High-temperature solid particle erosion test device

A test device, high-temperature solid technology, applied in the field of erosion test device, high-temperature solid particle erosion and wear test device, can solve the problems of test error, poor downward movement, complicated equipment, etc., to avoid discontinuity or jamming , Improve the energy conversion rate, reduce the effect of temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below:

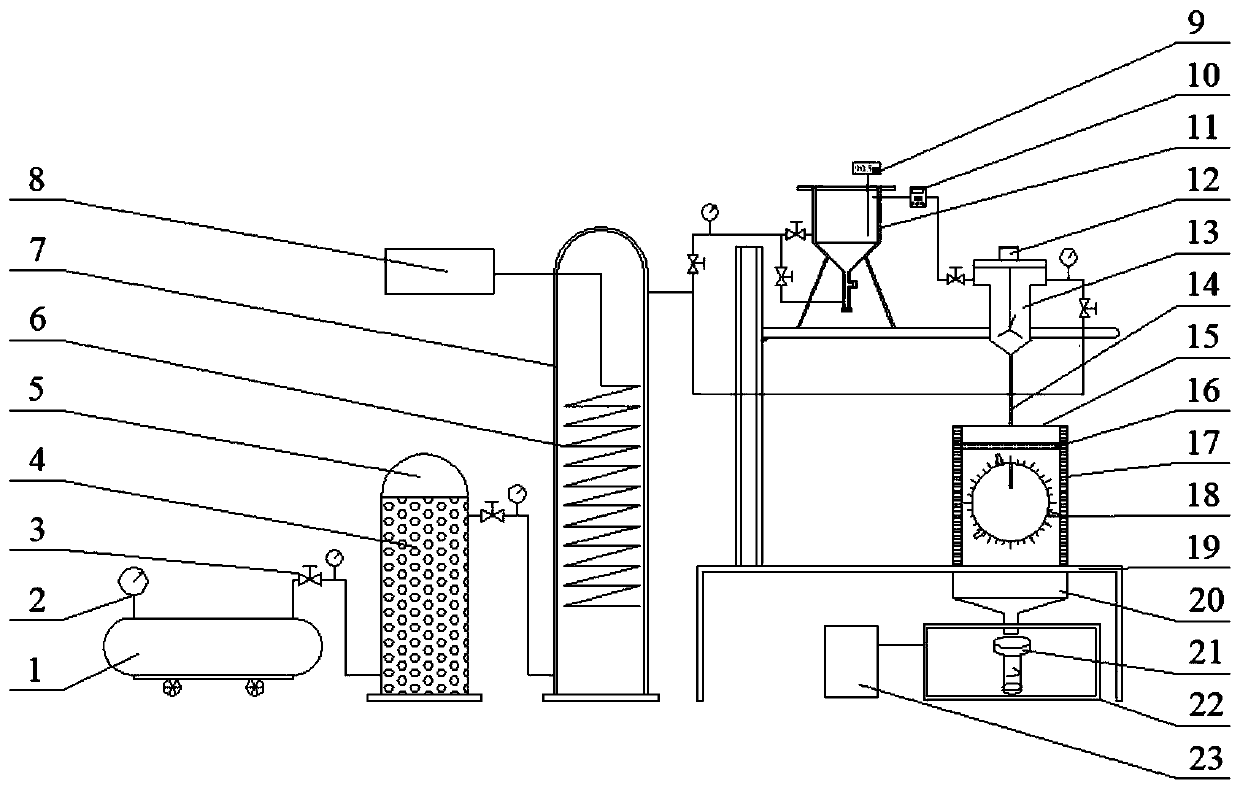

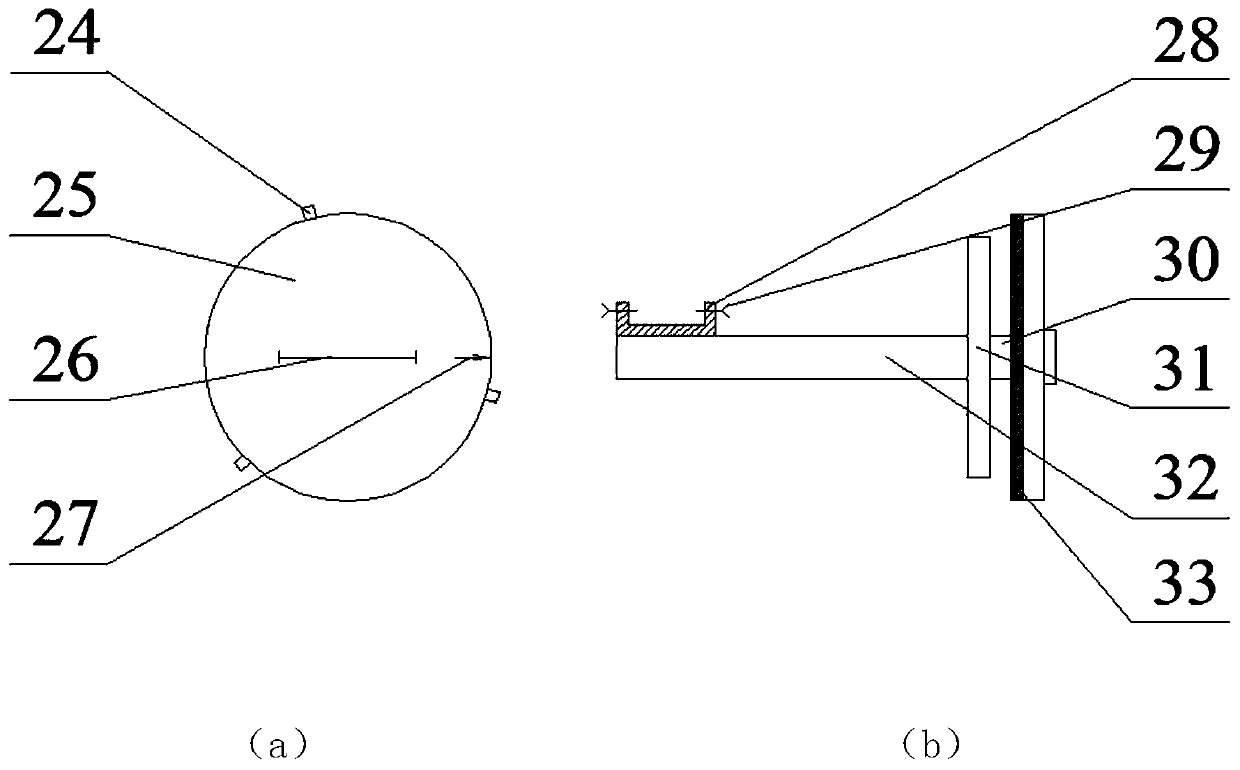

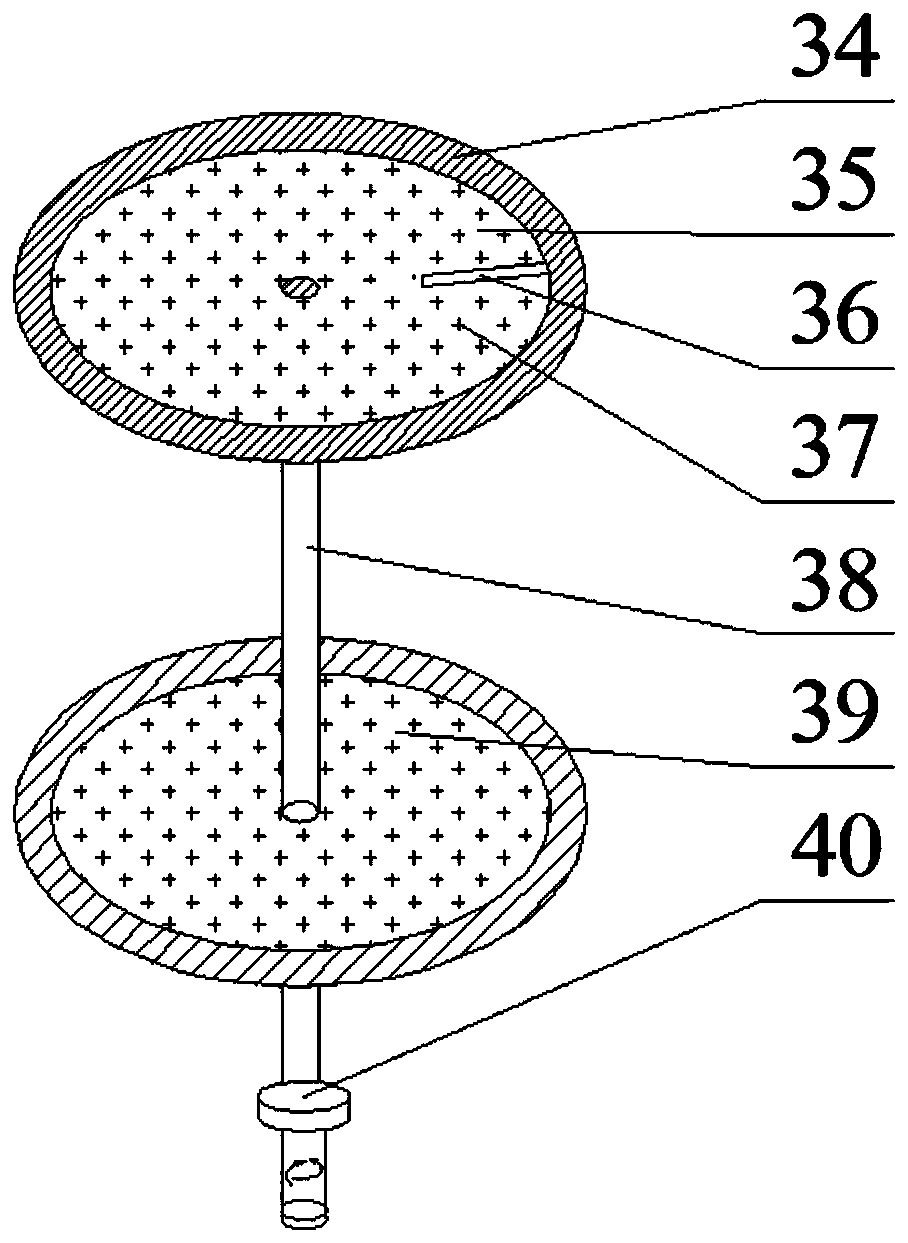

[0038] see Figure 1 to Figure 9 , a high-temperature solid particle erosion test device, mainly composed of an air compressor 1, a barometer 2, a flow regulating valve 3, a solid desiccant 4, a buffer tank 5, a heating coil 6, a high-temperature gas storage tank 7, and a temperature controller 8. Thermometer 9, mass flow meter 10, sand storage tank 11, magnetic stirrer 12, sand mixer 13, acceleration tube nozzle 14, upper sealing test chamber 15, strong adsorption sticky plate 16, adsorption soft brush 17, Limit card slot 18, workbench 19, lower sealing test chamber 20, rotating separator 21, particle collection box 22, dust collector 23, sample clamping tester, double-disk speedometer, etc. The air compressor 1 is connected to the bottom of the buffer tank 5 through an air pipe, and the first flow regulating valve 3 and the first air pressure gauge are sequentially arranged on the air pipe. The gas enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com