Fan for cooling tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

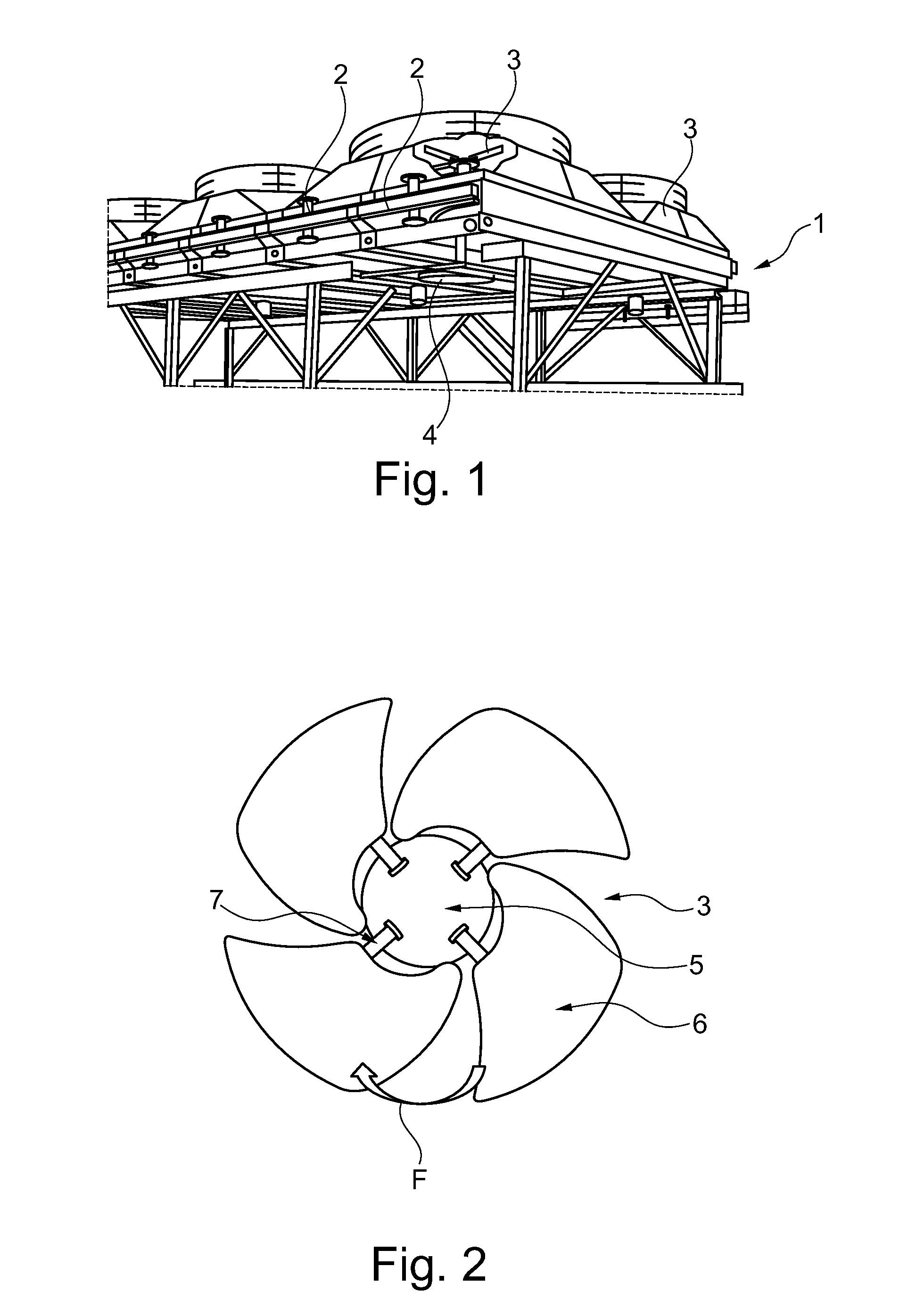

[0035]In FIG. 1, it is illustrated an example of a cooling tower used in oil, gas and chemical industries. In this Figure, an air heat exchanger 1 condenses and cools liquids circulating in finned tube bundles 2. The finned tube bundles 2 are installed on a structure and they are blown by at least one fan 3 actuated by electric motors 4.

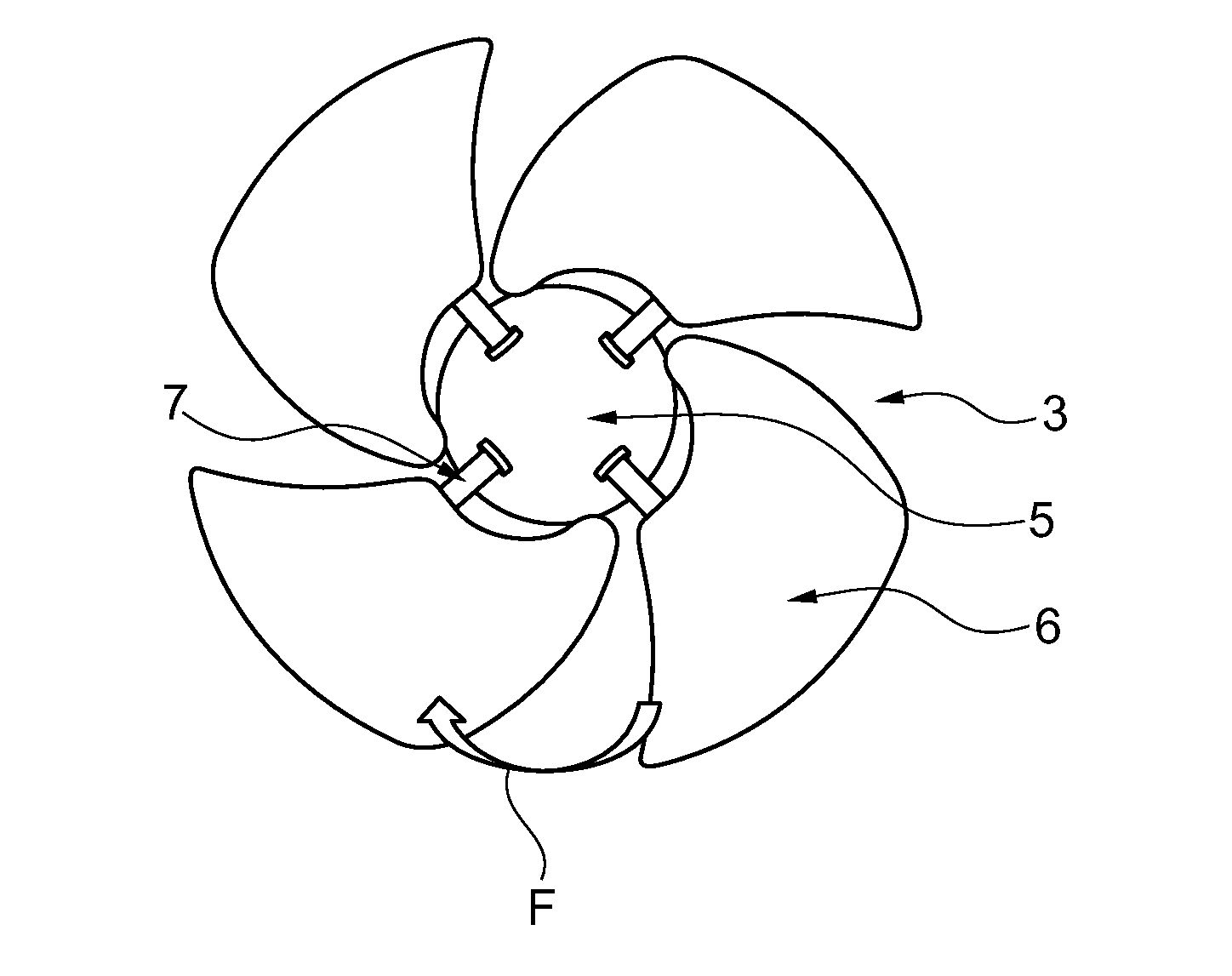

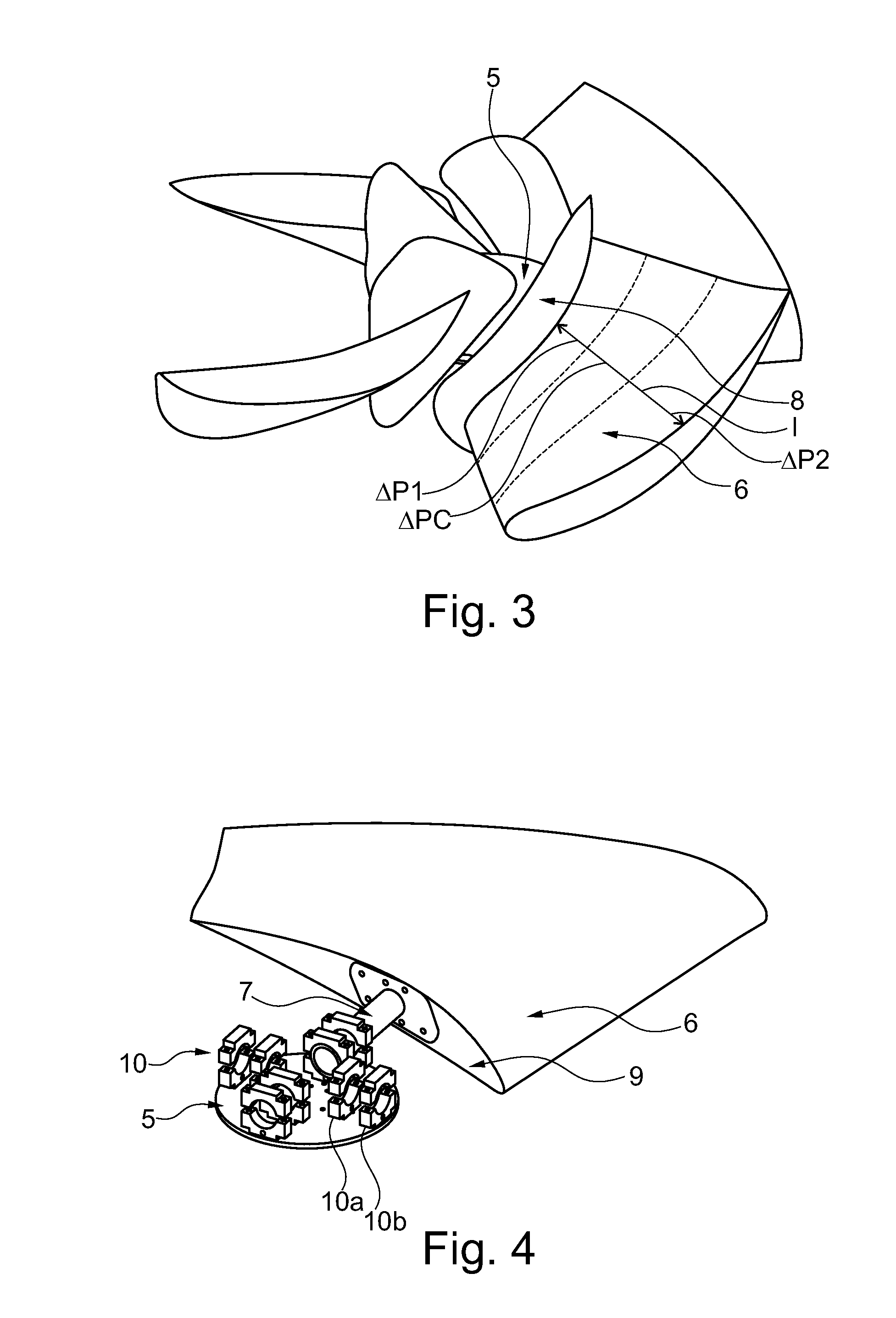

[0036]FIG. 2 illustrates an industrial fan 3 for a cooling tower according to the prior art. This fan 3 includes a disc-shaped hub 5 and a plurality of blades 6 radially connected to the hub disc 5 by means of a stud 7 provided on one end of each blade 6 and a flange (not shown) provided on one side of the hub disc 5 and into which the stud 7 of the blade 6 is inserted with a blade angle for generating an axial air flow.

[0037]The arrow F indicates the direction of rotation of the blades 6.

[0038]The blades 6 have a curvature at the leading and trailing edges, particularly the leading edges have a sweep forward angle of the front ends of the blades rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com