Industrial fan and blade rotation method thereof

A blade and fan technology, applied in the field of industrial fan and blade rotation, can solve problems such as unfavorable production cost, high manufacturing cost and maintenance cost, complex structure, etc., and achieve the effect of reducing maintenance cost, reducing manufacturing cost and simplifying fan structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

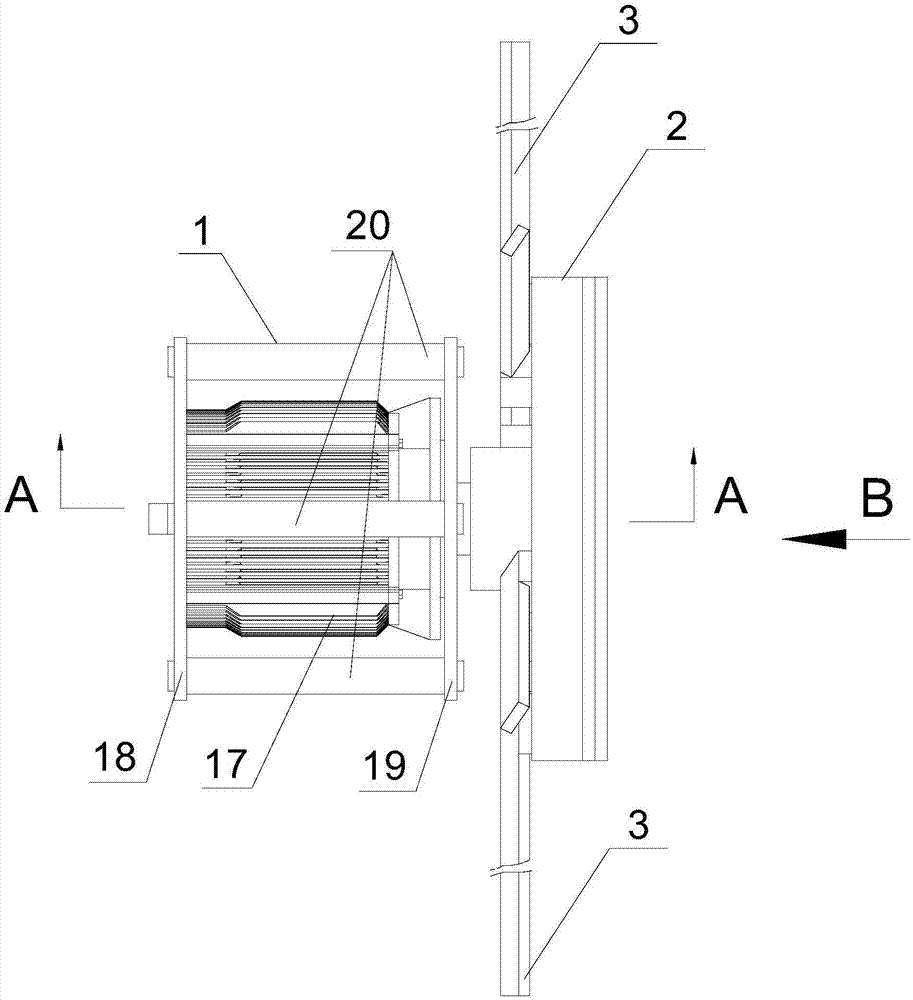

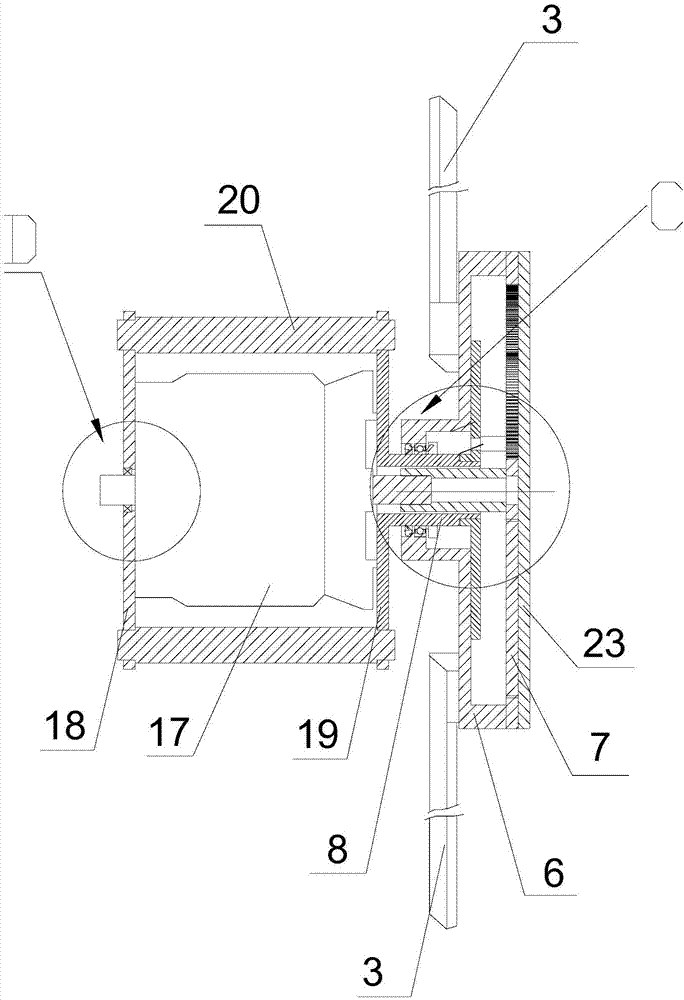

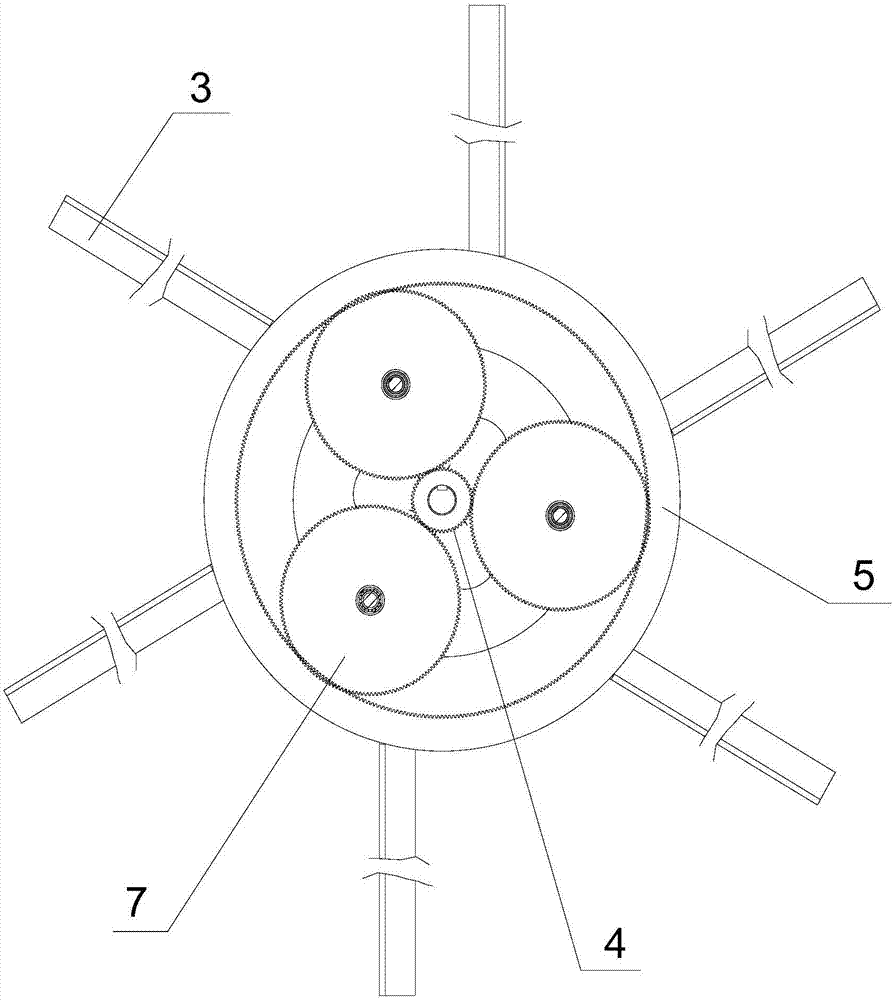

[0028] An industrial fan in this embodiment, such as figure 1 As shown, it includes a motor drive mechanism 1, a blade rotation mechanism 2 and a plurality of blades 3, the motor drive mechanism is connected to the blade rotation mechanism, and a plurality of blades are distributed on the blade rotation mechanism; as figure 2 or image 3 As shown, the blade rotation mechanism includes an input shaft gear 4, a planetary gear set, an internal gear 5, and a rotating disk 6. The output end of the motor drive mechanism is connected to the input shaft gear, and the input shaft gear is arranged at the center of the planetary gear set. The planetary gear set includes A plurality of planetary gears 7 (three planetary gears are used in this embodiment, and the number of planetary gears can be set according to the actual size of the industrial fan), each planetary gear meshes with the input shaft gear respectively, and the internal gear is arranged on the outer periphery of the planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com