Patents

Literature

169 results about "Industrial fan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

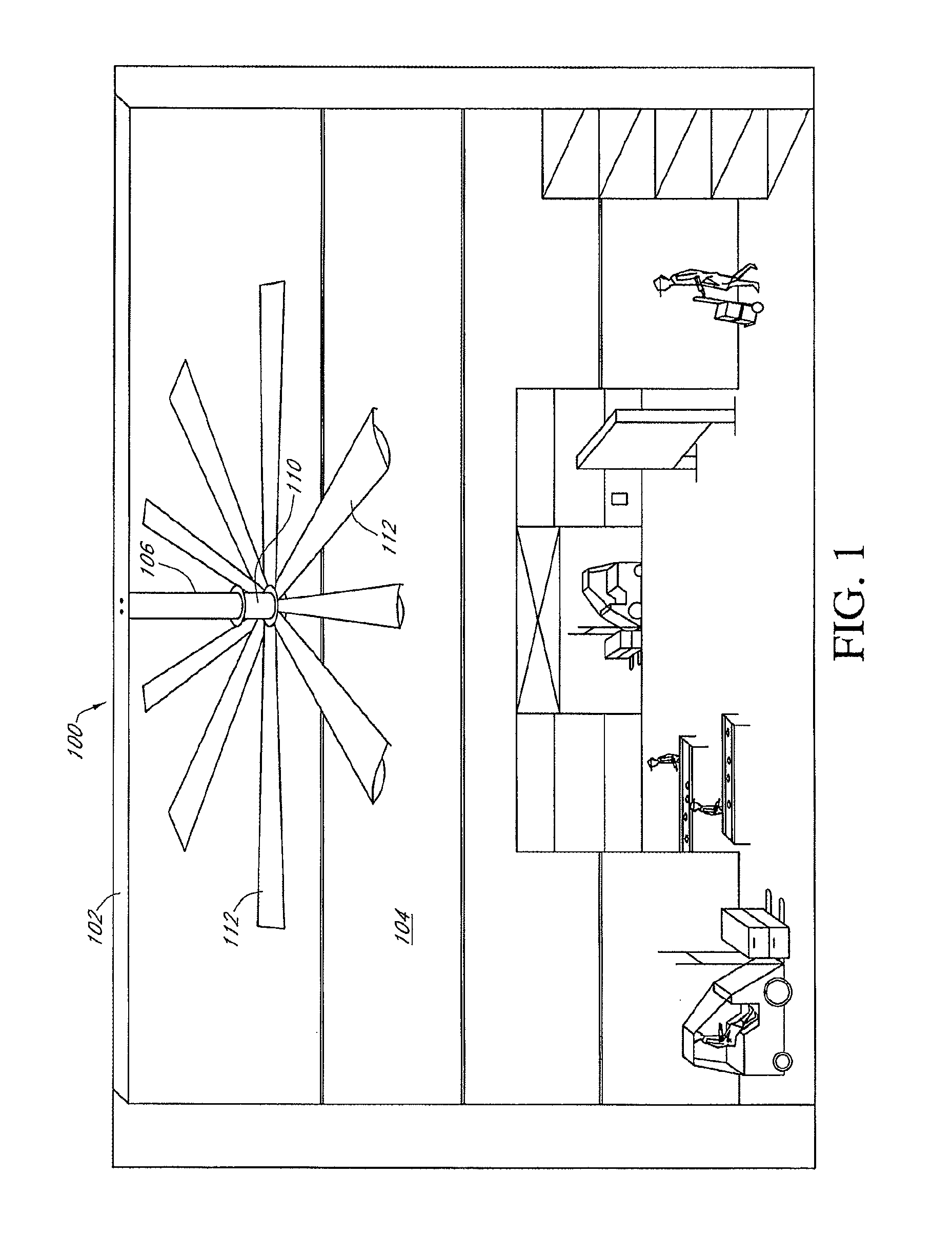

Industrial fans and blowers are machines whose primary function is to provide and accommodate a large flow of air or gas to various parts of a building or other structures. This is achieved by rotating a number of blades, connected to a hub and shaft, and driven by a motor or turbine. The flow rates of these mechanical fans range from approximately 200 cubic feet (5.7 m³) to 2,000,000 cubic feet (57,000 m³) per minute. A blower is another name for a fan that operates where the resistance to the flow is primarily on the downstream side of the fan.

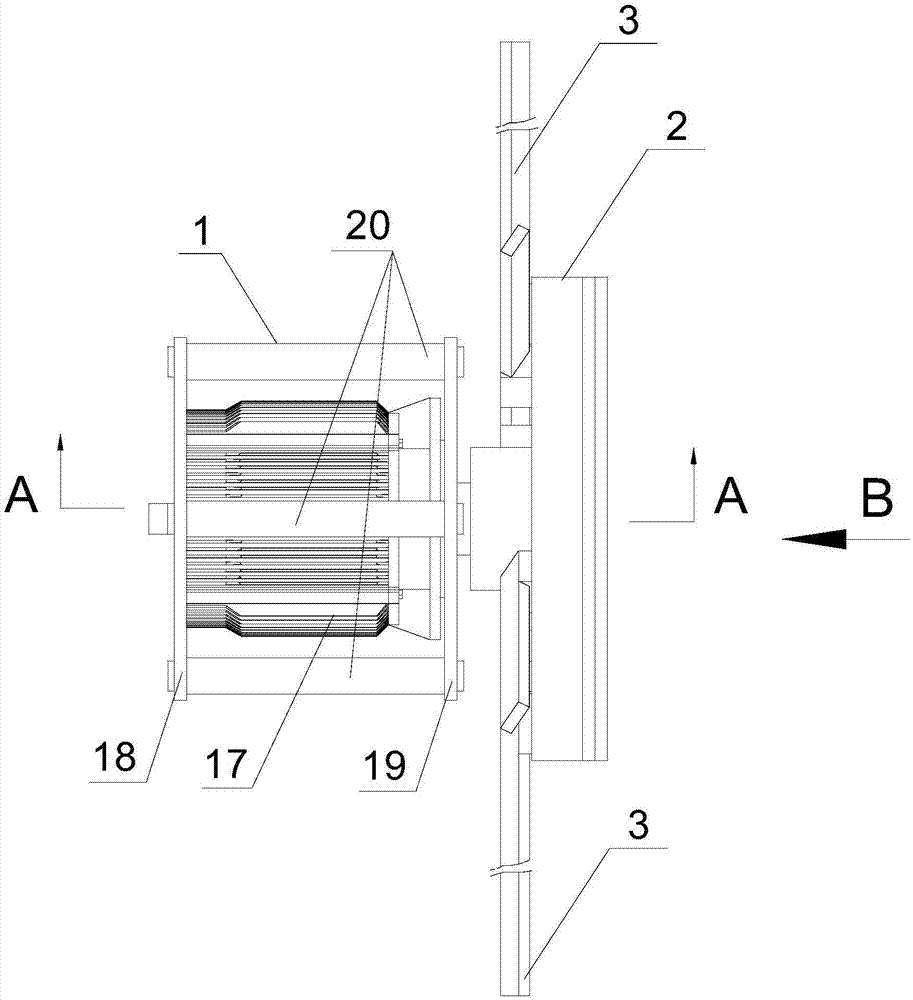

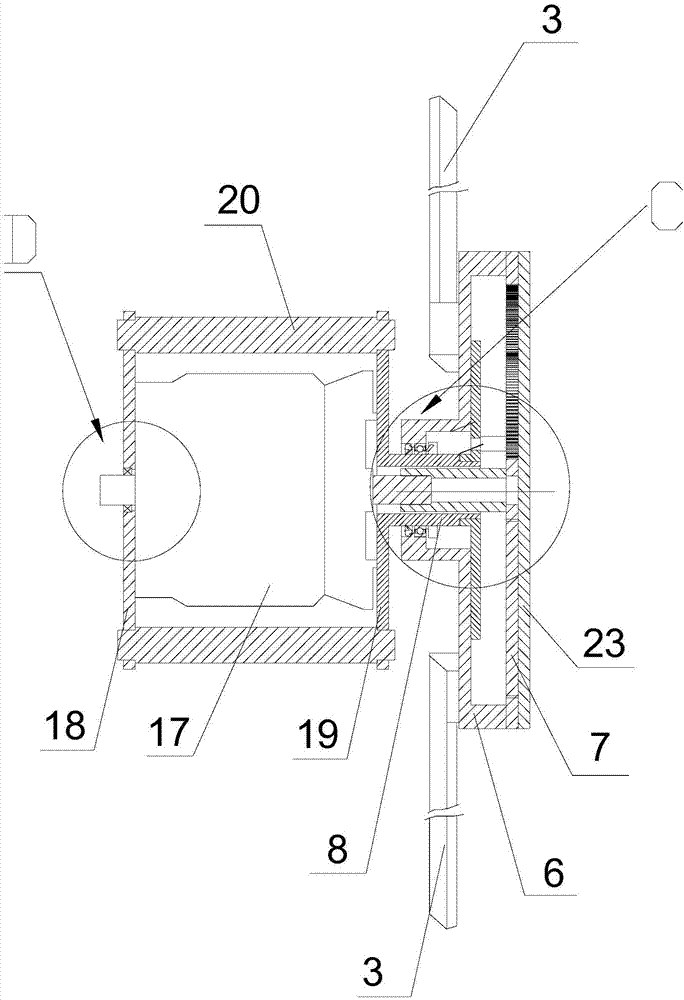

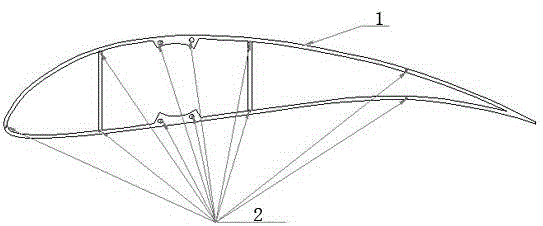

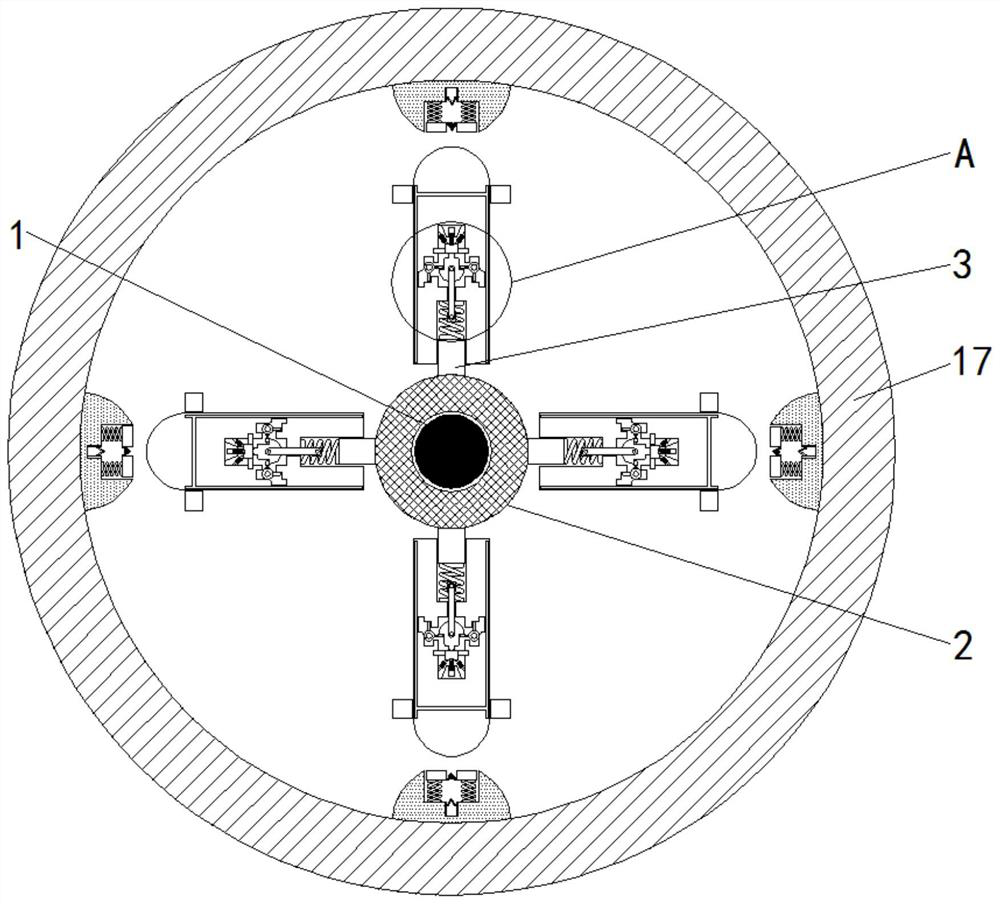

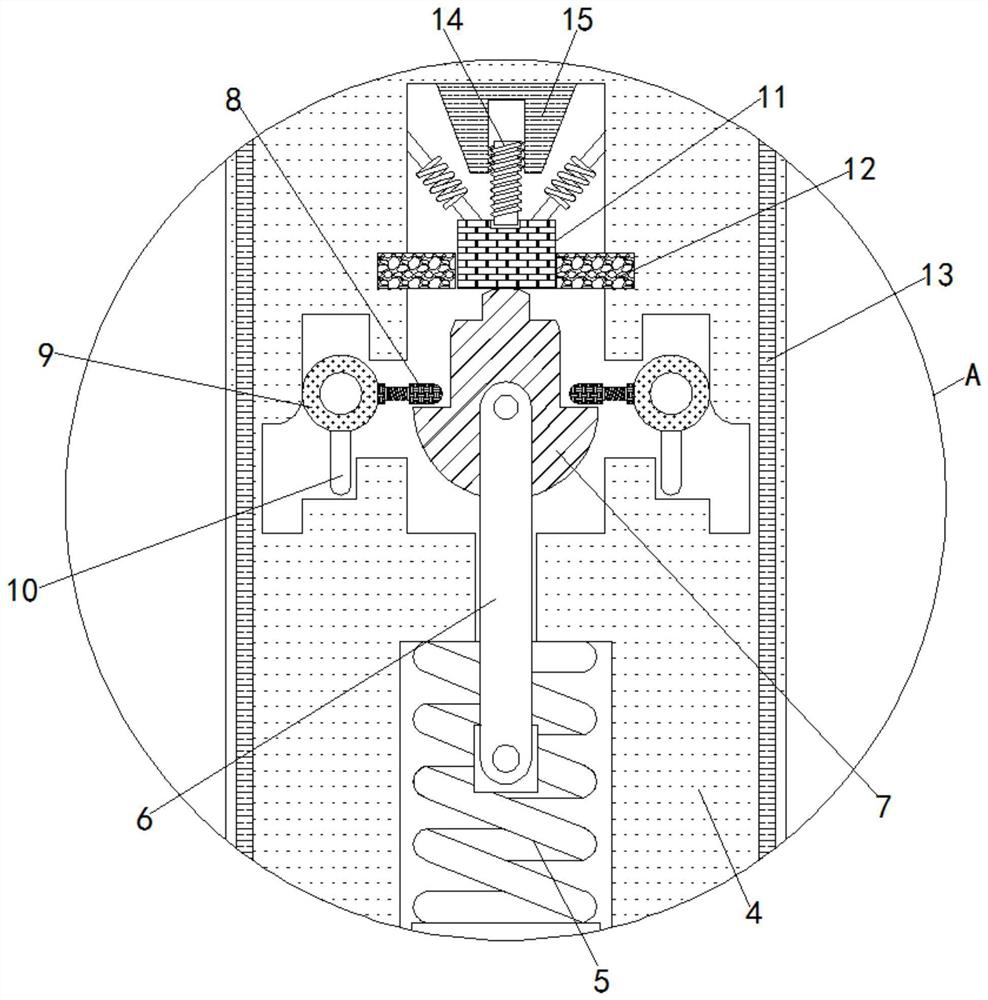

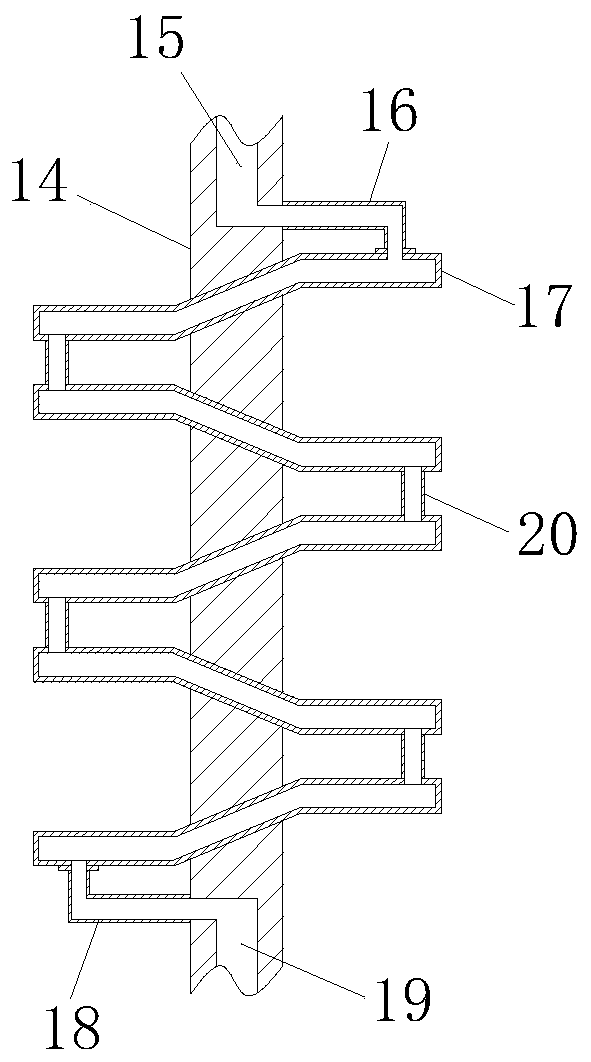

Moving-weight, dynamic balancing apparatus for a rotary machine, in particular for industrial fans

InactiveUS6210099B1Easy to implementLow costPropellersWind motor controlDynamic balanceSystem monitor

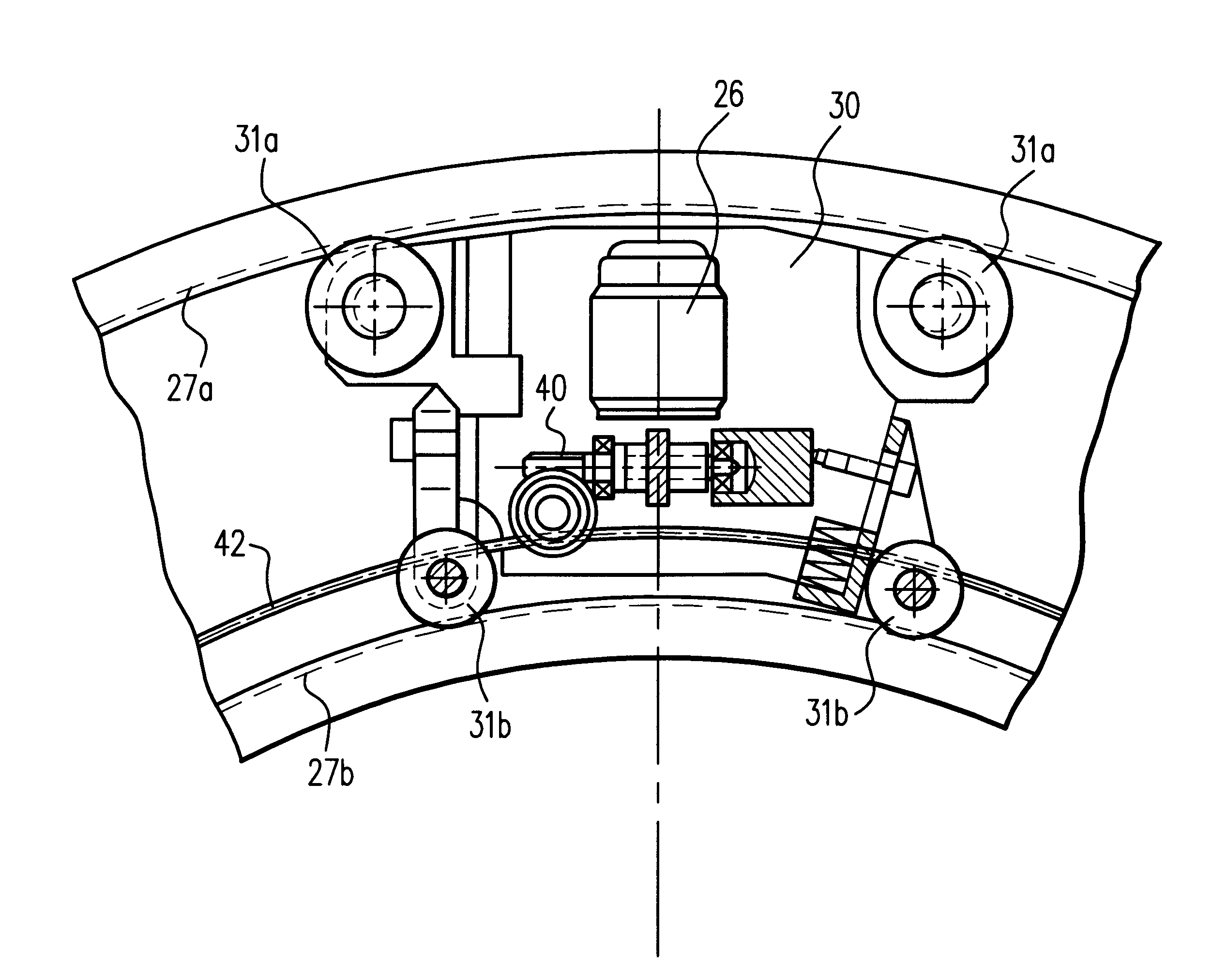

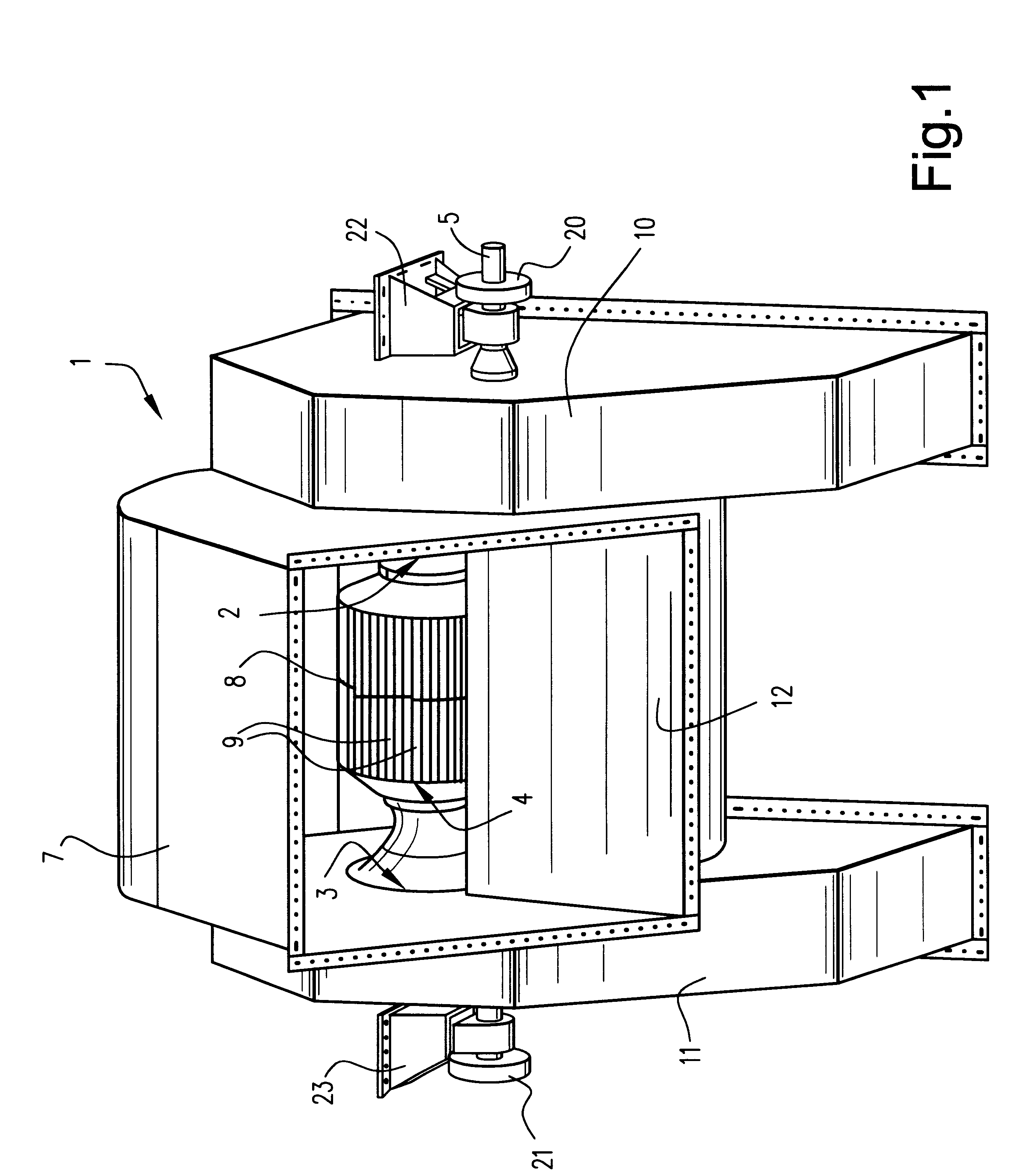

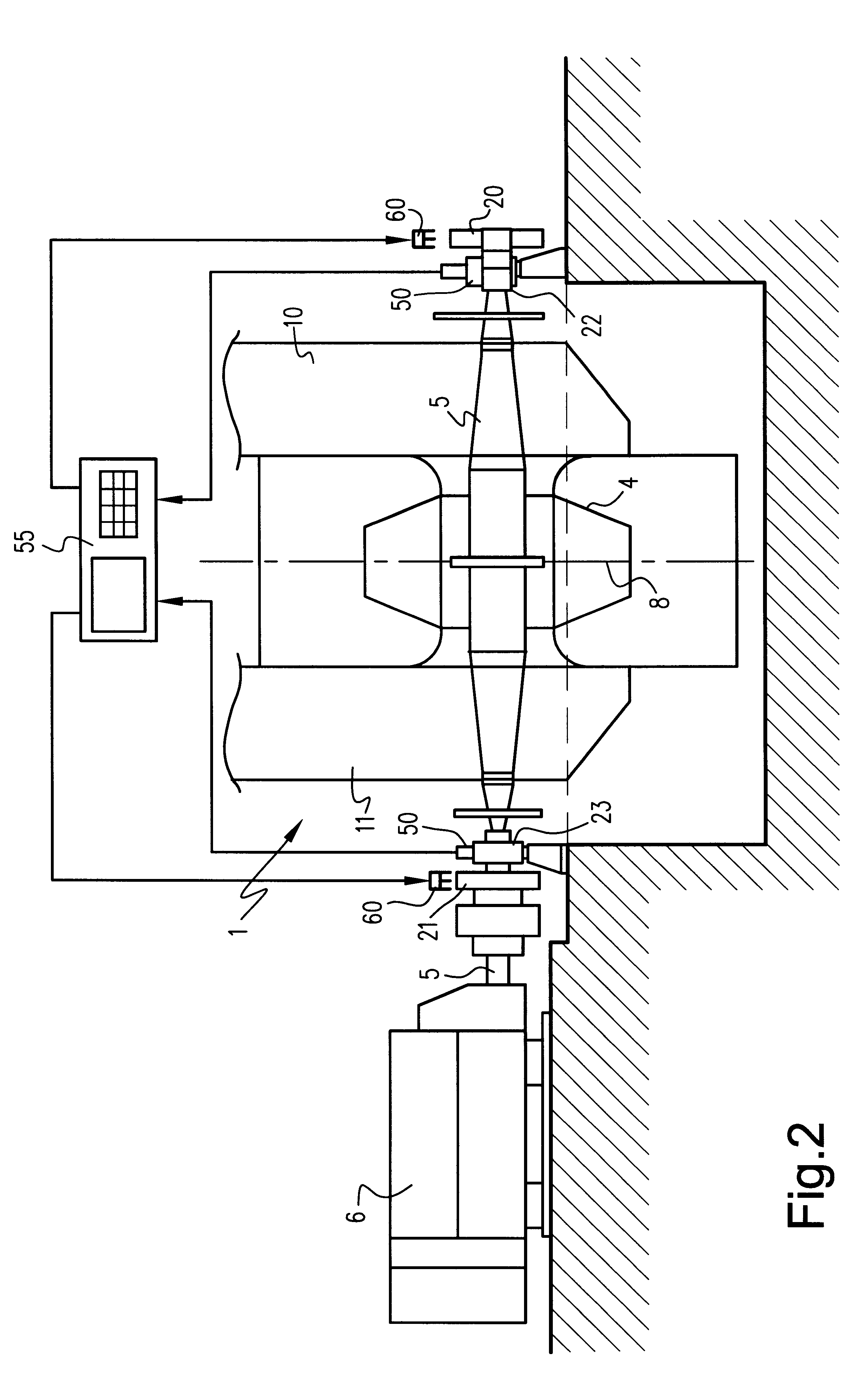

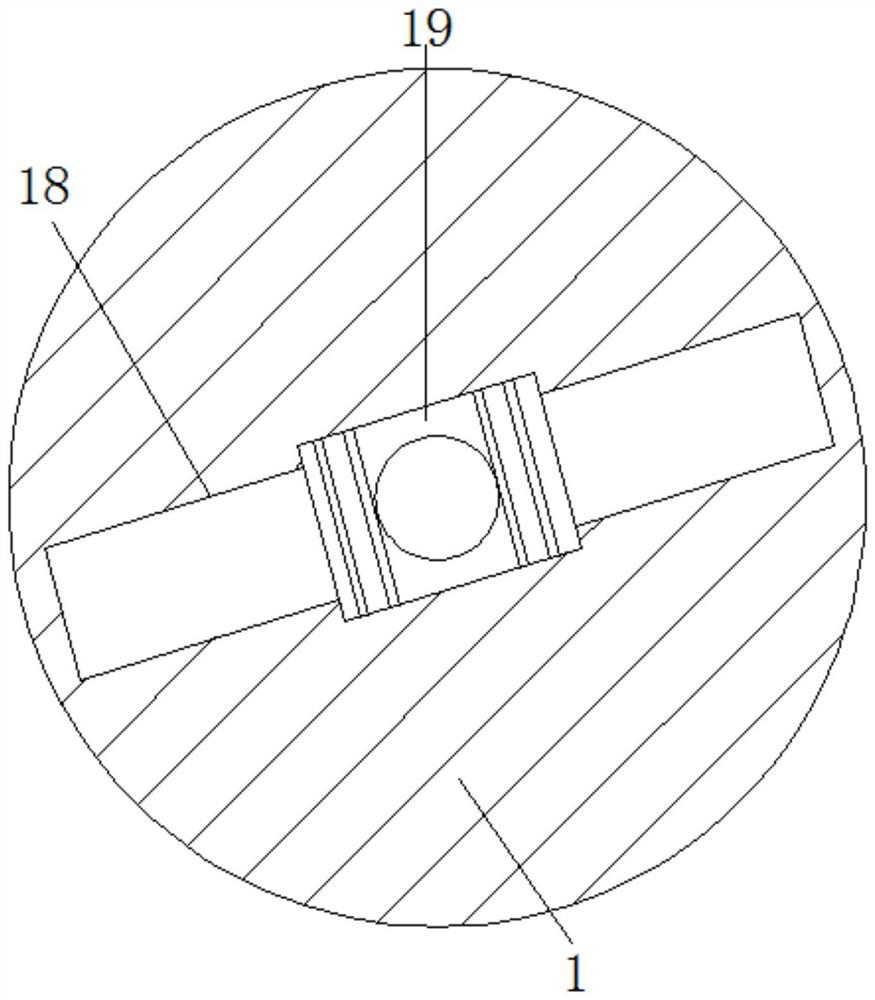

A moving-weight, dynamic balancing apparatus for a rotary machine, in particular an industrial fan, having a rotary shaft, and at least one rotor carried by the rotary shaft and provided with main rotor bearings to allow rotary movement thereof. The balancing apparatus includes at least one moving-weight balancing unit is carried by the rotary shaft, and at least one monitoring and correcting system having a drive assembly. The at least one monitoring and correcting system monitors and corrects the unbalanced state of the rotor, and acts continuously on the at least one moving-weight balancing unit when the rotor is rotating to monitor and correct for rotor unbalance. The at least one moving-weight balancing unit has at least two balancing masses mounted to be movable under drive from the drive assembly controlled by the monitoring and correction system. The at least one moving-weight balancing unit is situated axially at a distance from the rotor to be balanced beyond the main rotor bearings, and includes a ring and at least one guide assembly. The at least two balancing masses include respective carriages that are moveable in the ring, guided by the at least one guide assembly, independently of each other along trajectories that form closed circuits around the rotary shaft under drive from the drive assembly associated with each of said at least two balancing masses.

Owner:FLAKT SOLYVENT VENTEC

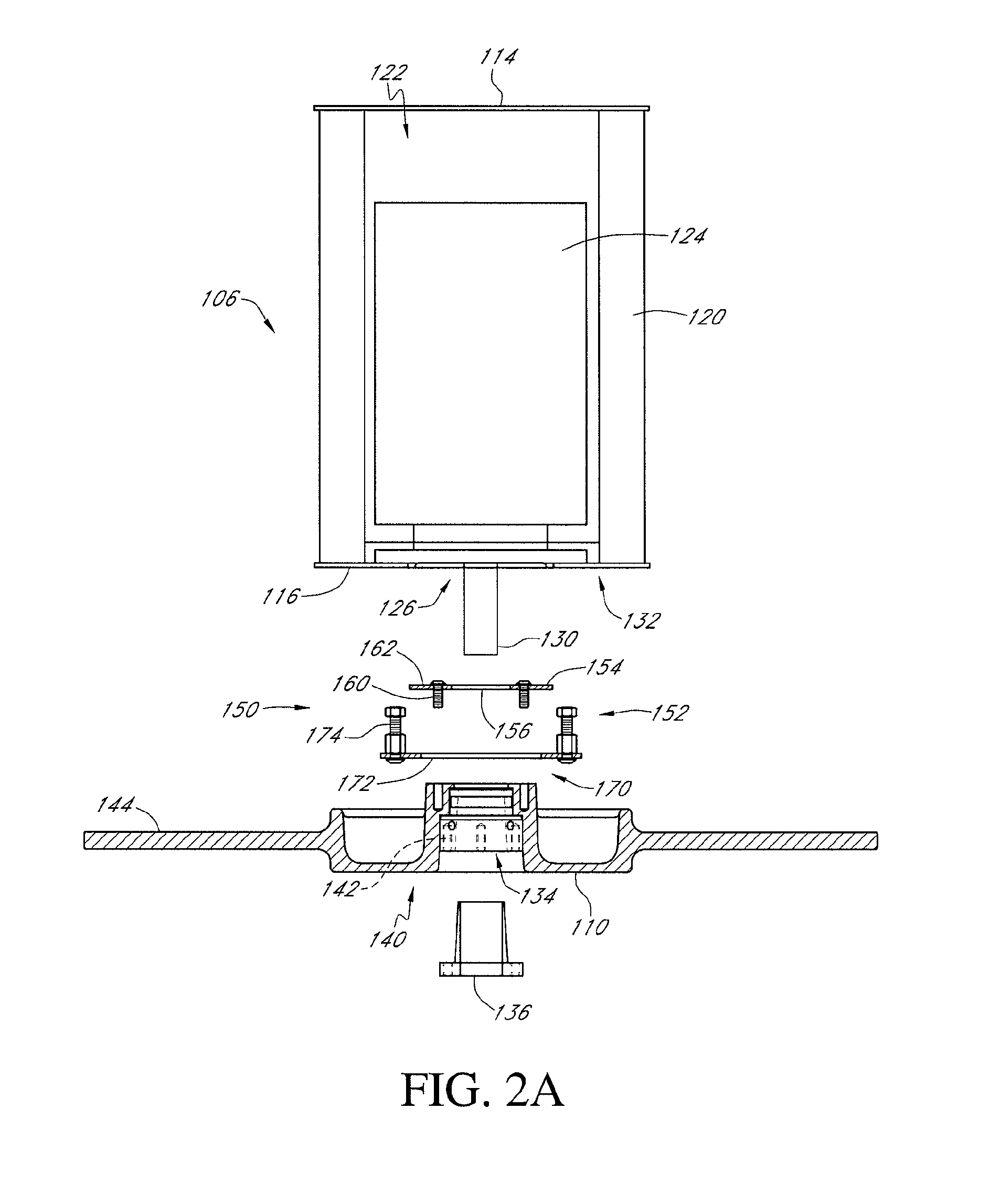

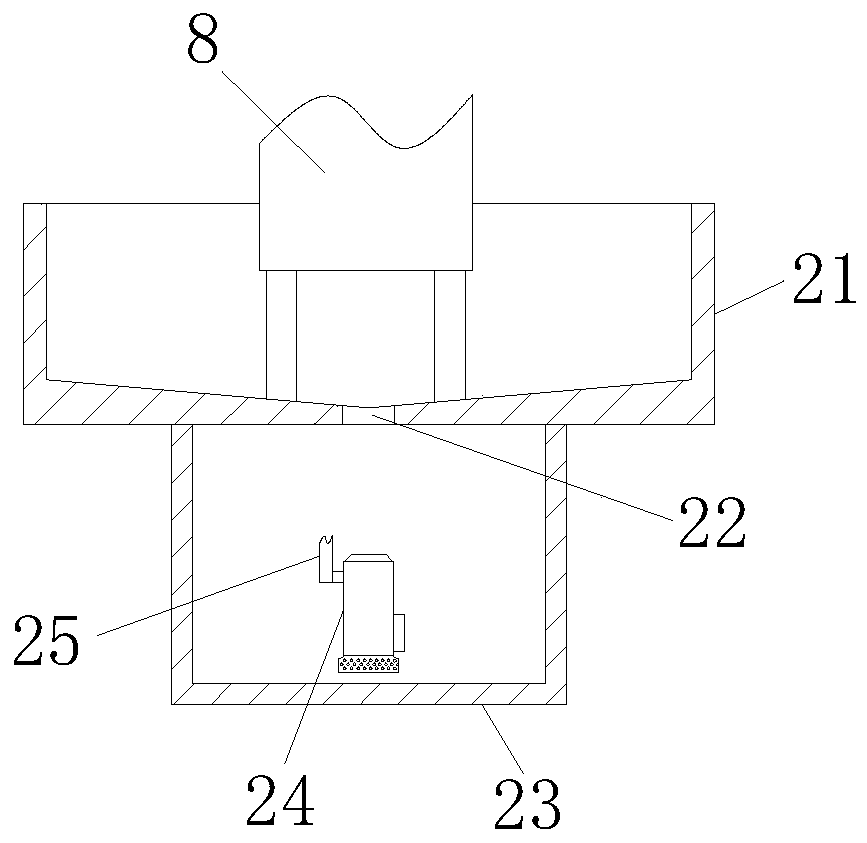

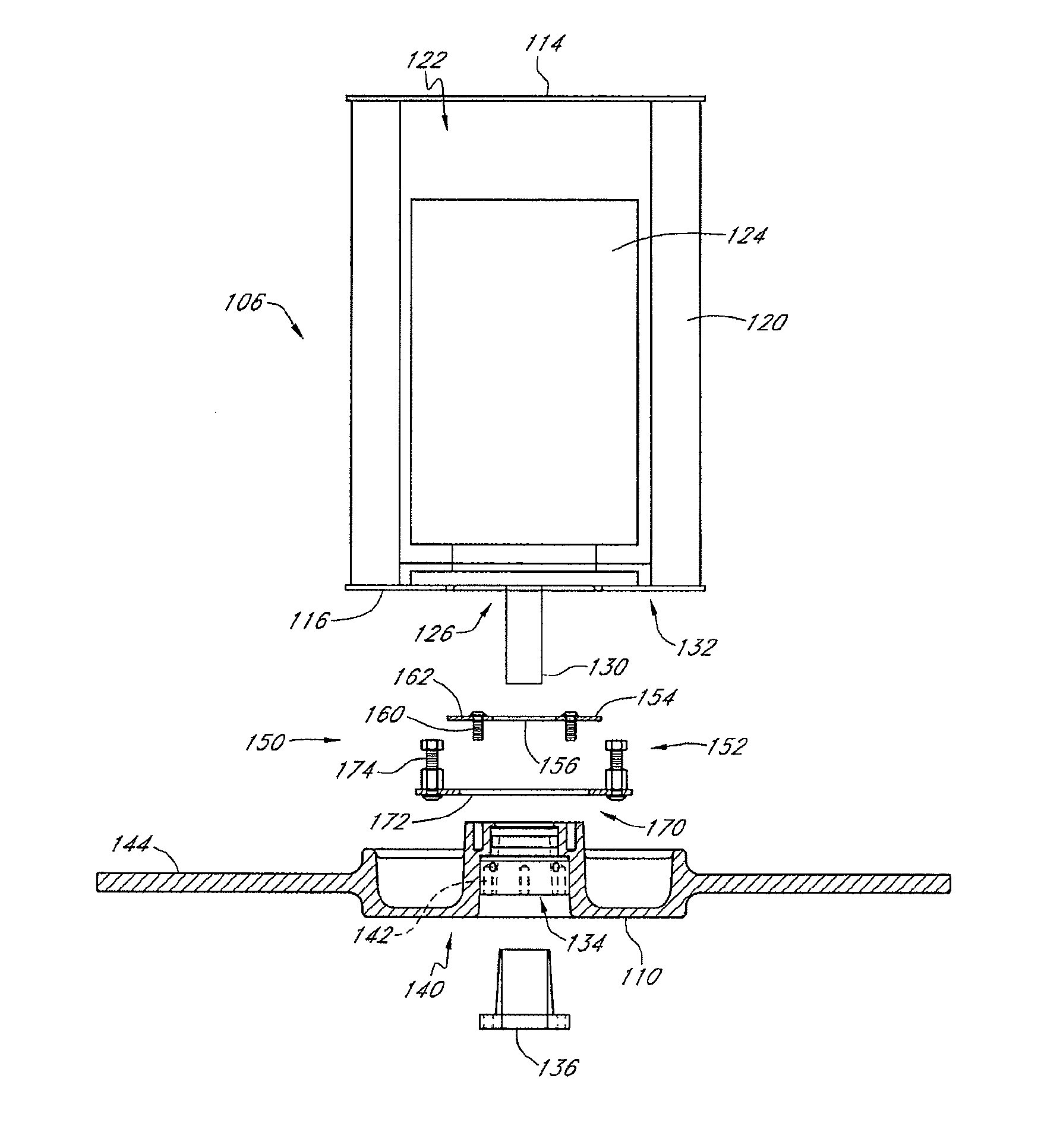

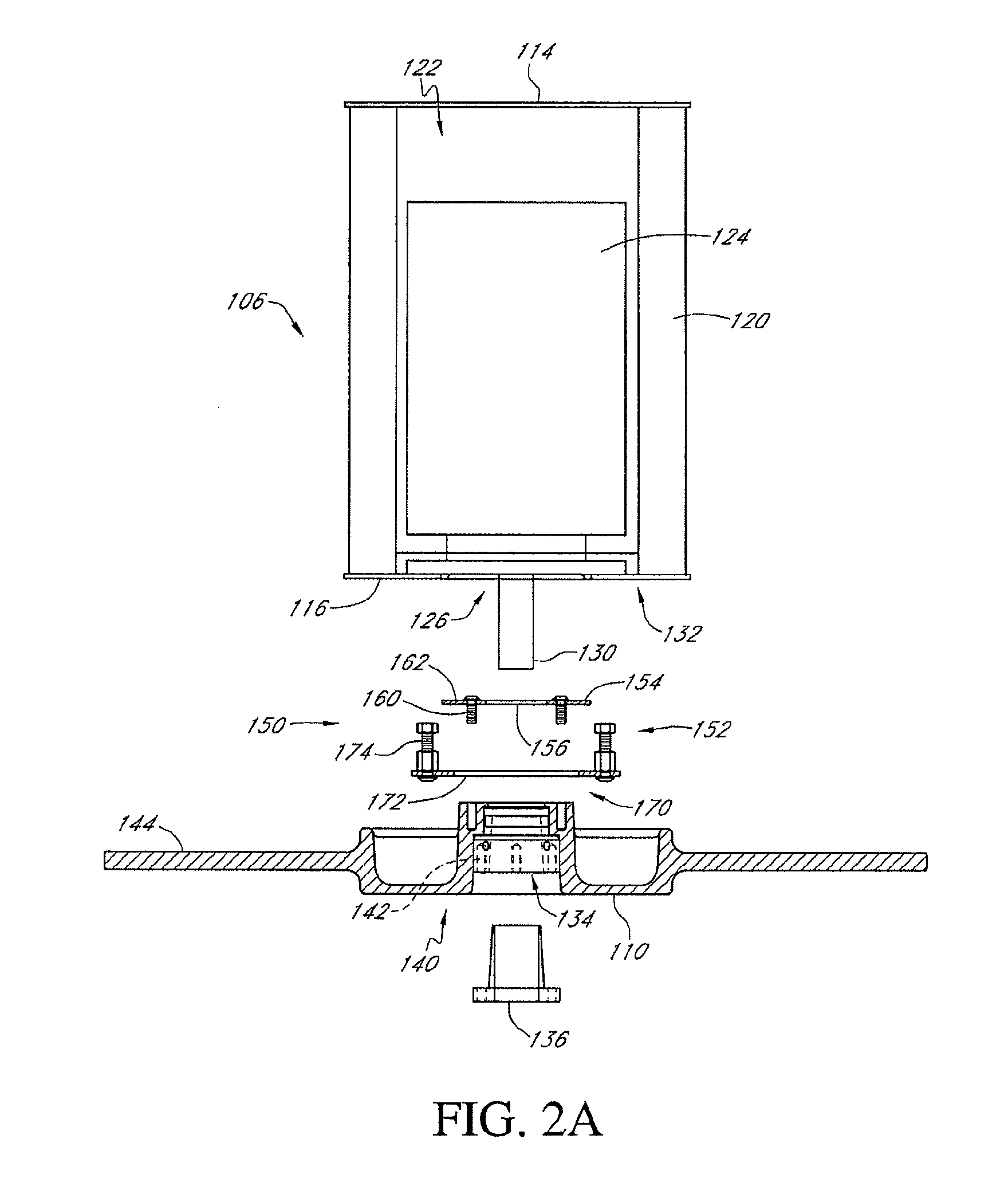

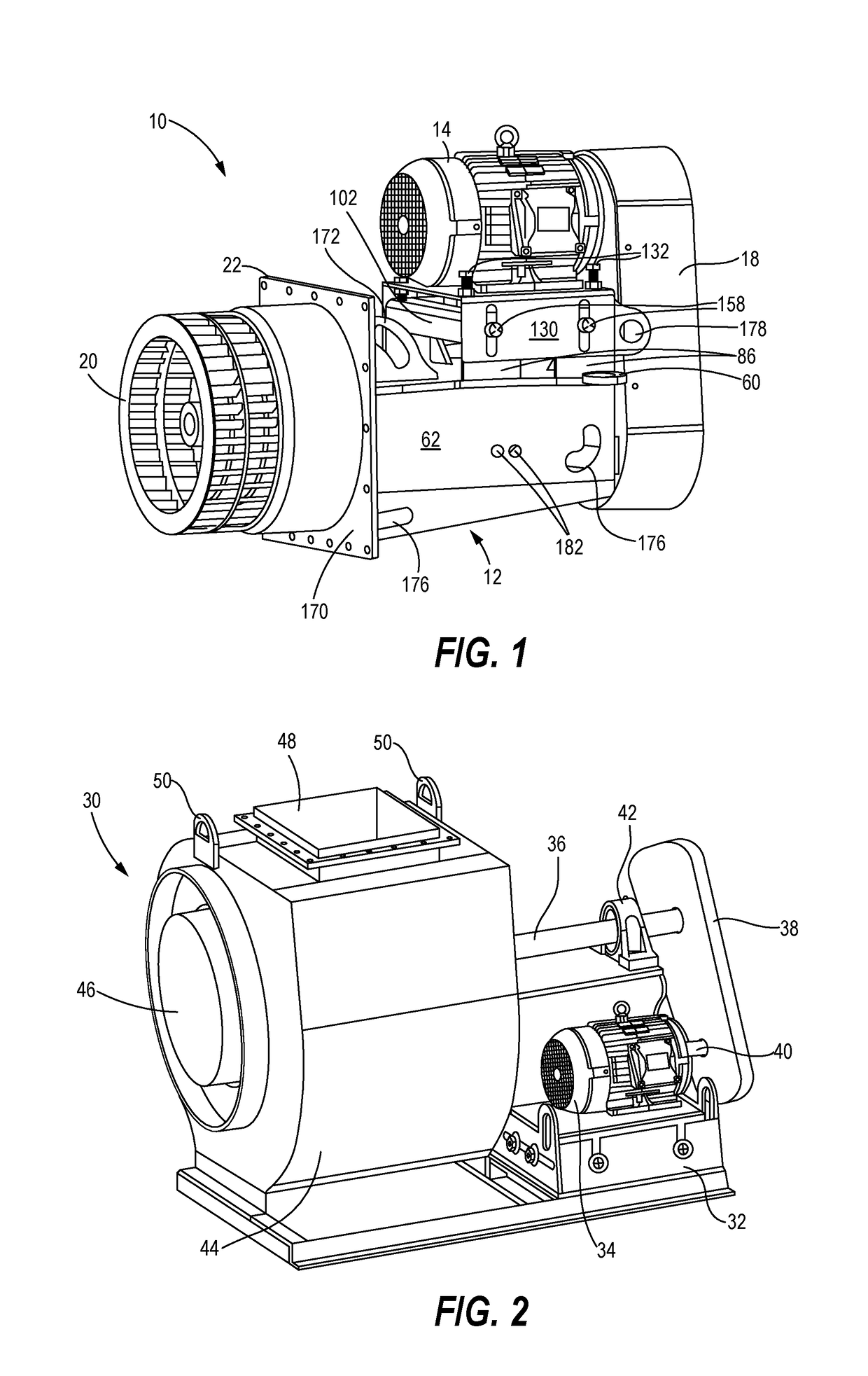

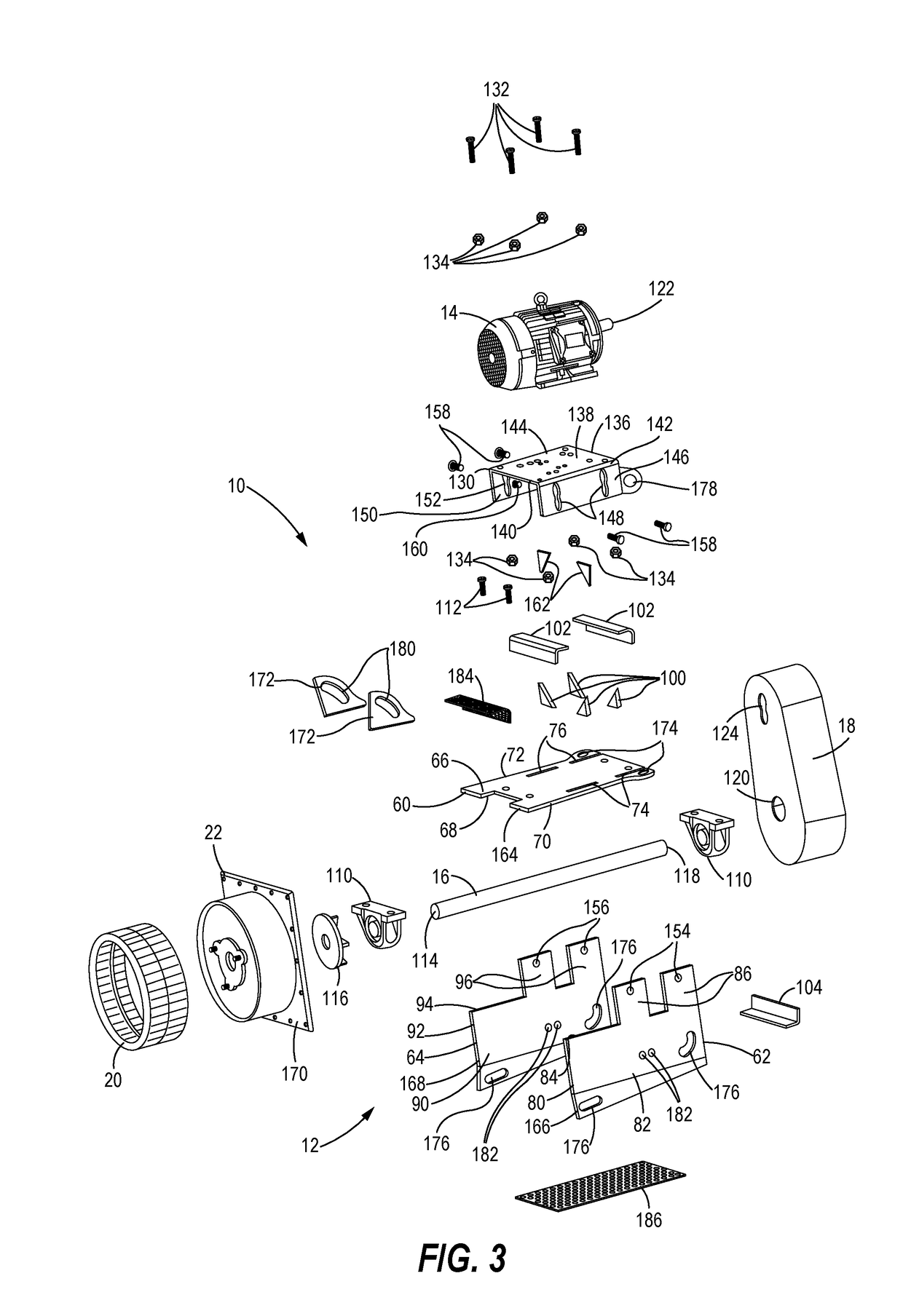

Safety retaining system for large industrial fan

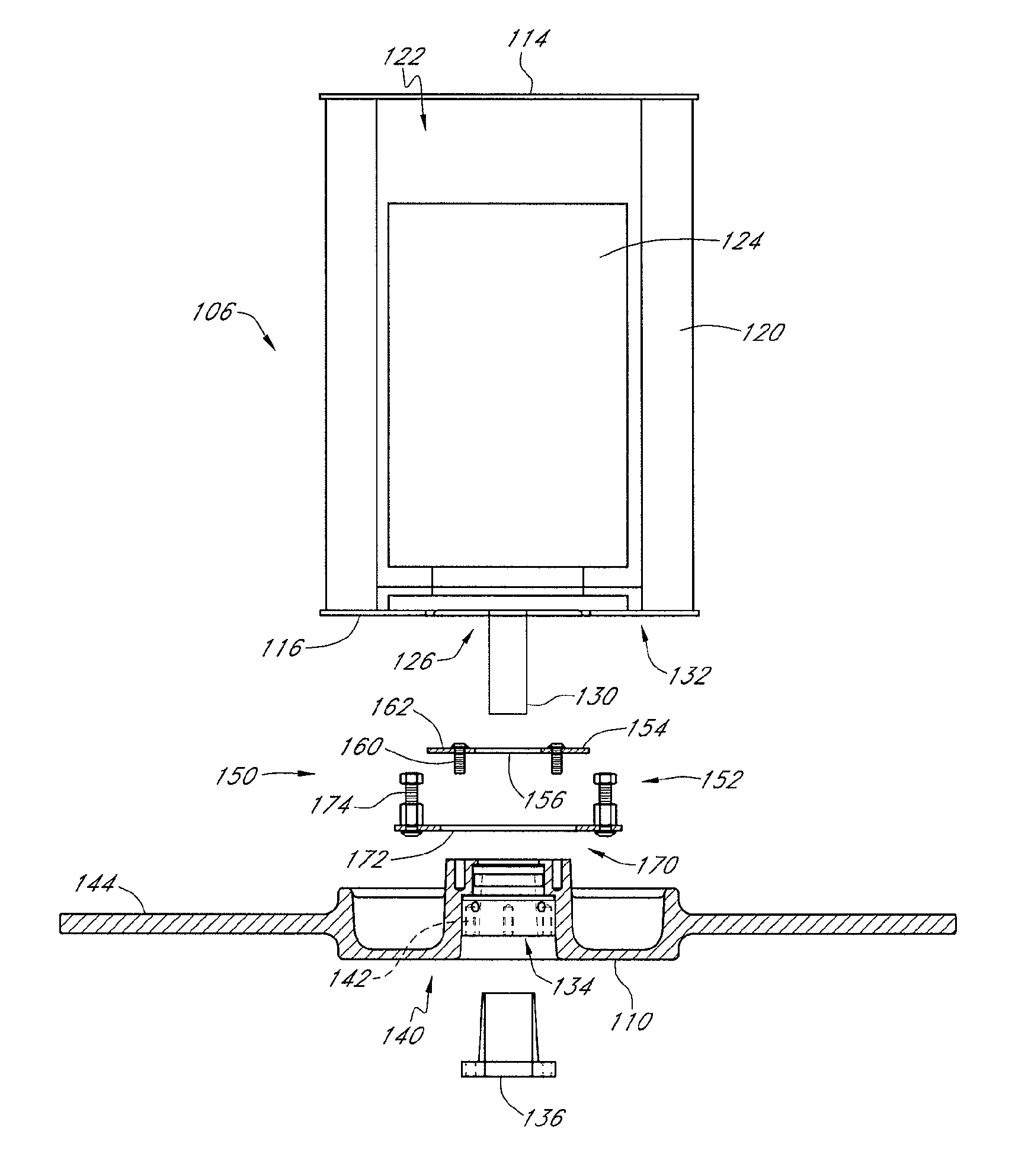

A securing system for a fan assembly. The securing system includes a first member which attaches to a motor mount and a second member which attaches to the hub of the fan assembly. The first member is interposed between the hub and the second member such that should the shaft of the motor break, the first and second members engage with one another and inhibit the fan assembly from falling away from the motor mount.

Owner:MACROAIR TECH

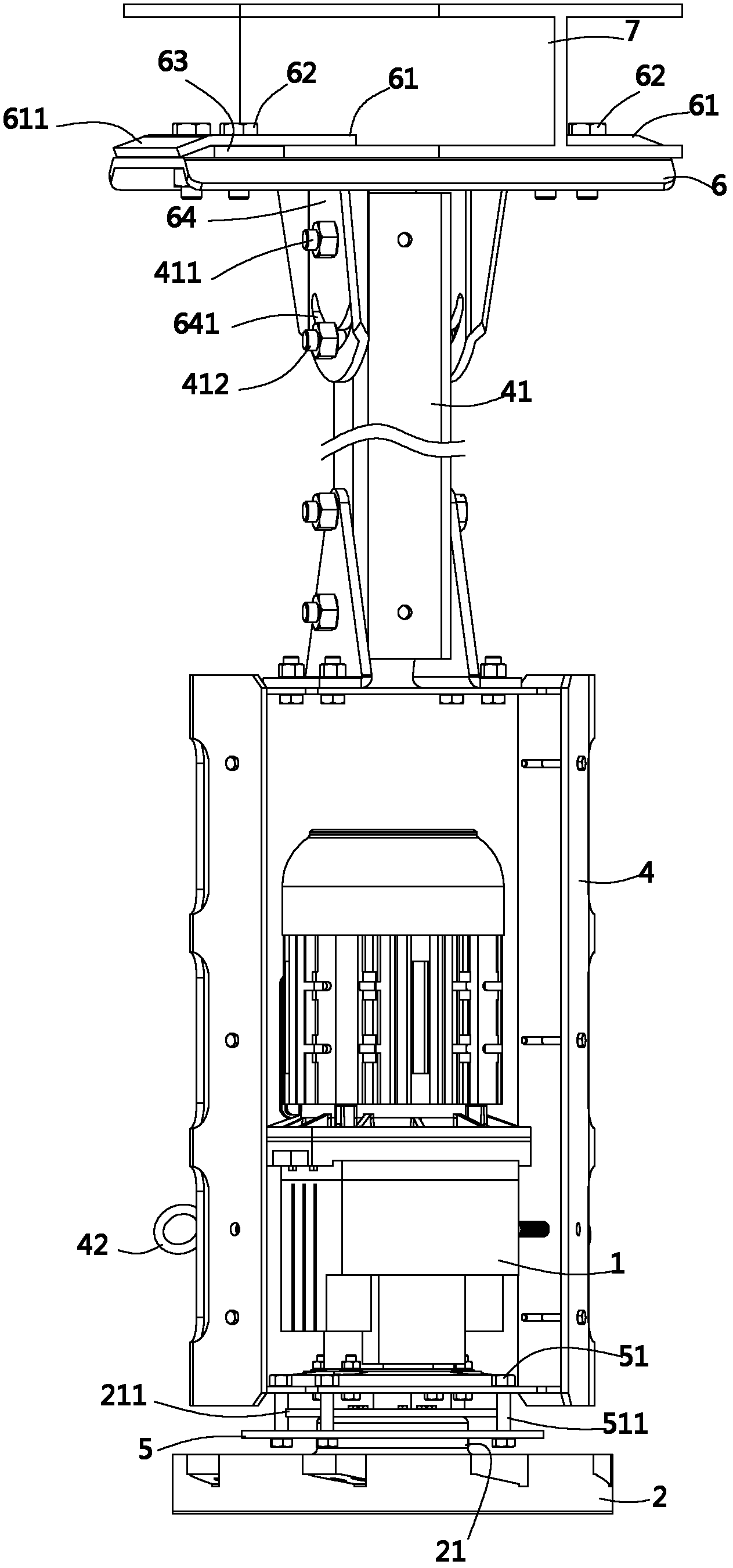

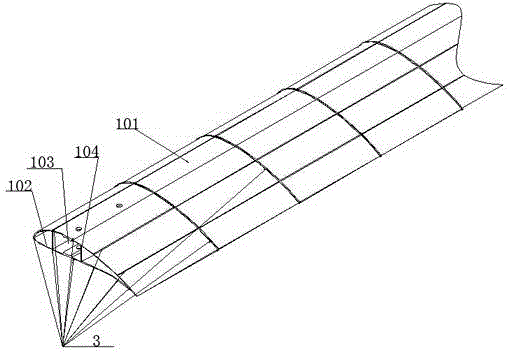

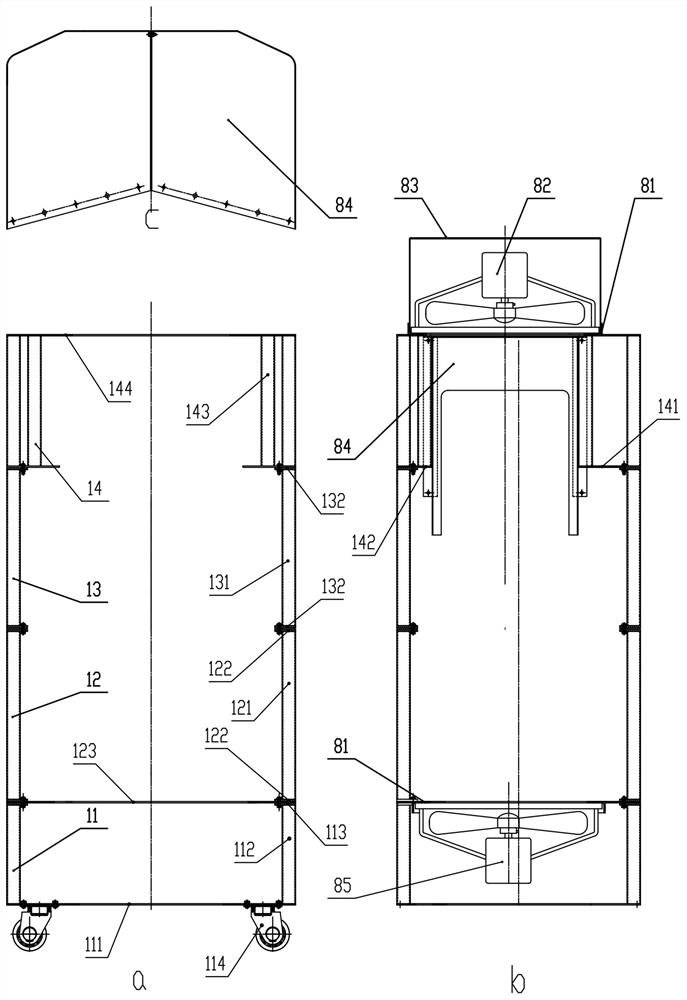

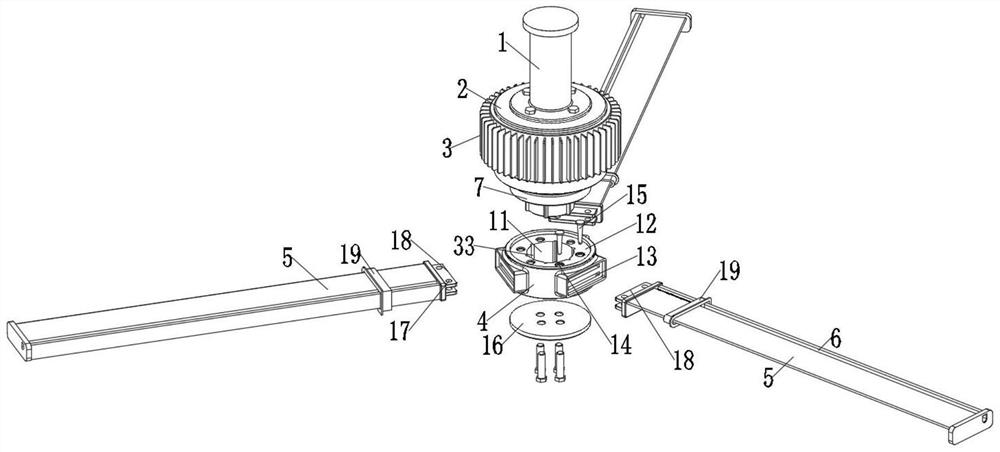

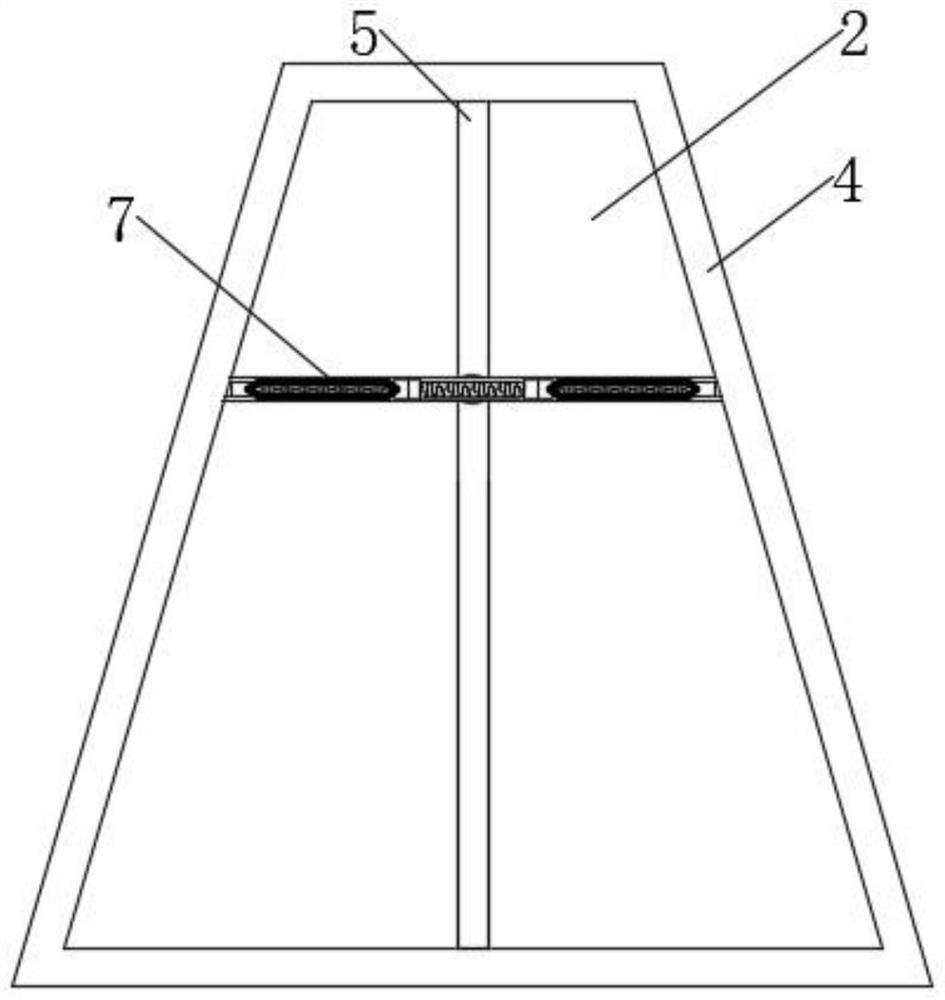

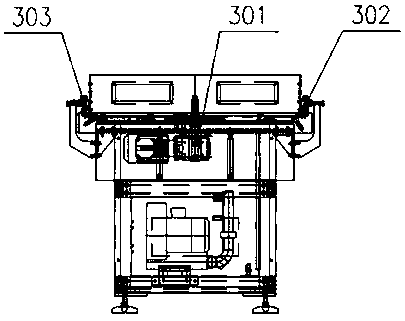

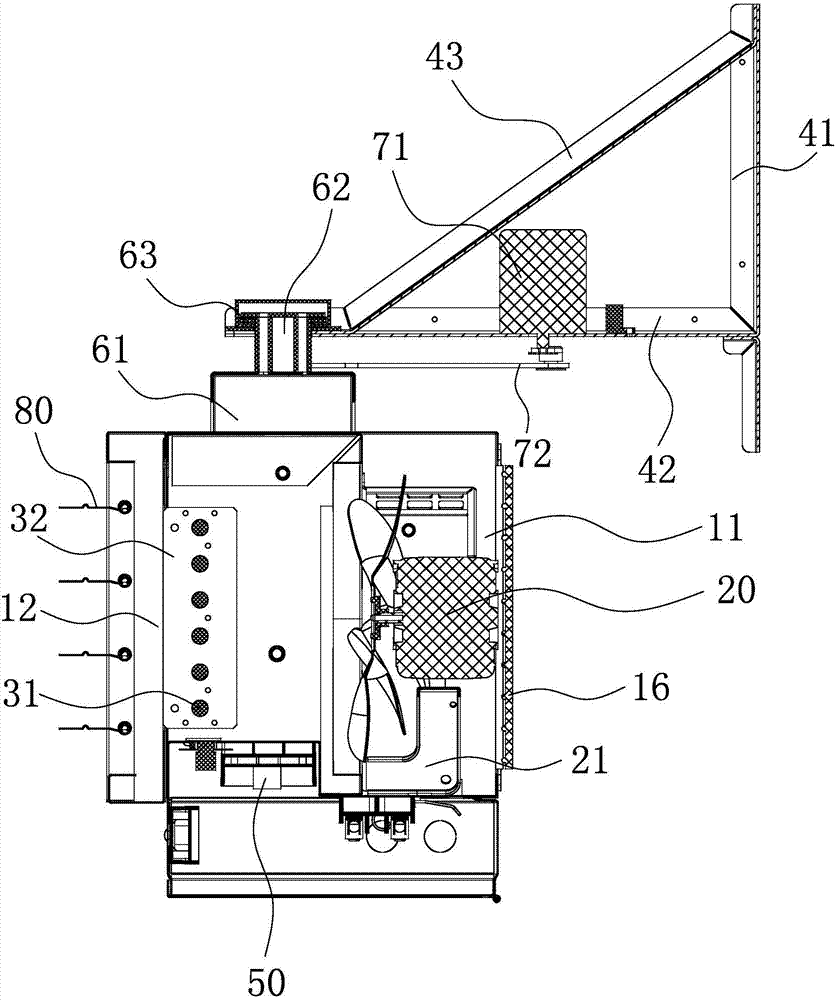

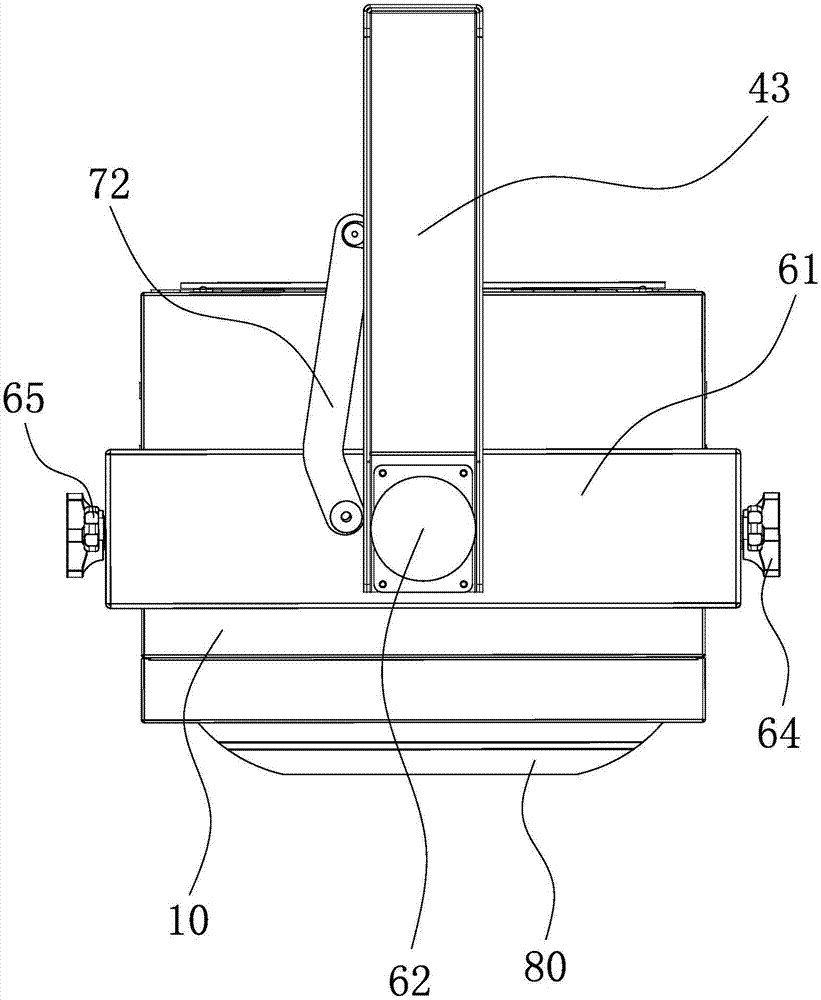

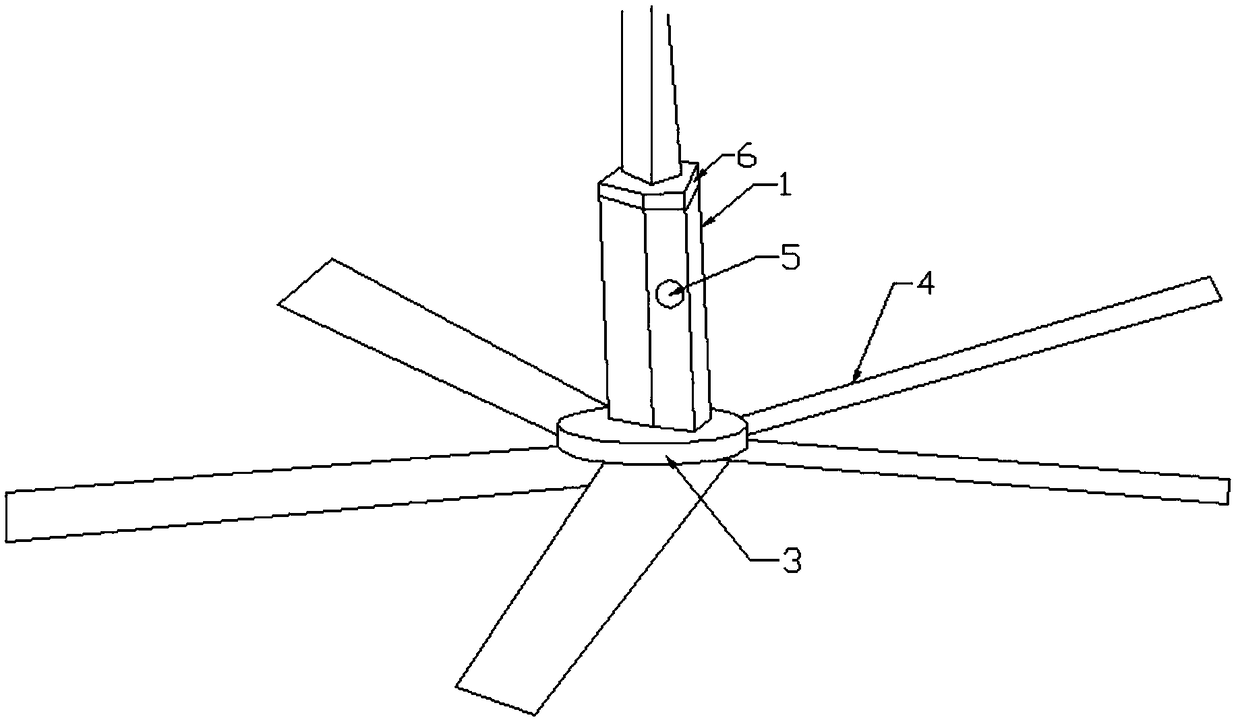

Large-scale hanging type industrial fan

ActiveCN102536864AFree from fallingAvoid accidentsPump componentsPump installationsMotor driveFan blade

The invention discloses a large-scale hanging type industrial fan. The large-scale hanging type industrial fan comprises a motor and a frame, wherein an output shaft of the motor is connected with a base plate, fan blades are arranged on the base plate, and the motor drives the base plate and the fan blades to run; the motor is fixed in the frame, and the output shaft of the motor penetrates through the bottom part of the frame and is connected with the base plate; a supporting frame is connected with the bottom part of the frame, and a through hole is formed in the bottom part of the supporting frame; and a base plate connecting end extends into the supporting frame from the through hole, and is provided with a chuck, the chuck is positioned in the supporting frame, and the diameter of the chuck is greater than that of the through hole. According to the large-scale hanging type industrial fan, an anti-falling safety mechanism is arranged on the connection part between the base plate and the motor, so that dangers caused by loosening of the base plate and the output shaft of the motor can be avoided; simultaneously, a novel hanging structure is adopted, so that the fan can be conveniently and quickly arranged on the top part of a factory building, the mounting position of the fan can be changed or the fan can be dismounted very easily; and the fan blades of the fan are provided with an anti-falling assembling mechanism, so that fan blade falling accidents can be effectively prevented. By adoption of a plurality of types of safety protection measures, the large-scale hanging type industrial fan can be operated safely and reliably.

Owner:开勒环境科技(上海)股份有限公司

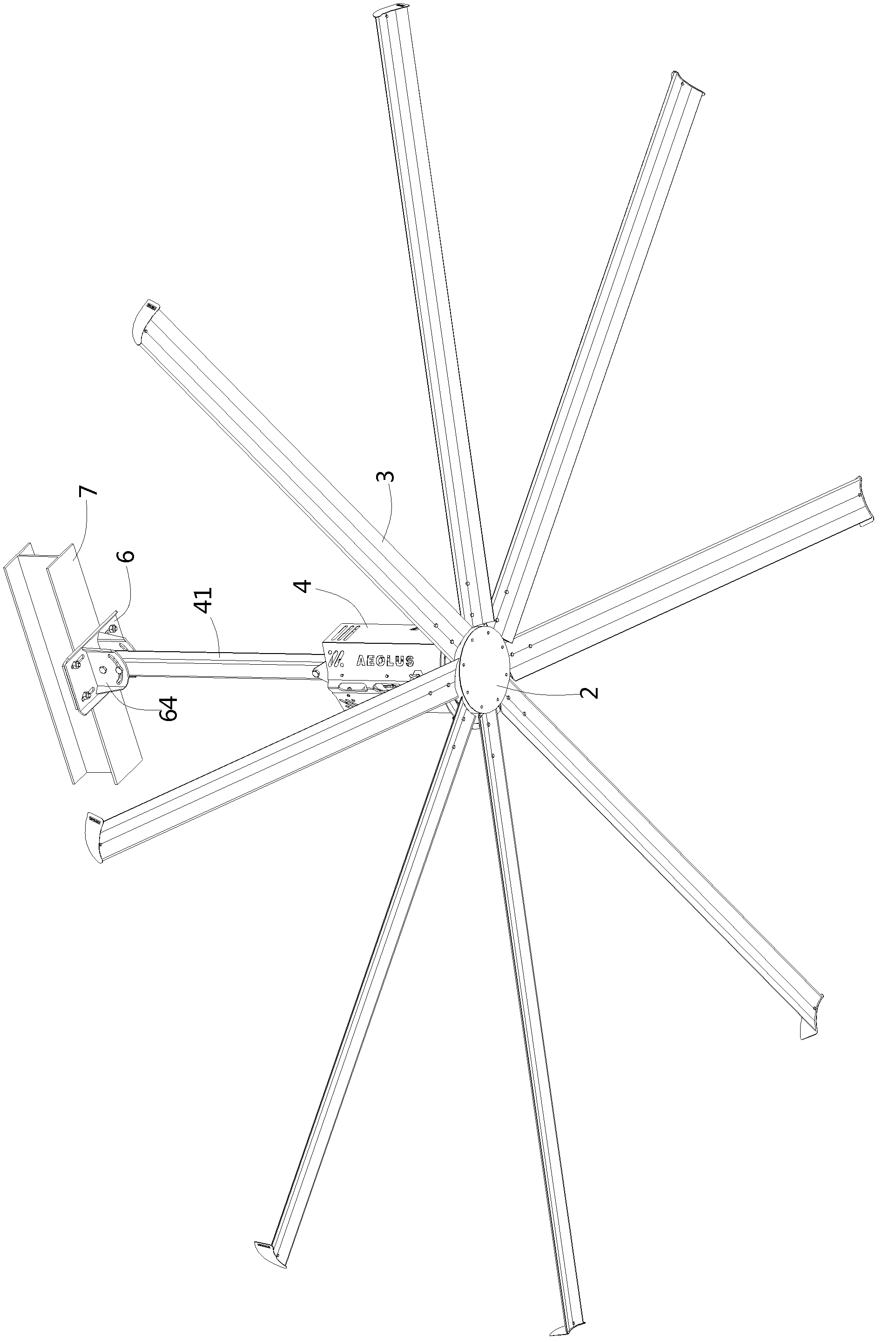

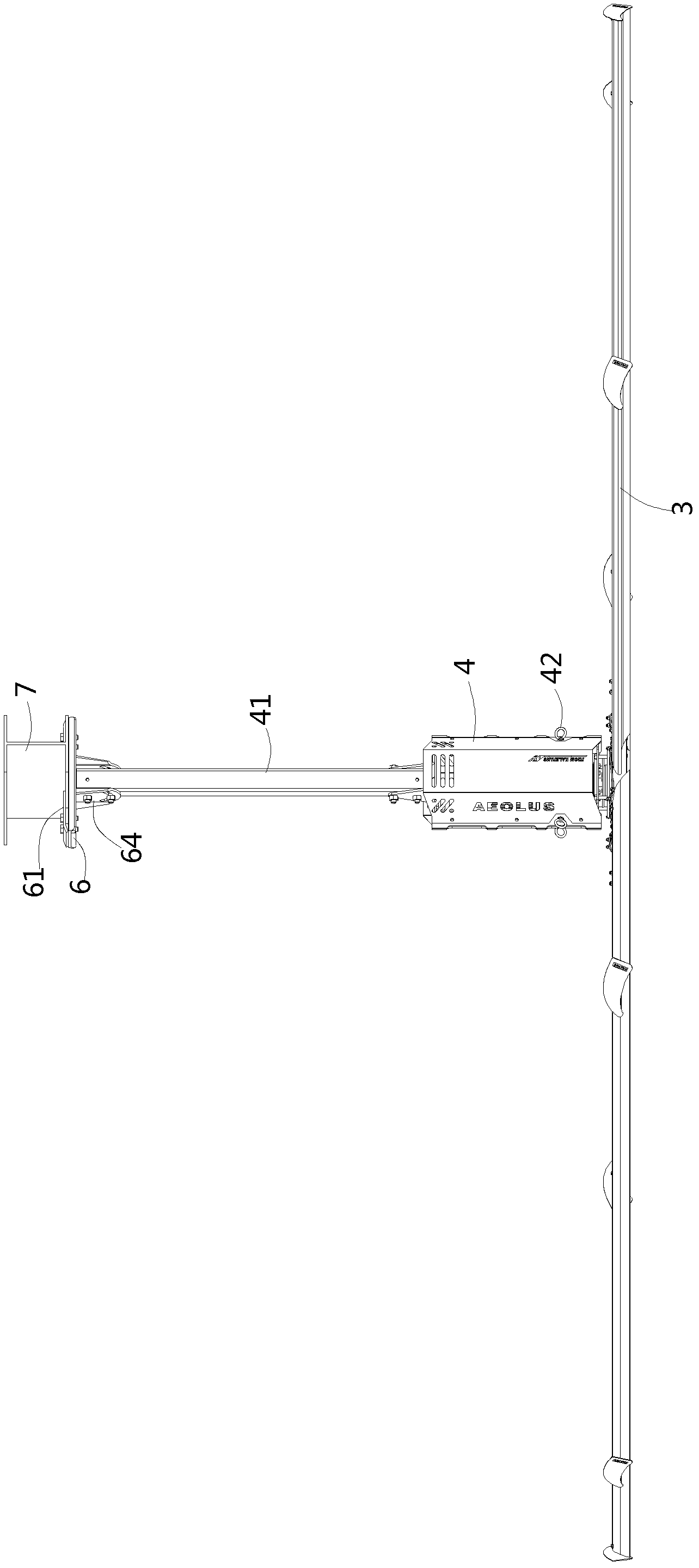

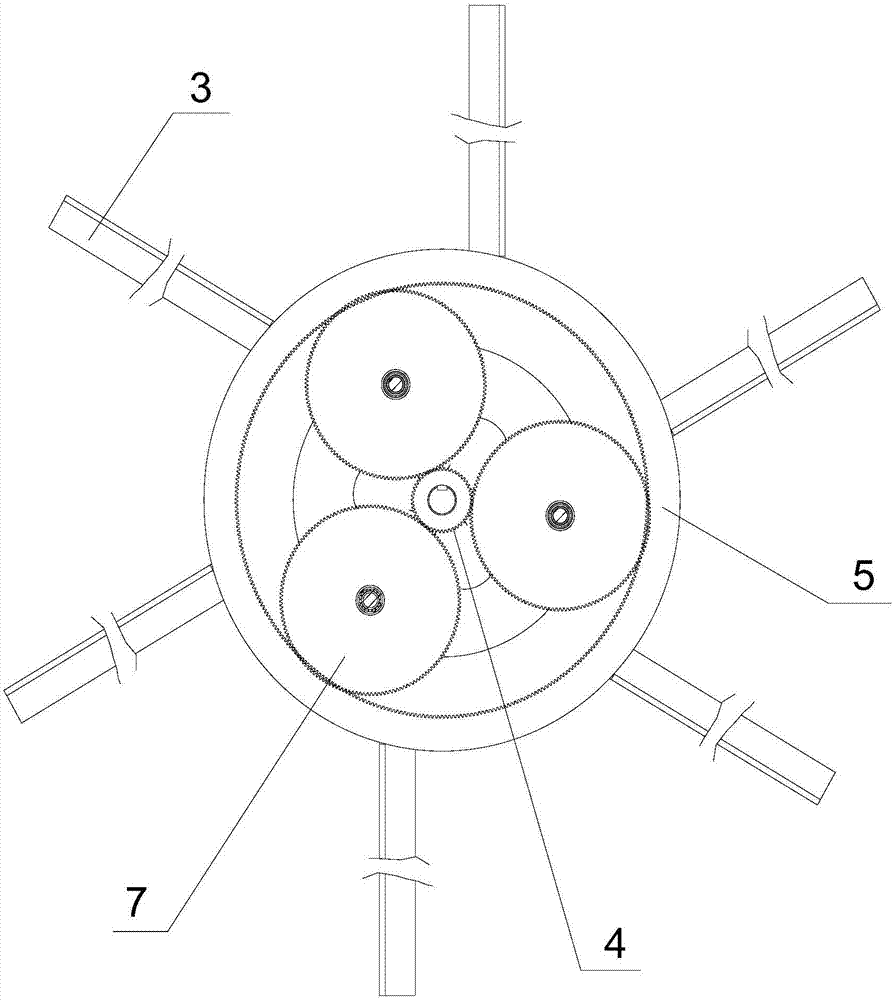

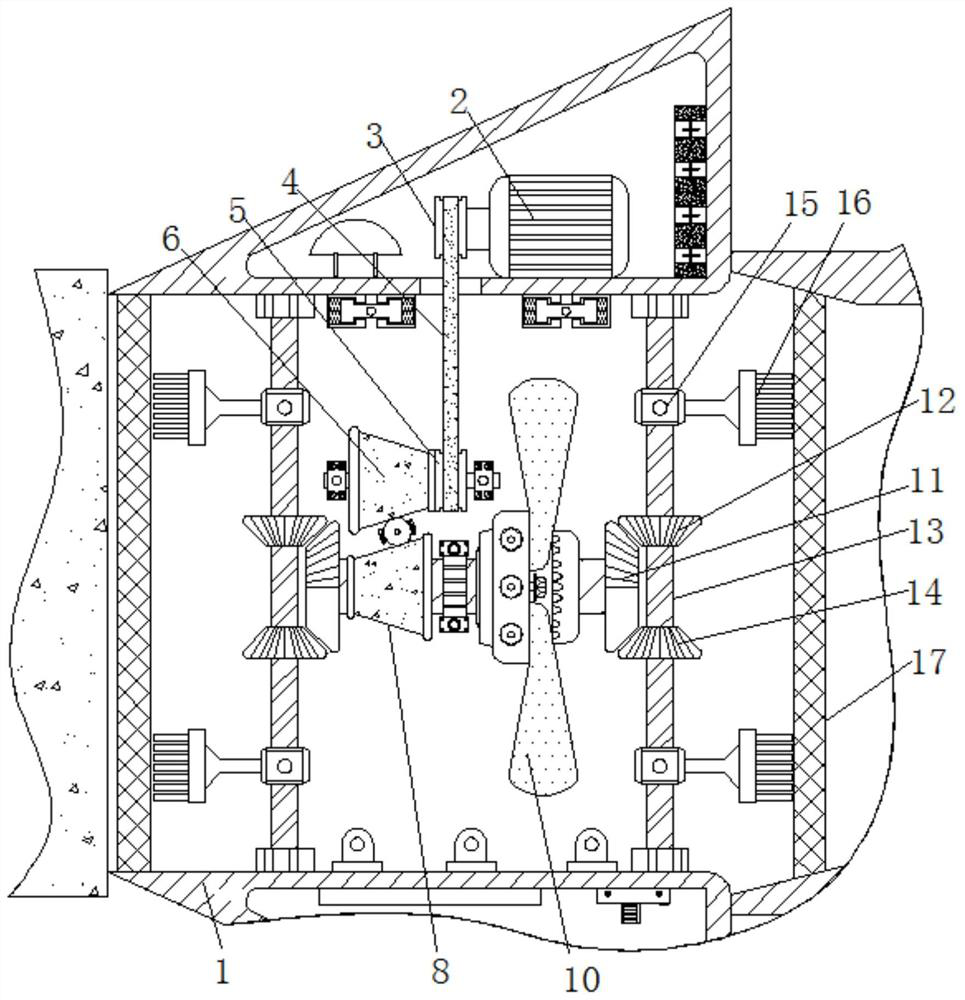

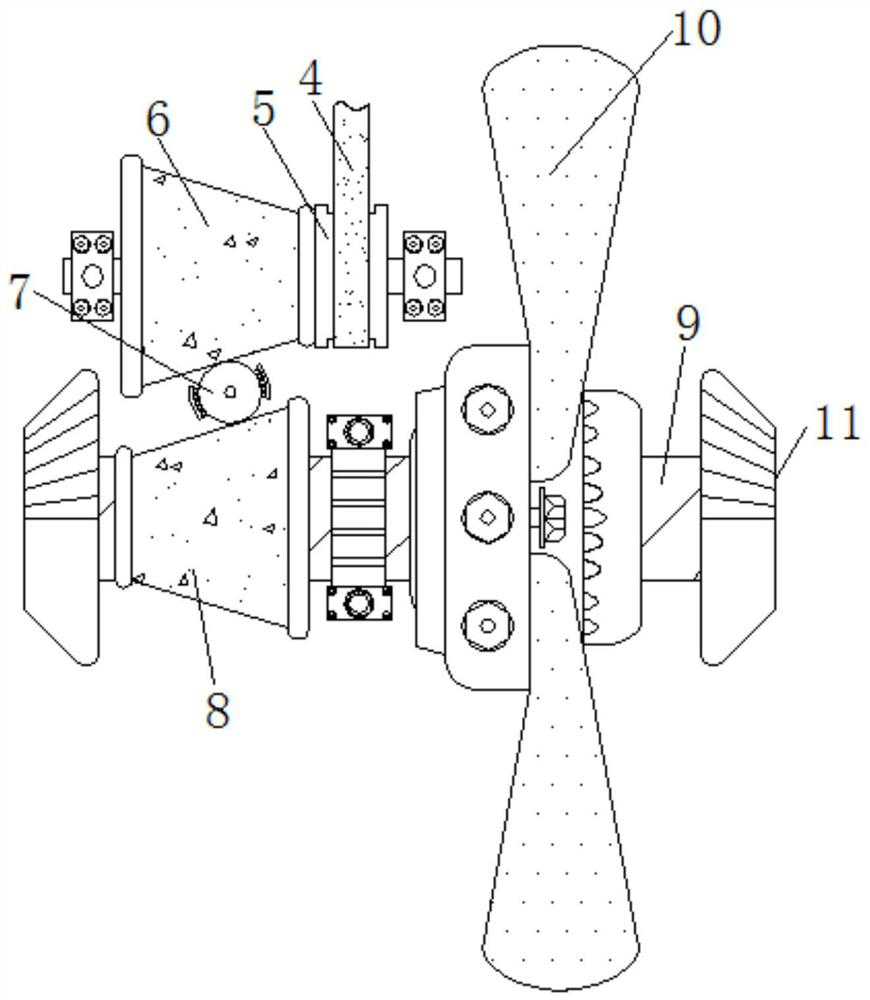

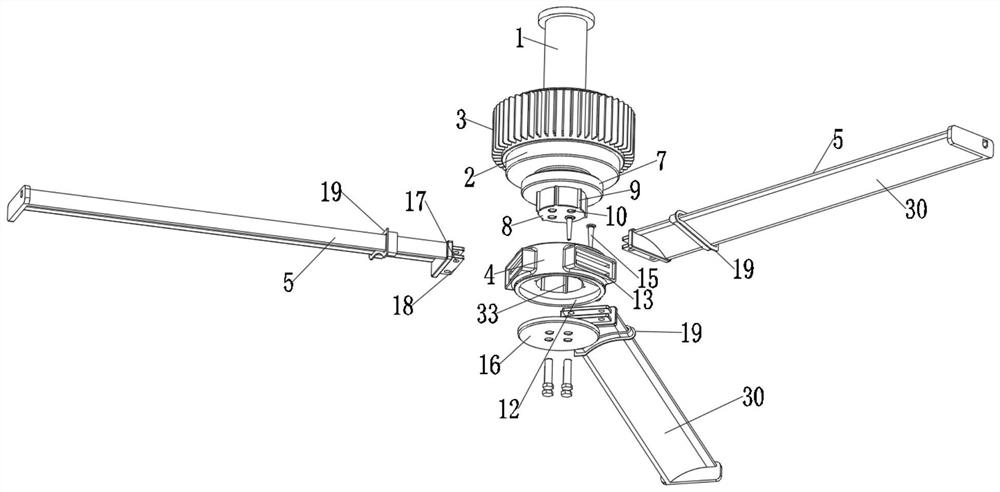

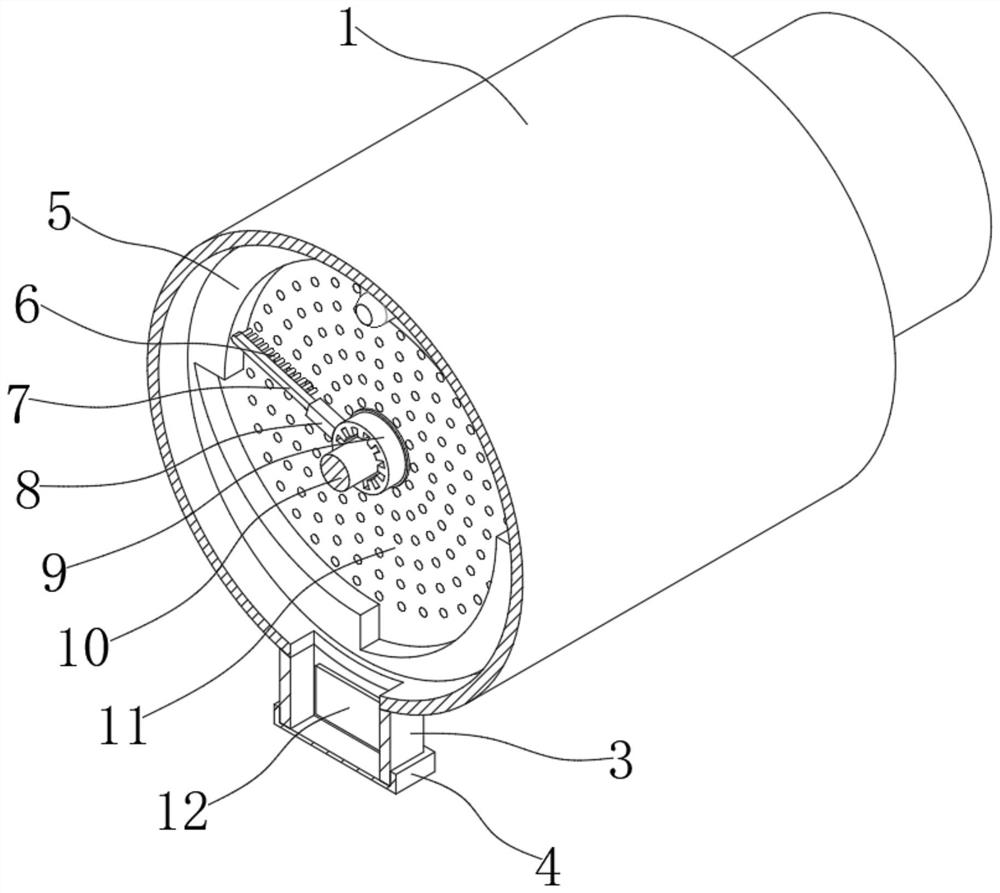

Industrial fan and blade rotation method thereof

ActiveCN107143518ASimple structureReduce manufacturing costPump componentsPumpsElectric machineGear wheel

The invention discloses an industrial fan and a blade rotation method thereof. The industrial fan comprises a motor driving mechanism, a blade rotating mechanism and a plurality of blades. The blade rotating mechanism comprises an input shaft gear, a planetary gear set, an internal gear and a rotating disk, the output end of the motor driving mechanism is connected with the input shaft gear, the input shaft gear is arranged in the center of the planetary gear set, planetary gears in the planetary gear set are meshed with the input shaft gear, the internal gear is arranged on the periphery of the planetary gear set and meshed with the planetary gear set, and the internal gear is fixed on the rotating disk. The blades are evenly distributed on the periphery of the rotating disk. The blade rotation method of the industrial fan comprises the steps that the motor driving mechanism outputs power, transfers the power to the input shaft gear and then drives the planetary gears to rotate, and the planetary gear set drives the internal gear to rotate and then drives the blades to rotate through the rotating disk. By using cooperation of the input shaft gear, the planetary gear set and the like, on one hand, an effect equal to a reduction gearbox is played, and on the other hand, a rotation driving device for the blades is formed, and the structure of the fan is simplified.

Owner:SOUTH CHINA UNIV OF TECH

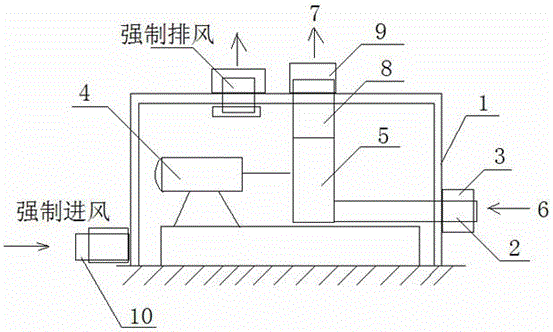

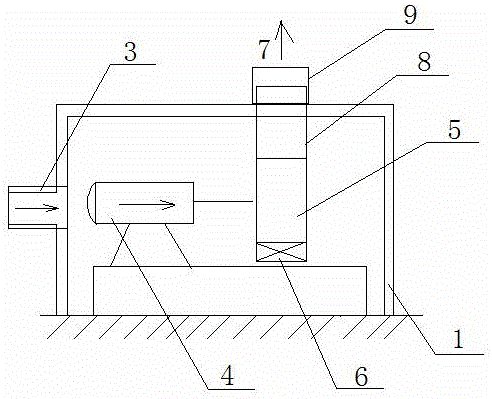

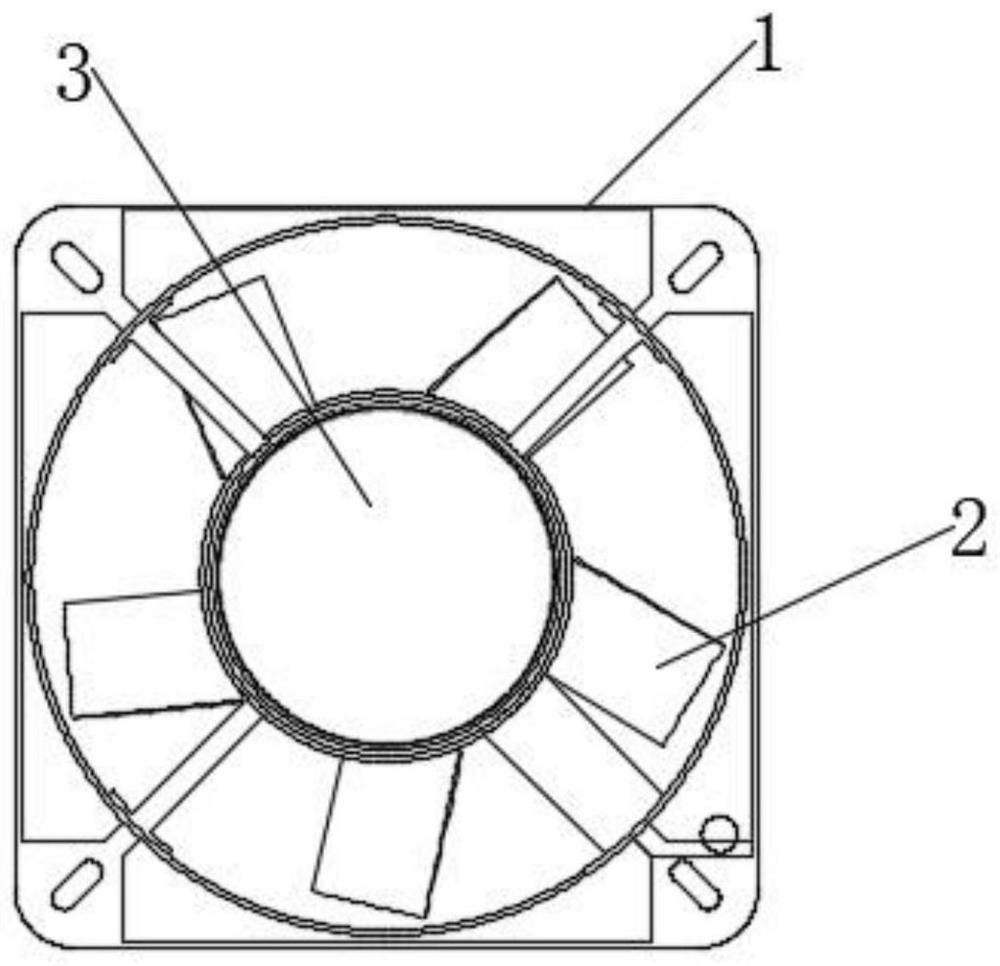

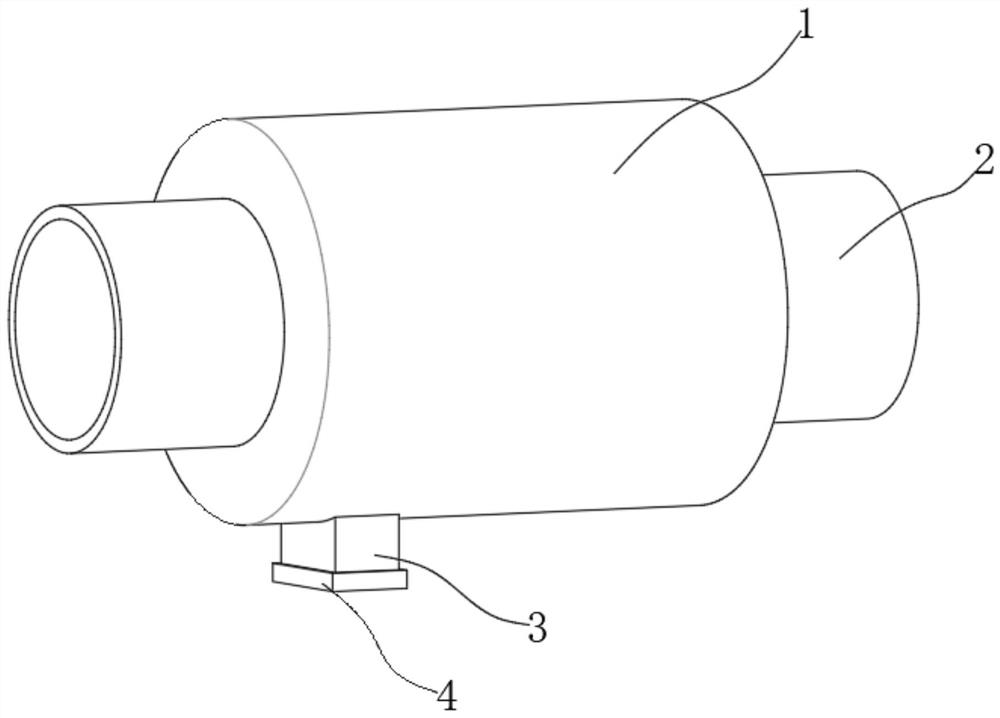

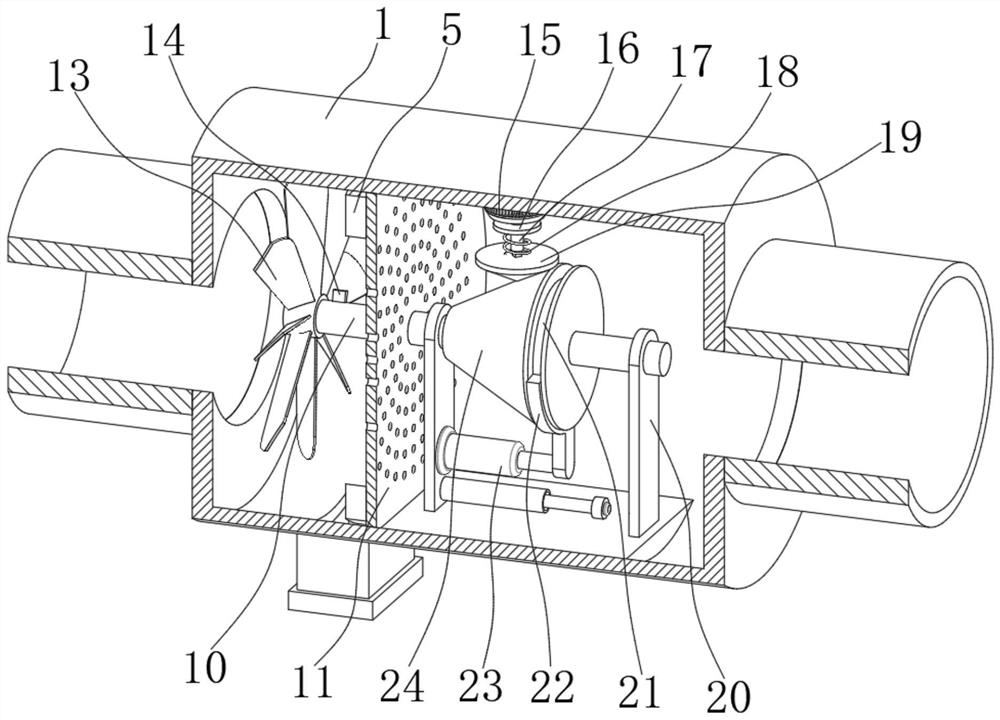

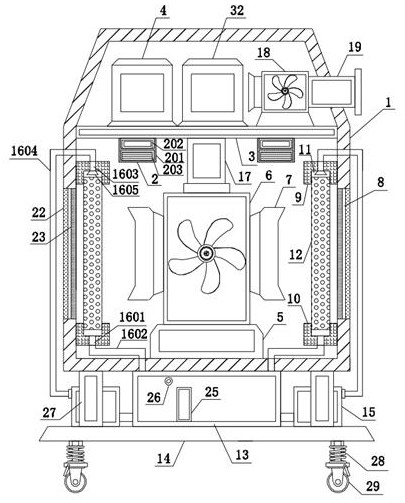

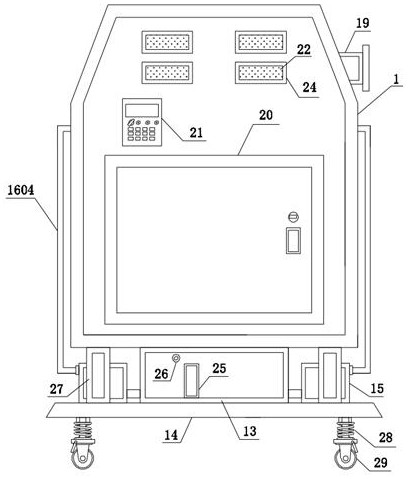

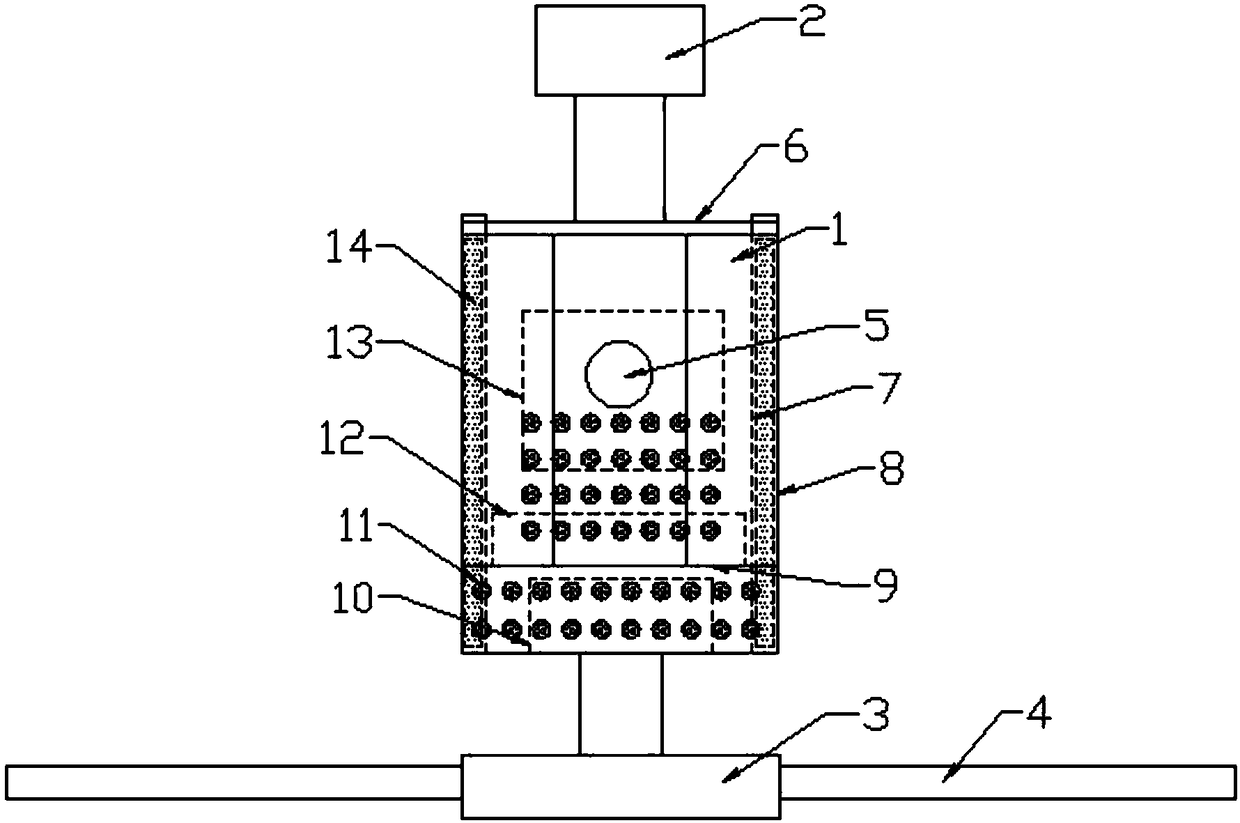

Noise reduction device for industrial fan

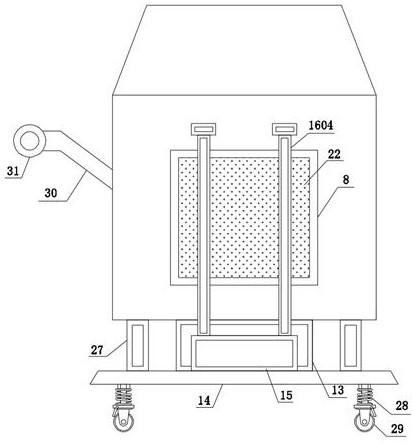

InactiveCN106762853AReduce Absorbent IsolationGuaranteed Absorbent IsolationPump componentsPump installationsWorking environmentEngineering

The invention discloses a noise reduction device for an industrial fan. A sound absorption and insulation chamber is arranged outside the fan and a motor; an air inlet is formed in a position facing the non-output end of the motor, in the sound absorption and insulation chamber; an air inlet silencer is arranged on the air inlet; the output end of the motor is connected with the fan; the air inlet of the fan is formed in the sound absorption and insulation chamber; an air outlet is connected to the outside of the sound absorption and insulation chamber through an air outlet pipe; and an air outlet silencer is arranged on the air outlet pipe. The noise reduction device disclosed by the invention has the advantages that the structural design is simple; the whole device is not provided with a forced air inlet heat dissipation motor in the prior art, and a plurality of air inlet pipes, air outlet pipes and silencers arranged on the air inlet pipes and the air outlet pipes are reduced, so that the manufacturing cost is reduced, and the absorption and the insulation of the noise of the motor and the fan are effectively guaranteed; indoor temperature can be kept within 30 DEG C in summer, so that the temperature in the sound absorption and insulation chamber is greatly lowered, and the service life of equipment and the working environment for maintenance staff are guaranteed.

Owner:吴光明

Automatic dust removal device for preventing indoor ventilation from being influenced by excessive dust in fan

InactiveCN112503033AAvoid affecting indoor ventilationAchieve automatic cleaningPump componentsDispersed particle filtrationElectric machineTransmission belt

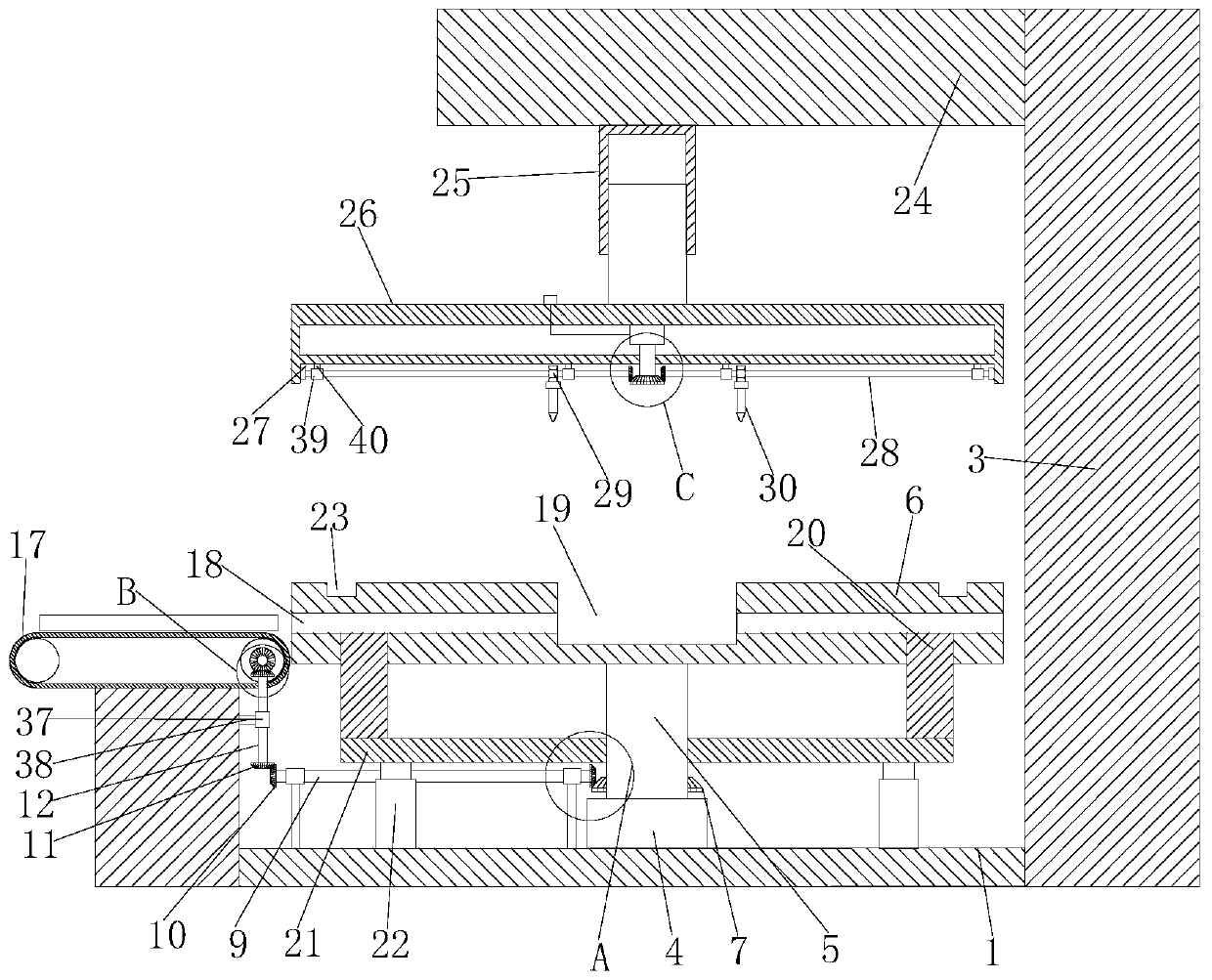

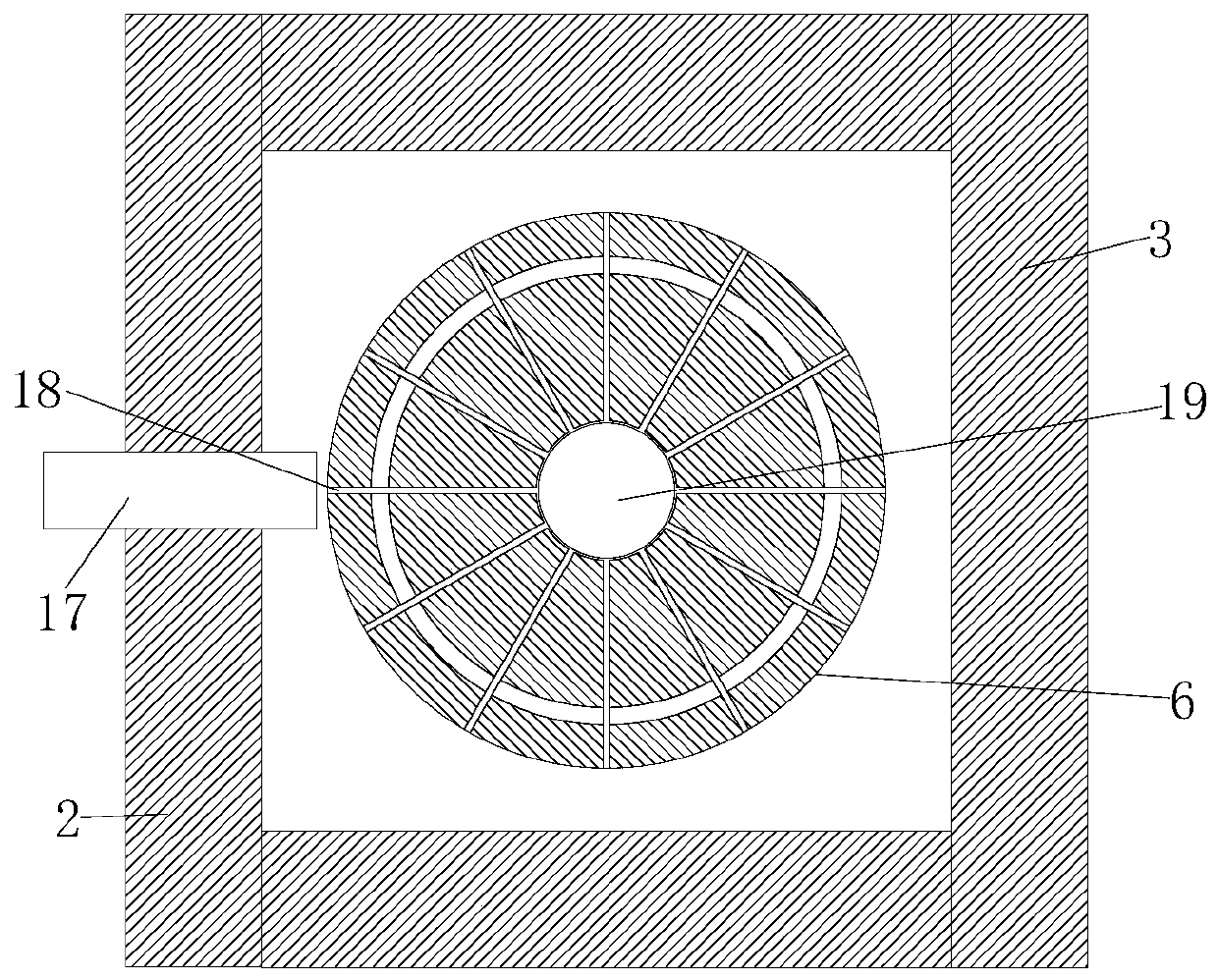

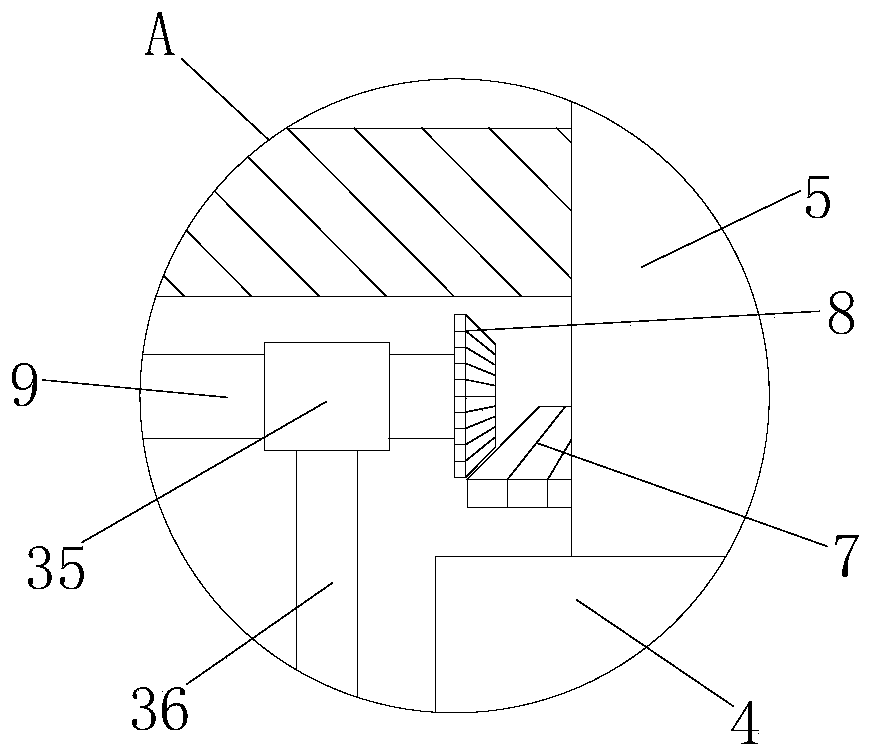

The invention relates to the technical field of industrial fans, and discloses an automatic dust removal device for preventing indoor ventilation from being influenced by excessive dust in a fan. Theautomatic dust removal device comprises a shell, the top in the shell is fixedly connected with a drive motor, the left side of the drive motor is fixedly connected with a driving disc, and the top ofthe driving disc is in transmission connection with a transmission belt. According to the automatic dust removal device for preventing indoor ventilation from being influenced by excessive dust in the fan, the drive motor is started, a screw periodically rotates forwards and reversely at the moment, furthermore a brush periodically sweeps a filter screen up and down, at the moment, falling dust can be blown out of the fan by wind generated by rotation of fan blades, and therefore the effect of automatically removing dust in the fan is achieved. A sliding block is pushed left and right, a fixed plate drives a transmission ball to move left and right at the moment, the transmission ratio between a driven cone and a driving cone is further changed, the rotating speed of the fan blades can also be changed at the moment, and therefore the effect of adjusting the wind speed according to field requirements is achieved.

Owner:林琴眉

Automatic welding device for industrial fan mesh enclosure

InactiveCN111515506AWire networkWelding/soldering/cutting articlesElectric machineryStructural engineering

The invention belongs to the technical field of fan mesh enclosure welding device, and particularly relates to an automatic welding device for an industrial fan mesh enclosure. The automatic welding device comprises a bottom plate, wherein three side plates and a stand column are fixedly connected to the four side surfaces of the bottom plate separately; a motor is connected to the center of the inner wall of the bottom plate; a first rolling shaft is connected to an output shaft of the motor; a welding die is connected to the top of the first rolling shaft; a first bevel gear fixedly sleevesthe first rolling shaft; a second bevel gear is arranged on the first bevel gear in a meshing manner; and one side of the second bevel gear is connected with one end of a second rolling shaft. According to the automatic welding device disclosed by the invention, the second rolling shaft can be rotated through the first bevel gear and the second bevel gear while the first rolling shaft and the welding die are rotated by the motor; a third bevel gear on the second rolling shaft can rotate a third rolling shaft through a fourth bevel gear; and a fifth bevel gear on the third rolling shaft can rotate a central shaft and a roller through a sixth bevel gear, and then a conveying belt is rotated, so that an iron wire can enter a corresponding iron wire groove, and the automatic welding device isconvenient and effective.

Owner:罗峰

Industrial large fan with fan protection measures

InactiveCN104314846AHigh strengthAvoid hurtingPump componentsPump installationsEngineeringIndustrial fan

Owner:洛阳北玻三元流风机技术有限公司 +2

Intelligent industrial fan capable of automatically cleaning dirt on fan blades

The invention relates to the technical field of ventilators, and discloses an intelligent industrial fan capable of automatically cleaning dirt on fan blades. The intelligent industrial fan comprises a support shaft, an inner wheel is slidably connected to the side surface of the support shaft, a bearing rod is fixedly connected to the side surface of the inner wheel, and the fan blades are slidably connected to the side surface of the bearing rod. Extension springs are arranged in the fan blades, electromagnet plates are arranged in the fan blades, scraping rings are slidably connected to the surfaces of the fan blades, a shell is arranged on the sides, away from the wheel center, of the fan blades, a water tank is fixedly connected to the inner wall of the shell, and a water receiving pipe is fixedly connected to the side face of the water tank. A magnetic plate is inserted into the side, close to the wheel center, of the water tank, and a one-way limiting valve is inserted into the side face of the magnetic plate. According to the intelligent industrial fan capable of automatically cleaning the dirt of the fan blades, through cooperative use of the scraping ring and the magnetic plate, the effect of automatically cleaning the fan when the dirt on the surface of the fan reaches a certain degree is achieved.

Owner:徐康

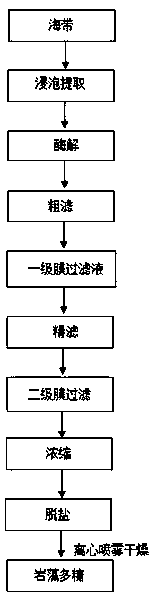

Technique for desalting fucoidin extracted from kelps by membrane filtration

InactiveCN110054707AReduce salt contentGood effectGeneral water supply conservationFiltration circuitsLow speedBristle

The invention discloses a technique for desalting fucoidin extracted from kelps by membrane filtration. The technique includes steps: after soaking in clear water, manually brushing fresh black and white truffles with hard-bristle toothbrushes until surfaces of the truffles are clean and water for washing the truffles is clear, manually checking whether the truffles are cleaned or not, placing thecleaned fresh truffles one by one in a ventilation platform without overlaying, putting the platform full of the truffles at a ventilation place, blowing the truffle platform for 15-30 days by oscillating industrial fans or blast blowers in a low-speed rotary blowing manner until the truffles are shrunk evidently, and knocking a wood board and the like with intact truffles to select qualified truffles which make clear and loud sound. By the technique for desalting fucoidin extracted from kelps by membrane filtration, the defect that the fresh truffles are short in fresh keeping time and highin aroma loss is overcome, and dried truffle products suitable for eating habits of Chinese can be provided.

Owner:WEIHAI YUWANG GRP MARINE BIOLOGICAL ENGCO

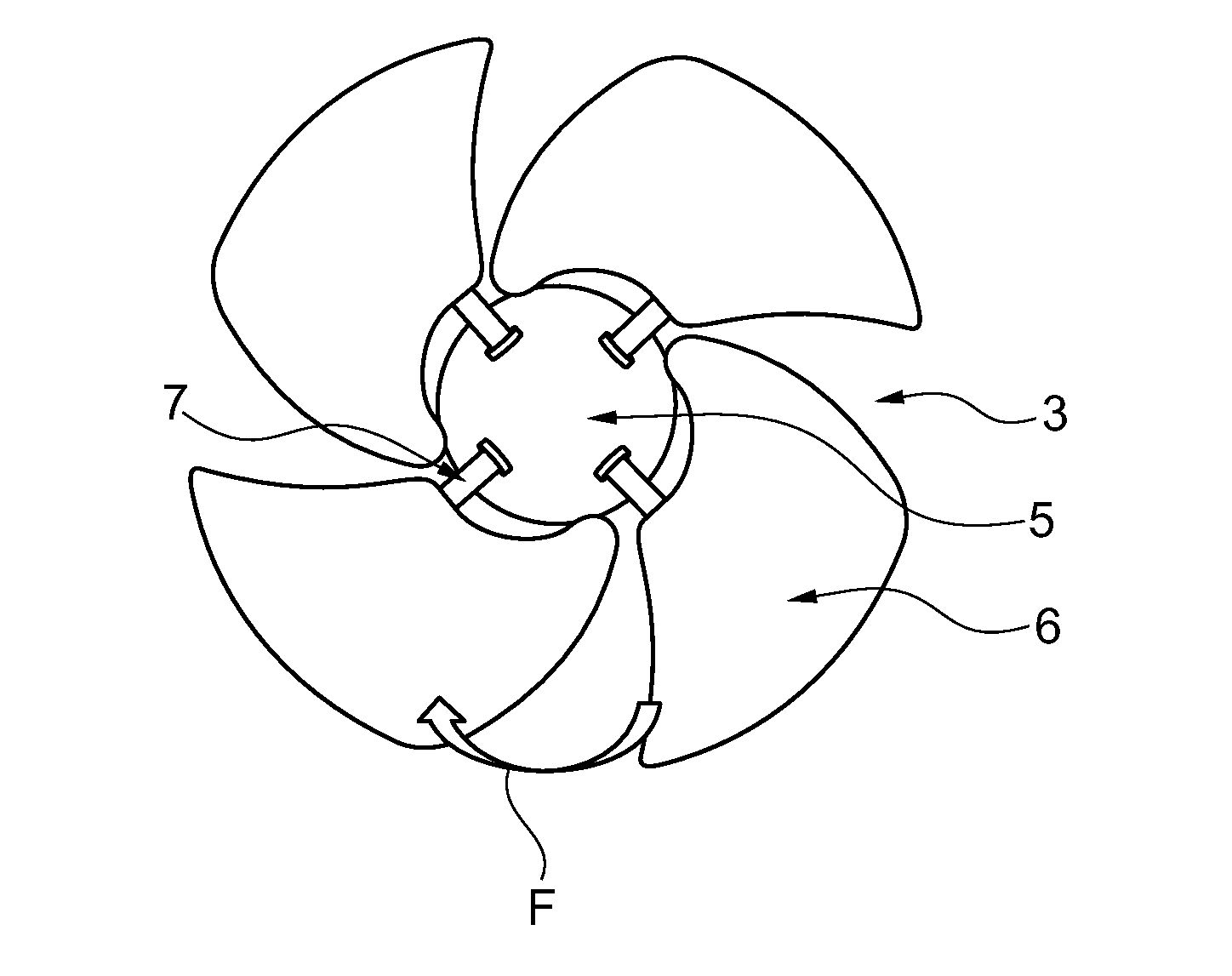

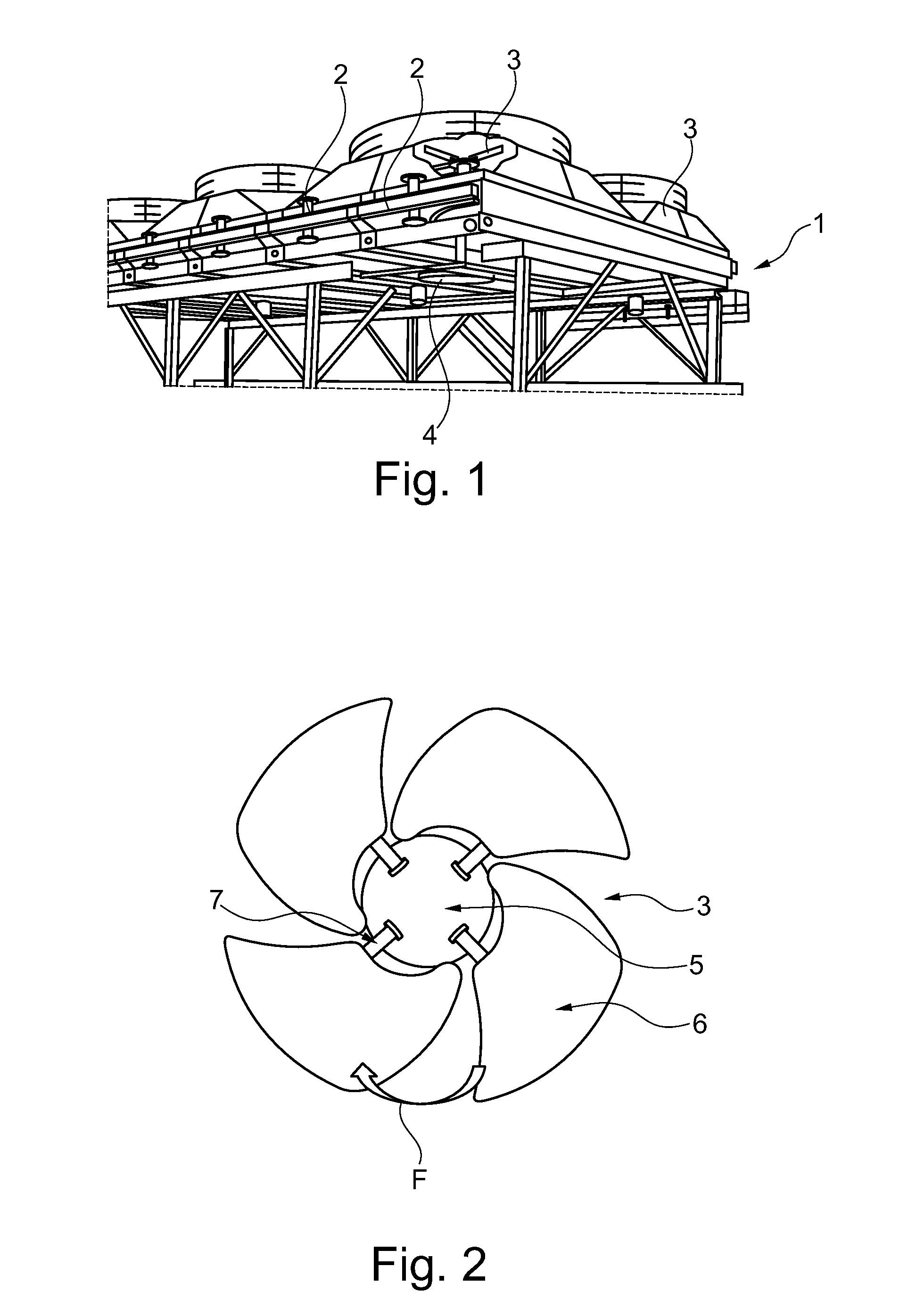

Fan for cooling tower

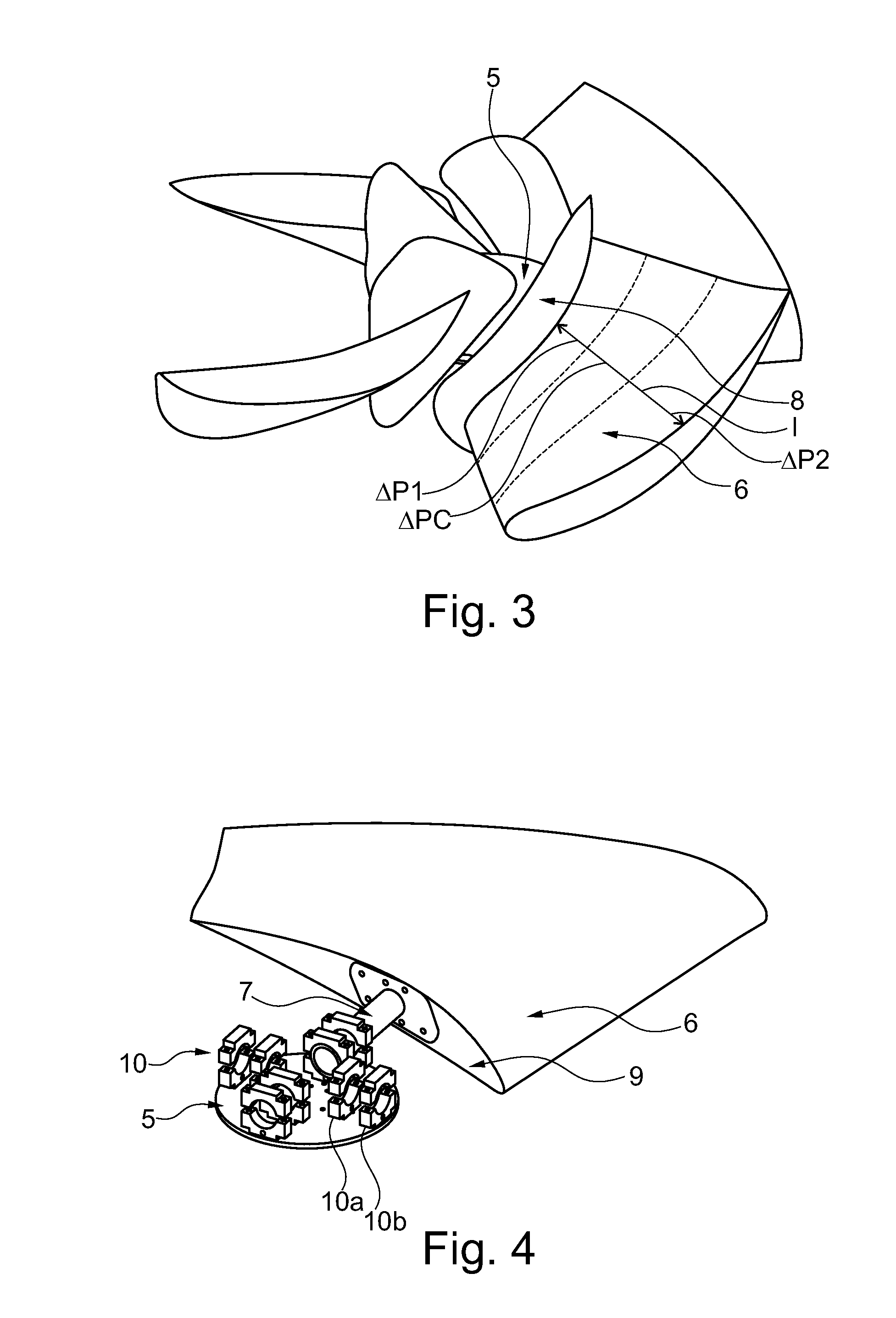

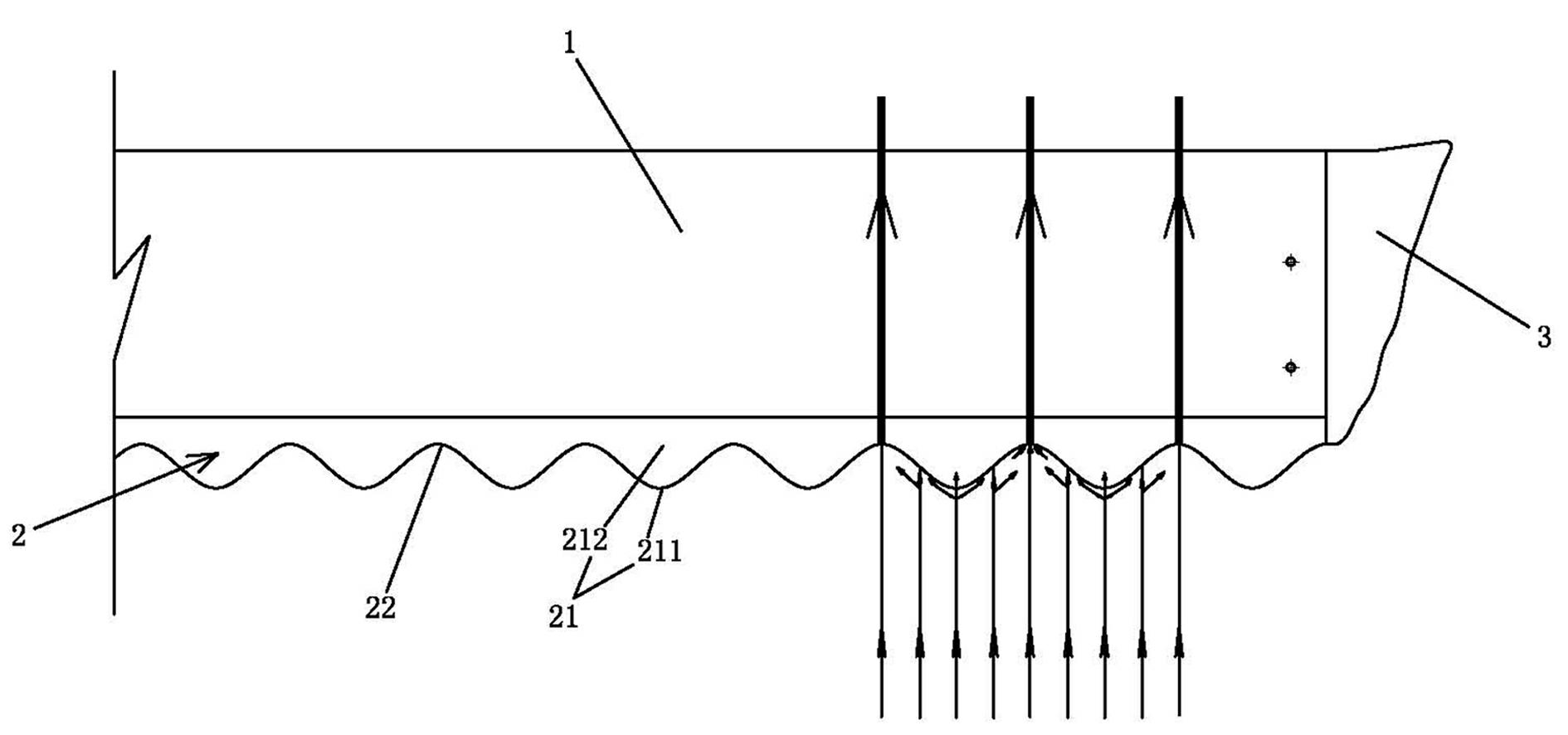

InactiveUS20160076546A1High mechanical strengthImprove flow efficiencyPropellersPump componentsIndustrial fanAirflow

An industrial fan for a cooling tower comprises a disc-shaped hub and a plurality of blades radially connected to the disc of the hub by means of a stud, provided on one end of each said blade, and a flange provided on one face of the hub and into which the stud of the blade is inserted with a blade angle for generating an axial air flow, each blade has such an aerodynamic profile that the pressure difference between pressure and suction faces is lower at the blade foot than at the middle of the blade chord and is higher at the blade head than at the middle of the blade chord, and it is provided a junction means for blocking the air recirculation between the pressure and suction faces at the blade foot.

Owner:GEA BATIGNOLLES TECH THERMIQUES

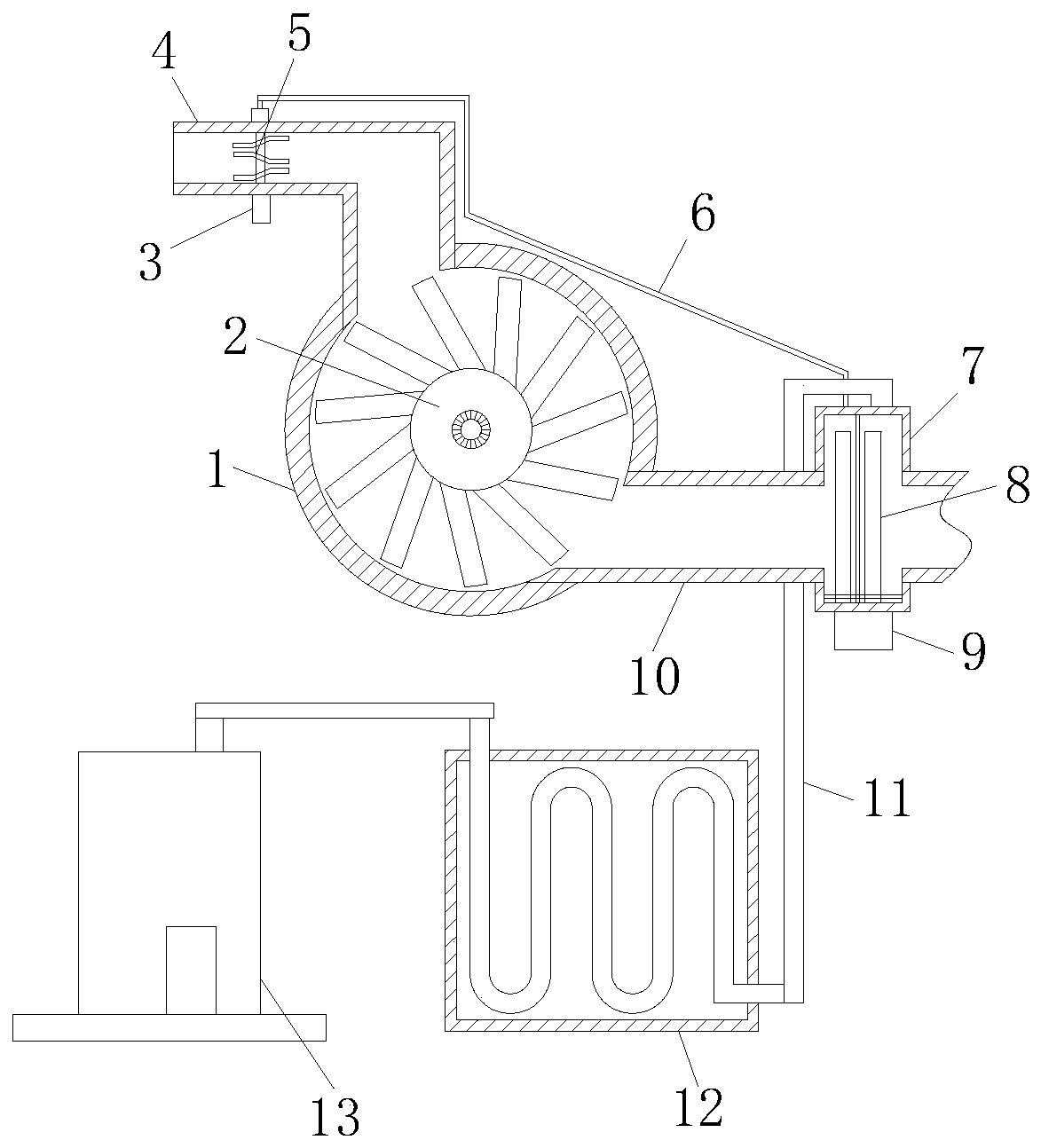

Efficient refrigeration industrial fan

InactiveCN110762666AImprove cooling effectGood cooling effectCondensate preventionLighting and heating apparatusRefrigerationExhaust pipe

The invention discloses an efficient refrigeration industrial fan. The efficient refrigeration industrial fan comprises a fan shell. A fan body is mounted in the fan shell, the upper left top positionon the fan shell is connected with an air inflow pipe, a precooling device is arranged in the air inflow pipe, the lower right bottom position on the fan shell is connected with an exhaust pipe, theair inflow pipe communicates with the fan shell and the exhaust pipe, an evaporator is mounted on a shell body on the exhaust pipe, a condenser and a compressor are further arranged on the outer sideof the exhaust pipe, and the compressor, the condenser and the evaporator communicate through an air conditioner pipe. The precooling device comprises two cooling fins arranged in the air inflow pipein an up-and-down symmetry manner, and the cooling fins are fixed into the air inflow pipe through a fixing column. Condensate water generated when steam on the evaporator makes contact with air is collected and conveyed to the position of the air inflow pipe, when the external air is sucked by the fan, entering air is firstly cooled and precooled through low temperature carried by the condensatewater, the precooled air is further cooled through the evaporator, and therefore the refrigeration effect is improved.

Owner:苏州诺华德工业风机制造有限公司

Safety retaining system for large industrial fan

Owner:MACROAIR TECH

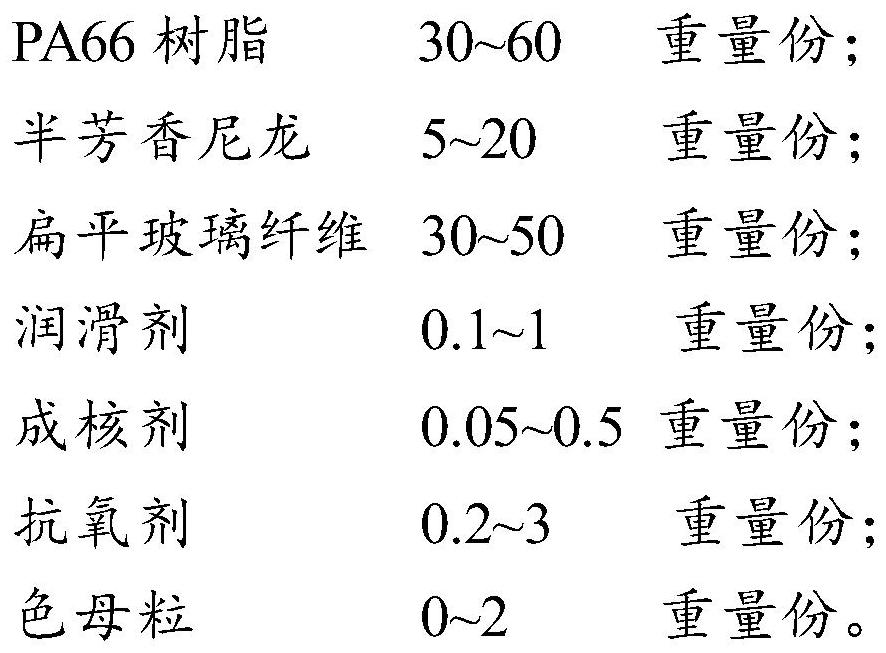

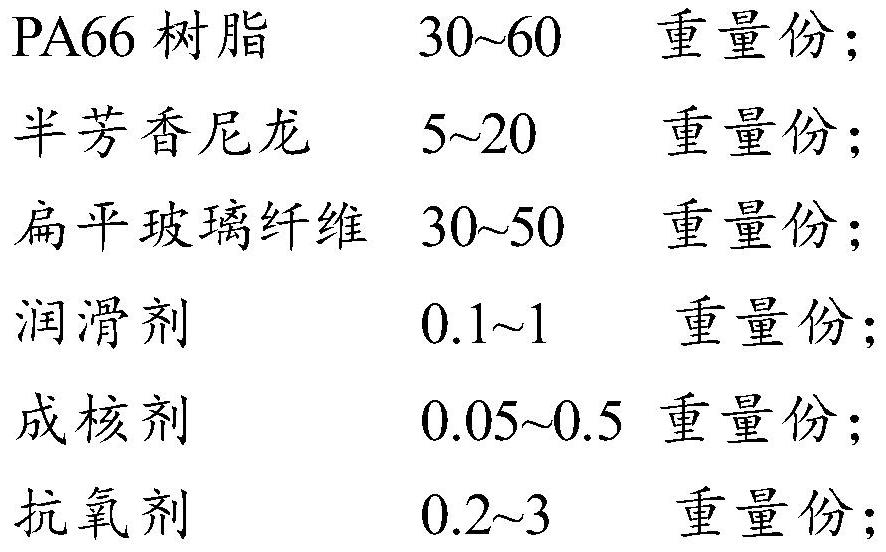

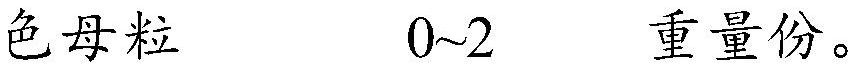

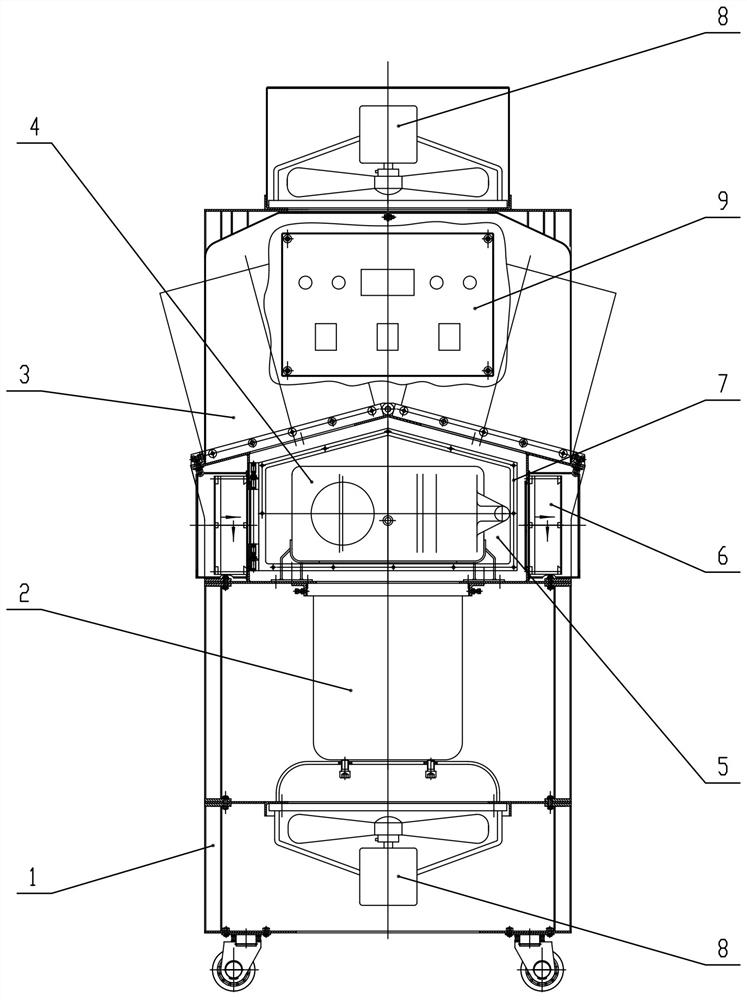

High-strength high-flowability low-warpage long glass fiber reinforced polyamide composite material as well as preparation method and application thereof

The invention provides a glass fiber reinforced polyamide composite material granule. The polyamide composite material granule comprises flat glass fibers, and the length direction of the flat glass fibers and the length direction of the polyamide composite material granules are distributed in the same direction. The invention further provides the high-strength flat continuous long glass fiber reinforced PA66 composite material, the mechanical property of the PA66 composite material is improved, the fluidity and the appearance of a product are improved, the buckling deformation of the composite material product is reduced, the mechanical property, the runner length and the surface quality of the long glass fiber reinforced PA66 composite material can be remarkably improved, and a prepared industrial fan blade is not easy to warp and deform, is stable to use under the condition of high-speed rotation, and meets the new development requirements of high mechanical property, high dimensional stability, high surface quality and low water absorption of an industrial fan blade material.

Owner:CHONGQING POLYCOMP INT

Terahertz wave seed activation processor

The invention discloses a terahertz wave seed activation processor which comprises a laminated framework, a single-irradiation source, a double-irradiation source, an irradiated object container, an irradiation chamber, a convection cooling device, a double-layer door, an industrial fan and an electric cabinet. The three terahertz wave irradiation sources are tightly attached to a peripheral window of the irradiation chamber, and one terahertz wave irradiation source irradiates vertically upwards; and the other two terahertz wave irradiation sources irradiate obliquely and downwards to form a three-dimensional triangular situation, so that the seeds in the container can be uniformly irradiated by the terahertz waves up and down and left and right. Modern agricultural biological breeding needs processing equipment which is excellent in structure, realizes digital display temperature measurement 0.1-DEG C intelligence and automatically stops when the irradiation dose reaches the standard, grain seeds and vegetable seeds can be activated and processed to ensure yield increase, and fish fries or shrimp seeds can also develop well and grow fast. By applying the terahertz wave technology, the terahertz wave seed activation processor has the characteristics of mechanical and electrical integration, multiple functions, stable operation, simplicity and convenience in use and the like.

Owner:上海鸿余环保科技有限公司

Permanent magnet synchronization axial magnetic field motor driven industrial fan

PendingCN110374901APrevent fallingCooperate wellPump componentsMechanical energy handlingLow speedMotor drive

The invention discloses a permanent magnet synchronization axial magnetic field motor driven industrial fan. The industrial fan comprises a mounting base; a lengthening rod is fixedly connected into the mounting base; the outer side of the lengthening rod is fixedly connected with a permanent magnet synchronization axial magnetic field motor main body; a stator main shaft is arranged in the permanent magnet synchronization axial magnetic field motor main body, and is fixedly connected with the outer side of the lengthening rod; the outer side of the stator main shaft is fixedly connected witha main shaft bearing; a rotor substrate is fixedly connected to the outer side of the main shaft bearing, and is rotationally connected with the stator main shaft through the main shaft bearing; and fan blades are fixedly connected to the outer side of the rotor substrate. The permanent magnet synchronization axial magnetic field motor driven industrial fan has such advantages as energy conservation, super thinness, low-speed high torque and excellent heat dissipation, effectively prevents falling in the use process to improve the overall safety, is simple and reliable, improves the overall practicability, and meanwhile, is convenient for overall adjustment and stable fixation.

Owner:苏州市德爱动力科技有限公司

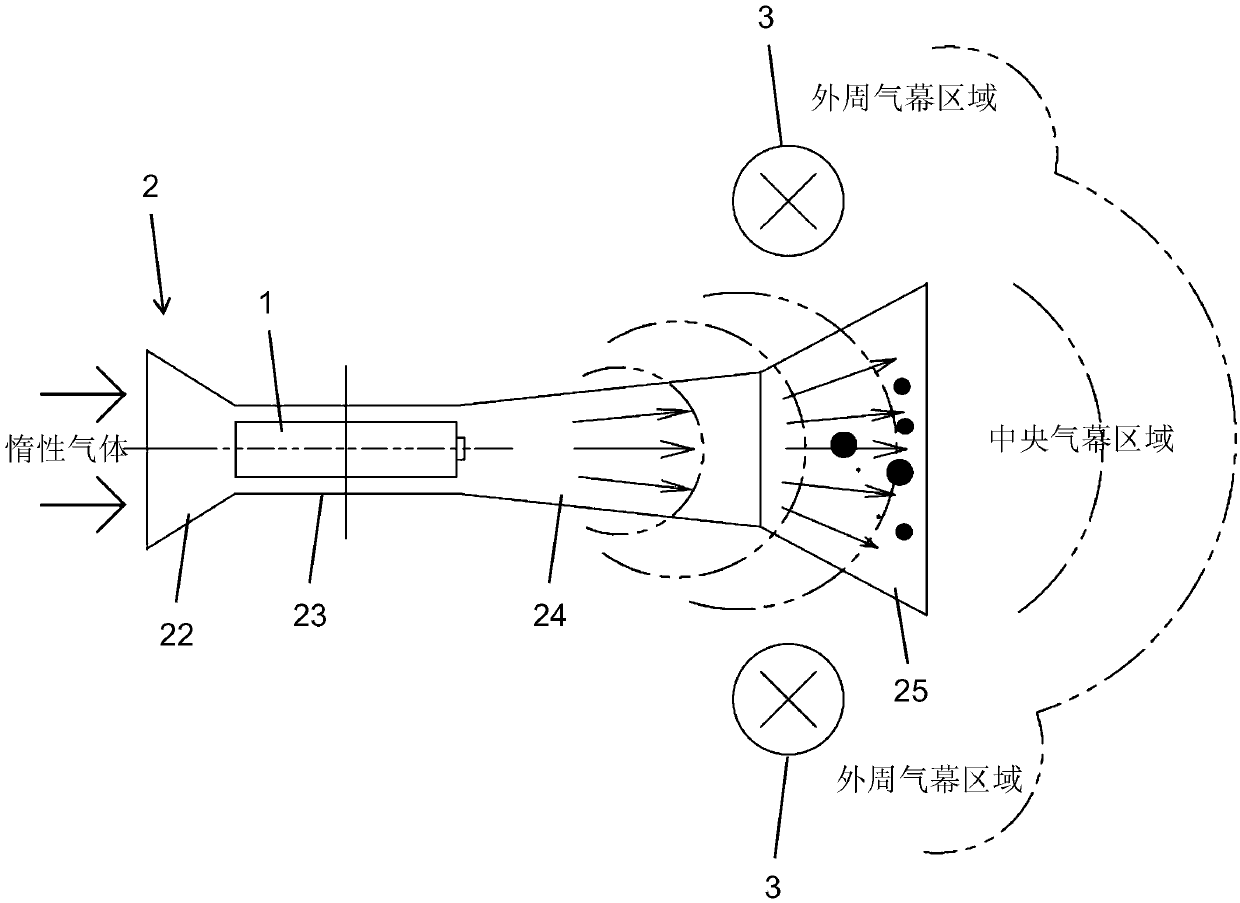

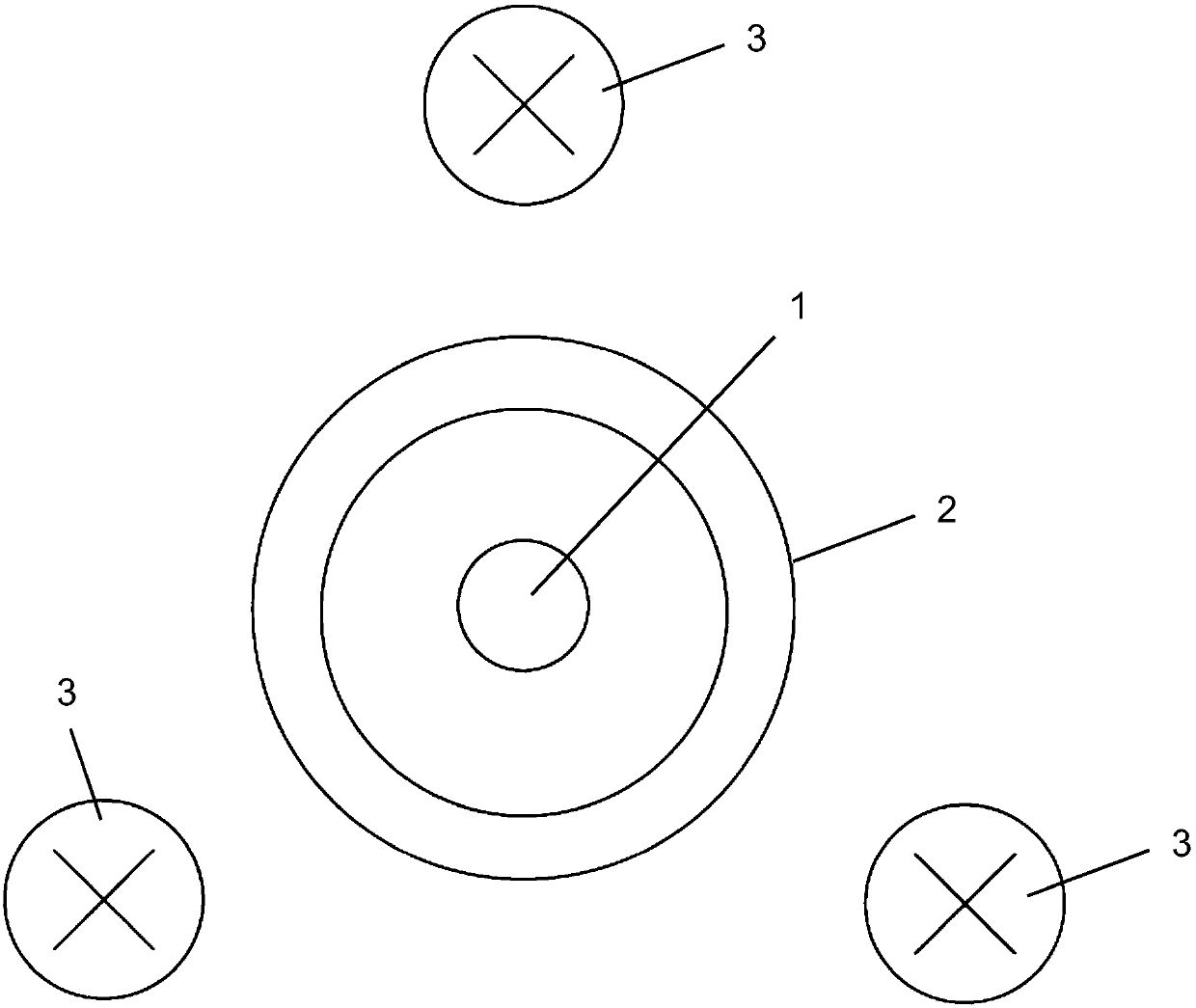

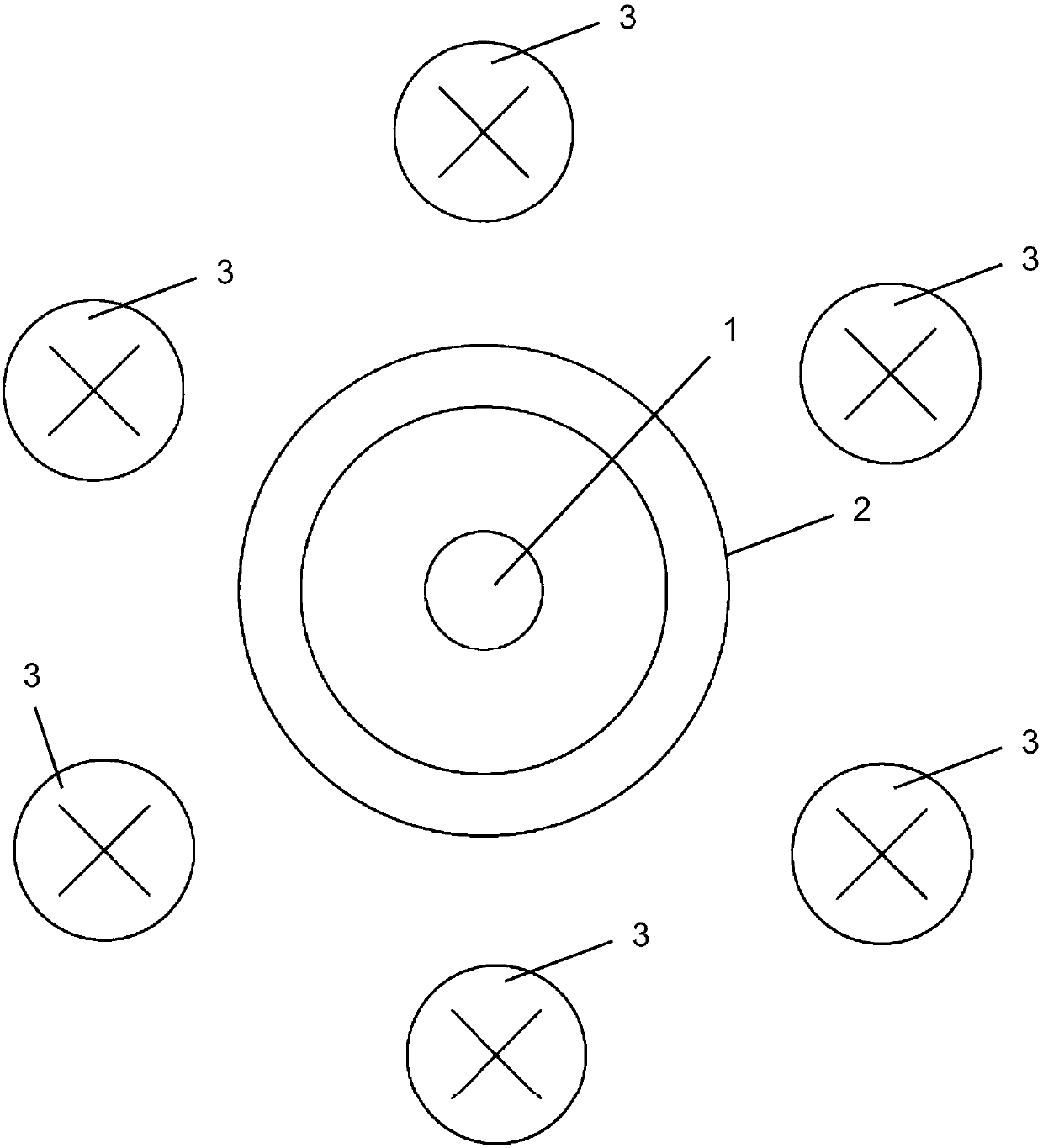

Air curtain system for improving imaging quality of intelligent slagging-off camera

InactiveCN110896434AImprove image qualityImprove cooling effectTelevision system detailsColor television detailsImaging qualityEngineering

The invention discloses an air curtain system for improving the imaging quality of an intelligent slagging-off camera. An airflow accelerating device is additionally arranged on the outer layer of anexisting camera, so that a layer of central air curtain area is formed, it is guaranteed that a formed air curtain can block most of dust, splashed molten iron and slag, and large impact fluctuation is not generated on the liquid level in a molten iron tank; besides, a plurality of industrial fans are arranged around the camera in an array mode, then a layer of peripheral air curtain area is formed, a complete air curtain wall is formed under the combined action of the peripheral air curtain area and the central air curtain area, the service life of the camera is prolonged while the camera isprotected, and the imaging quality of the camera is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Large industrial fan with fan blade floating dust cleaning function

PendingCN114542498AEasy to cleanRealize the cleaning functionPump componentsWind energy generationElectric machineStructural engineering

The invention relates to the technical field of fans, and discloses an industrial large fan with a fan blade floating dust cleaning function, the industrial large fan comprises a mounting column and a driving motor below the mounting column, a rotating shaft frame is mounted at the lower end of the driving motor, a mounting shaft is arranged at the lower end of the rotating shaft frame, and a connecting sleeve is mounted on the outer side of the mounting shaft; a fixing hole is formed in the lower surface of the mounting shaft, an inserting pin groove is formed in the outer side of the connecting sleeve, a flat fan blade is mounted in the inserting pin groove, and the flat fan blade and the inserting pin groove are fixed through an inserting flat pin. When the mounting shaft drives the flat fan blades to rotate, large centrifugal force can be generated to pull the sliding sleeve towards the outer side, the outer sides of the flat fan blades are swept while pulling is conducted, when rotation stops, the sliding sleeve is pulled back through the contraction spring, sweeping treatment can be conveniently conducted next time, through the structure, the sweeping function of the device can be achieved, and the sweeping efficiency is improved. The structure is simple to operate, and manual interference is not needed.

Owner:苏州郎昊工业科技有限公司

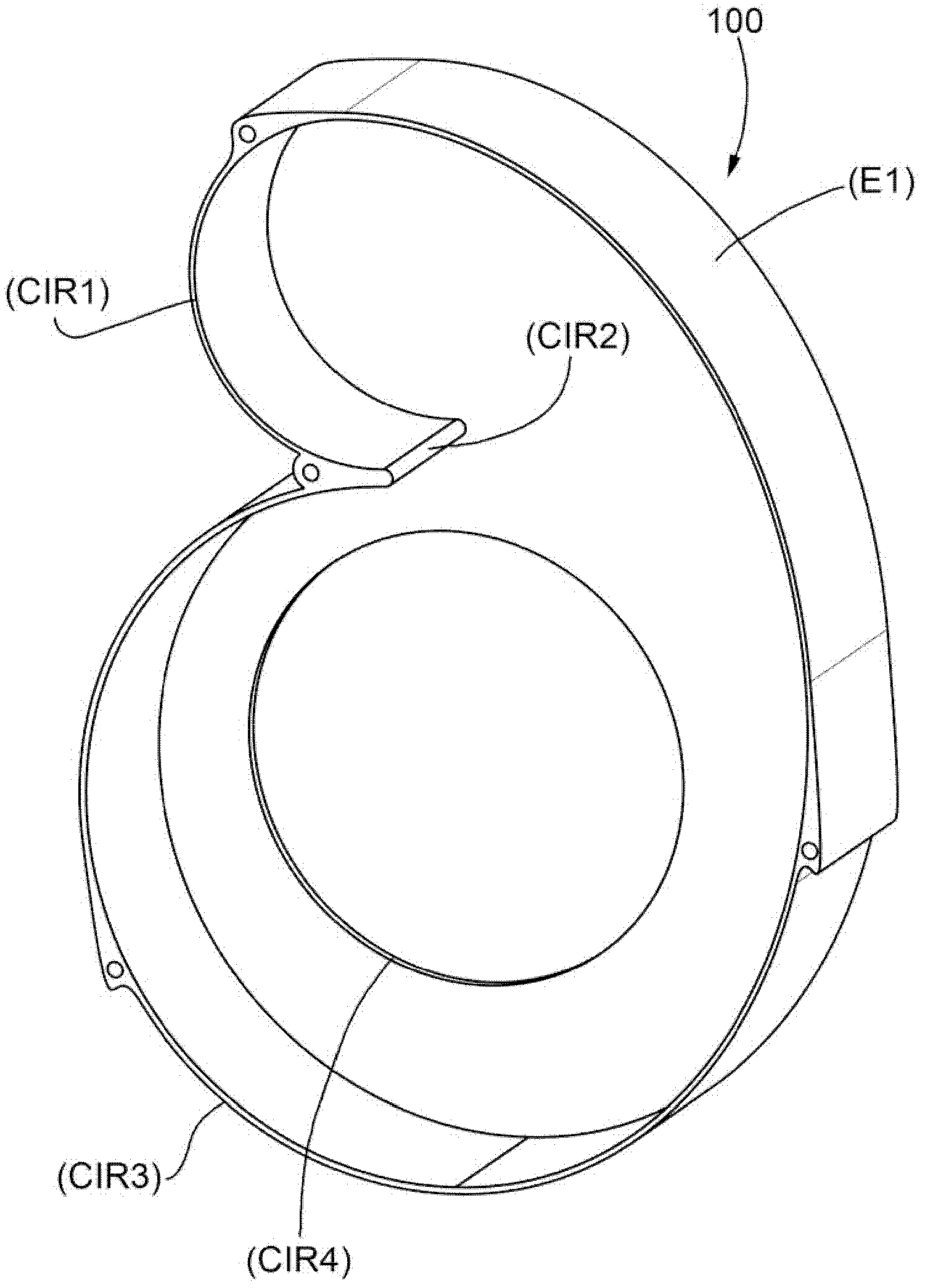

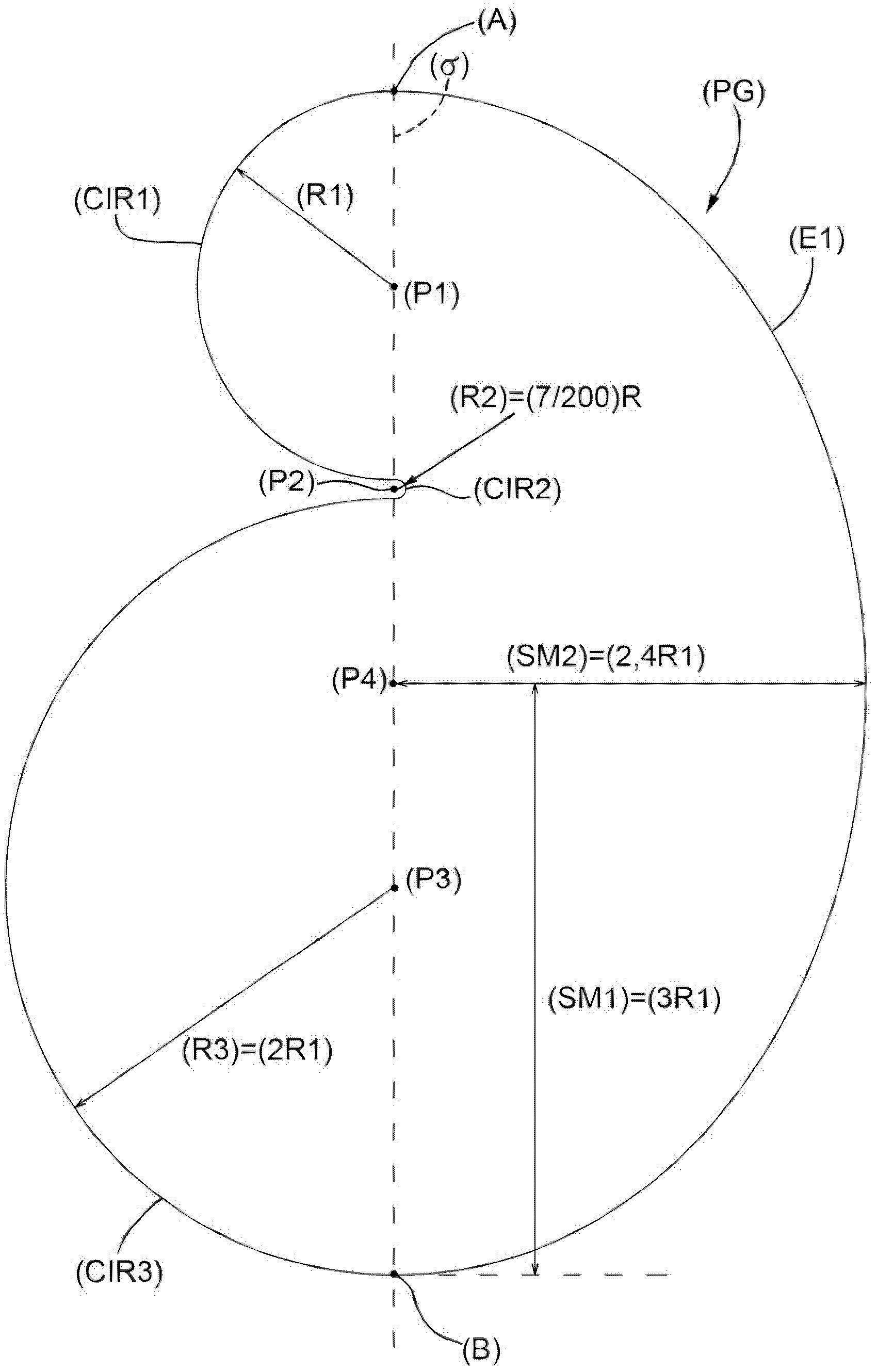

Industrial fan volute

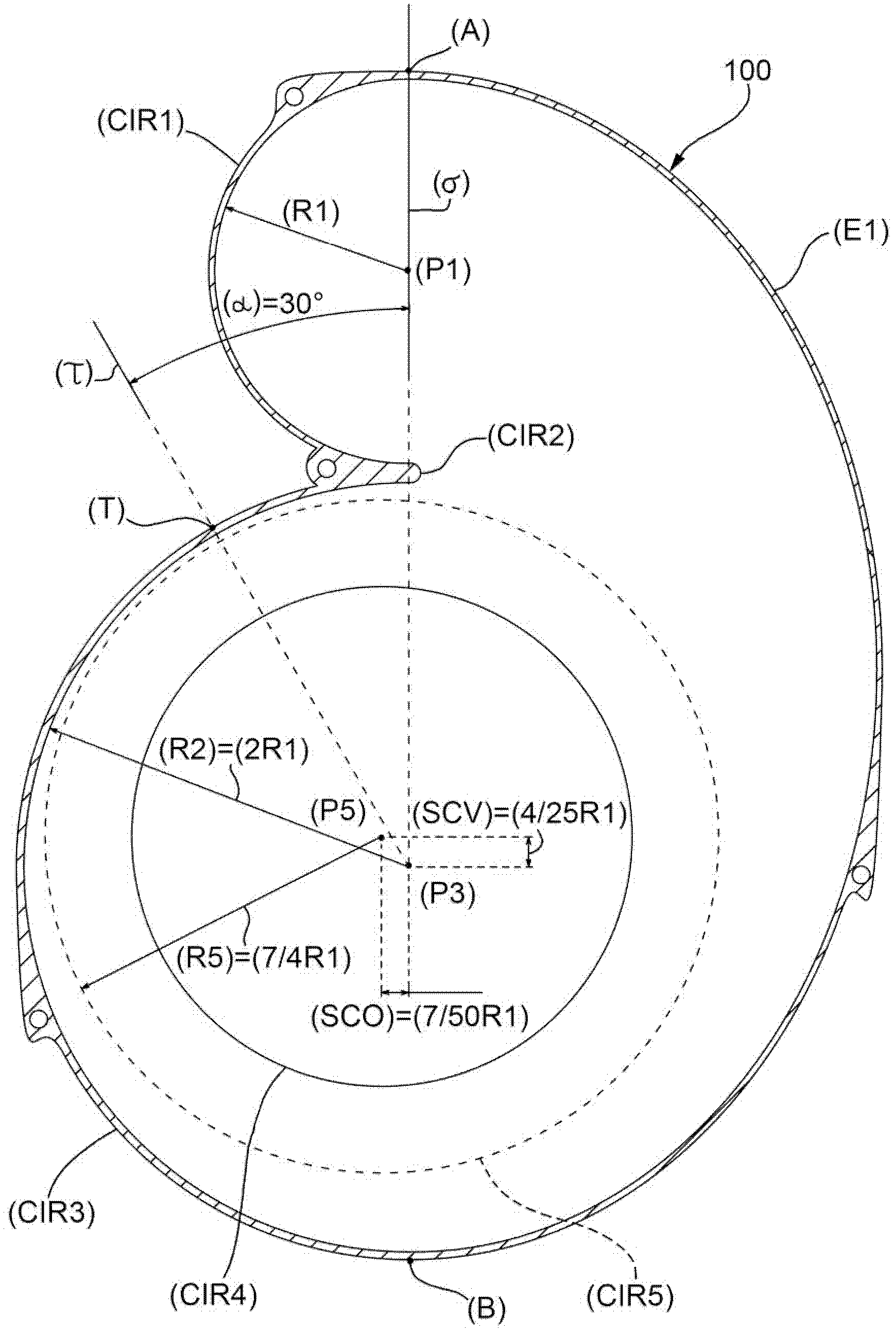

An industrial fan volute (100) is characterized in that the geometric outline (PG) of the industrial fan volute comprises a first semi-circle (CIR1) which is provided with a center of a circle (P1) and a radius (R1), a second semi-circle (CIR2) which is provided with a center of a circle (P2) and a radius (R2)=(7 / 200)(R1), a third semi-circle (CIR3) which is provided with a center of a circle (P3) and a radius (R3)=(2R1), and a semi-ellipse (E1) which is provided with a center (P4), an arc (AB), a main semi-axis (SM1)=(3R1) and an inferior semi-axis (SM2)=(2.4R1). The first semi-circle defines a round air outlet area, the second semi-circle defines an appearance of a 'cutwater' for parting airflow internally, and the third semi-circle defines a round area for confining the airflow in an impeller area.

Owner:RIELLO HEATING EQUIP SHANGHAI

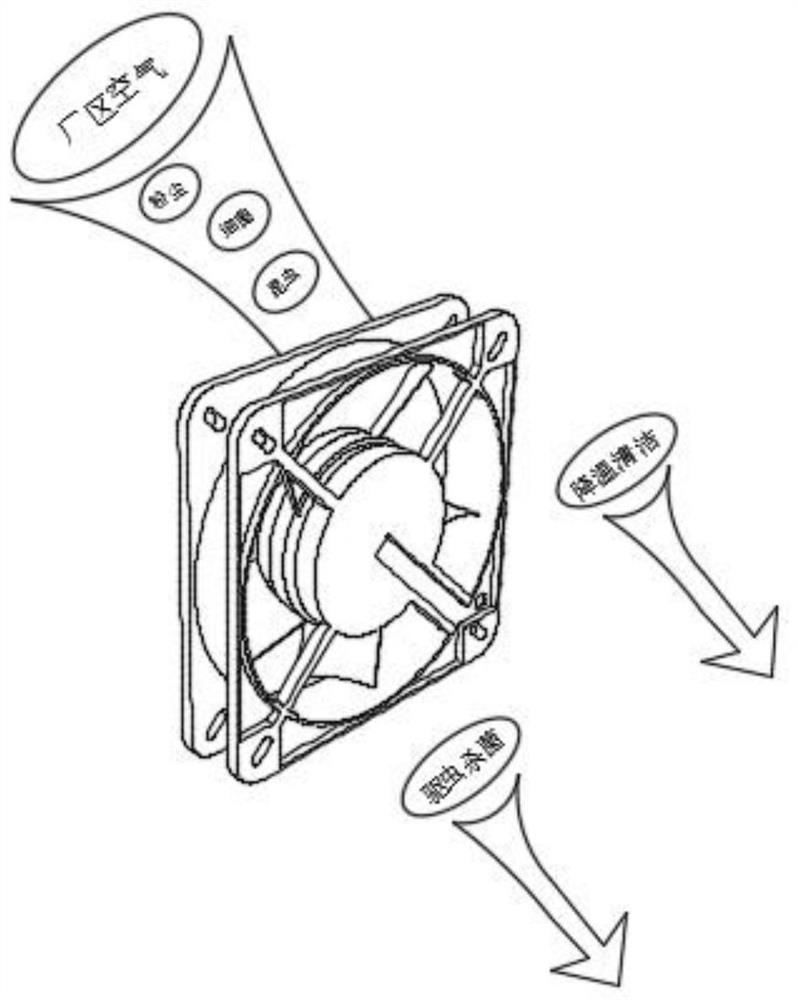

Auxiliary equipment for cooling and speed limiting during operation of industrial fan

InactiveCN113007112ATo achieve the purpose of coolingTo achieve the purpose of slowing down the movementPump componentsPump controlElectric machineryCentrifugal force

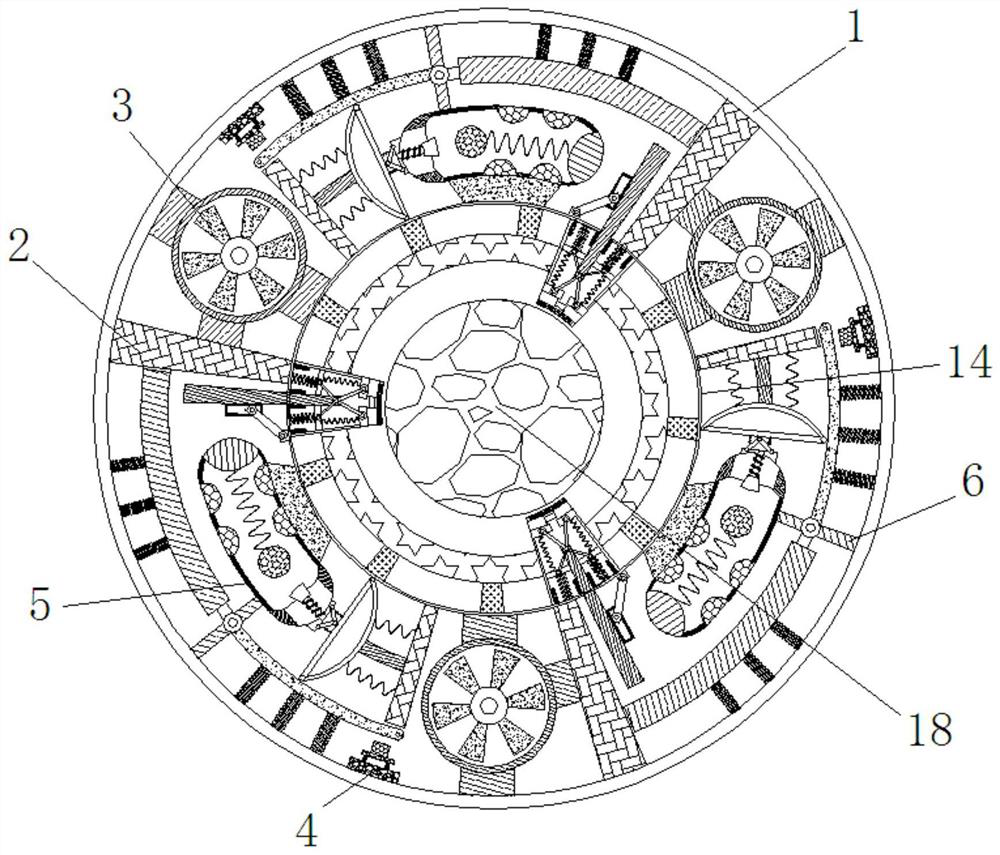

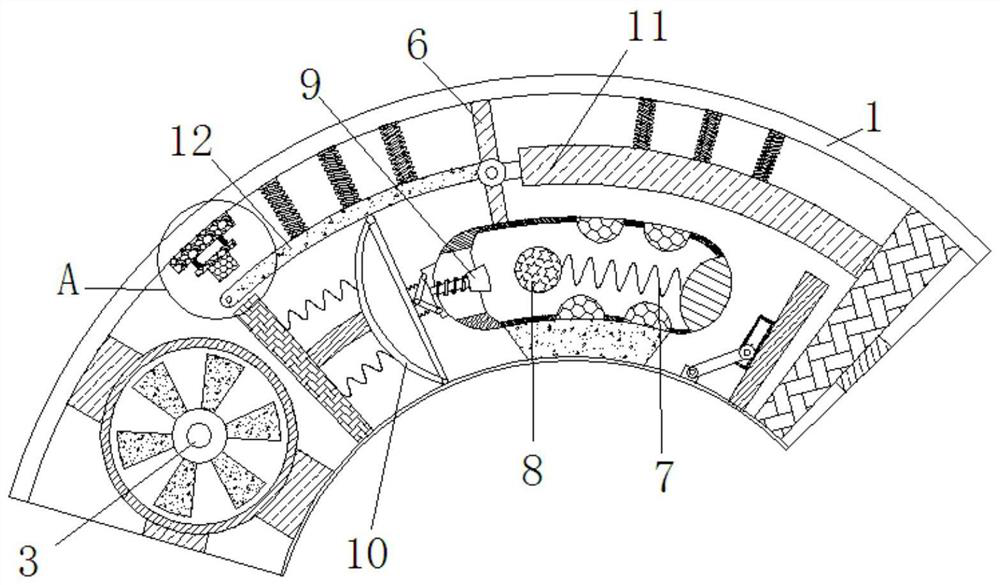

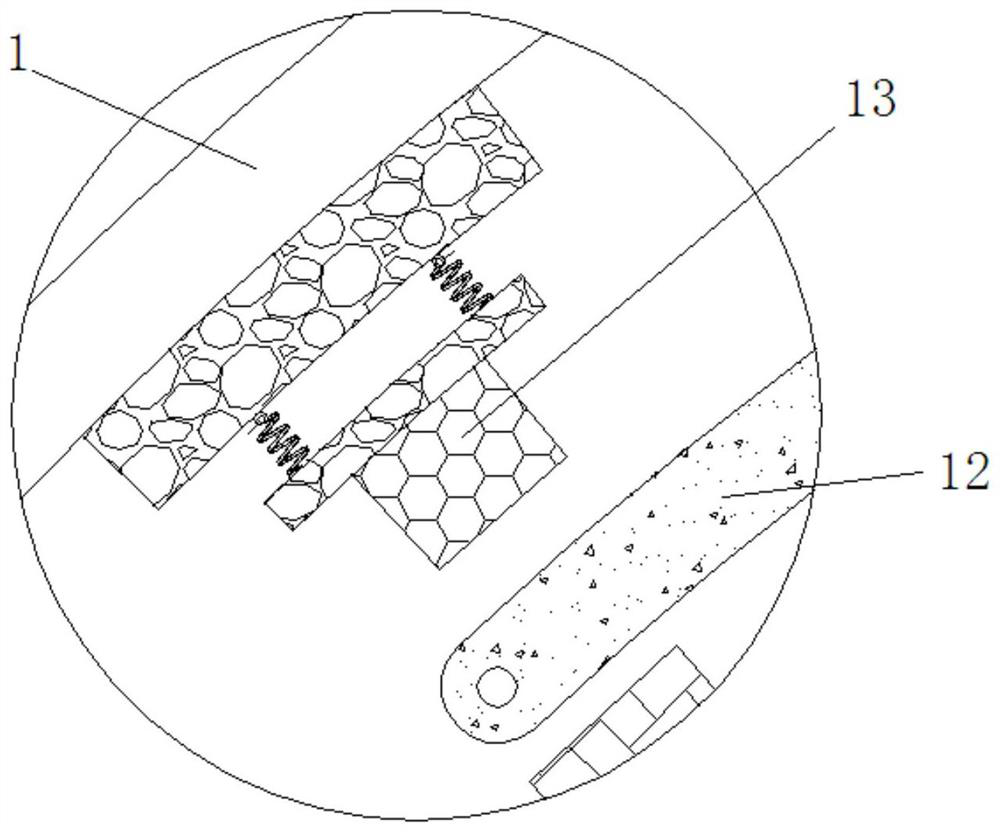

The invention relates to the technical field of industrial fans, and discloses auxiliary equipment for cooling and speed limiting during operation of an industrial fan. The auxiliary equipment comprises a shell, a supporting column is fixedly connected to the inner side of the shell, a fan is fixedly connected to the position, located on the outer side of the supporting column, of the inner side of the shell, and a fixing block and a fixing frame are fixedly connected to the inner side of the shell; the end, away from the shell, of the fixing frame is fixedly connected with a power frame, the inner side of the power frame is fixedly connected with an extension spring, the end, away from the power frame, of the extension spring is fixedly connected with a gravity ball, and the inner side of the power frame is movably connected with a telescopic rod. According to the auxiliary equipment, the fan operates to drive the shell 1 to move, when the speed is too high, due to the effect of centrifugal force, the gravity ball can extrude the telescopic rod, the telescopic rod drives an arc-shaped frame to expand outwards, the arc-shaped frame drives a starting rod to move, and then the starting rod, a control button and the fan are used in cooperation, the purpose of cooling the motor of the fan is achieved.

Owner:梁守旺

Novel self-cleaning type multifunctional industrial fan

PendingCN111980948AReduce breedingGuaranteed surface cleanlinessPump componentsPump controlDisinfectantSurface cleaning

The invention discloses a novel self-cleaning type multifunctional industrial fan, and belongs to the field of industrial fan equipment. According to the novel self-cleaning type multifunctional industrial fan, a timing motor controller controls a three-phase motor to enable fan blades to start to rotate, a balancing weight does centrifugal motion away from the timing motor controller under the action of centrifugal force, a cleaning brush head cleans dust on the surfaces of the fan blades, the surface cleanliness is maintained, and the possibility of bacterium breeding is reduced; under the stretching action of a second connecting block, a compression film shrinks, the inner diameter is reduced, and therefore a compression ball is extruded; an atomization spray head atomizes and sprays out disinfectant and clear water, the clear water can wet the dust to enable the dust to be prone to sedimentation, the atomized clear water is prone to vaporization and heat absorption for cooling, theevenly-spread disinfectant can sterilize and disinfect the space, and the healthy air environment is maintained; and the timing motor controller can control the three-phase motor to periodically andintermittently run, a side sliding block is pulled and dragged to reset along a side sliding groove under the elastic force action of an extension spring, and one-time periodic sterilization and cleaning are completed.

Owner:ANHUI JINWAN PUMP TECH CO LTD

Intelligent industrial fan adopting pipeline connection

InactiveCN113685364ASpeed up emissionsIncrease speedPump componentsPump controlElectric machineStructural engineering

The invention discloses an intelligent industrial fan adopting pipeline connection. The intelligent industrial fan comprises a mounting pipe and pipelines connected to the two sides of the mounting pipe, a filter screen is fixed to the inner wall of the mounting pipe, two bearing plates are fixed to the position, close to the filter screen, of the inner wall of the mounting pipe, and a rotating shaft is jointly and rotationally mounted on the axes of the two bearing plates; a through hole allowing the rotating shaft to penetrate through is formed in the outer wall of the filter screen, fan blades are fixed to the end, penetrating through the filter screen, of the rotating shaft, a circular truncated cone block is fixed to the portion, located between the two bearing plates, of the outer wall of the rotating shaft, a driving mechanism used for driving the circular truncated cone block to rotate is further installed on the inner wall of the mounting pipe, and the driving mechanism comprises a motor; and the motor is fixed on the inner wall of the mounting pipe. Through cooperation of the structures, the effect that the rotating speed of the fan blades is increased while the smoke concentration is increased is achieved, so that the smoke emission speed is increased, and then the effect of self-adaptive adjustment of the rotating speed of the fan blades is achieved.

Owner:苏凤均

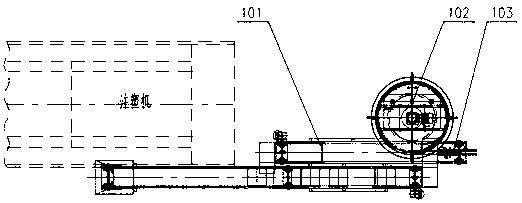

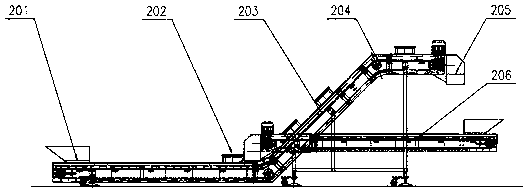

Rotary bottle blank arrangement system and bottle blank arrangement method

InactiveCN108284580AAvoid problems such as forced downtimeReduce occupancyDomestic articlesHollow articlesEngineeringFood packaging

The invention discloses a rotary bottle blank arrangement system, and belongs to the field of food packing machinery. The rotary bottle blank arrangement system comprises a bottle blank conveying part, a rotary arrangement part and an arrangement outlet part; the bottle blank conveying part comprises an inlet conveyor and a recovery conveyor; the rotary arrangement part consists of a high-speed rotating disc, a buffer edge bar, a bottle blank size adjusting device and a support mechanism; the bottle blank size adjusting device and the support mechanism are connected with the high-speed rotating disc and the buffer edge bar; the arrangement outlet part comprises a guide groove channel and a blank arrangement device; one end of the guide groove channel is tightly connected with the rotary arrangement part; and the other end of the guide groove channel is connected with the blank arrangement device. The rotary bottle blank arrangement system adopts an industrial fan for refrigeration, performs cooling during conveying to shorten the bottle blank cooling time, and uses a rotary centrifugal principle for arranging the rotating disc of bottle blanks to reduce equipment occupied field space; and the outlet guide groove channel is provided with the automatic blank arrangement device to greatly improve the whole blank supply continuity and stability.

Owner:广州市博仕机电工贸有限公司

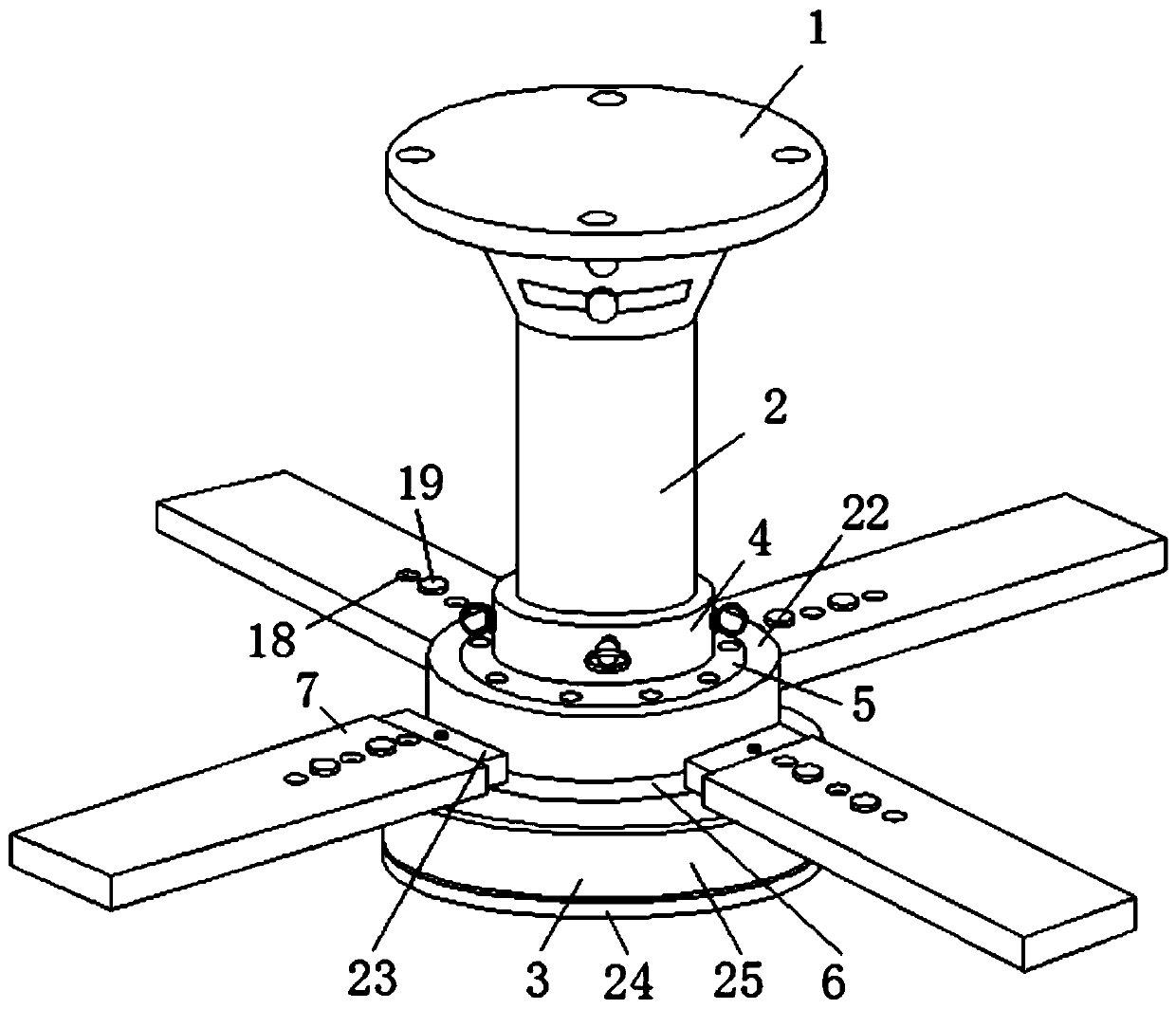

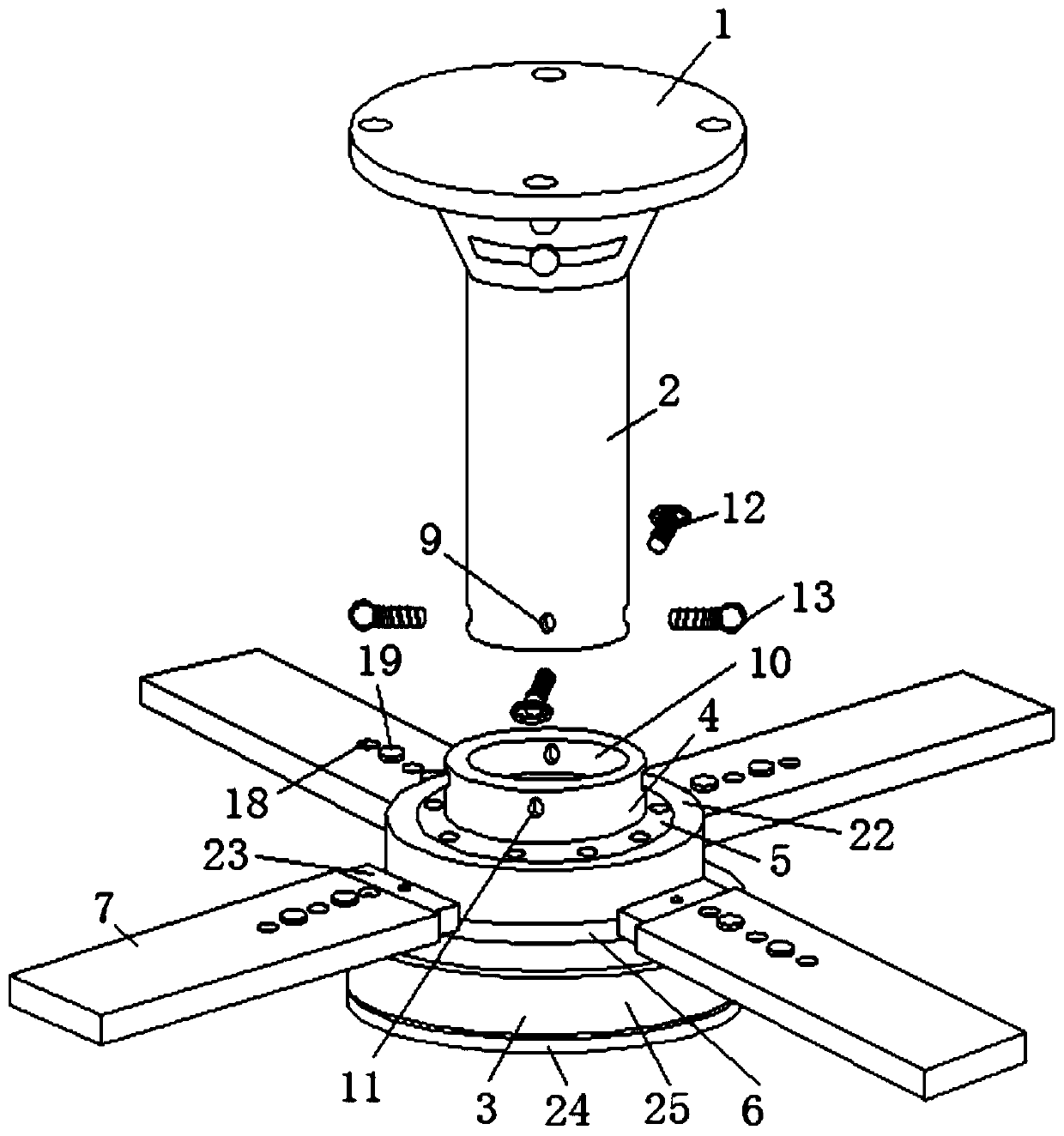

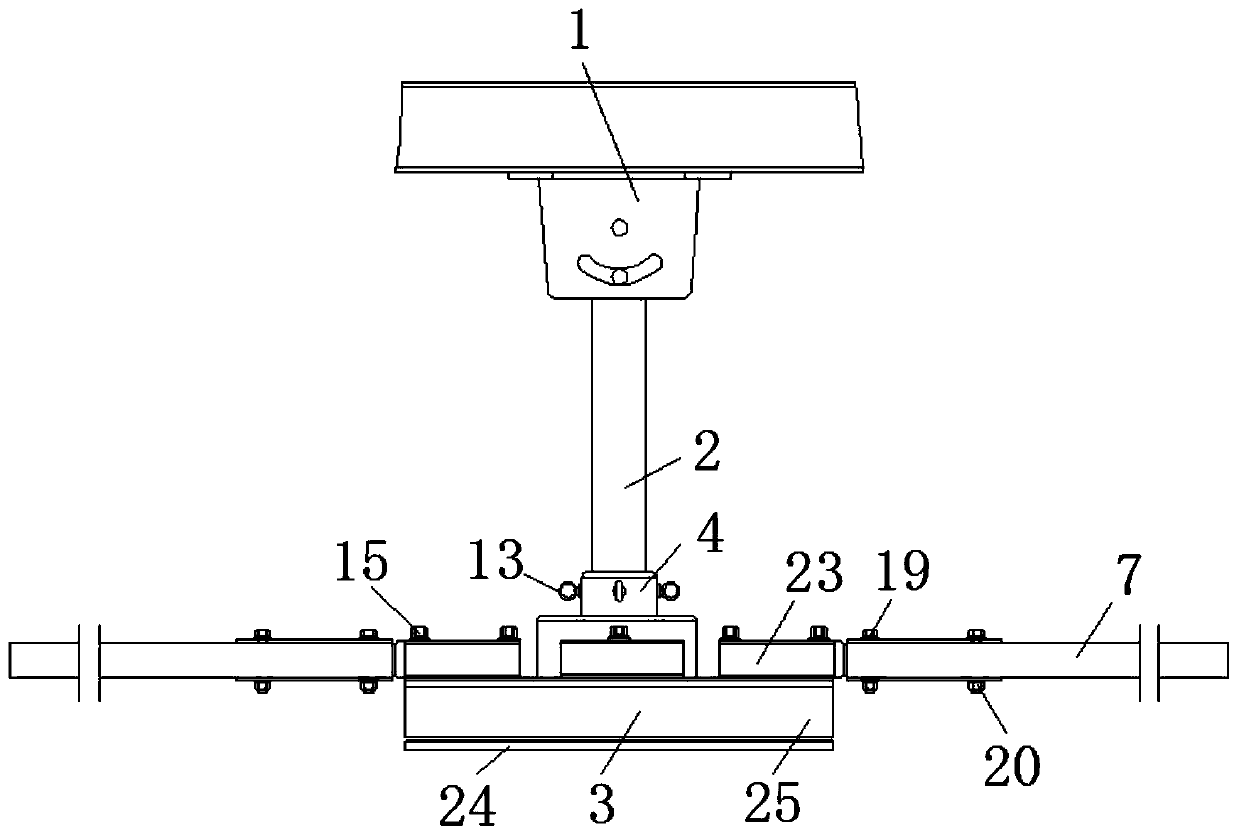

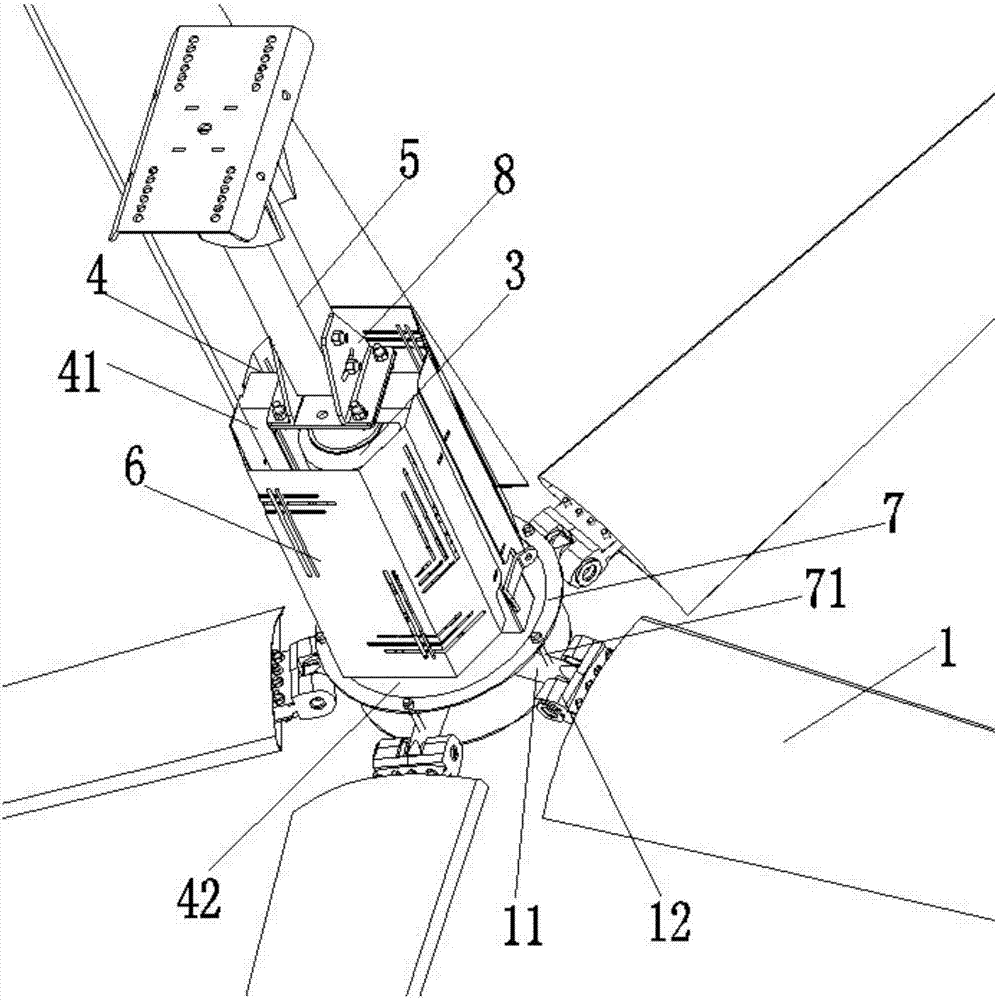

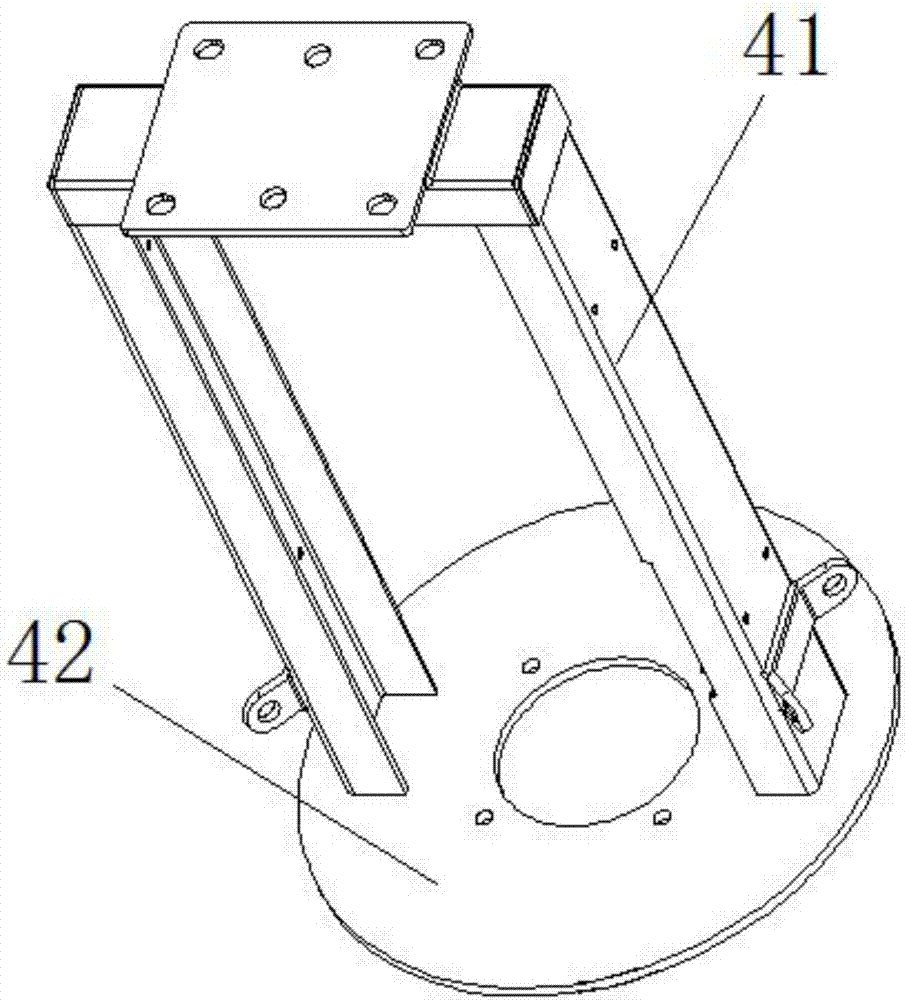

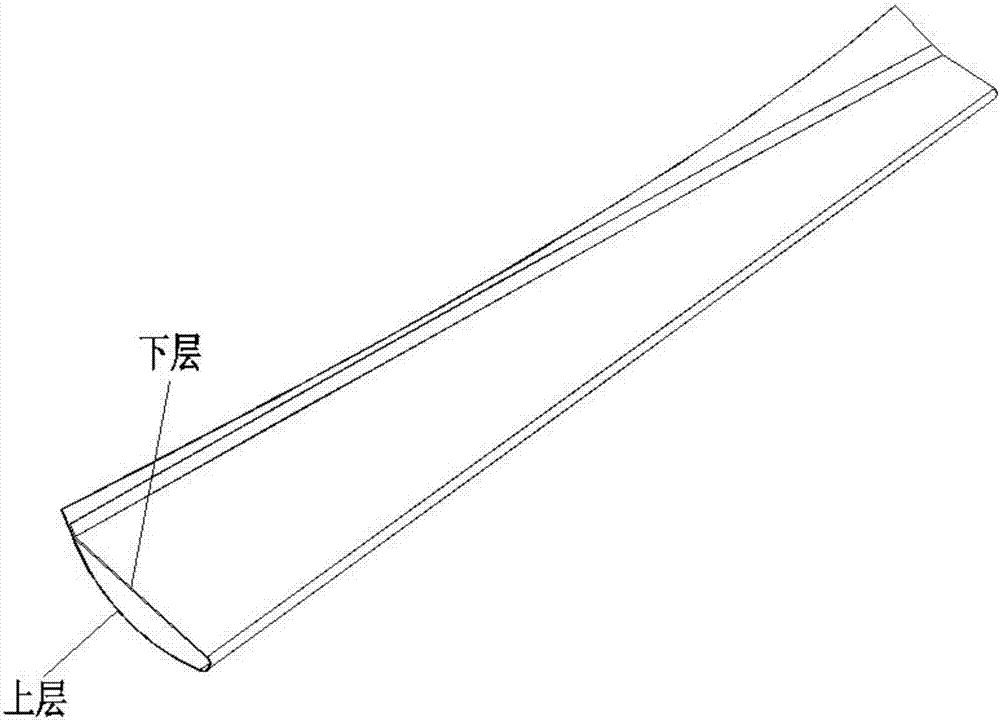

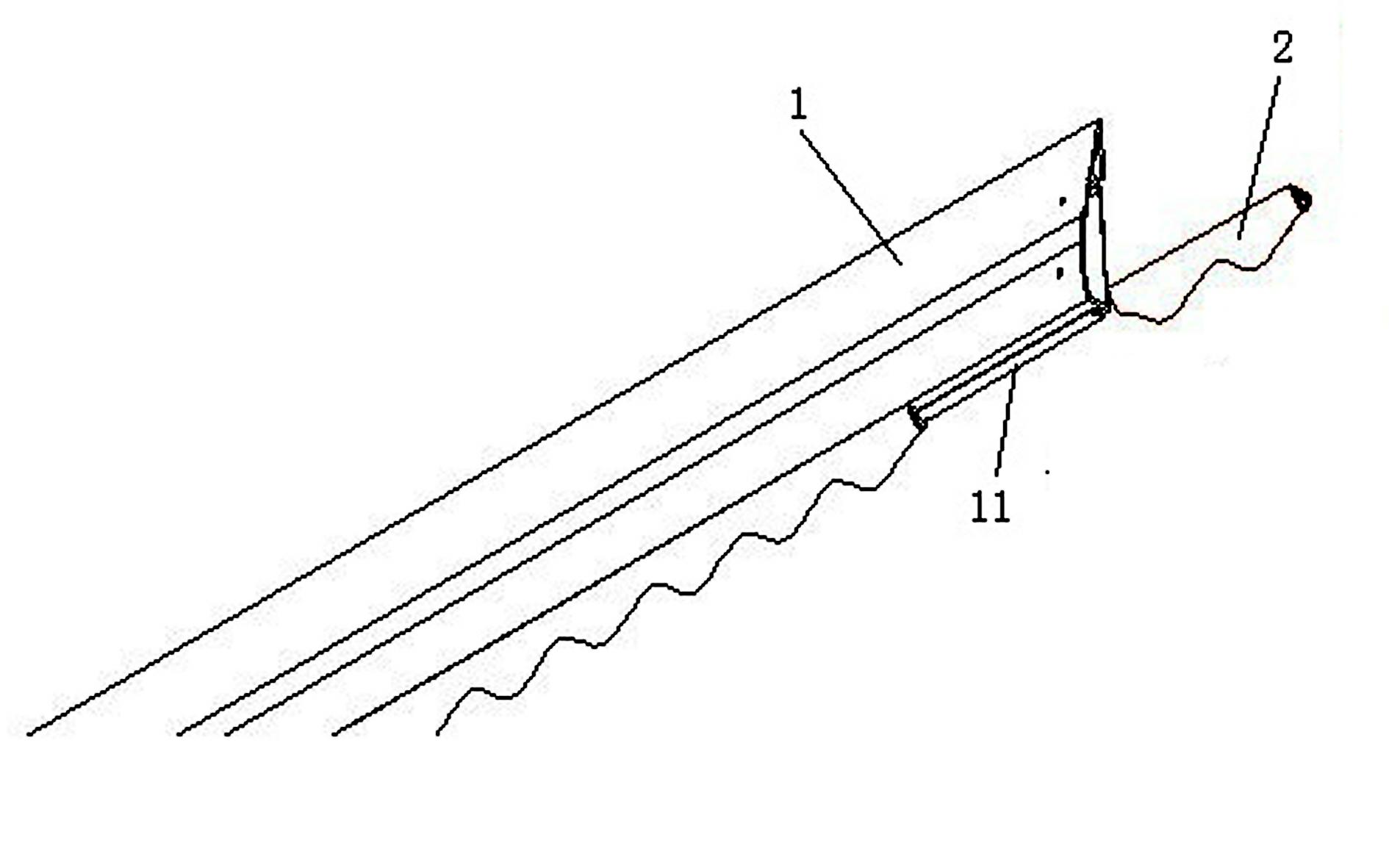

Industrial fan

PendingCN107228079AWide coverageUniform air volumePump componentsPump installationsLow noiseIndustrial fan

The invention relates to an industrial fan, comprising a plurality of fan blades, a wheel disc, a deceleration motor, a frame and a hanger rod. The fan blade includes upper and lower layers, which are formed by bending at one time, wherein there is a gap between the upper and lower layers. ; The fan blade and the stalk are connected by a connecting piece; the connecting piece is formed with two concentric bushings, left and right, which are arranged at intervals, and a special-shaped piece is embedded in the two bushings, and a special-shaped piece is embedded on the special-shaped piece. The vibration isolation rubber sleeve is sleeved, so that the outer wall of the special-shaped part and the inner wall of the shaft sleeve are separated by the vibration isolation rubber sleeve; the leaf stalk is inserted between the two concentric shaft sleeves, and is connected with the connecting parts; the flange plate under the frame An anti-falling ring is hung on the upper sleeve; the inner diameter of the anti-falling ring is smaller than the outer diameter of the flange, and the outer diameter is larger than the outer diameter of the flange; the anti-falling circle is connected with the fan blade shank. The invention has wide wind coverage, low energy efficiency, long service life and low working noise, and can effectively prevent the fan blades from falling.

Owner:江苏大王通风机械有限公司

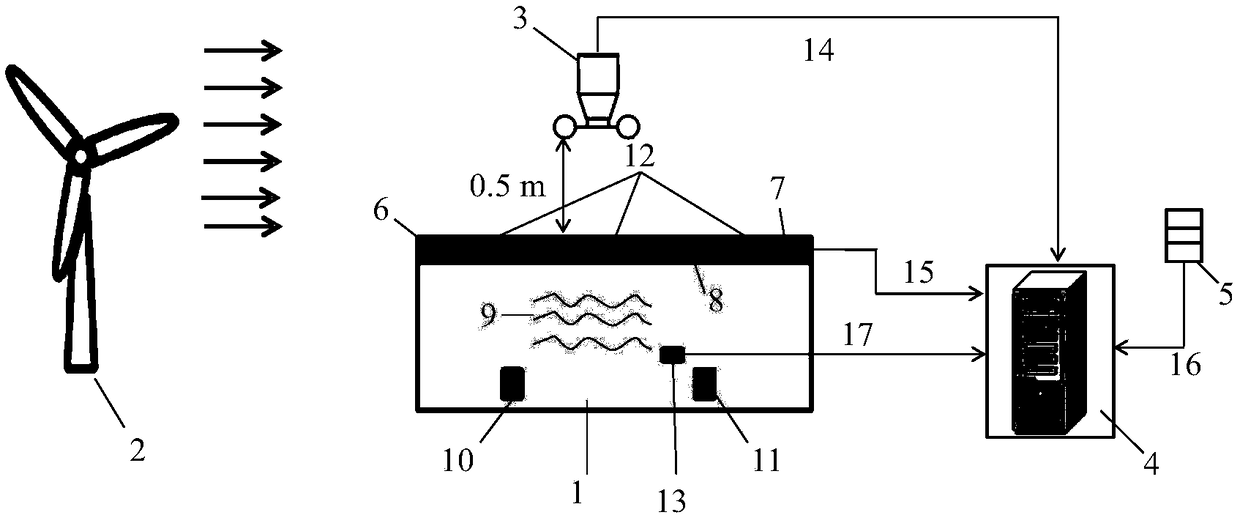

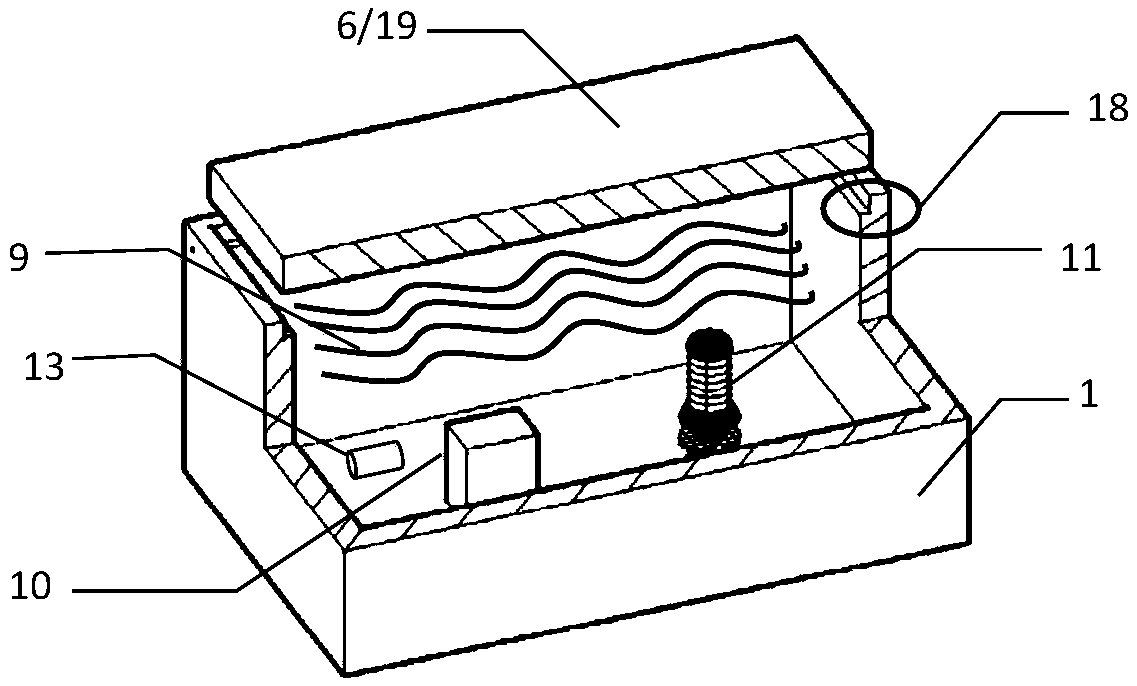

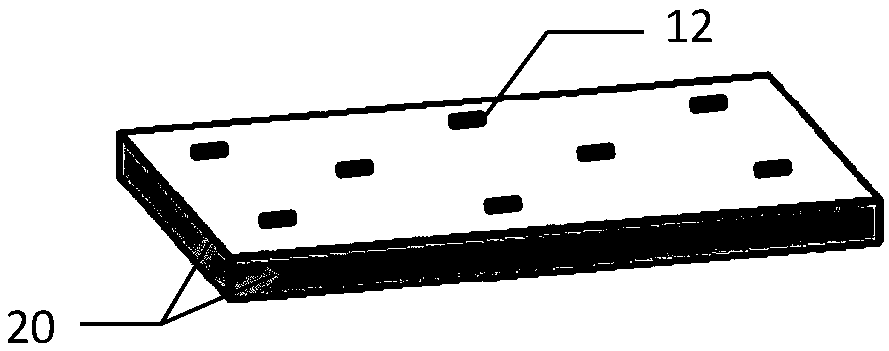

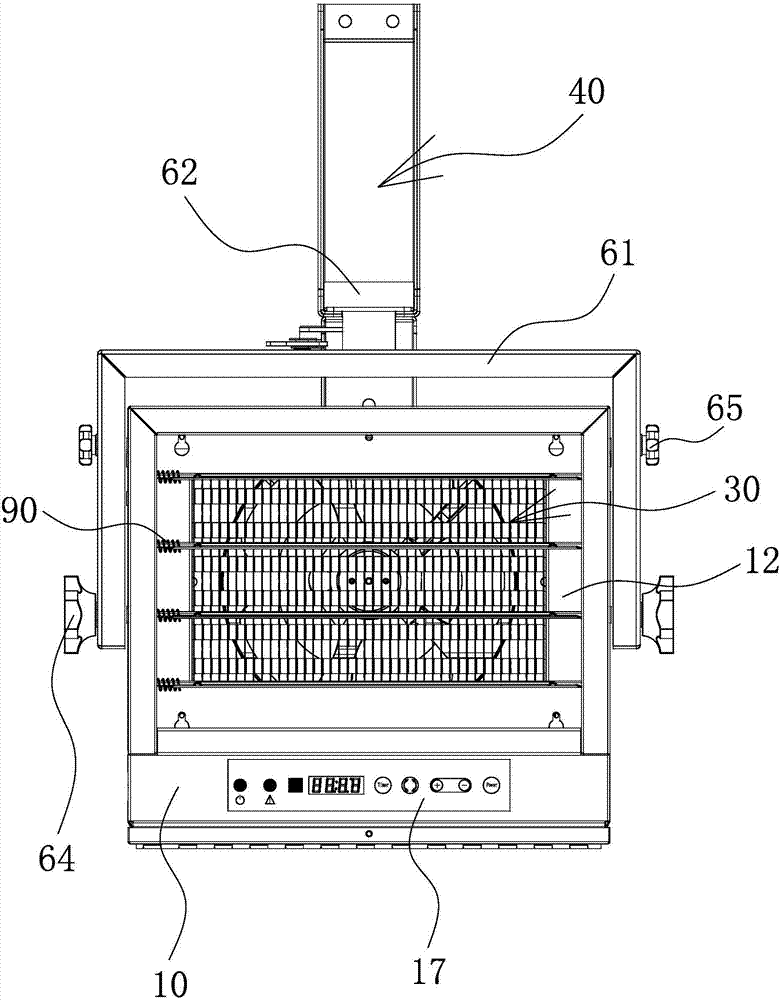

Measurement system and method for building material surface convective heat exchange coefficient

InactiveCN108776152AReduce testing costsGood repeatabilityMaterial heat developmentThermal insulationEngineering

The invention discloses a measurement system for a building material surface convective heat exchange coefficient. The measurement system consists of a thermal insulation box, industrial fan, an anemometer, a small automatic weather station, thermocouple temperature sensors, an air temperature sensor, a water temperature sensor and a building material test piece. Thermal insulation box and the building material test piece compose an enclosed box; the water temperature sensor is disposed in the thermal insulation box; the thermocouple temperature sensors are disposed on the surface of the building material test piece; the air temperature sensor is arranged in an external environment; and the thermocouple temperature sensors, the air temperature sensor, the water temperature sensor and the anemometer are all connected to the small automatic weather station for real-time acquisition and storage of test data. Based on the theory of heat transfer, the measurement system and method providedby the invention can achieve efficient, simple and accurate measurement of the convective heat exchange coefficient between a building material and the external environment, also take the heat absorption and heat release processes into account, can better simulate the thermal behavior of an actual engineering structural material in a service environment, and have good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Industrial fan heater

PendingCN107192129AUniform divergenceReasonable structureAir heatersElectricityBiochemical engineering

The invention provides an industrial fan heater, and belongs to the technical field of machinery. The industrial fan heater solves the problem that an existing industrial fan heater is not ideal in use effect. The industrial fan heater comprises a support, a machine body, a heating body, a fan and a controller, wherein the machine body is movably connected to the support can rotate around the axis lead of the machine body, an air inlet and an air outlet are formed in the machine body, the heating body is arranged in the machine body and is arranged close to the air outlet; the fan is arranged in the machine body, is arranged close to the air inlet and can suck air into the machine body and convey the air outwards towards the air outlet, the controller is arranged at the bottom of the machine body, and the heating body and the fan are electrically connected to the controller. The industrial fan heater has the advantage of being simple in structure.

Owner:红杉树电器有限公司

High-efficiency refrigeration industrial fan

ActiveCN111895560APlay an initial cooling roleAchieve recyclingPump componentsLighting and heating apparatusCooling effectEngineering

The invention discloses a high-efficiency refrigeration industrial fan, and belongs to the field of fan equipment. The fan comprises a machine body, a sterilization mechanism is fixedly installed inside the machine body, a partition plate is fixedly connected to the middle end inside the machine body, an evaporator and a condenser are fixedly installed on the left side and the right side of the top of the partition plate correspondingly, a bearing seat is fixedly connected to the bottom inside the machine body, an exhaust fan is fixedly installed on the top of the bearing seat, the left side and the right side of the exhaust fan are provided with exhaust ports correspondingly, air inlets are formed in the left side and the right side of the machine body correspondingly, upper fixing seatsare fixedly connected to the left side and the right side inside the machine body and located at the upper ends of the air inlets, lower fixing seats are fixedly connected to the left side and the right side inside the machine body and located at the lower ends of the air inlets, and corresponding positions of the bottoms of the upper fixing seats and the tops of the lower fixing seats are provided with installation grooves. Air is extracted by the exhaust fan through the air inlets, and the air firstly passes through a cooling water curtain when entering the machine body. The cooling water curtain has an initial cooling effect on the air.

Owner:江苏凯华冷能技术有限公司

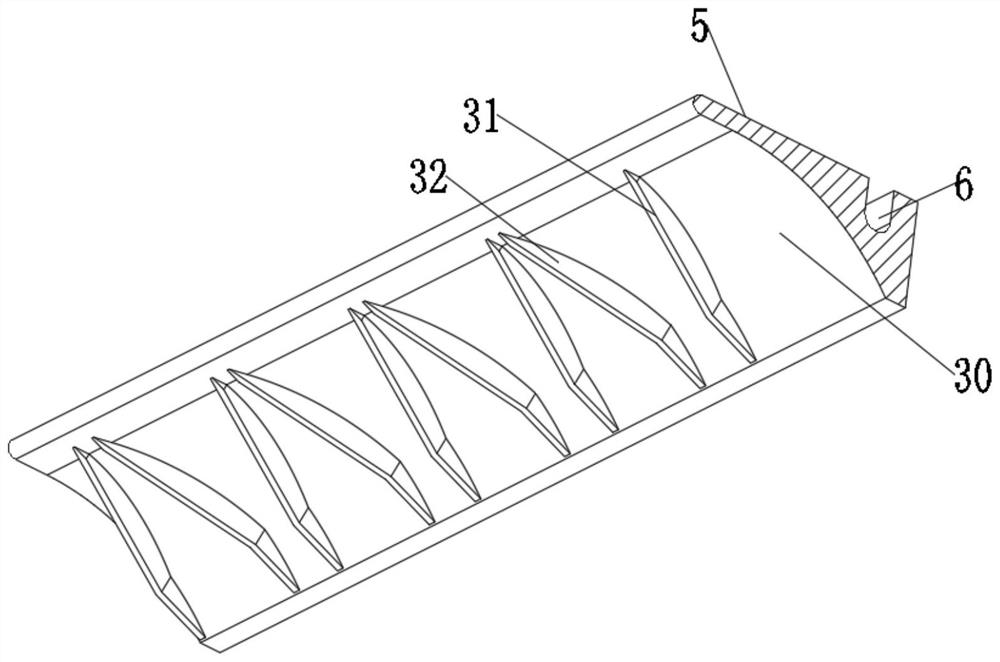

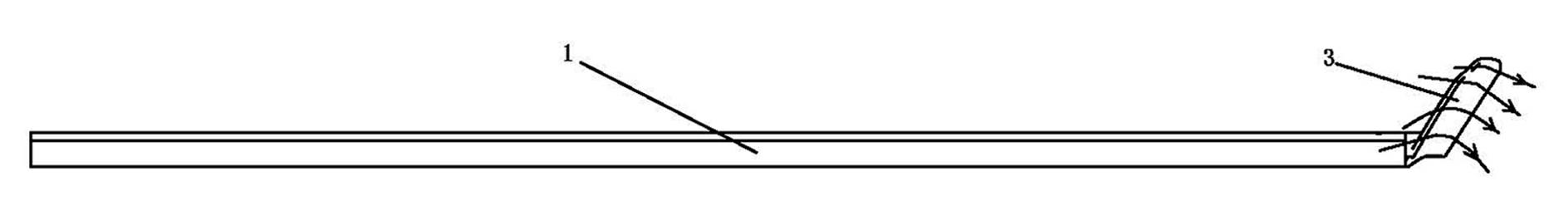

Fan blade for industrial fan

InactiveCN102661290AReduce resistanceImprove fan efficiencyPump componentsPumpsBusiness efficiencyFan blade

The invention discloses a fan blade for an industrial fan. The fan blade comprises a fan blade body, wherein a gas guide plate is arranged on one side of the fan blade body; a plurality of sawtoothed bulges which are distributed along the length direction of the gas guide plate are formed on the gas guide plate; and a sawtoothed recess is formed between every two adjacent sawtoothed bulges. By the fan blade for the industrial fan, the gas flow noise during operation of the industrial fan can be reduced, and the energy efficiency ratio of the industrial fan is improved.

Owner:苏州欧比特机械有限公司 +1

Liftable industrial fan convenient to clean

InactiveCN108167235AImprove personal safetyReduce speedPump componentsPump controlEngineeringMicrocomputer control

The invention discloses a liftable industrial fan convenient to clean. A control box is internally provided with a control element and then externally provided with a temperature sensor, and the temperature inside a factory is detected through the temperature sensor. When the indoor temperature is excessively high and larger than the preset highest temperature value, and an MCU single chip microcomputer controls a servo motor to increase the rotation speed, so that the heat dissipation effect of the industrial fan is enhanced; when the indoor temperature is lower than the set lowest temperature value, the MCU single chip microcomputer controls the servo motor to lower the rotation speed, so that the wind speed of the industrial fan is reduced; the top end of the control box is then provided with an electric push rod, when the industrial fan requires to be cleaned, a switch of the electric push rod is turned on, a push rod body of the electric push rod is elongated to drive the fan to move downwards, workers can clean the fan on the ground, and the personal safety of the workers can be improved; and the control box is then internally provided with filtering cotton, dust on the periphery of the fan can be adsorbed through the filtering cotton, and dust can be prevented from entering the control box.

Owner:江苏丹特斯科技有限公司

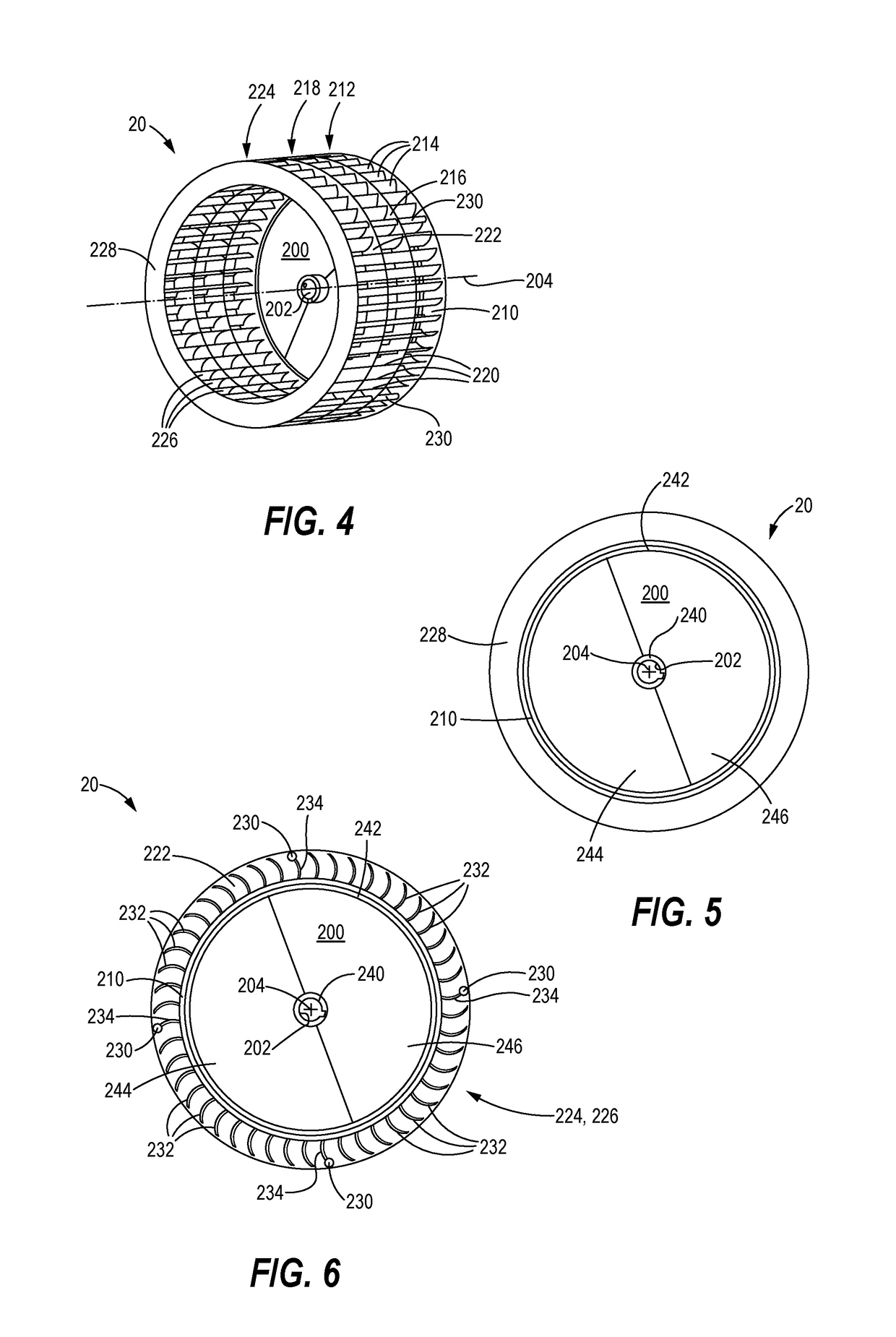

Radial Blade Impeller for an Industrial Fan Assembly

A radial blade impeller for an industrial fan assembly may include a cylindrical impeller hub having a hub outer surface and a hub shaft bore, a plurality of impeller blade assemblies circumferentially spaced about the hub outer surface and extending outward from the hub outer surface. A first sprocket disposed on a first end of the impeller hub engages a lateral edge of each of the impeller blade assemblies and has a plurality of first sprocket teeth extending outward from a first sprocket outer edge. Each of the first sprocket teeth corresponds to one of the impeller blade assemblies and engages and is secured to the first lateral edge of the corresponding one of the impeller blade assemblies. A second sprocket disposed on a second end of the impeller hub has a similar configuration with second sprocket teeth aligning with and engaging opposite lateral edges of the impeller blade assemblies.

Owner:DEKALB BLOWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com