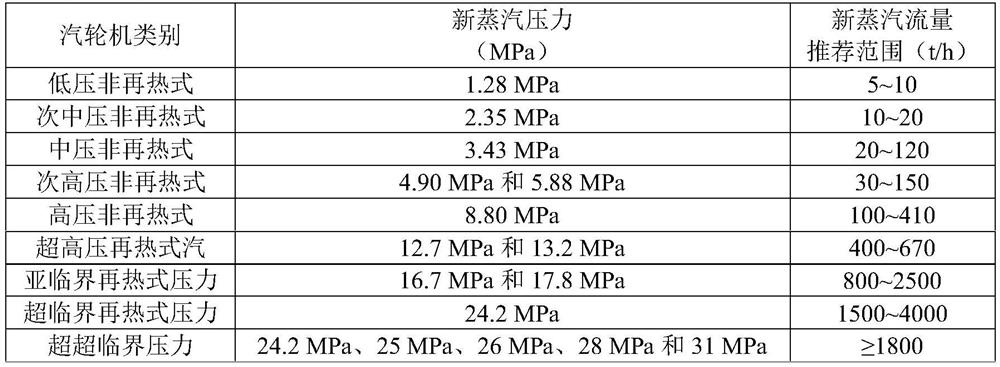

Method for reducing solid particle erosion to supercritical steam turbine

The invention discloses a method for reducing solid particle erosion to a supercritical steam turbine. The method comprises the following steps: 1) controlling the evaporation capacity, steam pressureand steam temperature of a boiler; 2) closing high and medium pressure main steam valves and regulating steam valves of the steam turbine, and opening a high pressure by-pass valve and a low pressureby-pass valve; 3) increasing the purge flow; 4) reducing the purge flow; 5) increasing the purge flow; 6) repeating the steps (1) and (5); and (7) collecting solid particulates. The method for reducing solid particle erosion to the supercritical steam turbine has the benefits as follows: by repeatedly changing the opening degree of the by-pass valves, the repeated changing of the purge steam pressure and flow is realized, the falling off of metallic oxides on the inner wall of the boiler tube is facilitated, the purging effect is ensured, the falling metallic oxides is blown into a condenserhot well through the steam turbine bypasses and collected and removed through a solid particle collecting device arranged in the hot well, solid particles generated are removed in time during the start-up phase of the turbine unit, the damage to the blade profile is avoided, the operation safety and economic efficiency of the turbine unit are improved, and the service life of the turbine unit is prolonged.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

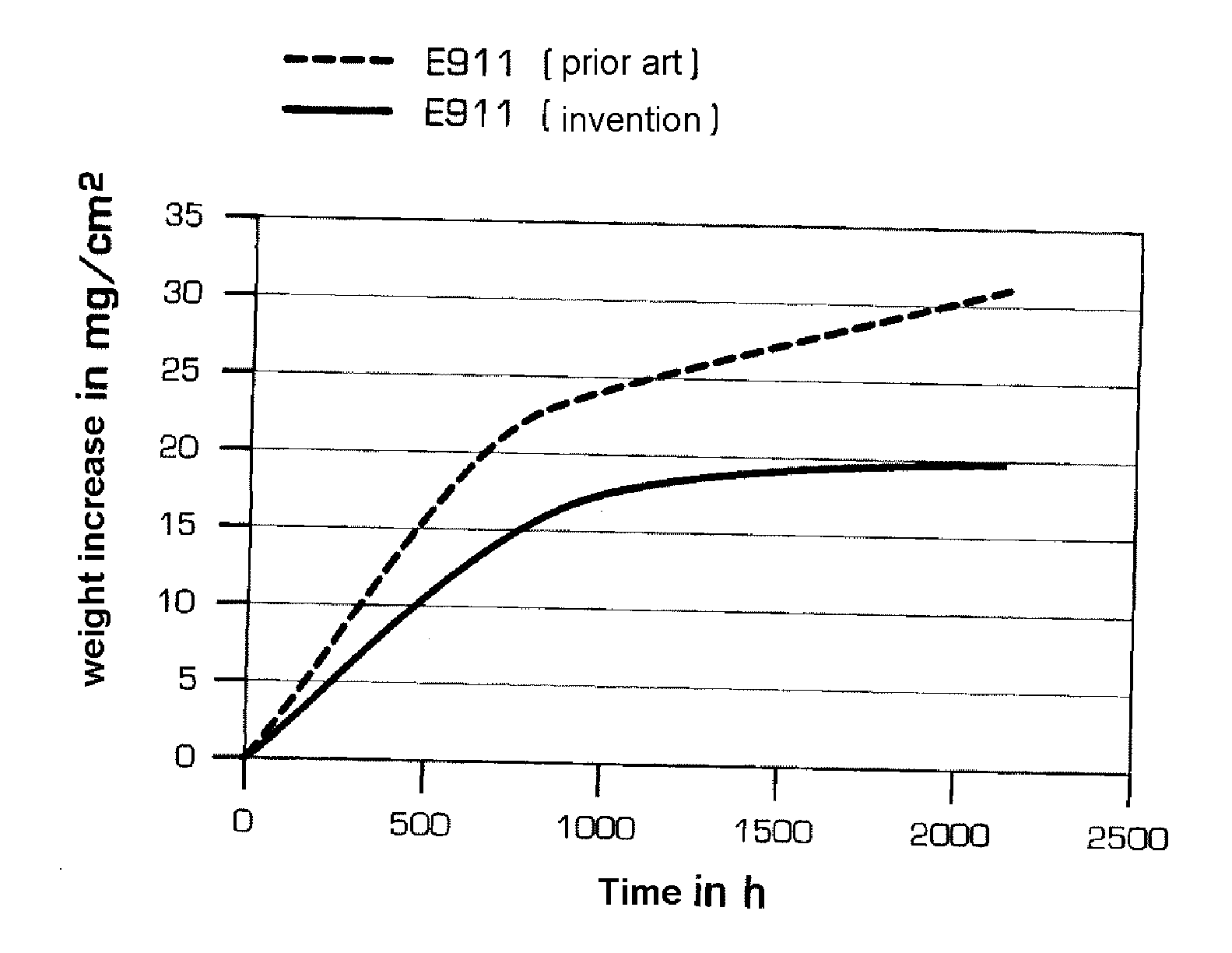

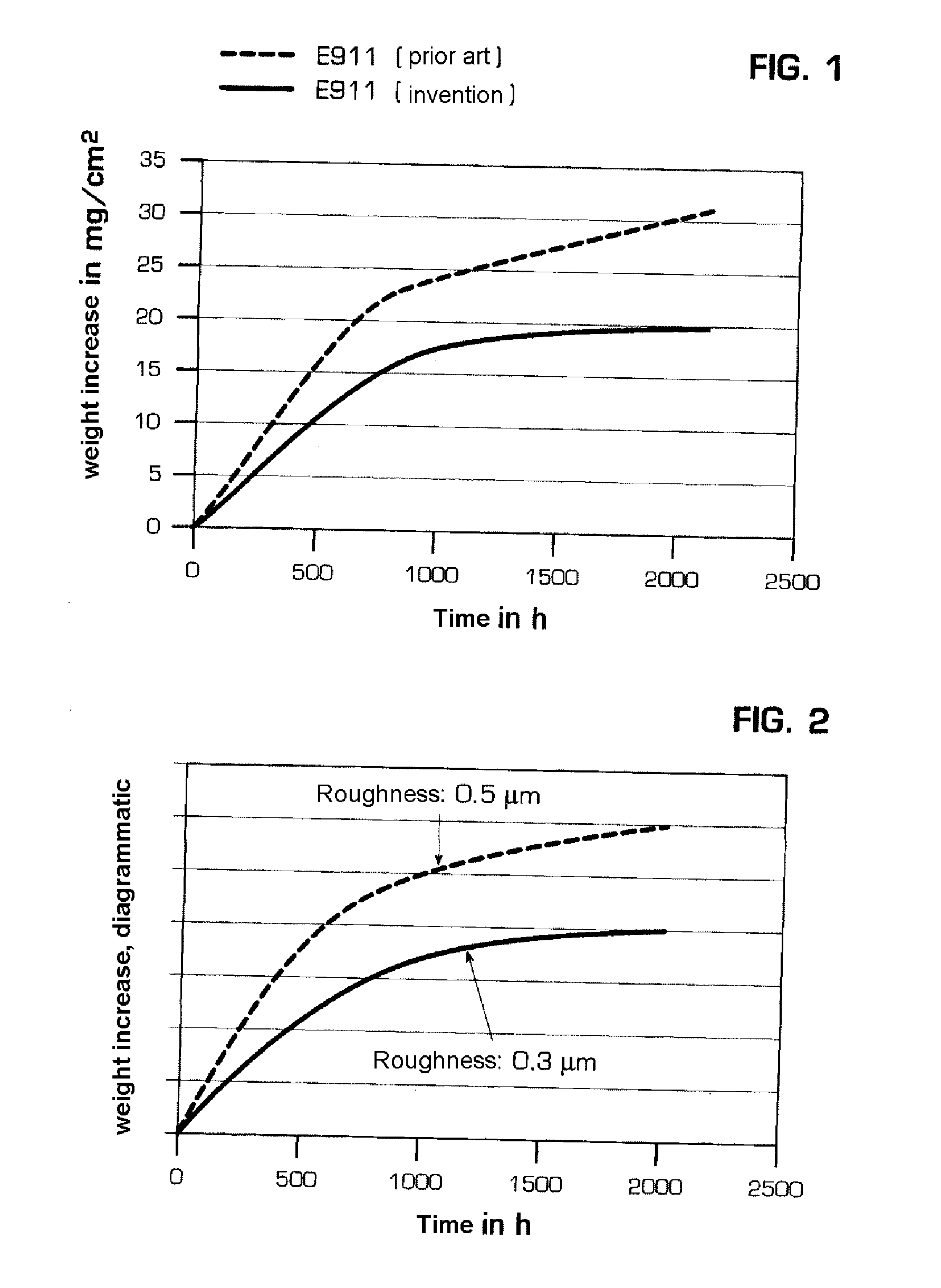

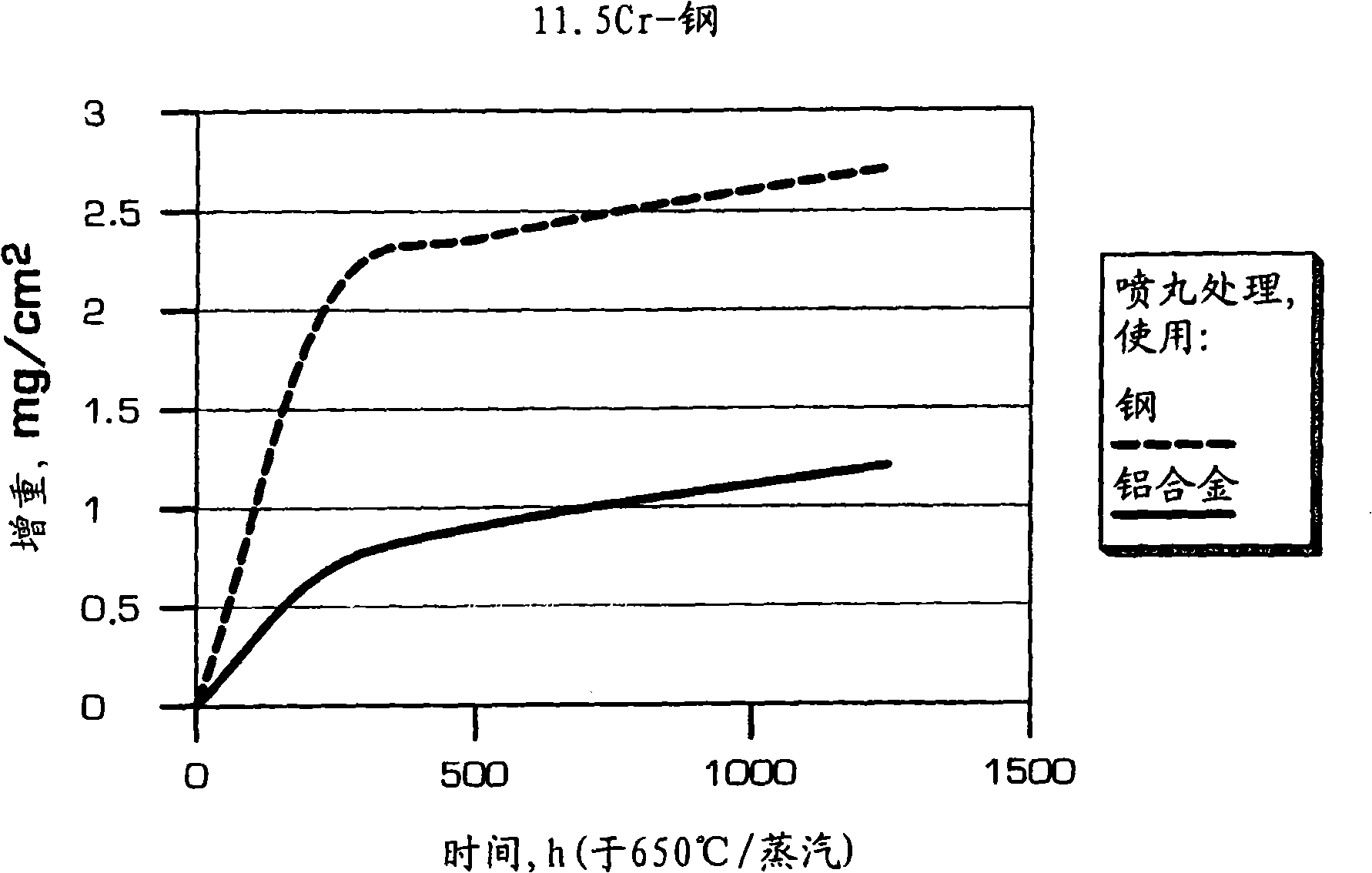

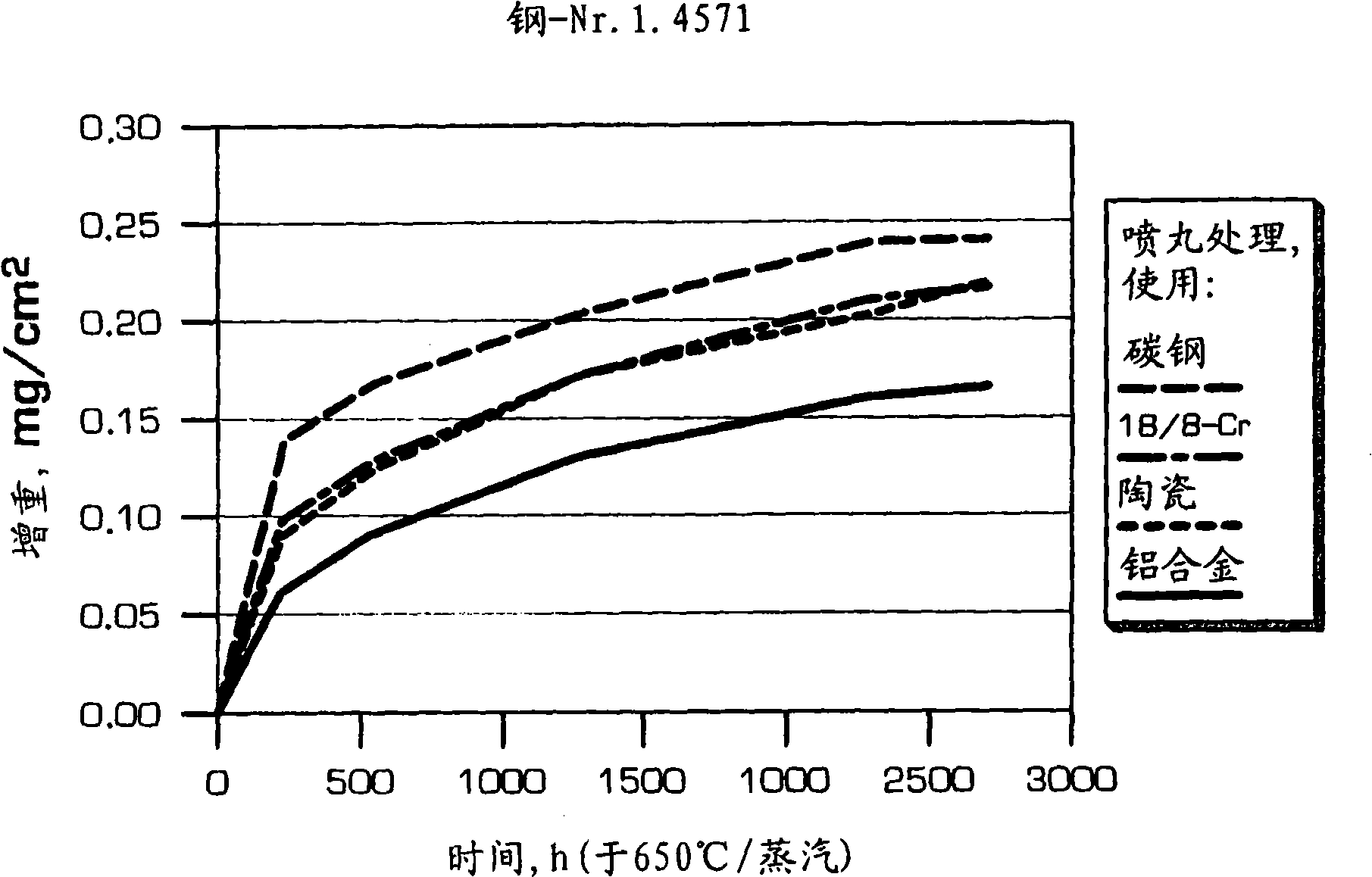

Method for the surface treatment of cr steels

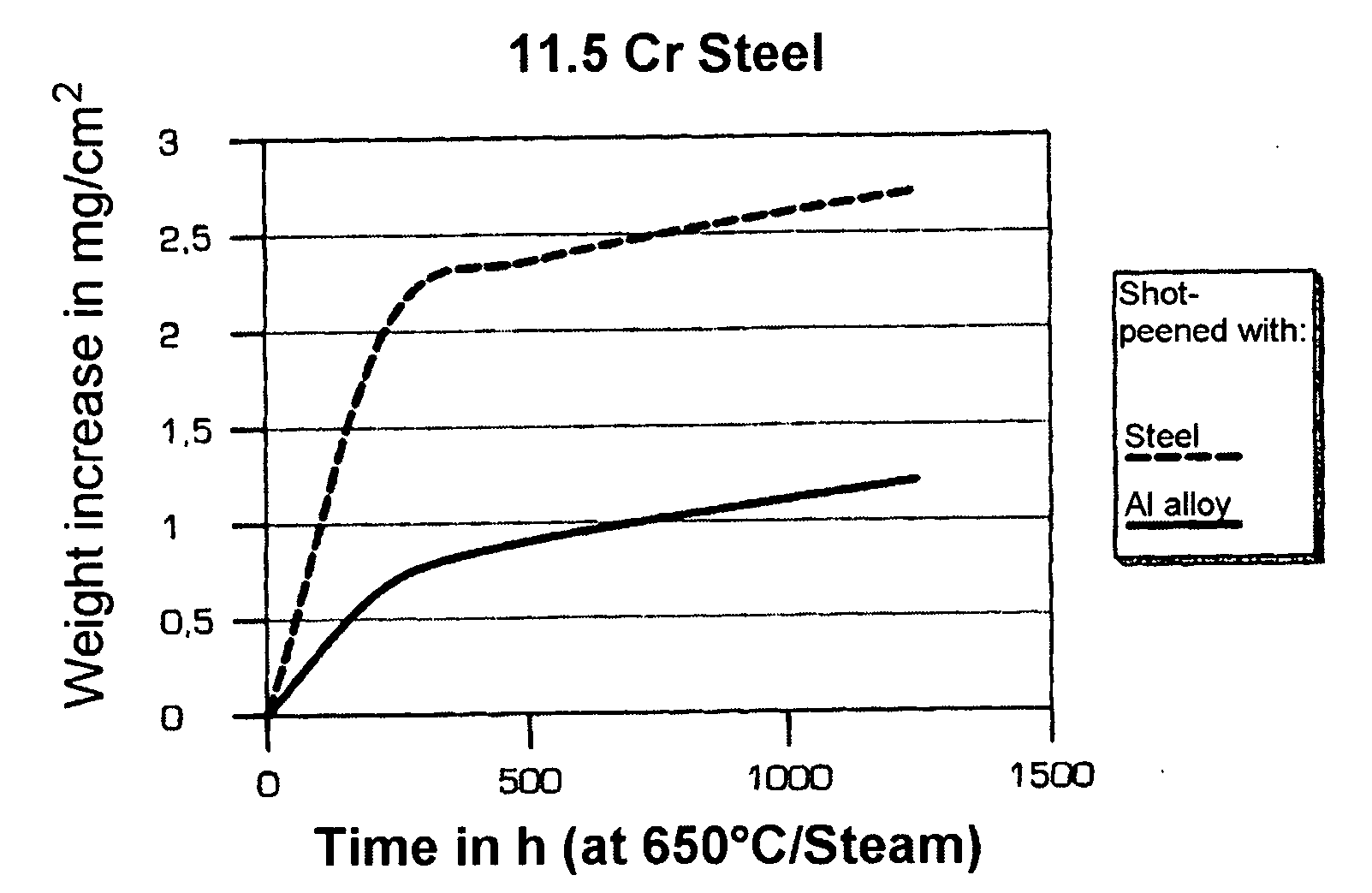

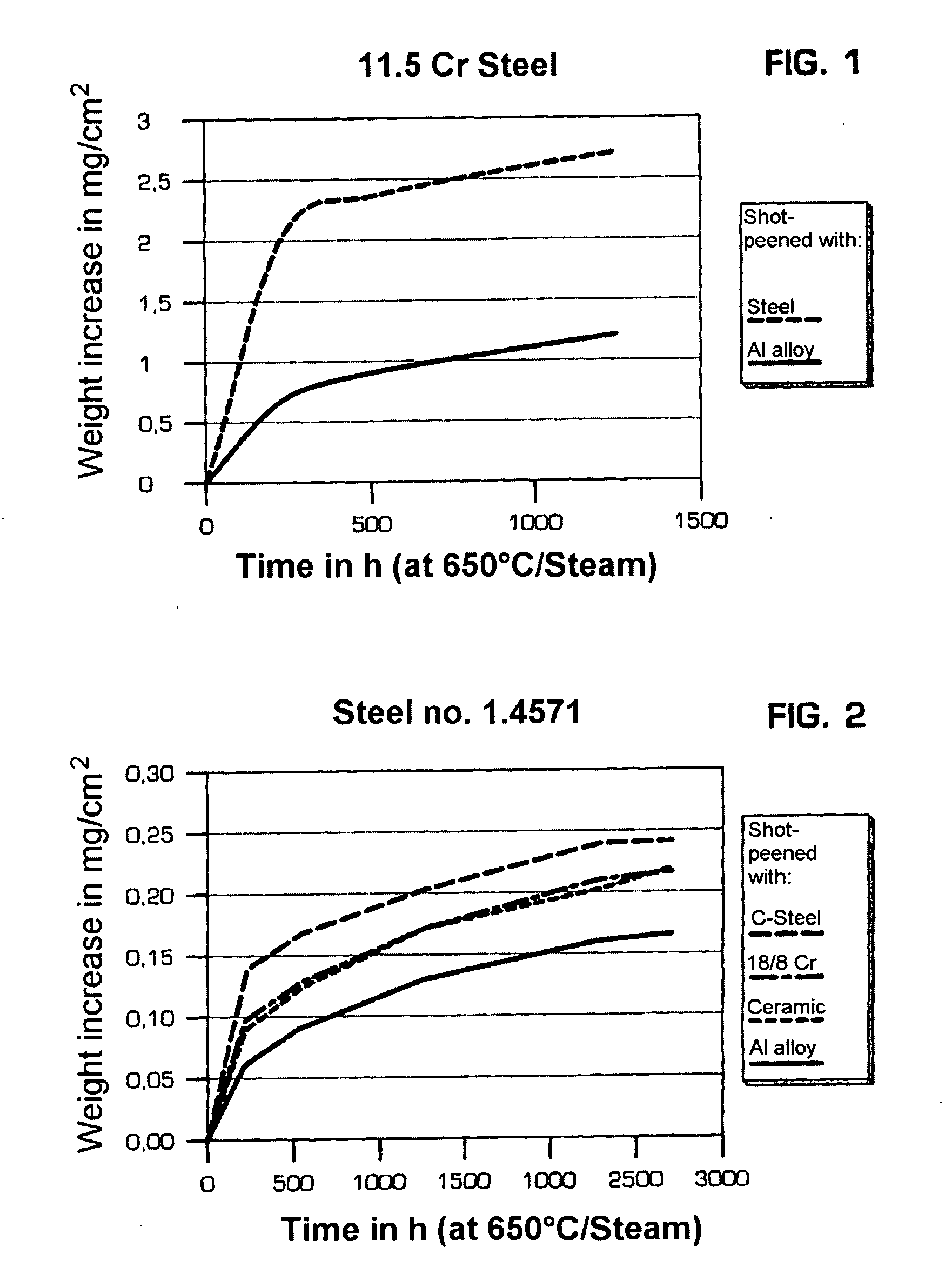

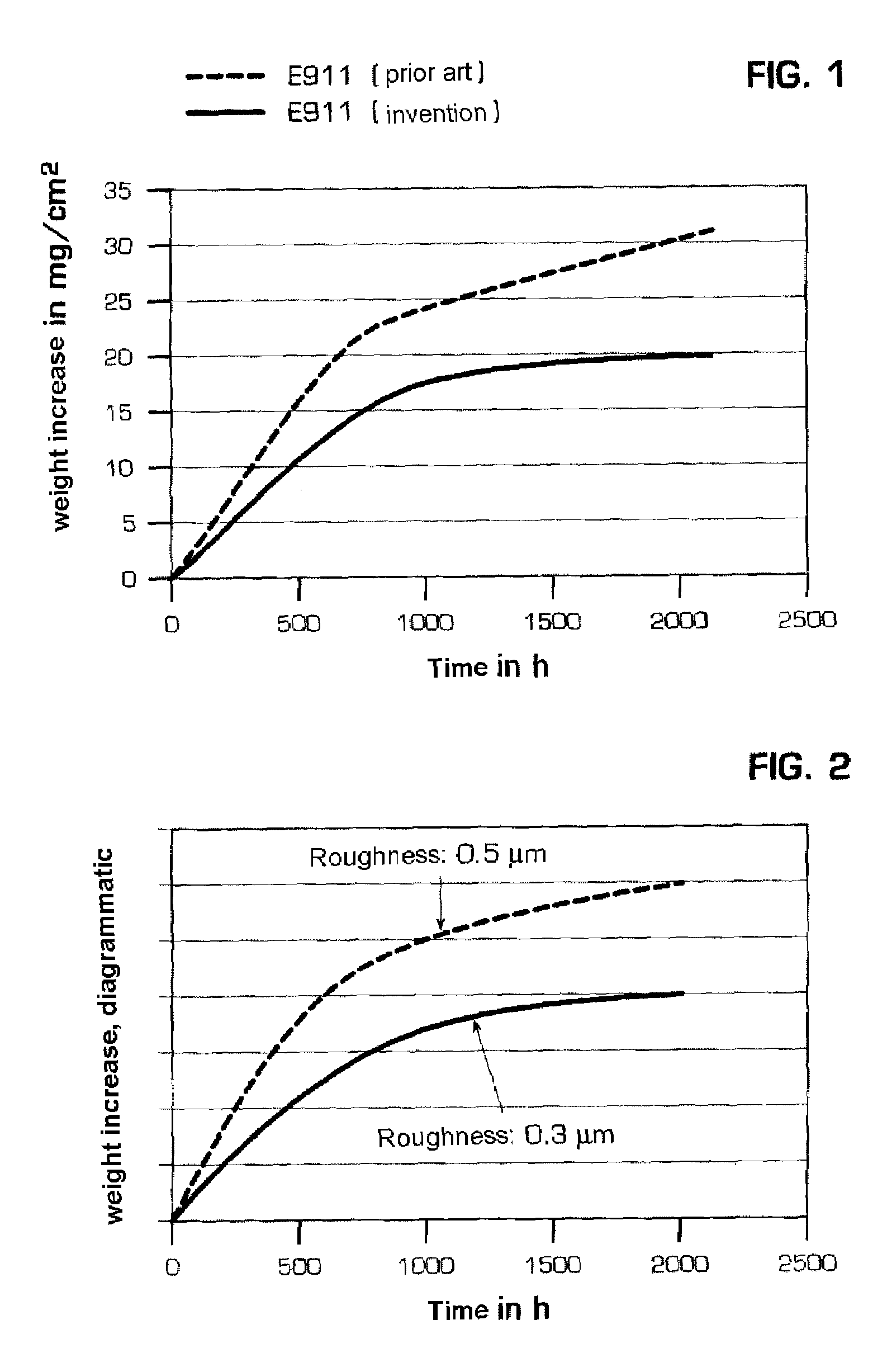

InactiveUS20090077801A1Promote oxidationImprove the immunityMetal-working apparatusEngine componentsSolid particle erosionPeening

A method for the surface treatment of ferritic / martensitic 9-12% Cr steels and of austenitic Cr steels for the purpose of achieving increased resistance to oxidation and solid particle erosion at application temperatures of above 500° C., in particular of approximately 650° C., in steam, includes that the surface of the steel is shot-peened with particles of aluminum or of an aluminum alloy; optionally, in a subsequent step, the surface of the steel is smoothed to a roughness of <0.5 μm, preferably <0.3 μm. Following additional heat treatment is not necessary, and the parts thus treated may be employed, for example, as blades in steam turbines.

Owner:ALSTOM TECH LTD

Method for the surface treatment of ferritic/martensitic 9-12% Cr steel

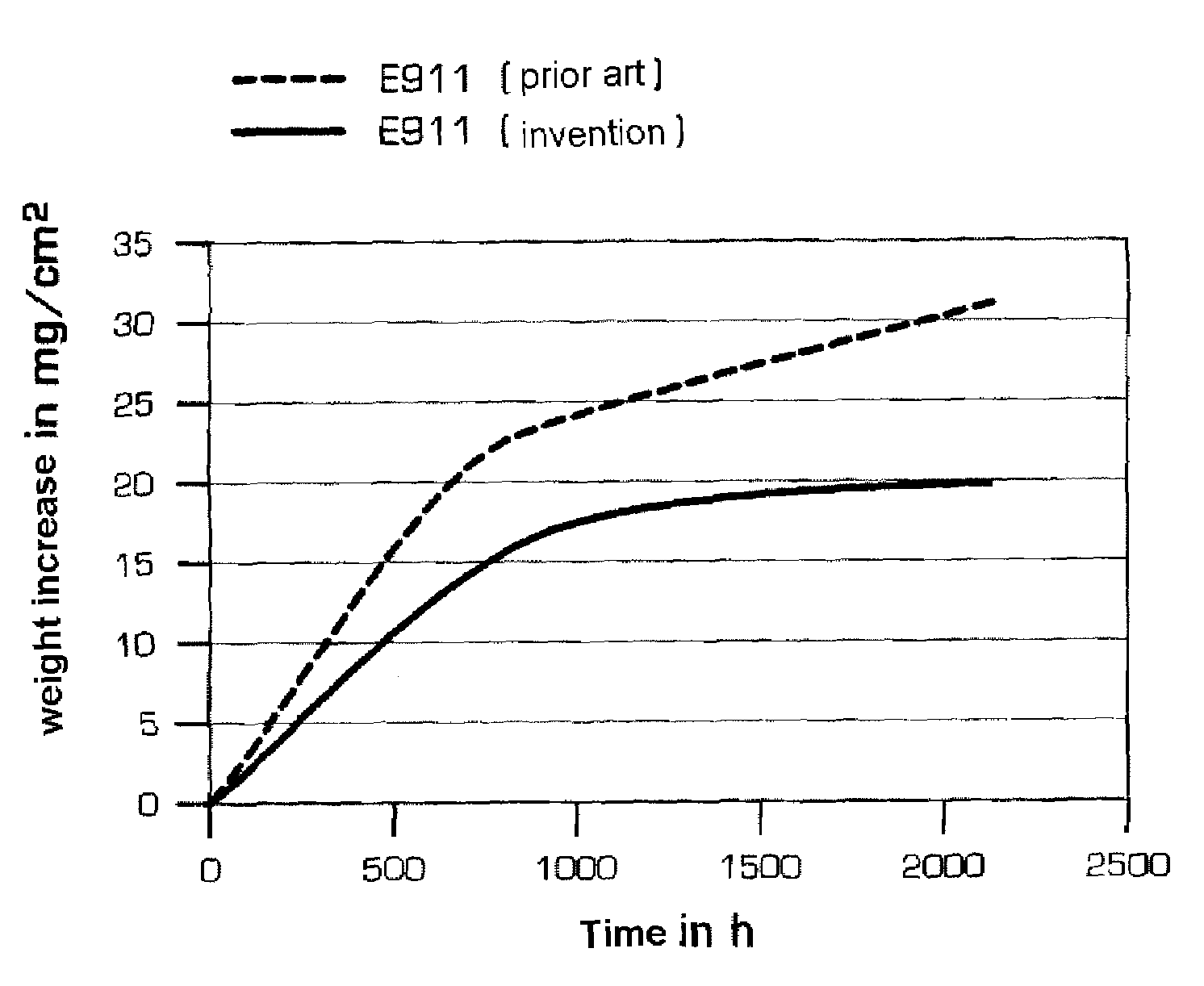

InactiveUS7568368B2Promote oxidationImprove the immunityBlade accessoriesBurnishing machinesSolid particle erosionPeening

A method for the surface treatment of ferritic / martensitic 9-12% Cr steels for the purpose of achieving an improved oxidation behavior and increased resistance to solid particle erosion at application temperatures of above 500° C., in particular around 650° C., in steam includes, in a first step, a known shot peening of the surface of the steel with steel particles, and, subsequently, in a second step, shot peening with glass particles, optionally, in a following third step, the surface of the steel being smoothed. A subsequent additional heat treatment is unnecessary.

Owner:ALSTOM TECH LTD

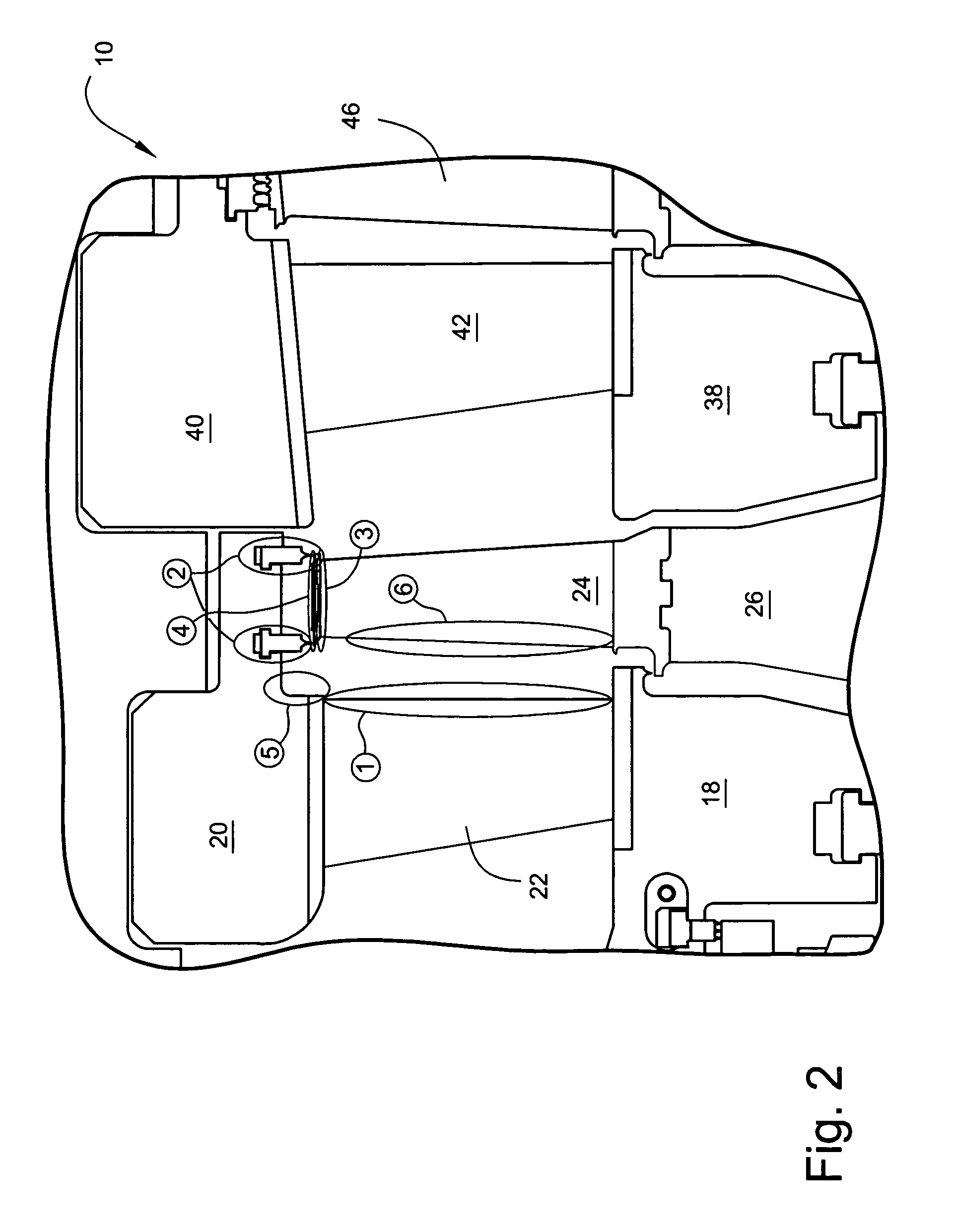

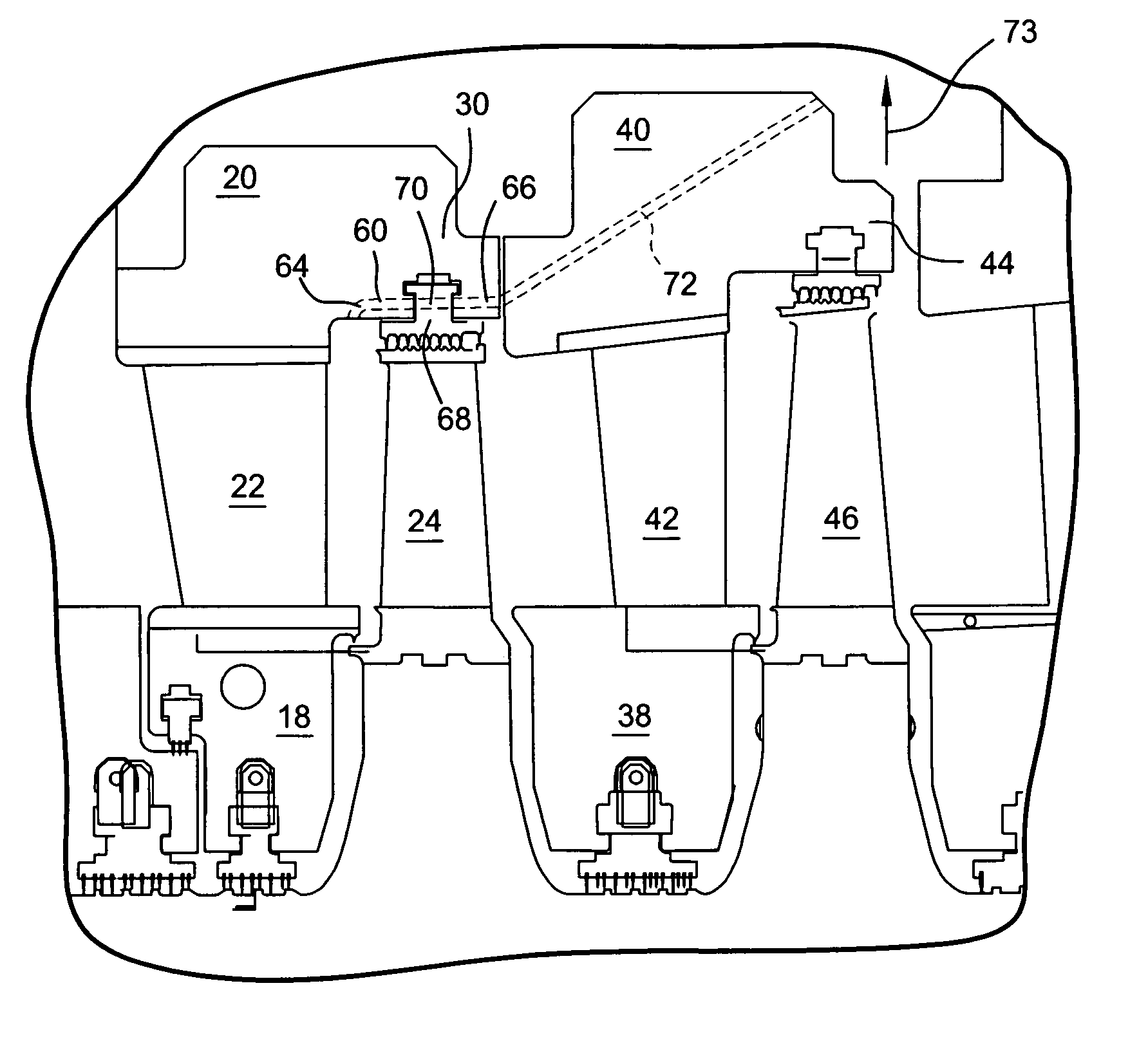

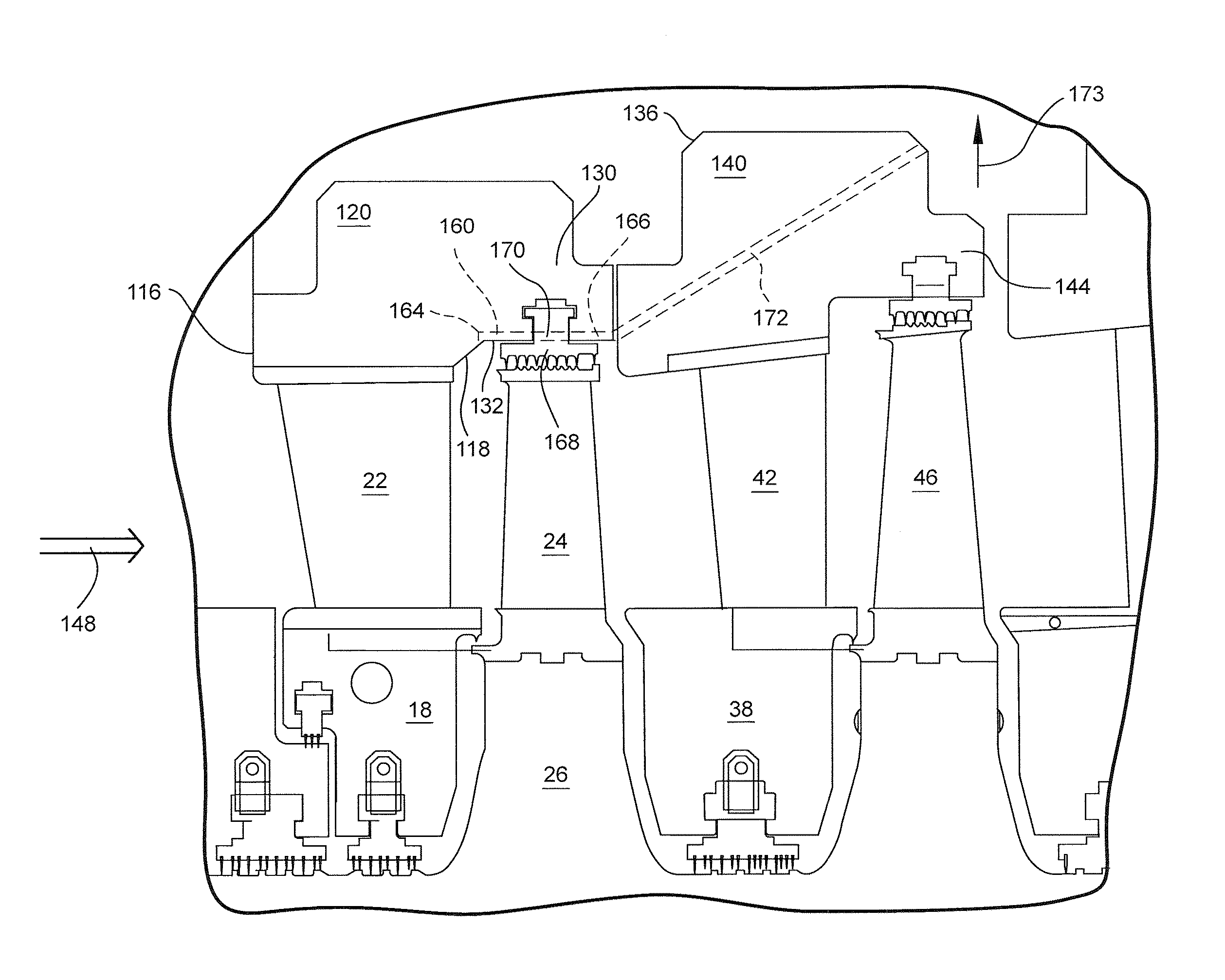

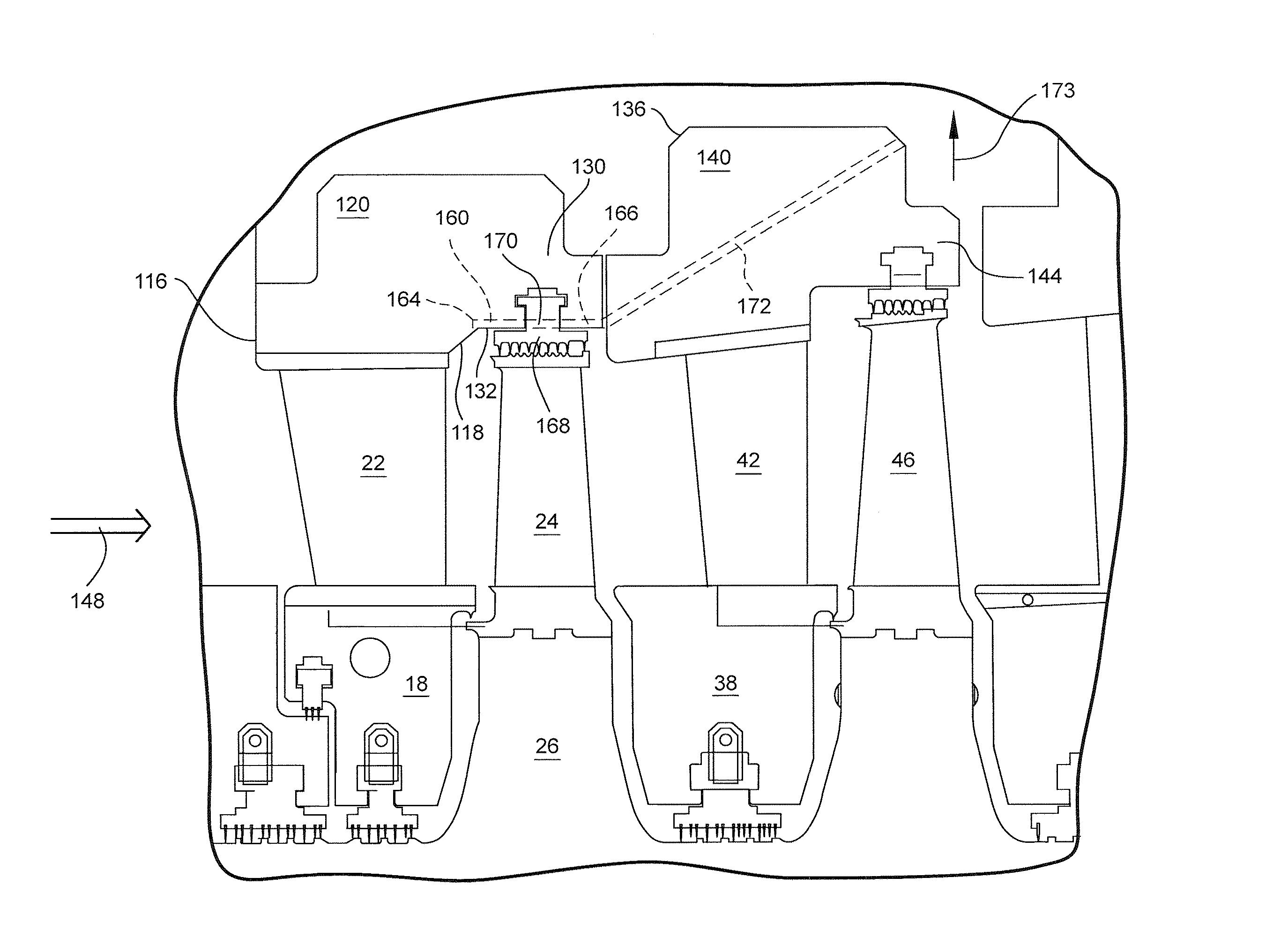

Apparatus for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through angled slots formed in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The slot through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The slot in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices is thereby minimized.

Owner:GENERAL ELECTRIC CO

Apparatus for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through angled slots formed in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The slot through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The slot in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices is thereby minimized.

Owner:GENERAL ELECTRIC CO

Solid particle erosion indicator module for a valve and actuator monitoring system

The present application provides a method of evaluating valve conditions in a turbine by a data acquisition system. The method may include the steps of receiving a number of operating parameters from a number of sensors, wherein the operating parameters may include steam temperatures determined over time and steam pressure, determining a steam chemistry, a throttling history, and a piping material, determining a probability of valve erosion based upon the steam temperatures determined over time, the steam chemistry, the throttling history, and the piping material, and altering one or more of the operating parameters and / or initiating repair procedures based upon the determined probability.

Owner:GENERAL ELECTRIC TECH GMBH

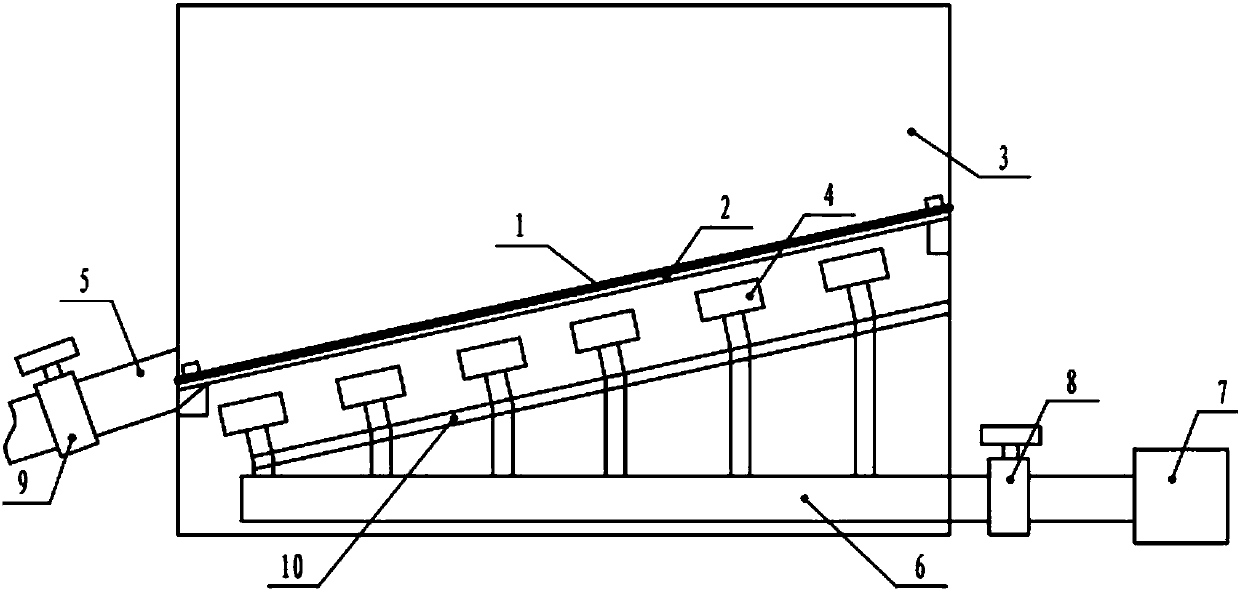

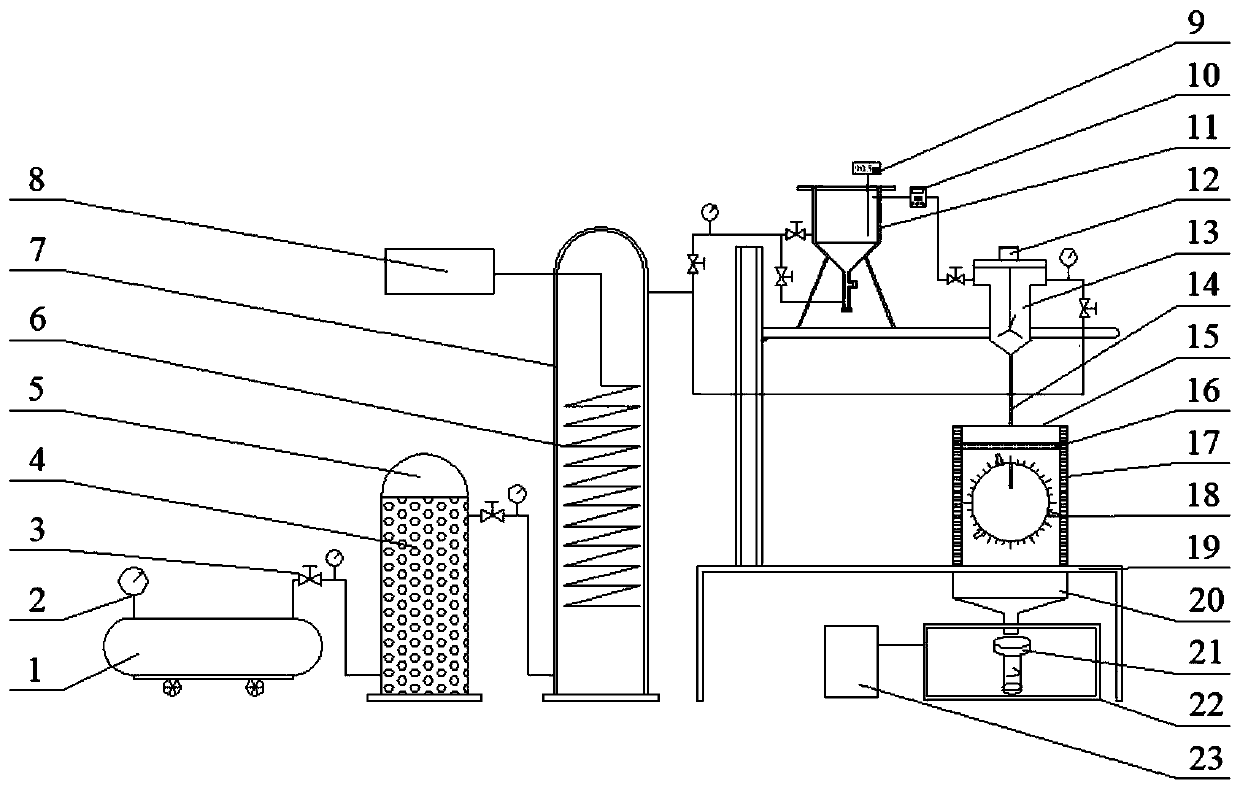

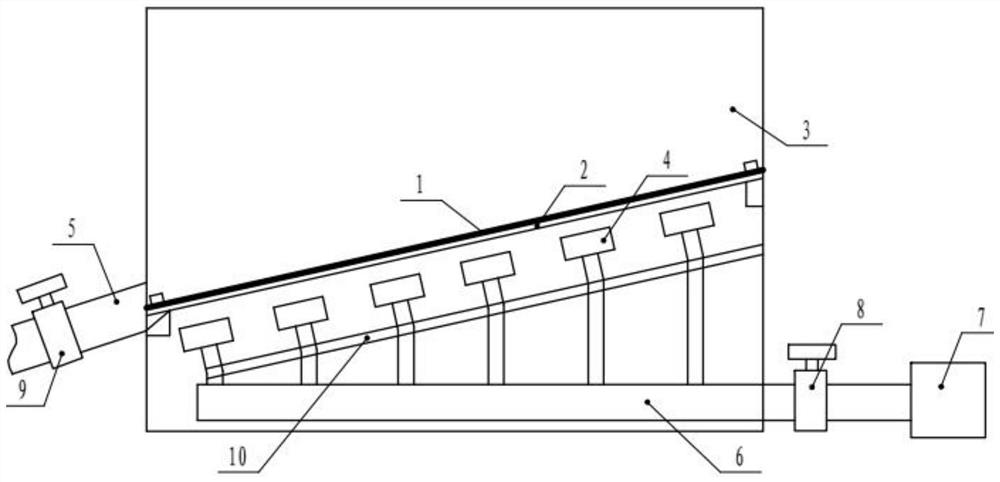

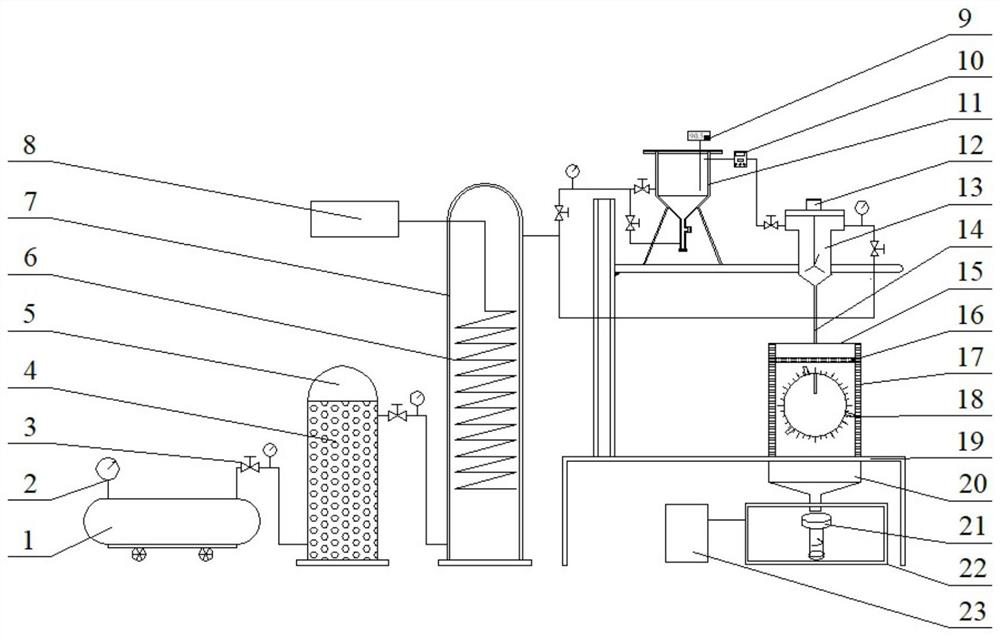

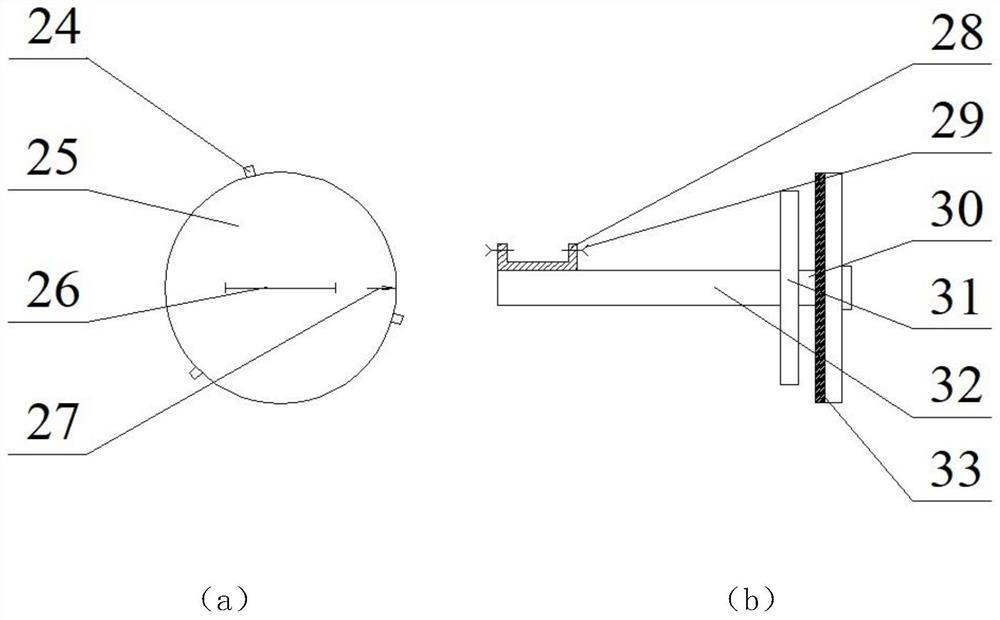

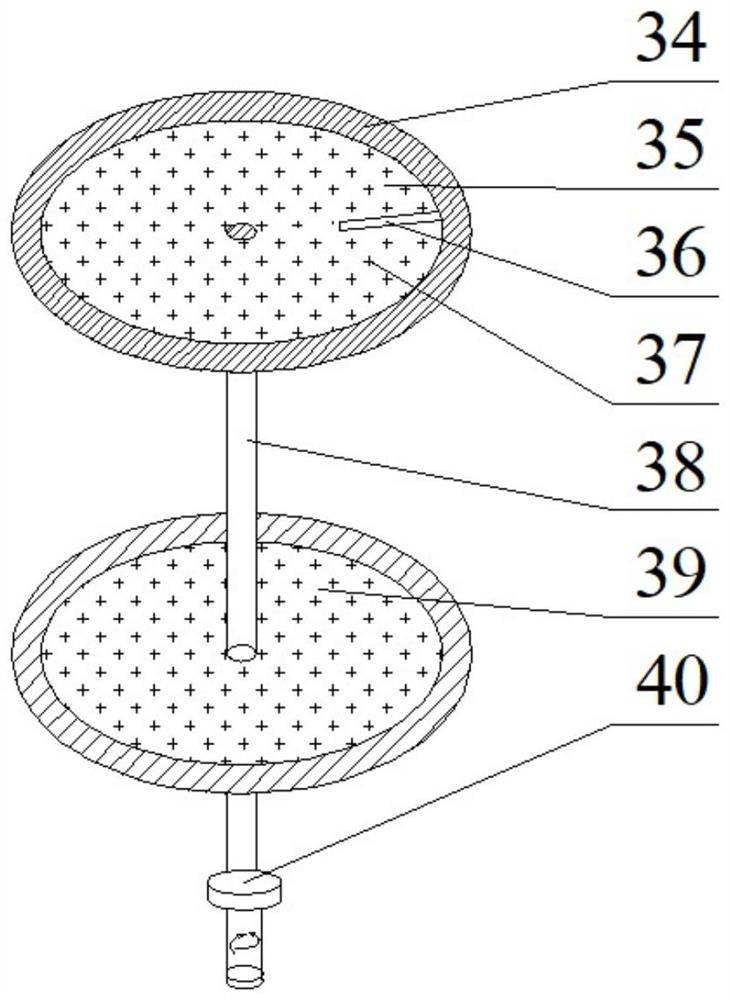

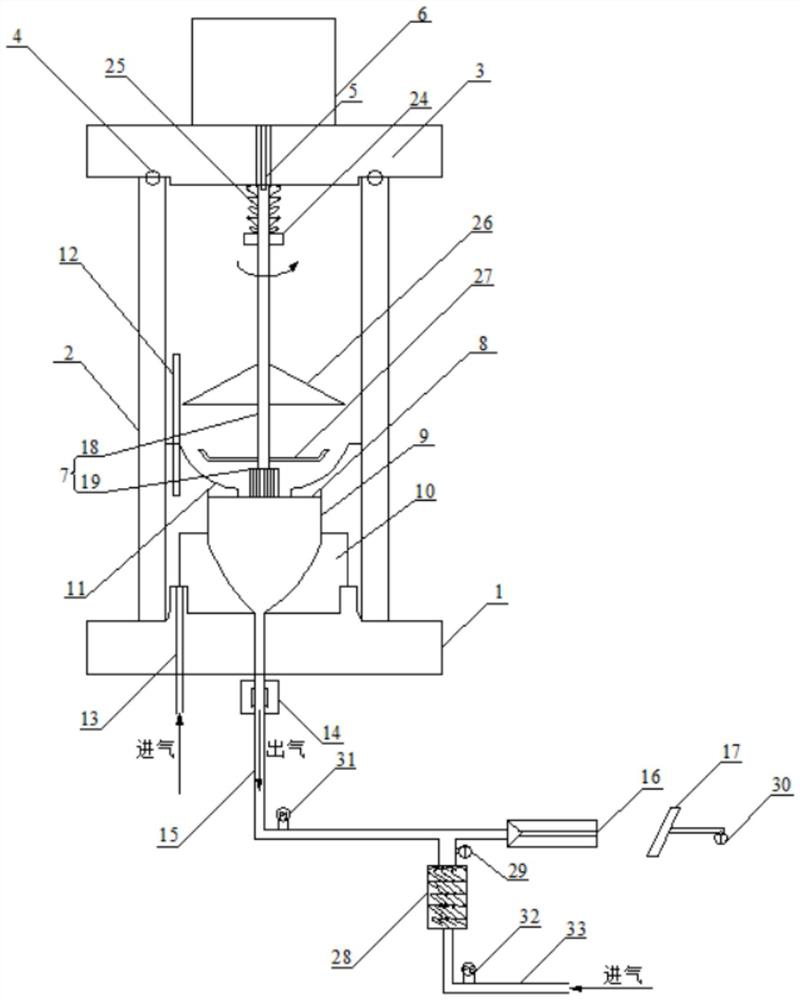

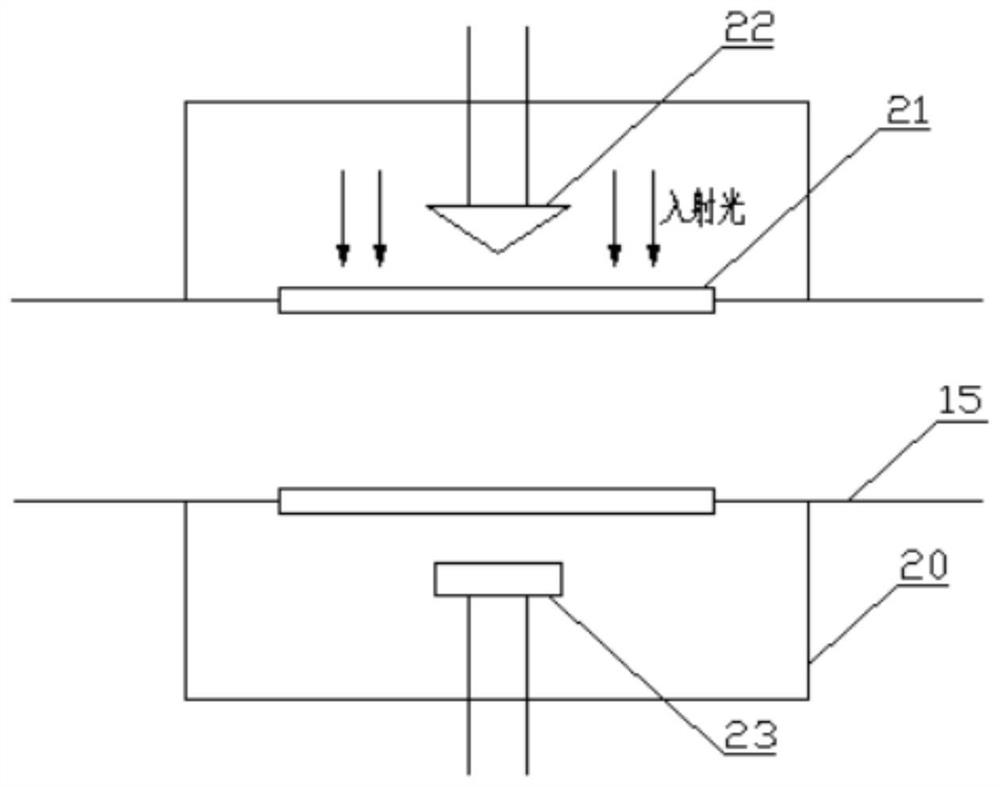

High-temperature solid particle erosion test device

ActiveCN111257148AStir wellImprove sealingInvestigating abrasion/wear resistanceTacheometrySolid particle

The invention discloses a high-temperature solid particle erosion test device, and relates to the technical field of material erosion wear and protection. The high-temperature solid particle erosion test device mainly comprises a plurality parts such as an air compressor, an air pressure gauge, a flow regulating valve, a solid desiccant, a buffer tank, a heating coil pipe, a high-temperature gas storage tank, a temperature controller, a thermodetector, a mass flow meter, a sand storage tank, a magnetic stirrer, a sand mixer, an accelerating tube nozzle, an upper sealing test cavity, a strong adsorption sticky plate, an adsorption banister brush, a limiting clamping groove, a workbench frame, a lower sealing test cavity, a rotary separator, a particle collection box, a dust collection purifier, a sample clamping tester, a double-disc tachymeter and the like. Solid particles are uniformly stirred, heated and heated by a high-temperature gas, and the heat efficiency is high; secondary interference of the solid particles is avoided through speed measuring of the double-disc speedometer, and the double-disc speedometer is simple in equipment and convenient to operate; and a magnetic stirring device ensures the continuity of sand discharge of a nozzle on the premise of ensuring sealing.

Owner:XI'AN PETROLEUM UNIVERSITY

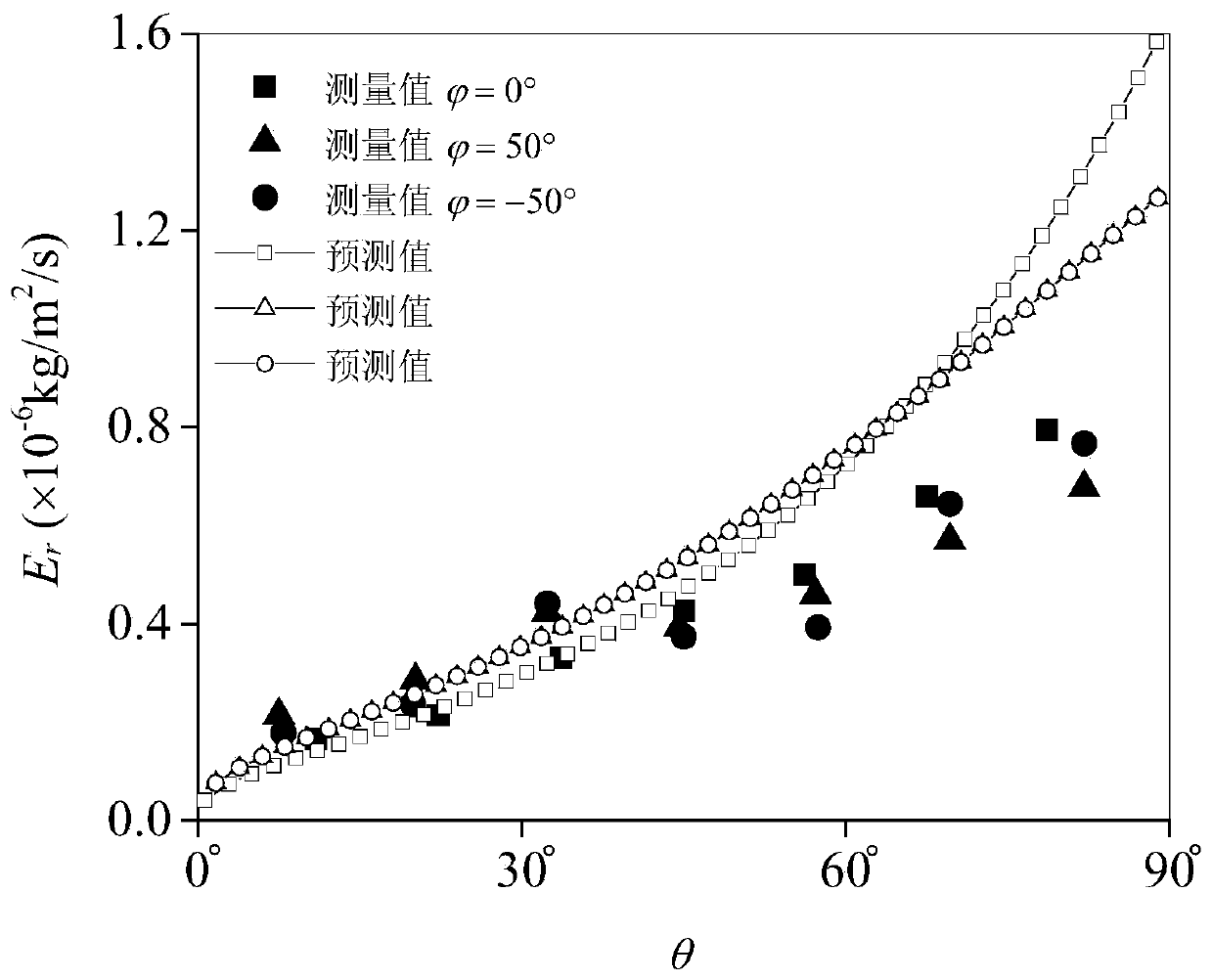

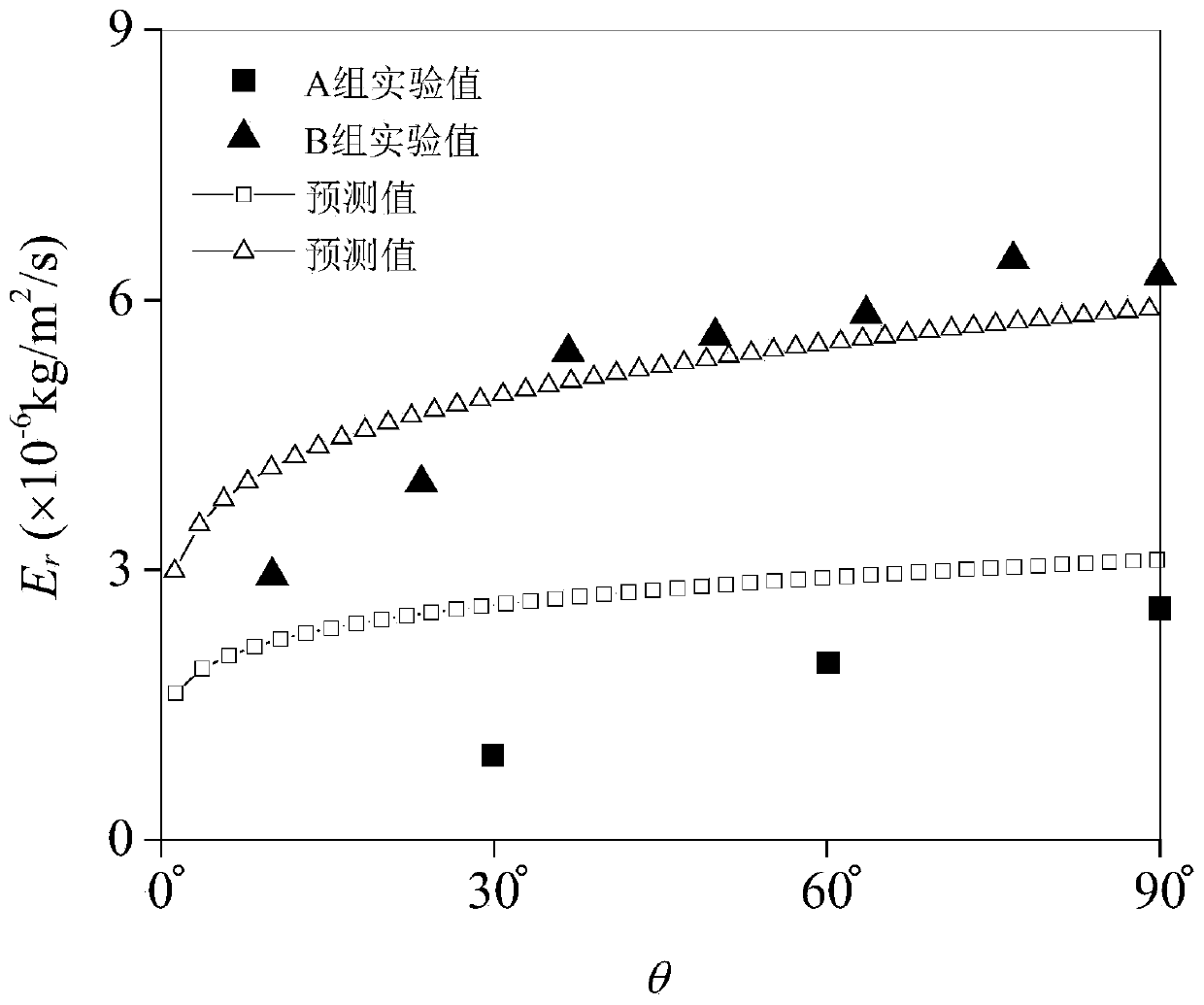

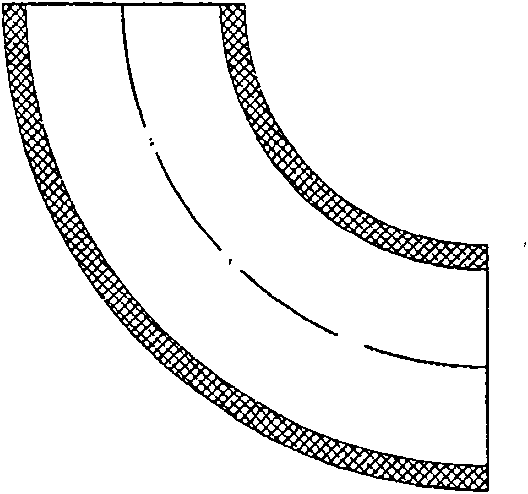

Explicit algorithm for solid particle erosion in liquid-phase elbow

ActiveCN110134980ASave computing resourcesDesign optimisation/simulationSpecial data processing applicationsDiffusionParticle collision

The invention discloses an explicit algorithm for solid particle erosion in a liquid-phase elbow. The explicit algorithm comprises the following steps: (1) solving basic characteristics of a flow field in a pipeline; (2) solving an elbow internal flow field; (3) calculating drop points of the particles; (4) calculating the collision speed of the particles; (5) solving the collision angle of the particles; (6) solving a material loss ratio at a particle collision point; (7) solving the effective sand conveying rate at the particle impact position; (8) solving an inlet erosion diffusion coefficient; and (9) calculating solid particle erosion on the elbow. The invention aims to provide an explicit algorithm for calculating the motion trail of solid particles in a liquid-phase elbow and causing erosion, an approximate flow field in the elbow is constructed based on related theories, an explicit solution of the motion trail is obtained by simplifying a particle motion equation, and materialloss caused by collision of particles with a pipe wall is tracked.

Owner:OCEAN UNIV OF CHINA

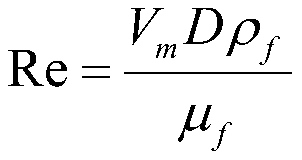

Method for preparing ceramic coating resistant to solid particle erosion by plasmas

PendingCN111485204AImprove toughnessHigh bonding strengthVacuum evaporation coatingSputtering coatingCeramic coatingMetallic materials

The invention provides a method for preparing a ceramic coating resistant to solid particle erosion by plasmas. The method comprises the following steps that the TiZrN ceramic layer is prepared on thesurface of titanium alloy by changing element components of original cathode evaporation source, namely, TiZr alloy target material is adopted, so that the ceramic coating with high strength, high toughness and excellent comprehensiveness is obtained, the anti-erosion performance of large-attack-angle solid particles on the surface of metal materials such as titanium alloy is improved, and meanwhile the excellent anti-erosion performance of small-attack-angle solid particles is achieved. According to the method, Zr atoms with good solid solubility with Ti atoms are added into a Ti target material, the TiZr alloy target material is obtained, and the ceramic coating resistant to solid particle erosion is prepared on the surface of the titanium alloy through plasma arc deposition technology,the ceramic coating resistant to solid particle erosion is high in bonding strength with the titanium alloy matrix and good in toughness and comprehensive performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

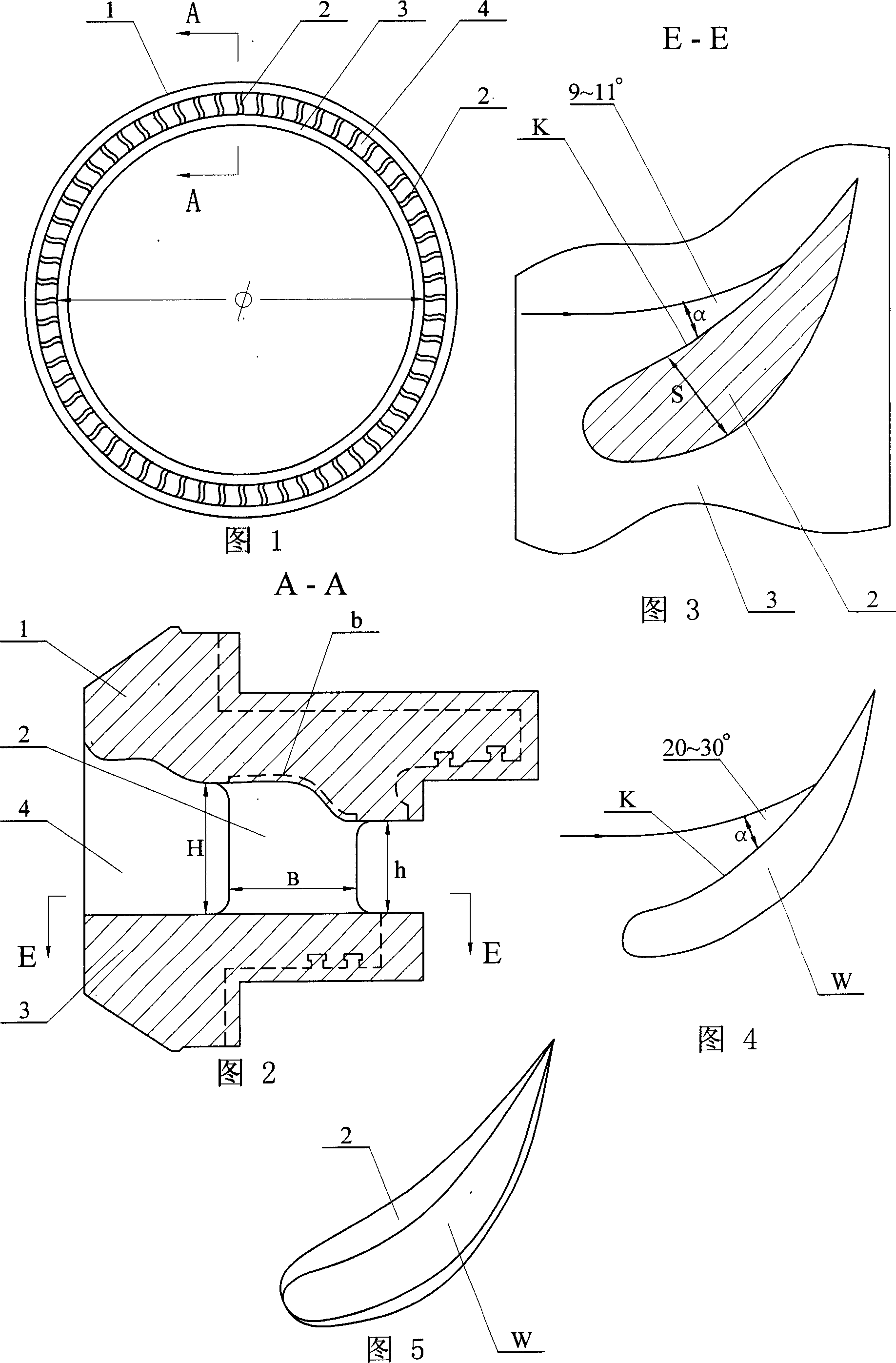

Solid particle erosion resistant steam turbine nozzle

ActiveCN1730913AReduce corrosionExtended service lifeStatorsMachines/enginesSolid particleSolid particle erosion

The present invention is steam turbine nozzle resisting solid grain corrosion, relates to the improvement of nozzle structure for steam turbine, and aims at solving the problem of solid grain corrosion of steam turbine nozzle. The present invention has regulating stage blades fixed between inner nozzle ring and outer nozzle ring, nozzle passages formed with inner nozzle ring, outer nozzle ring and two adjacent regulating stage blades, and solid grain impact angle to the pressure surface of the regulating stage blades of 9-11 deg. The present invention has the solid grain impact angle to the pressure surface of the regulating stage blades greatly decreased from available technology, so as to avoid the high erosion area of the blade material and decrease the number of solid grains nozzle exit surface obviously. The present invention has less stage efficiency degradation each month and longer nozzle service life compared with available technology.

Owner:HARBIN TURBINE +1

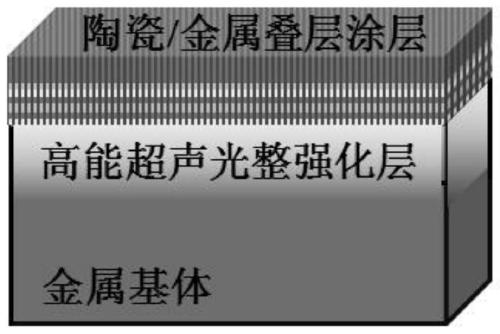

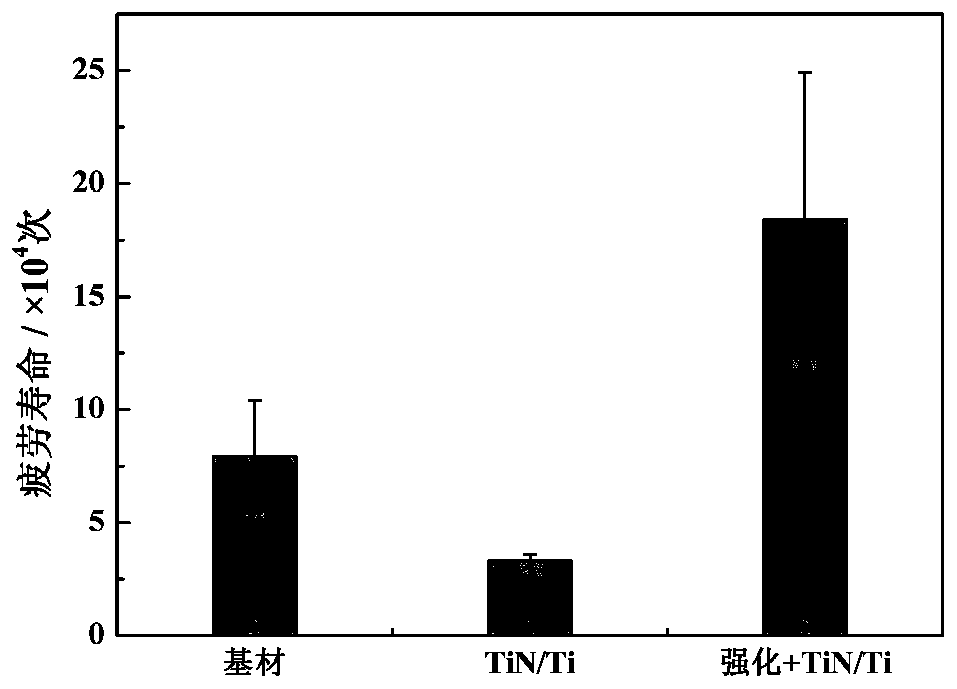

Composite surface reinforcement method capable of considering erosion resistance and anti-fatigue property of metal material

InactiveCN111593297AReduce surface roughnessExcellent resistance to solid particle erosionVacuum evaporation coatingSputtering coatingComposite ceramicMetallic materials

The invention relates to a composite surface reinforcement method capable of considering erosion resistance and anti-fatigue property of a metal material, and belongs to the field of metal material surface coating layer and modification. The method comprises the following steps: firstly, pretreating the surface of a titanium alloy or steel sample by a high-energy ultrasonic finishing reinforcementtechnology to form a gradient structure on the surface layer of titanium alloy or steel and introduce a residual compressive stress layer; and then preparing a ceramic / metal composite structural coating by a plasma enhanced deposition technology. Through combination of the plasma enhanced deposition ceramic / metal laminated technology and the high-energy finishing enhancement technology, on one hand, the titanium alloy or steel is subjected to high-energy ultrasonic reinforcement treatment by a spherical tool head capable of rolling freely to obtain a gradient layer structure with low surfaceroughness (0.1 to 0.2 um), and on the other hand, a composite ceramic layer with solid particle erosion resistance more excellent than that of a titanium alloy or steel matrix is obtained by controlling the plating time and the cycle period of the composite coating metal layer and the ceramic layer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for the surface treatment of ferritic/martensitic 9 - 12% cr steel

InactiveUS20080307847A1Improve the immunityCost-effectiveBurnishing machinesGlass particleSolid particle erosion

A method for the surface treatment of ferritic / martensitic 9-12% Cr steels for the purpose of achieving an improved oxidation behavior and increased resistance to solid particle erosion at application temperatures of above 500° C., in particular around 650° C., in steam includes, in a first step, a known shot peening of the surface of the steel with steel particles, and, subsequently, in a second step, shot peening with glass particles, optionally, in a following third step, the surface of the steel being smoothed. A subsequent additional heat treatment is unnecessary.

Owner:ALSTOM TECH LTD

A Method for Reducing Solid Particle Erosion of Supercritical Steam Turbine

The invention discloses a method for reducing solid particle erosion to a supercritical steam turbine. The method comprises the following steps: 1) controlling the evaporation capacity, steam pressureand steam temperature of a boiler; 2) closing high and medium pressure main steam valves and regulating steam valves of the steam turbine, and opening a high pressure by-pass valve and a low pressureby-pass valve; 3) increasing the purge flow; 4) reducing the purge flow; 5) increasing the purge flow; 6) repeating the steps (1) and (5); and (7) collecting solid particulates. The method for reducing solid particle erosion to the supercritical steam turbine has the benefits as follows: by repeatedly changing the opening degree of the by-pass valves, the repeated changing of the purge steam pressure and flow is realized, the falling off of metallic oxides on the inner wall of the boiler tube is facilitated, the purging effect is ensured, the falling metallic oxides is blown into a condenserhot well through the steam turbine bypasses and collected and removed through a solid particle collecting device arranged in the hot well, solid particles generated are removed in time during the start-up phase of the turbine unit, the damage to the blade profile is avoided, the operation safety and economic efficiency of the turbine unit are improved, and the service life of the turbine unit is prolonged.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

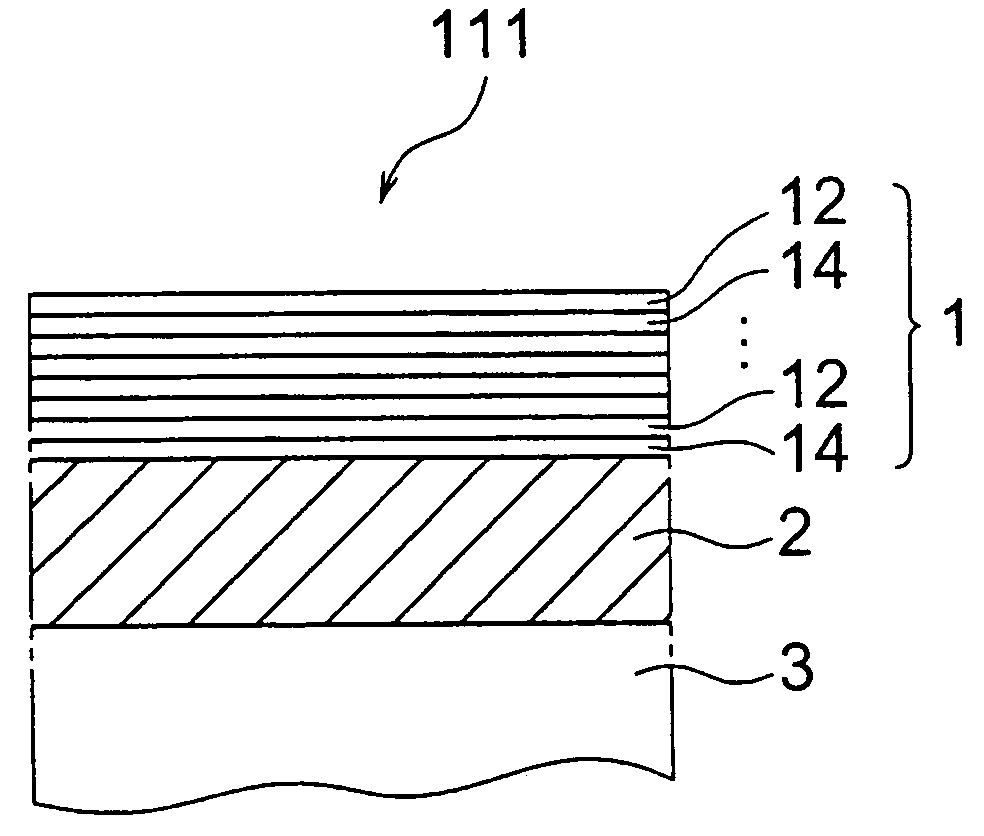

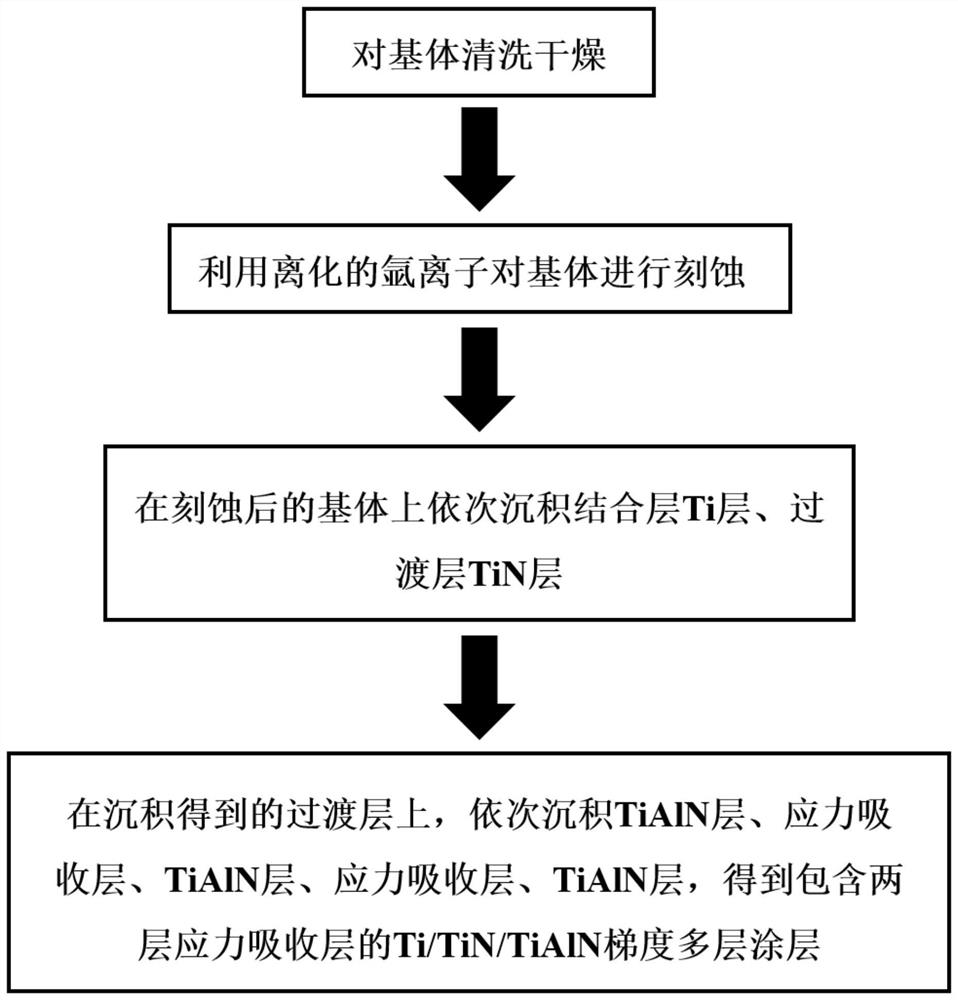

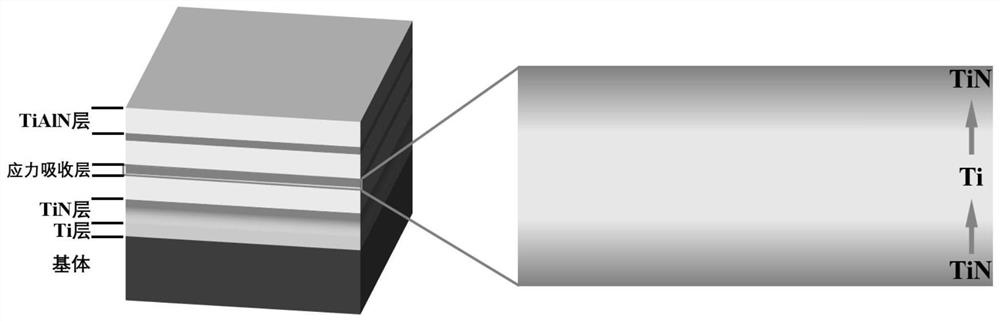

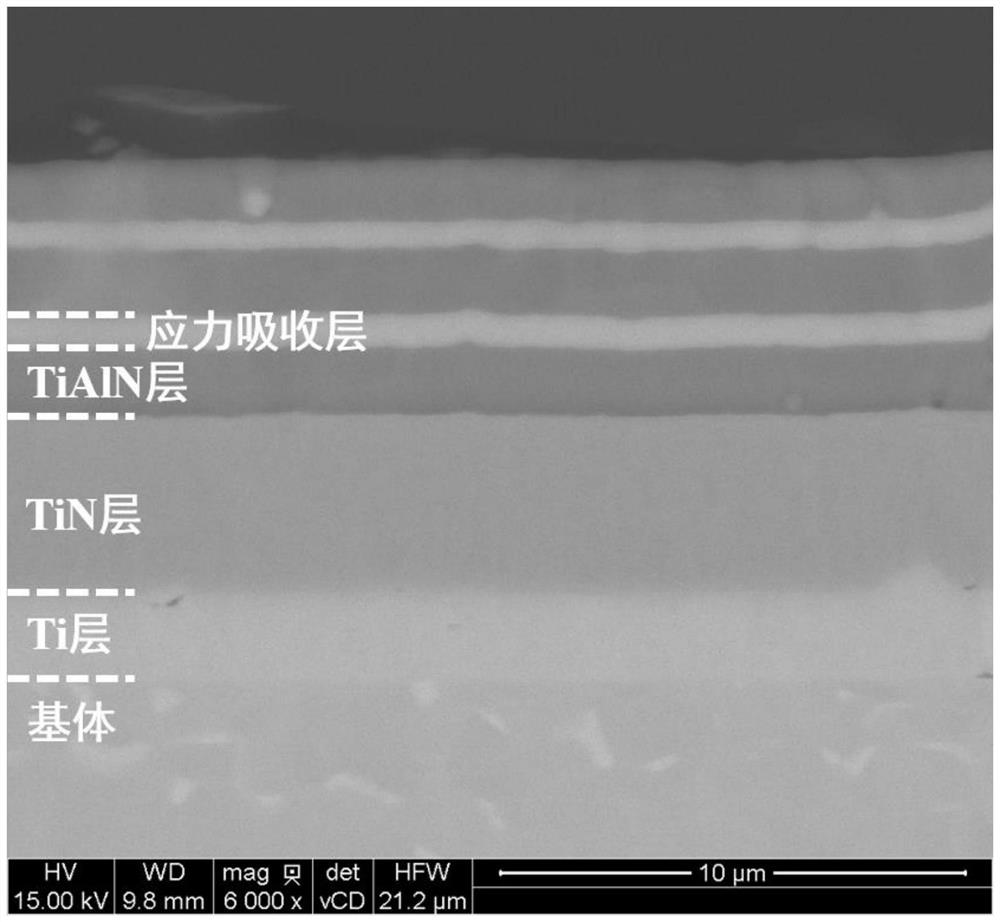

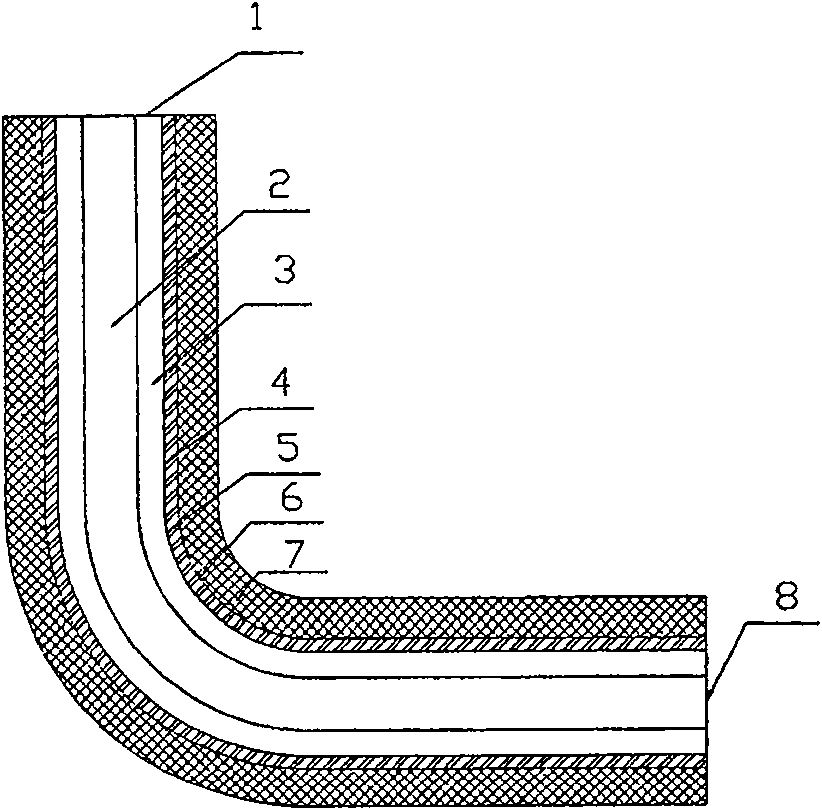

Gradient multi-layer protective coating capable of resisting erosion of solid particles and preparation method of gradient multi-layer protective coating

PendingCN114807846ASimple preparation processThe operation process is easy to controlVacuum evaporation coatingSputtering coatingSolid particle erosionAbsorption layer

The invention discloses a solid particle erosion resistant gradient multilayer protective coating which comprises a base body, a Ti layer deposited on the surface of the base body, a TiN layer deposited on the surface of the Ti layer and a TiAlN layer deposited on the surface of the TiN layer, the TiAlN layer comprises at least one stress absorption layer, and the stress absorption layer is a TiN-Ti-TiN layer of a gradient sandwich structure. The gradient multi-layer protective coating has high multi-angle resistance, high heat and high-strength erosion resistance. The invention further discloses a preparation method of the gradient multi-layer protective coating resistant to solid particle erosion. The operation process of the method is simple and easy to control, large-area uniform deposition is easy, and industrial production and application are facilitated.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Comprehensive performance evaluation method for surfacing layer of sealing surface of valve seat

PendingCN114152430AEvaluate fatigue resistanceEvaluation of high temperature resistanceMachine valve testingWorking temperatureWear resistance

The invention discloses a method for evaluating the comprehensive performance of a surfacing layer of a sealing surface of a valve seat, which comprises the following steps of: (1) determining the working temperature of the valve seat according to the purpose of the valve seat; (2) at the working temperature of the valve seat, performing a high-low temperature cycle test to obtain the fatigue resistance and high temperature resistance of the surfacing layer of the sealing surface of the valve seat; (3) performing a high-temperature impact test at the working temperature of the valve seat to obtain the impact resistance and high-temperature resistance of the surfacing layer of the sealing surface of the valve seat; (4) performing a high-temperature friction wear test at the working temperature of the valve seat to obtain the wear resistance and high-temperature resistance of the surfacing layer of the sealing surface of the valve seat; and (5) performing a high-temperature solid particle erosion test at the working temperature of the valve seat to obtain the erosion resistance and high-temperature resistance of the surfacing layer of the sealing surface of the valve seat. According to the evaluation method, whether the performance of the sealing surface surfacing layer reaches the standard or not is comprehensively evaluated through multiple performance tests, and an evaluation analysis method is provided for the valve seat sealing surface surfacing layer.

Owner:DONGFANG TURBINE CO LTD +1

A high temperature solid particle erosion test device

ActiveCN111257148BStir wellEvenly heatedInvestigating abrasion/wear resistanceTest chamberEngineering

The invention discloses a high-temperature solid particle erosion test device, which relates to the technical field of material erosion wear and protection. Mainly composed of air compressor, barometer, flow control valve, solid desiccant, buffer tank, heating coil, high temperature gas storage tank, temperature controller, thermometer, mass flow meter, sand storage tank, magnetic stirrer, mixer Sand filter, acceleration tube nozzle, upper sealing test chamber, strong adsorption stick, adsorption soft brush, limit slot, workbench, lower sealing test chamber, rotary separator, particle collection box, vacuum cleaner, test It is composed of several parts such as sample clamping tester, double disc velocimeter and so on. The solid particles are stirred and heated by high-temperature gas and heated evenly, with high thermal efficiency; the speed measurement of the double-disc velocimeter avoids the secondary interference of solid particles, the equipment is simple, and the operation is convenient; the magnetic stirring device ensures the continuity of the nozzle sand production under the premise of ensuring sealing. .

Owner:XI'AN PETROLEUM UNIVERSITY

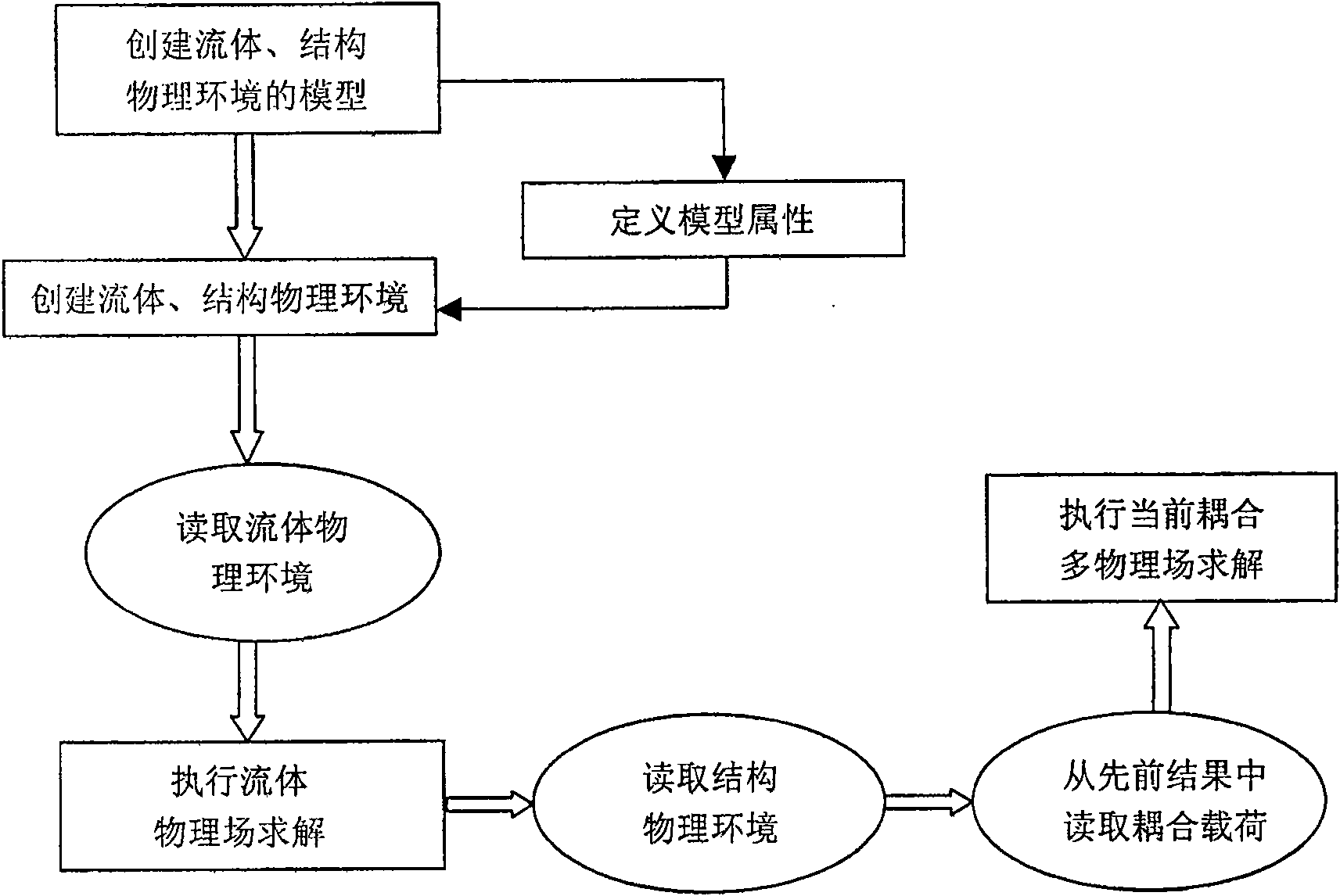

Fluid-solid coupling analysis based erosion destruction invalidation quantitative forecast method

InactiveCN100552423CPredict failure hazardLocation determinationWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceTectorial membranePredictive methods

The invention discloses a quantitative prediction method of erosion damage failure based on fluid-solid coupling analysis, which includes two processes of corrosion product protective film characteristic analysis and failure prediction analysis under the action of fluid; according to the actual working conditions of the pipeline, the fluid mechanics similarity theory is used , determine the specifications of the pipe fittings to be tested, the test conditions and the fluid medium, and use the electrochemical test method to test the transient characteristics of erosion damage; establish a fluid-solid coupling model, preliminarily set the characteristic parameter values of the corrosion product protective film, and apply the finite element method The analysis software performs fluid-solid coupling simulation calculations, combined with experimental research, to correct the characteristic parameter values of the corrosion product protective film; performs fluid-solid coupling simulation calculations for typical pipe fittings in actual pipeline systems, and realizes quantitative prediction of pipeline system erosion damage failures, which can be scientifically and accurately Predict the failure danger point of the entire pipeline system, and provide theoretical support for the safety assurance technology of the pressure pipeline system.

Owner:ZHEJIANG SCI-TECH UNIV

Solid particle pre-whirl mixing pneumatic acceleration device and method

InactiveCN102744173BStable spatial distributionImprove uniformityLiquid spraying apparatusCycloneThermal spraying

The invention discloses a solid particle pre-whirl mixing pneumatic acceleration device and method. An acceleration nozzle is of a contraction-straight pipe type or scaling type; the primary air flow generates moderate rotational flow before entering the acceleration nozzle through a specially-designed cyclone or a similar device; the solid particles are directly sprayed to the front part of the nozzle throat in an air flow carrying mode; the solid particles sprayed from a thin pipe are accelerated along the flow direction while generating radial diffusion under the dragging of the rotating air flow; the rotation kinetic energy of the air flow can be gradually dissipated under the mutual effect between the wall surface and the solid particles; the space distribution of the particles is dissipated along with the rotational flow and tends to be stable; and finally, a uniform high-speed air-solid two-phase jet flow is formed. The device and method disclosed by the invention can be used for improving the uniformity of the space distribution of the particles and the speed consistency of the particles, and are of great significance in improving the technology quality of the industrial production of a material thermal spraying technology, sand blasting and the like and improving the test precision of the scientific research field of solid particle erosion acceleration test and the like.

Owner:XI AN JIAOTONG UNIV

Device for realizing erosion resistance test

ActiveCN113514359ARealize quantitative evaluationOutflow smoothlyInvestigating abrasion/wear resistanceElectric machineEngineering

The invention discloses a device for realizing an erosion resistance test, which is characterized in that a stirrer is driven by a stepping motor to rotate so as to stir an erosion medium on a scraping disc, the erosion medium enters a funnel after being stirred by the stirrer and filtered by the scraping disc, airflow carries the erosion medium to flow out from a powder outlet pipe, then is sprayed out through a nozzle of a spray gun to an erosion sample on a movable sample table. Accurate quantitative supply of the erosion medium can be achieved by adjusting the rotating speed of the stepping motor, and by arranging a second gas inlet pipe provided with a heater, heated gas carries the erosion medium flowing out of the powder outlet pipe to be jetted to the to-be-eroded sample on the movable sample table, the erosion medium sprayed on the to-be-eroded sample is a heated erosion medium, and the erosion resistance test at a specific temperature can be realized, so that the solid particle erosion resistance test of a to-be-detected material from room temperature to high temperature can be met, and the quantitative evaluation of the erosion resistance of the material is realized.

Owner:BEIHANG UNIV +4

Method for surface treatment of Cr-steel

InactiveCN101328532BImprove antioxidant capacityLess weight gainBlade accessoriesMachines/enginesMartensiteSolid particle erosion

A method for the surface treatment of ferritic / martensitic 9-12% Cr steels and of austenitic Cr steels for the purpose of achieving increased resistance to oxidation and solid particle erosion at application temperatures of above 500° C., in particular of approximately 650° C., in steam, includes that the surface of the steel is shot-peened with particles of aluminum or of an aluminum alloy; optionally, in a subsequent step, the surface of the steel is smoothed to a roughness of <0.5 mum, preferably <0.3 mum. Following additional heat treatment is not necessary, and the parts thus treated may be employed, for example, as blades in steam turbines.

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com