Patents

Literature

84 results about "Forward angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

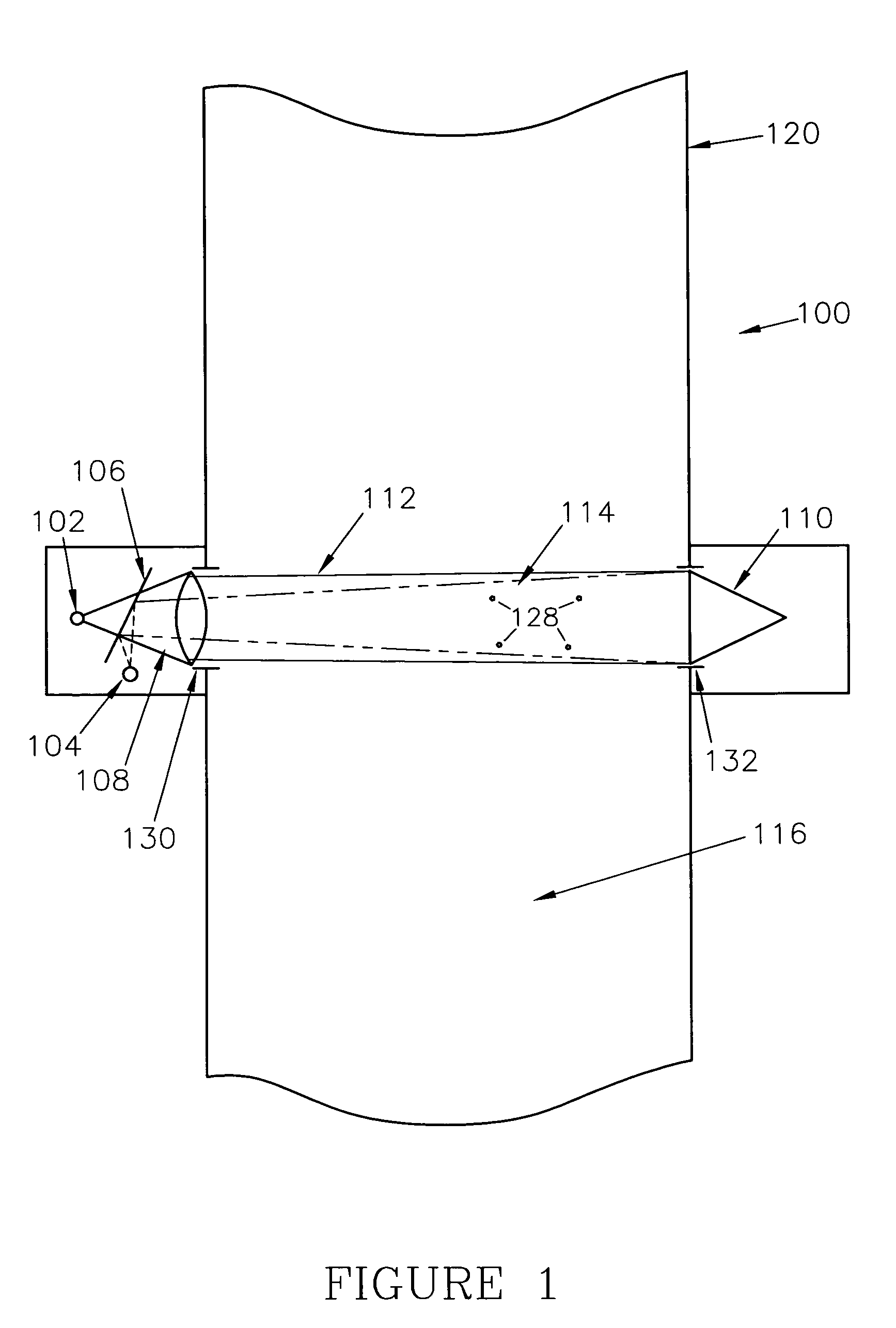

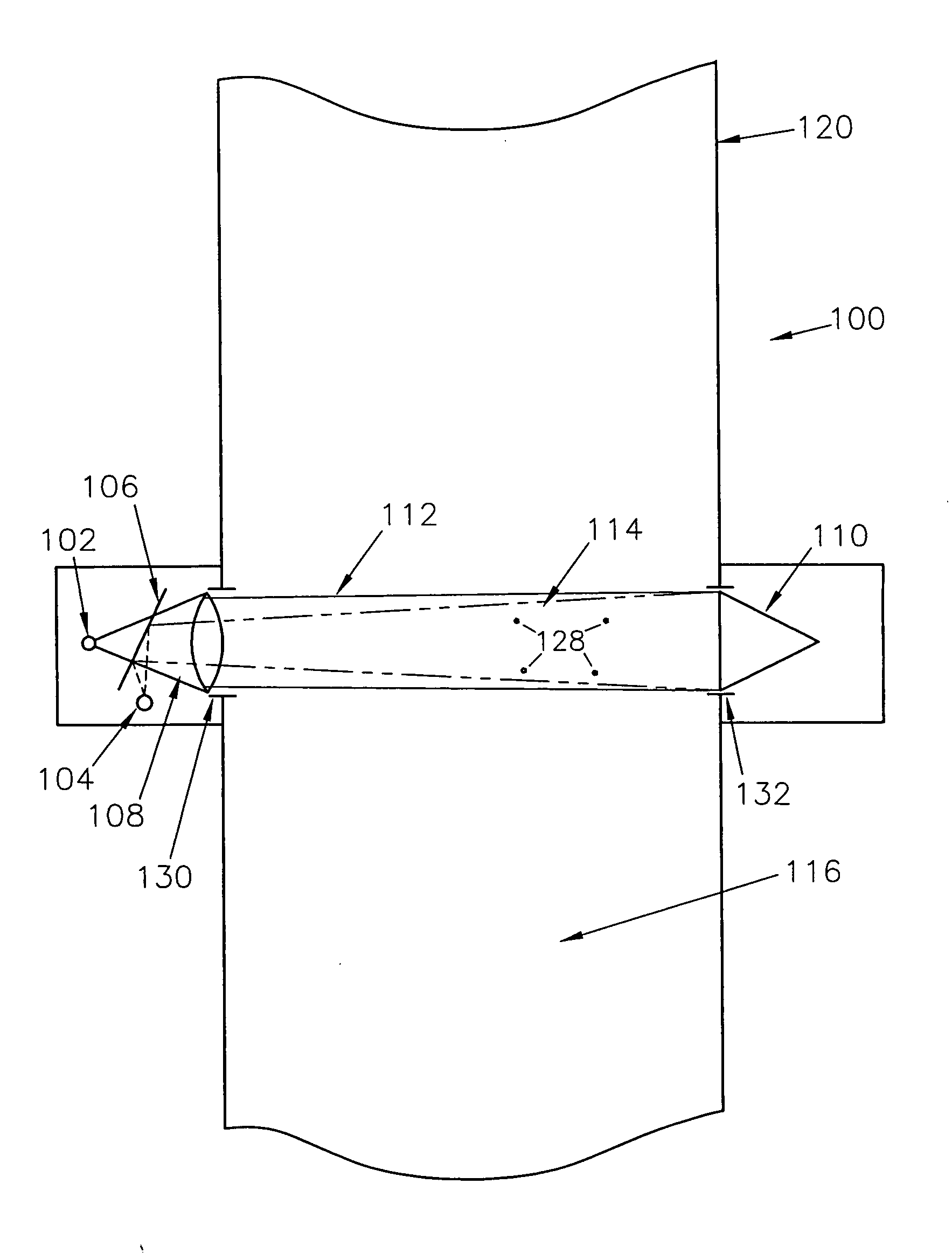

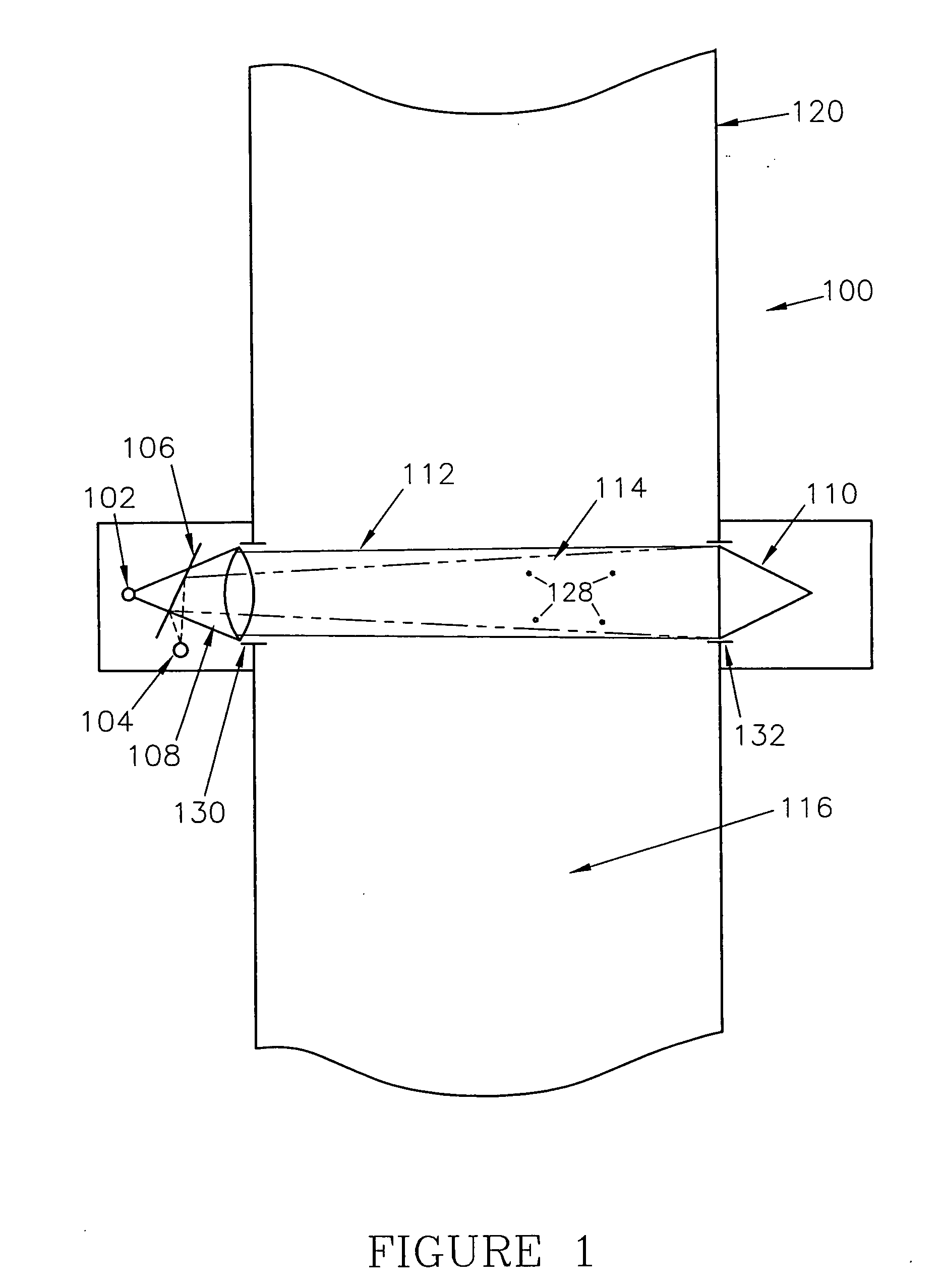

Optical method and apparatus for red blood cell differentiation on a cell-by-cell basis, and simultaneous analysis of white blood cell differentiation

InactiveUS6630990B2Accurate methodMaterial analysis by observing effect on chemical indicatorPhase-affecting property measurementsWhite blood cellForward angle

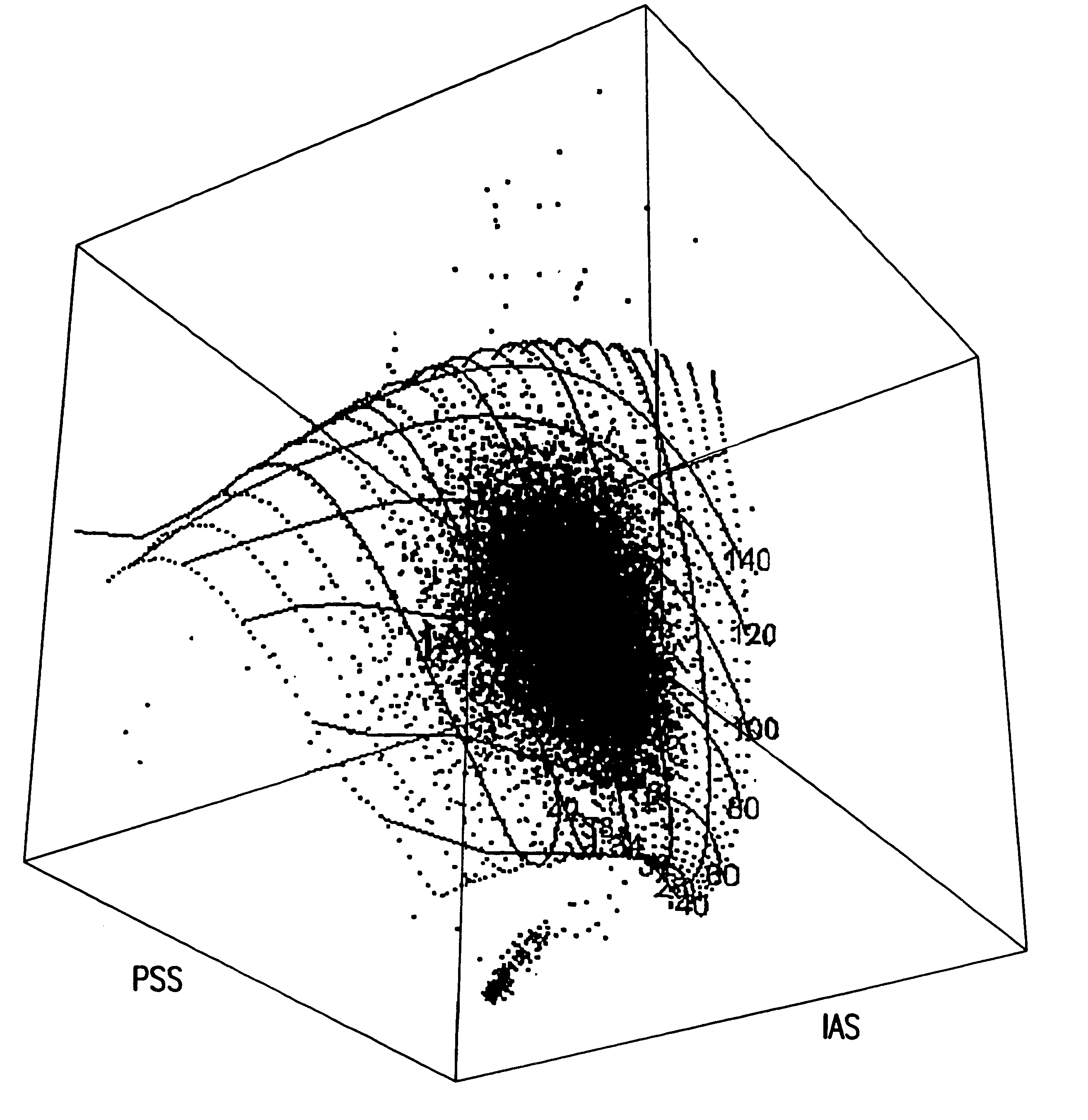

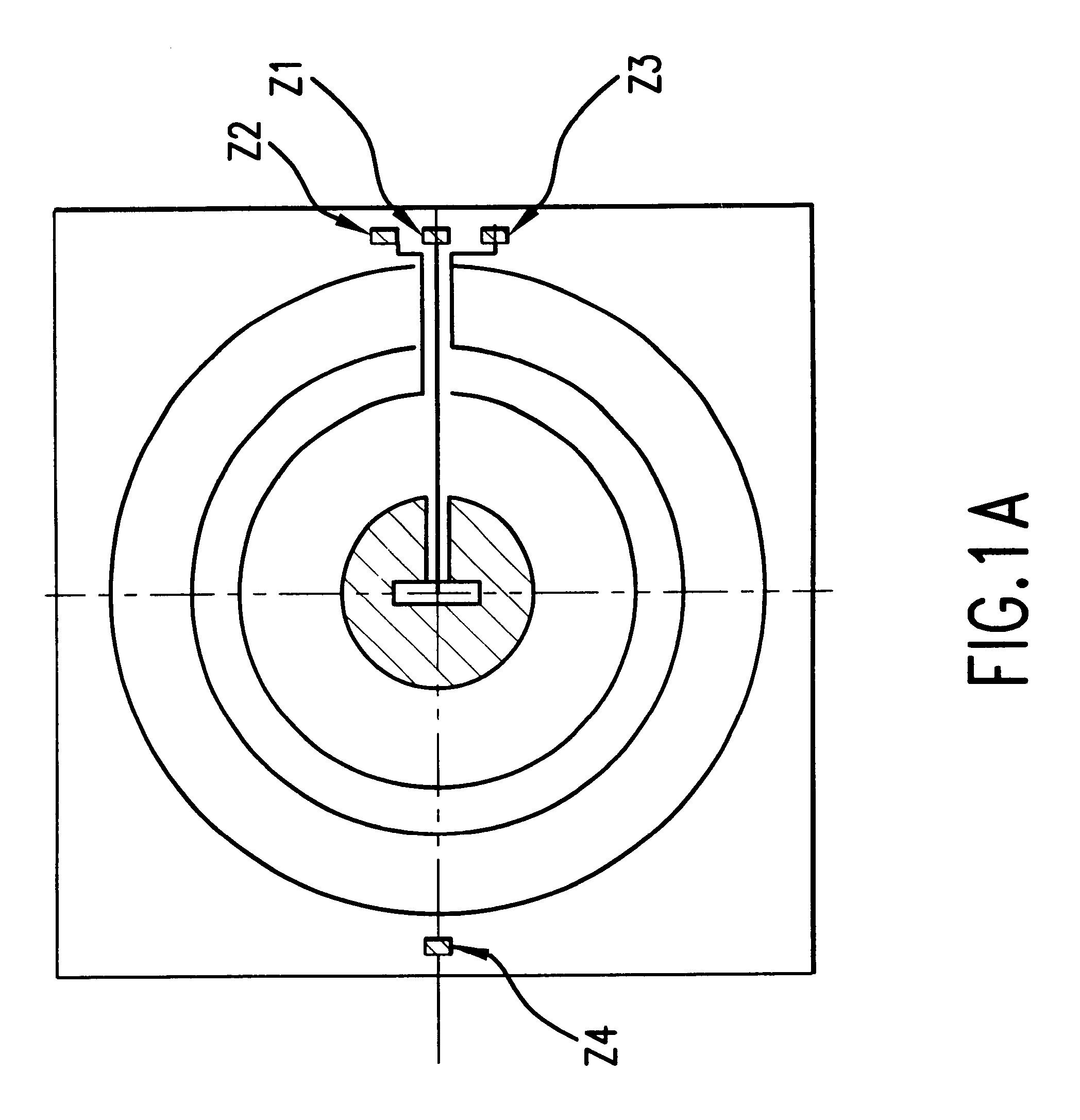

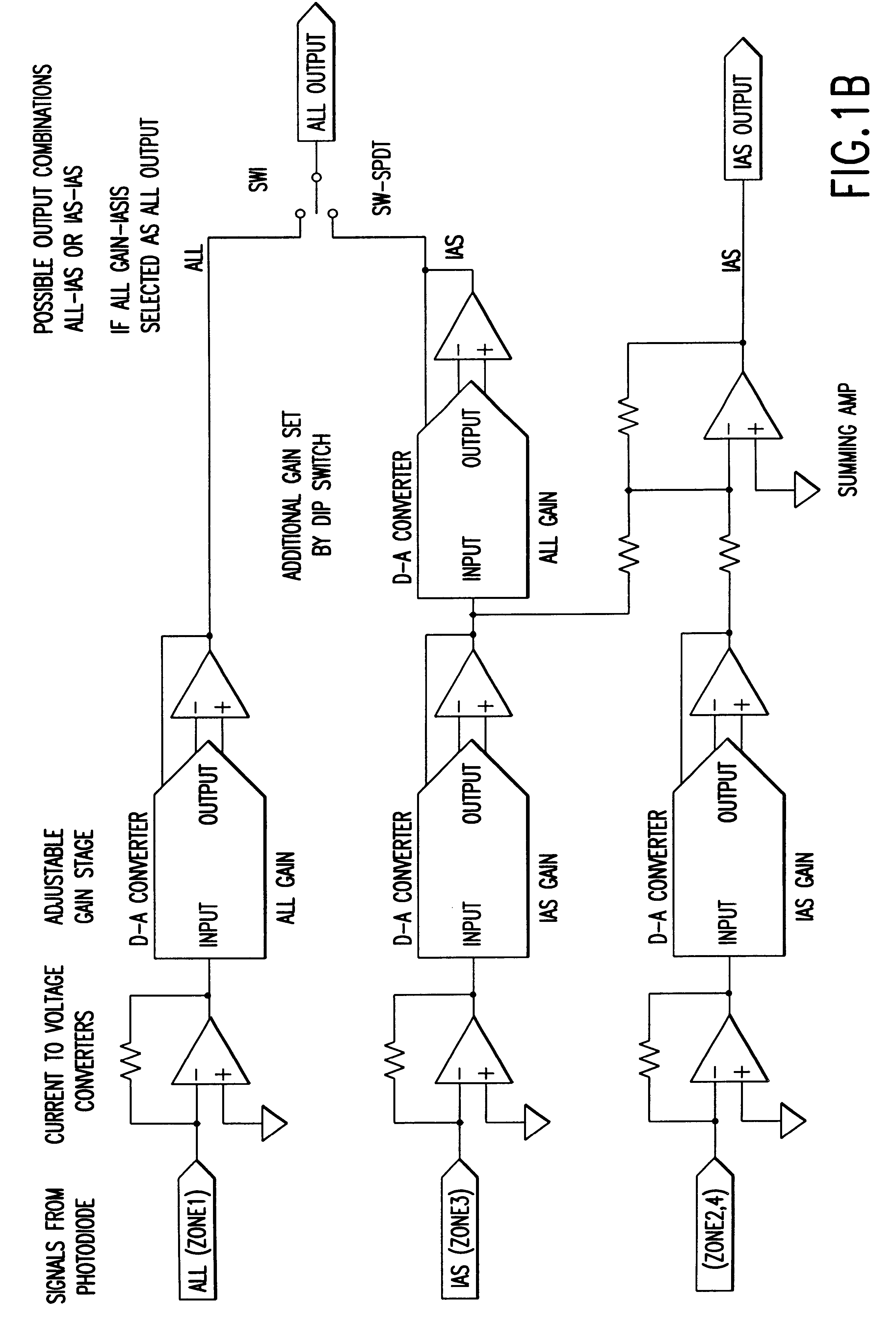

Methods and apparatus are disclosed for determining the volume, hemoglobin concentration, maturity and cell shape of mammalian red blood cells in a whole blood sample and simultaneously monitoring system standardization. Methods for distinguishing red blood cells from other cellular particles, prior to the red blood cell analysis are also disclosed. Red blood cells are passed through a beam of light in single file at a selected wavelength, obtaining an initial cytogram by means of the resultant magnitude of one light loss signal and one forward angle light scatter signal at a selected angular interval and a third side angle light scatter or two forward angle light scatter signals at a selected angular intervals and a third side-angle light scatter signal, projecting the cytogram, point by point, onto a pre-calibrated 3-dimensional surface containing grid lines of volume and hemoglobin concentration and determining accurate values of cell volume and hemoglobin concentration.

Owner:ABBOTT LAB INC

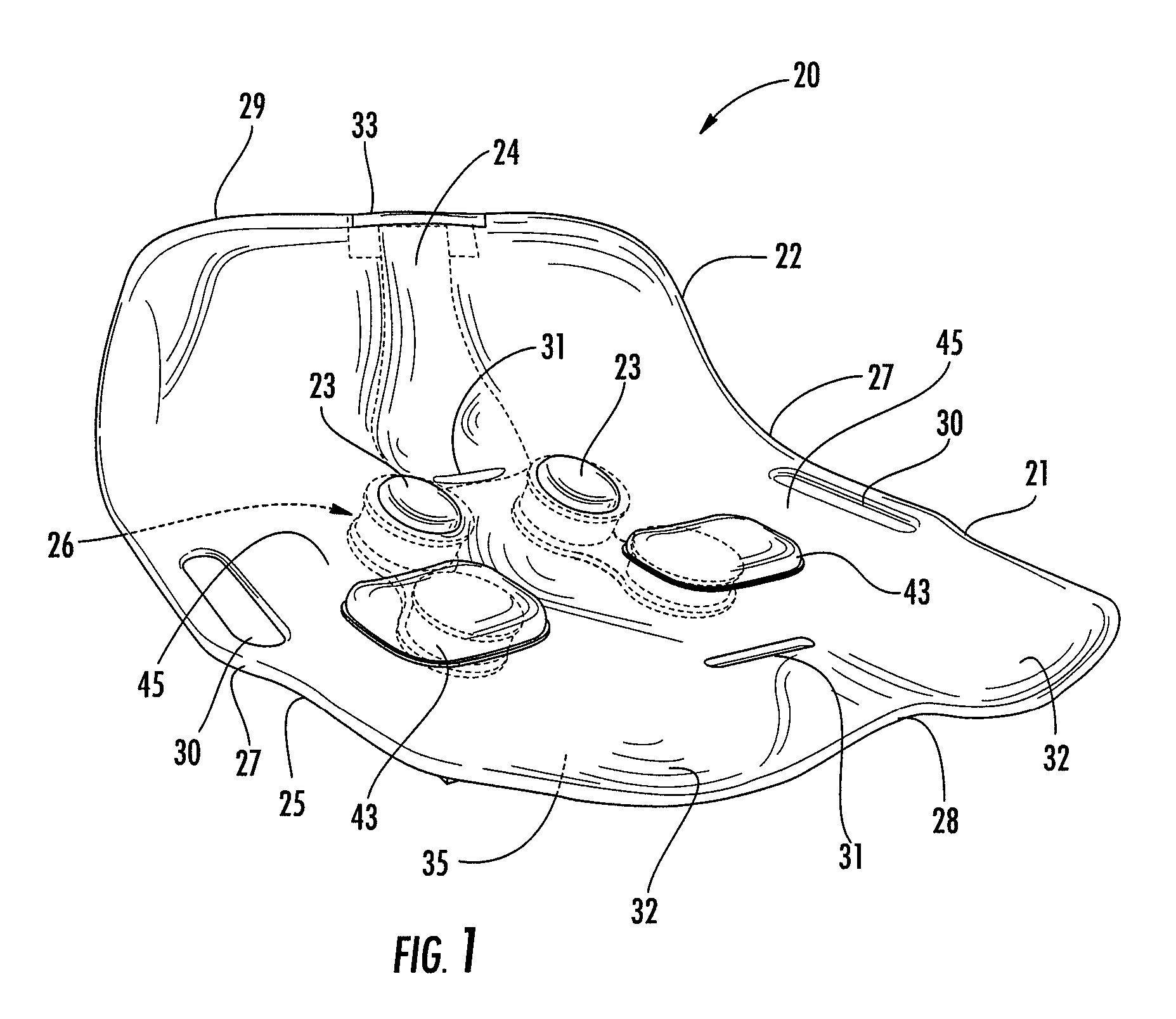

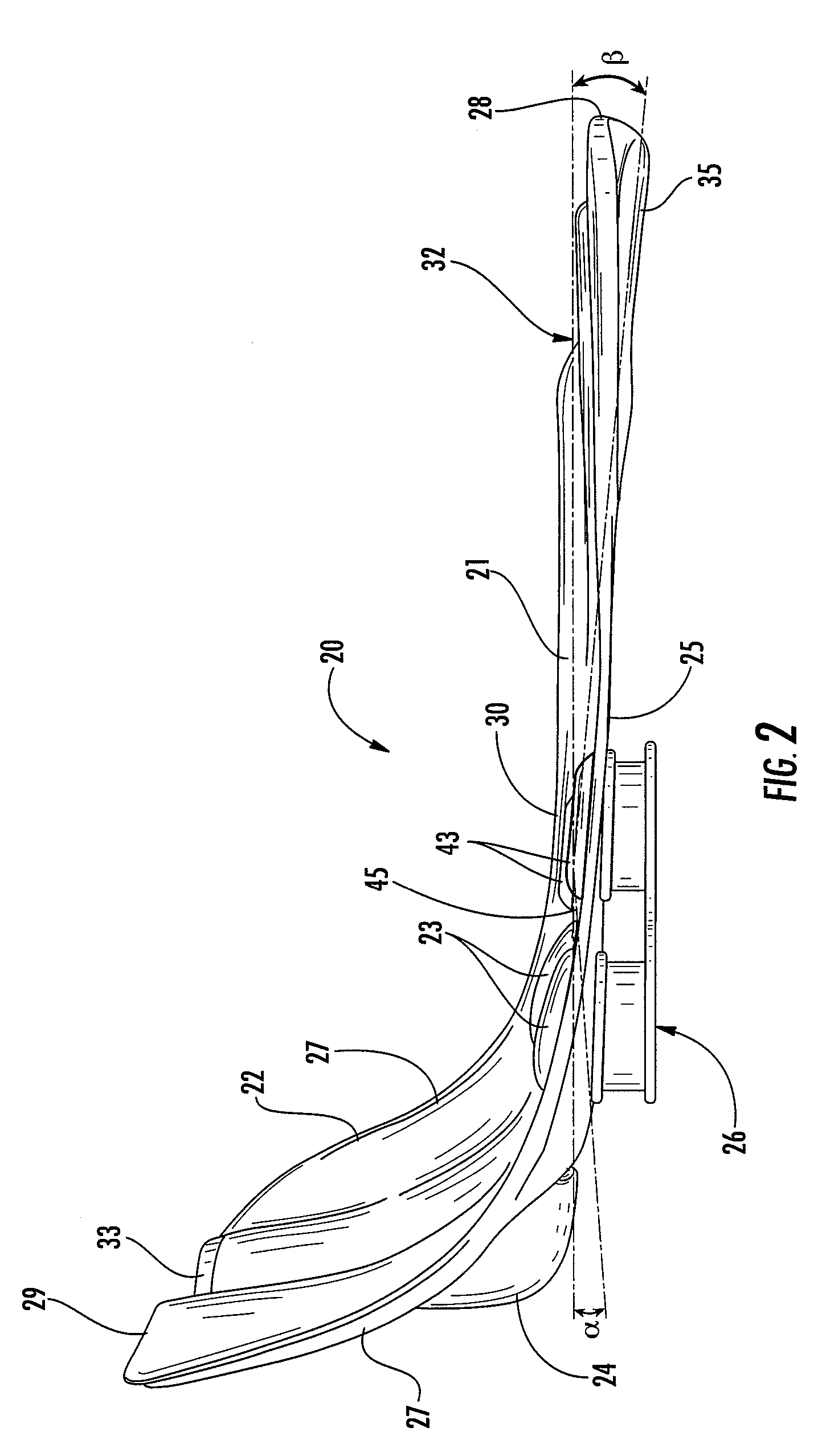

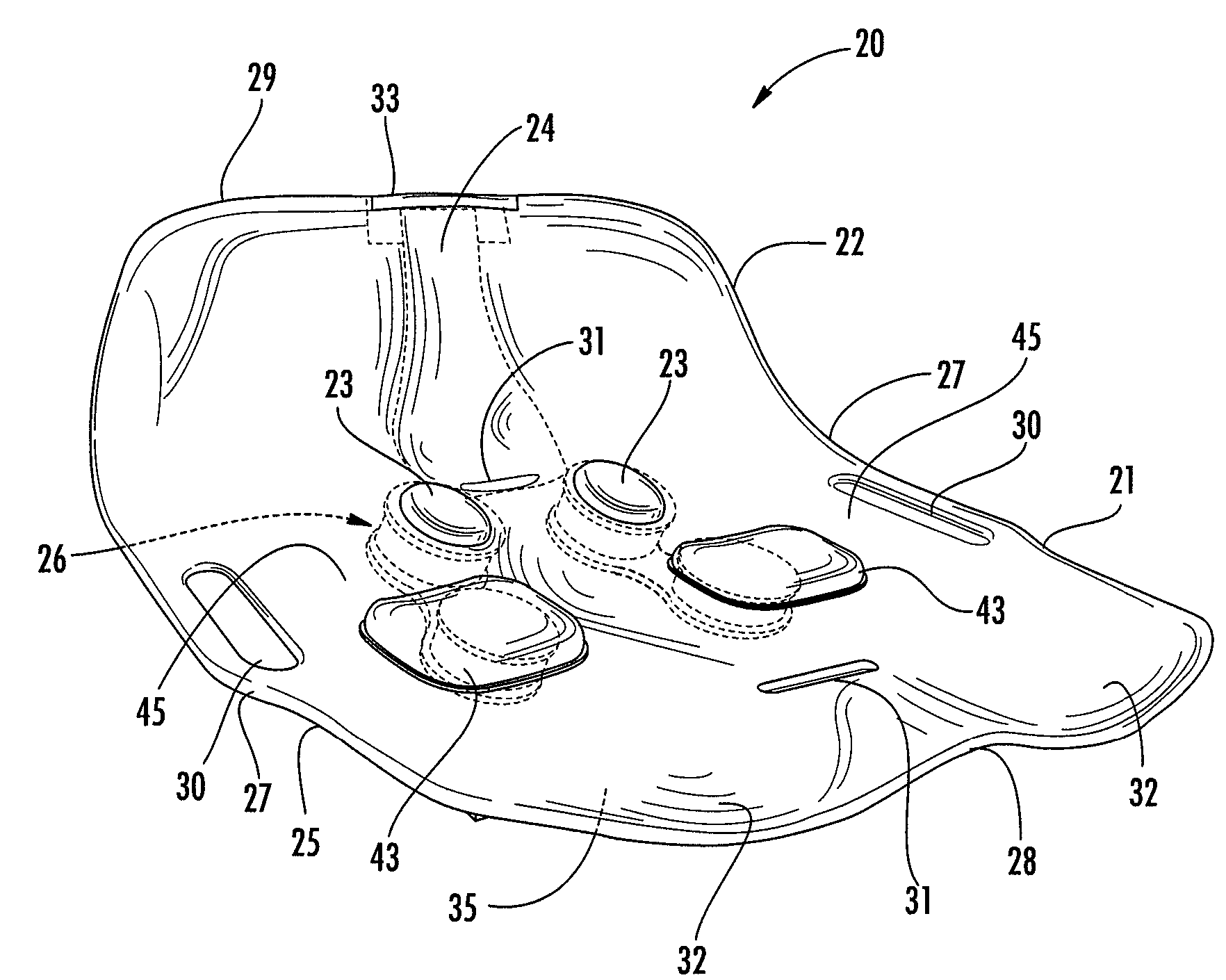

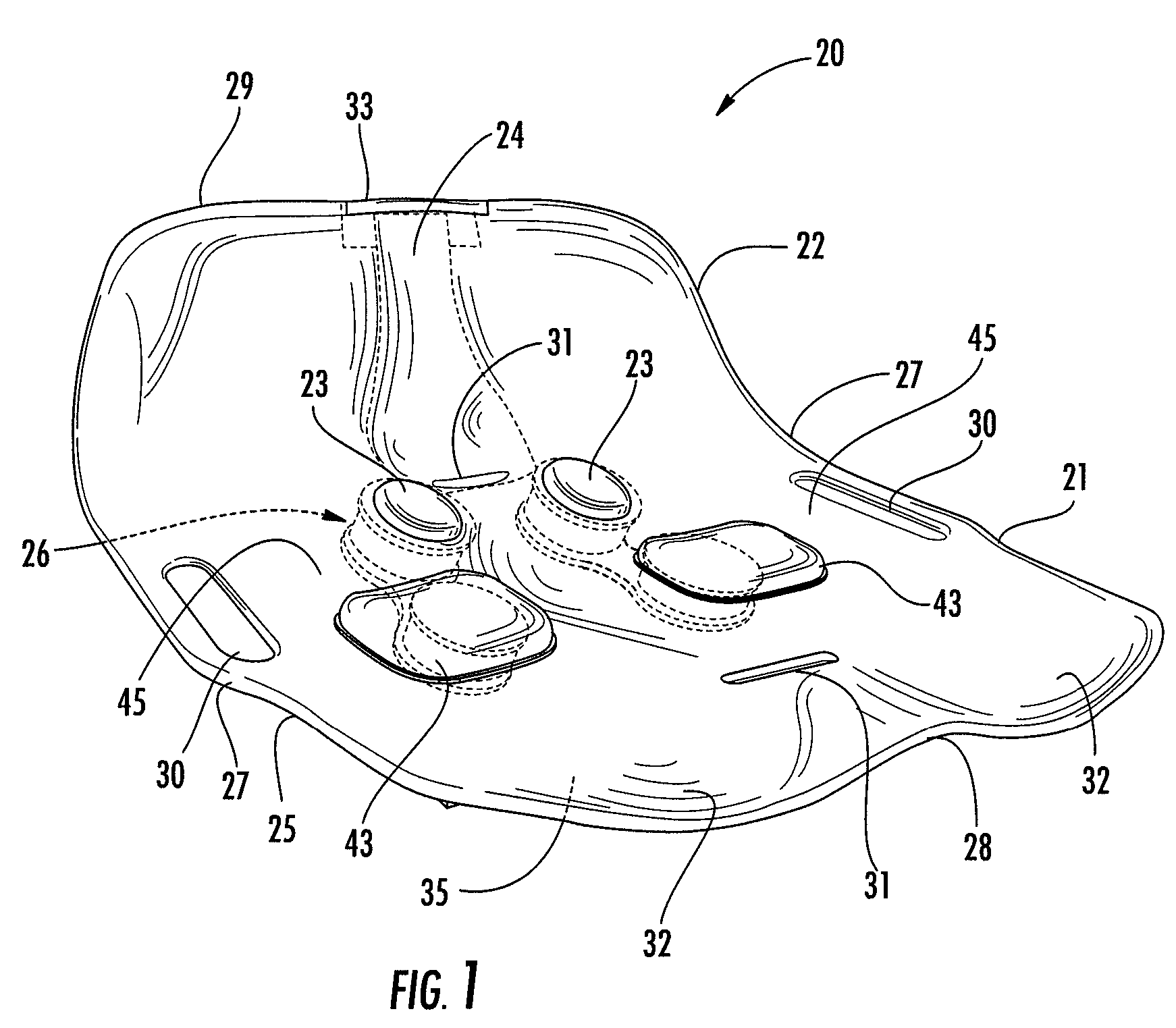

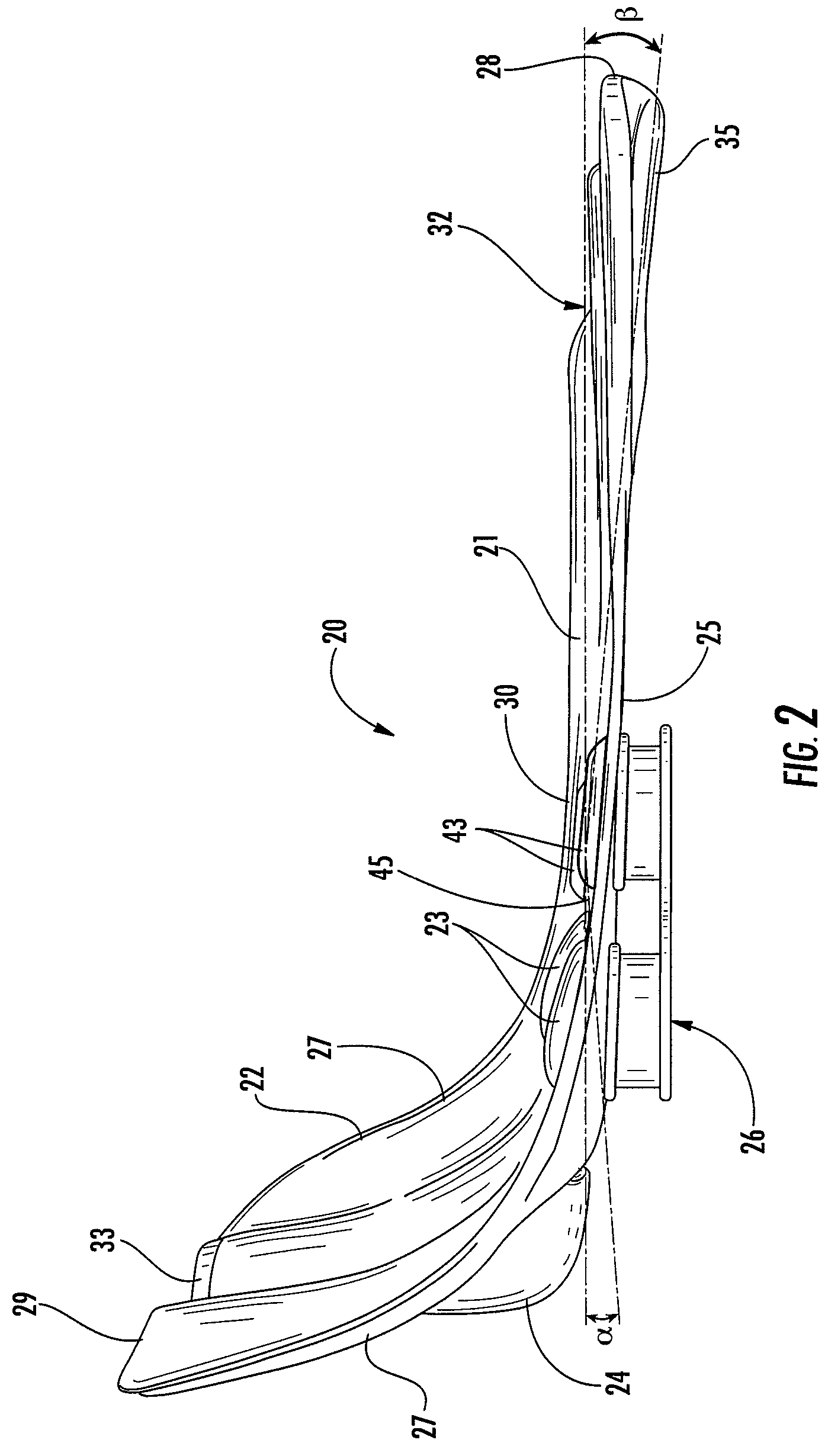

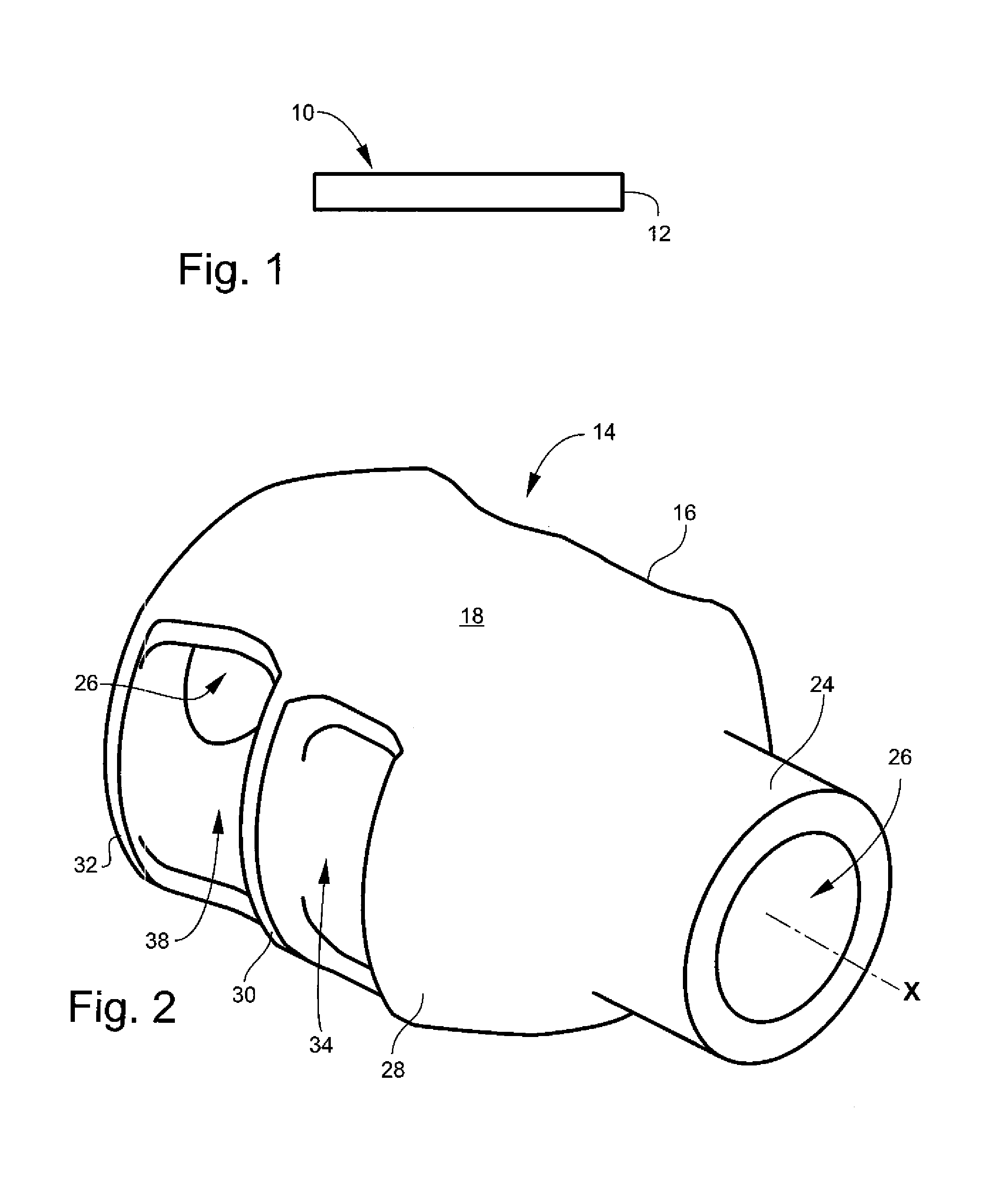

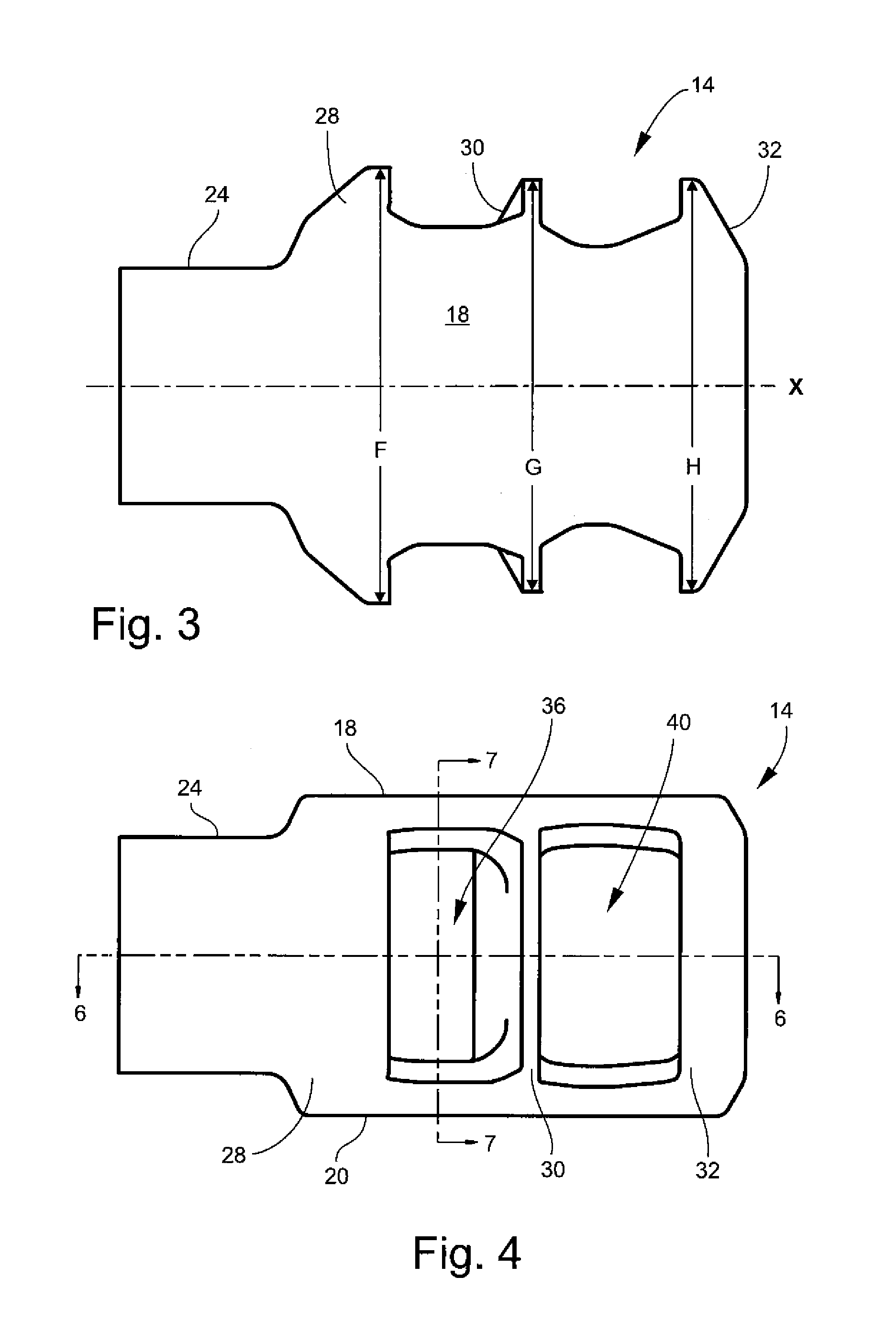

Contoured Seat And Method

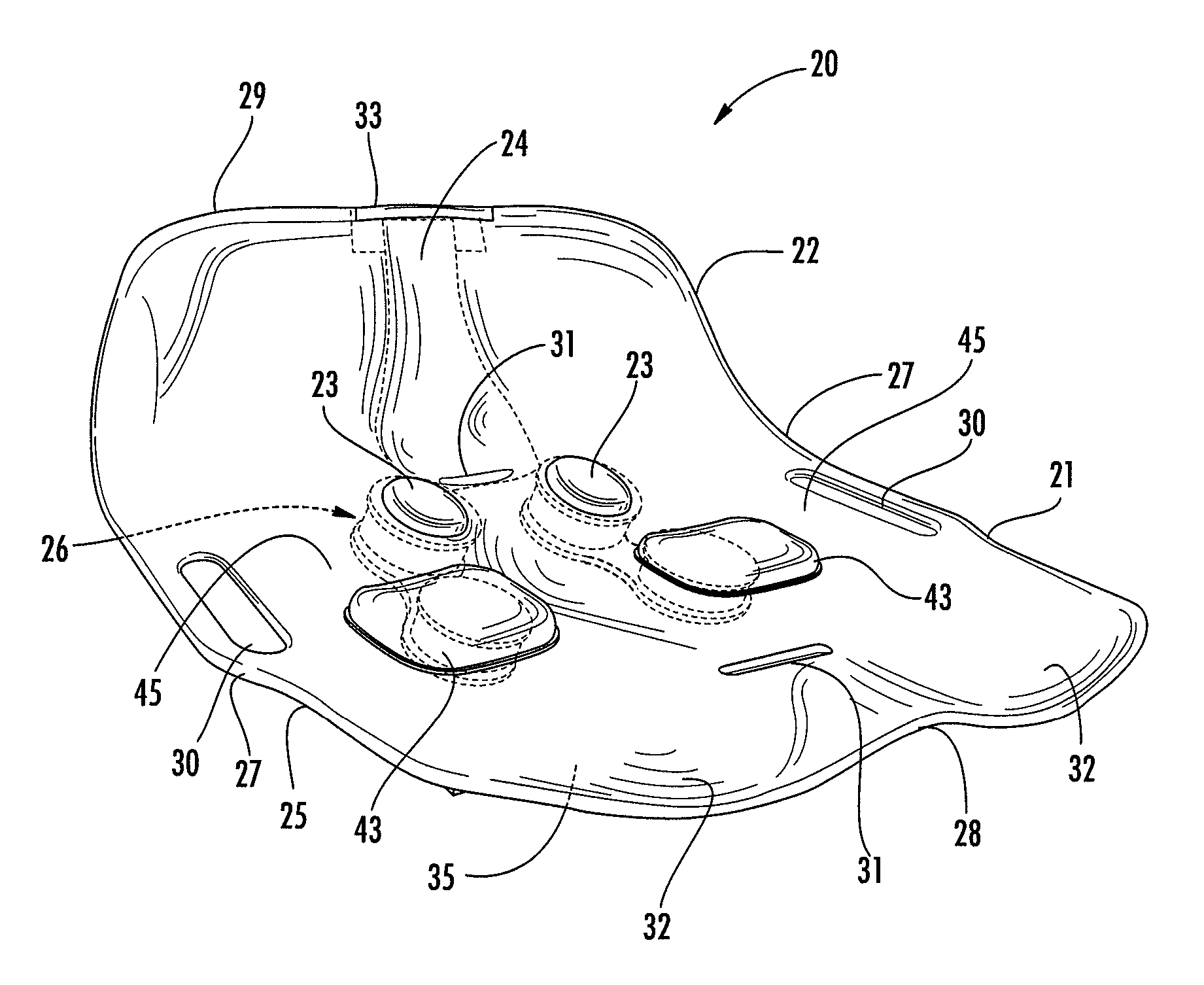

A contoured seat generally includes a seat surface for supporting the thighs and buttocks of a sitter and a back surface for supporting the lower back of a sitter. Defined by the seat surface are a pair of bilateral, spaced protrusions that are positioned to extend into piriformis musculature of the sitter. Preferably, the seat surface is inclined at a 5° to 15°, and more preferably a 7.5°, angle to induce forward pelvic tilt in conjunction with lower lumbar support of a forward angle of the back surface. The seat and back surfaces may define a sacral-coccyx pocket that has a depth that varies, along its proximal-distal path to allow for sacral stabilization. The sacral-coccyx pocket preferably is relatively narrow and deep proximally and flares as it extends in the distal direction. A reinforcing ridge may extend across a top edge of the sacral-coccyx pocket to provide additional support.

Owner:GREGORY MATTHEW WAYNE +1

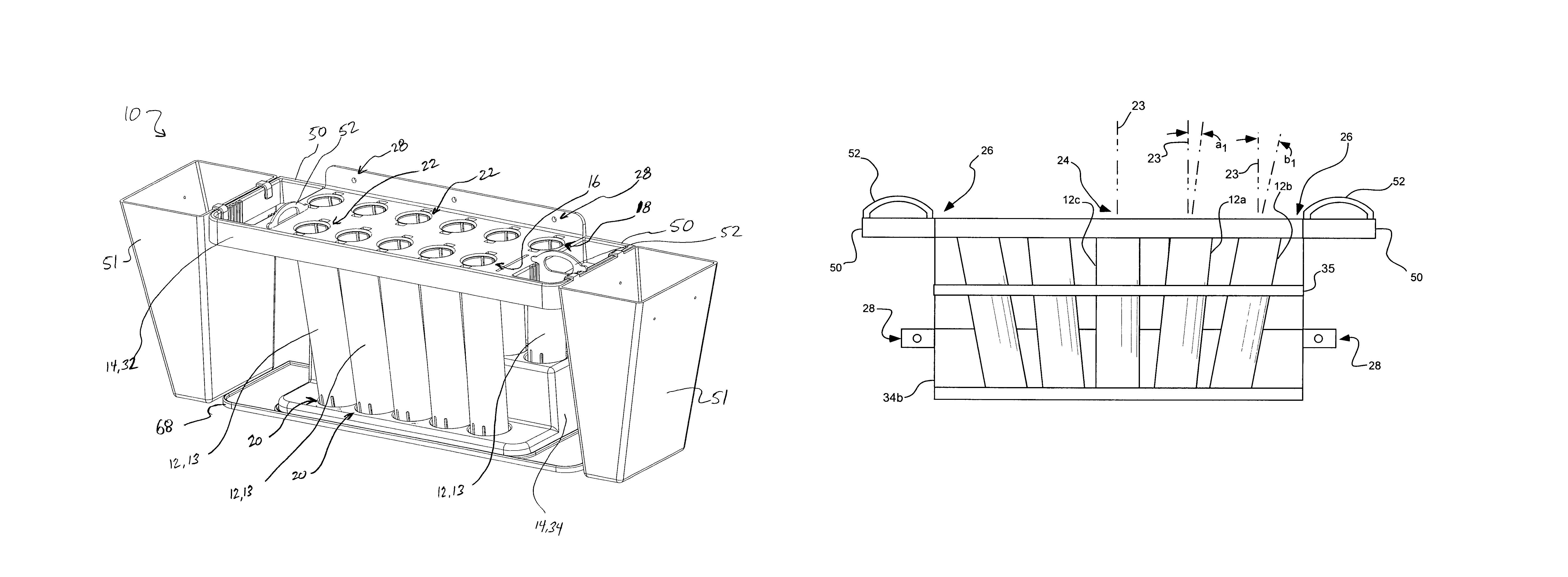

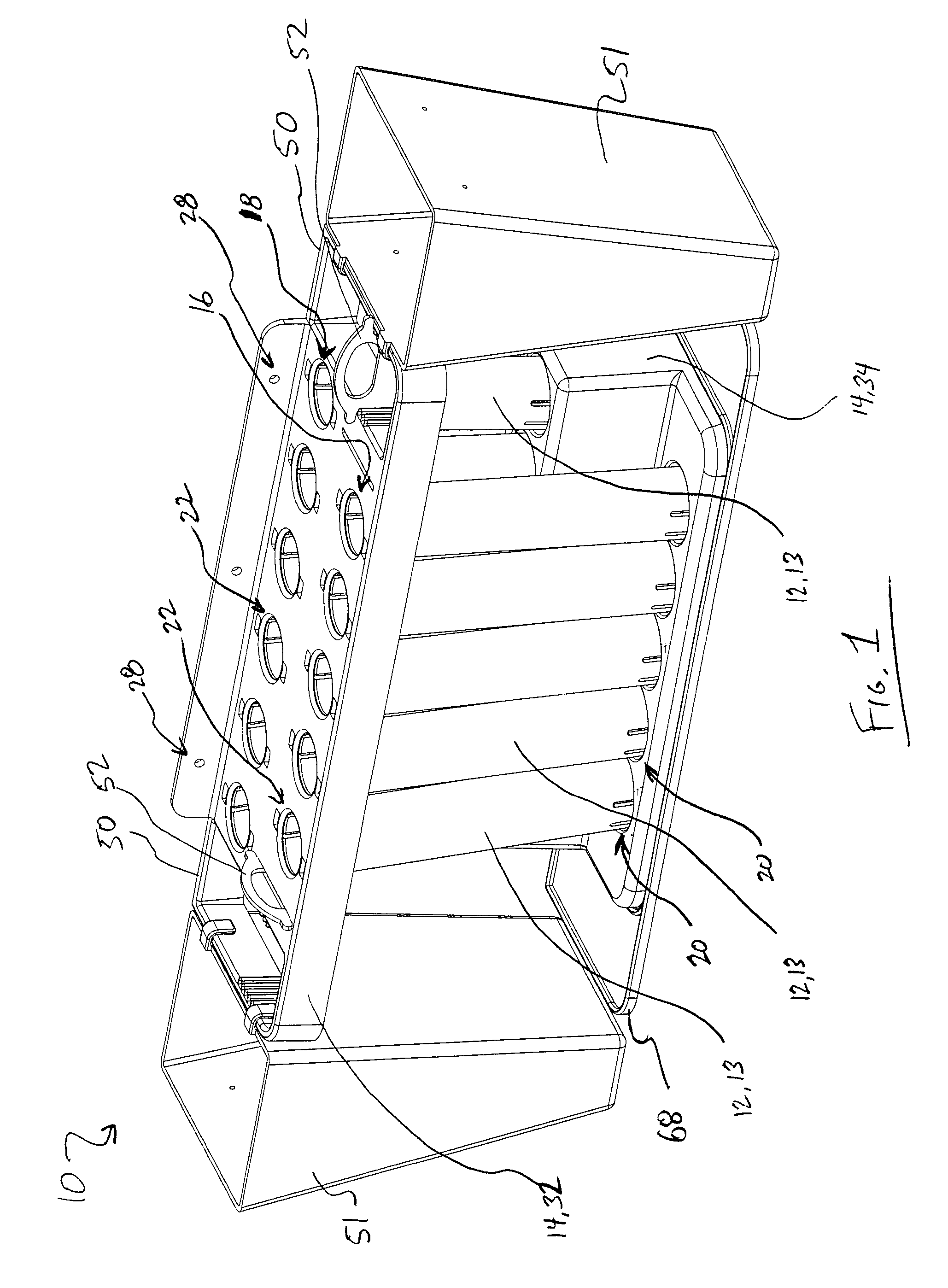

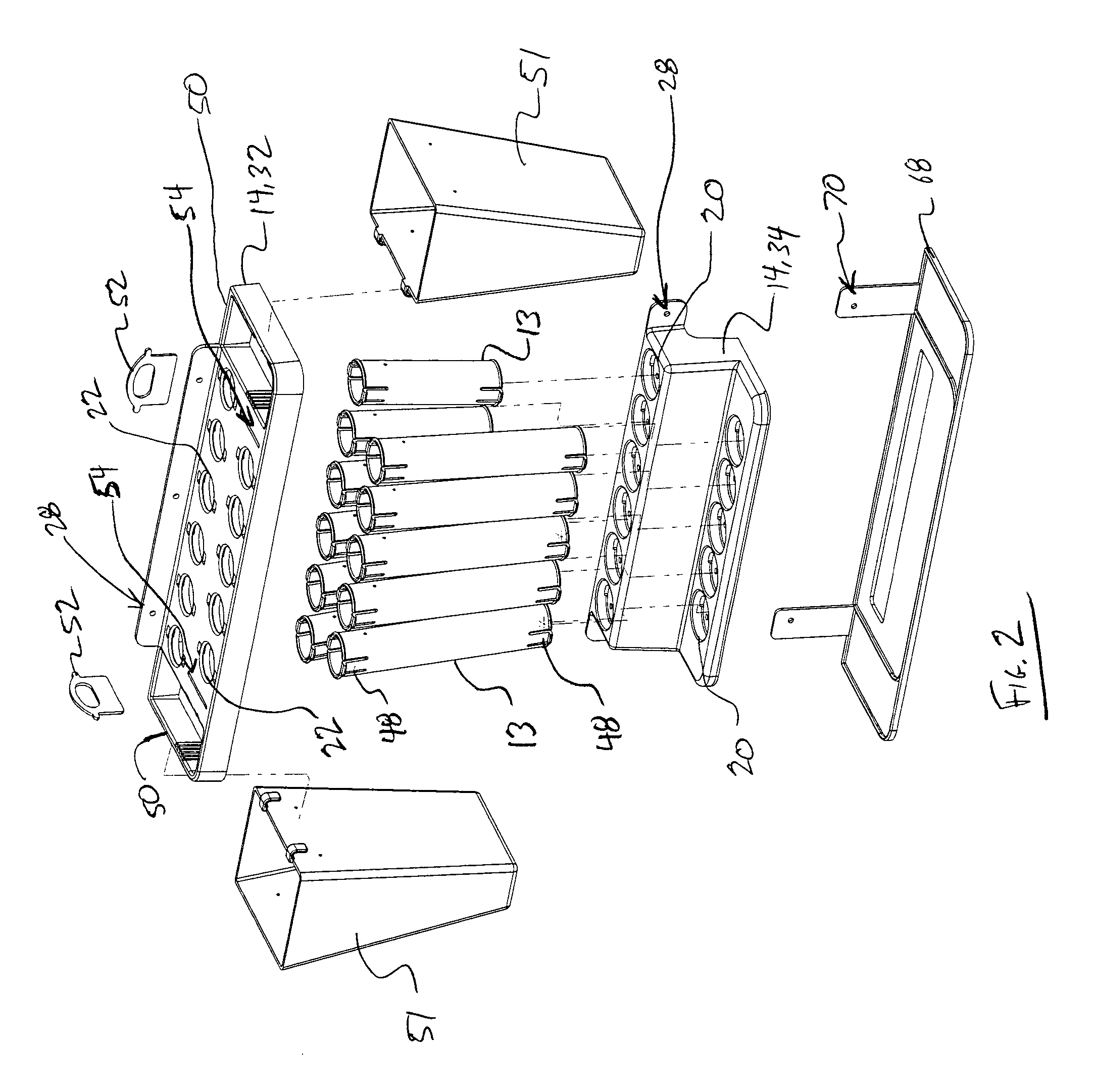

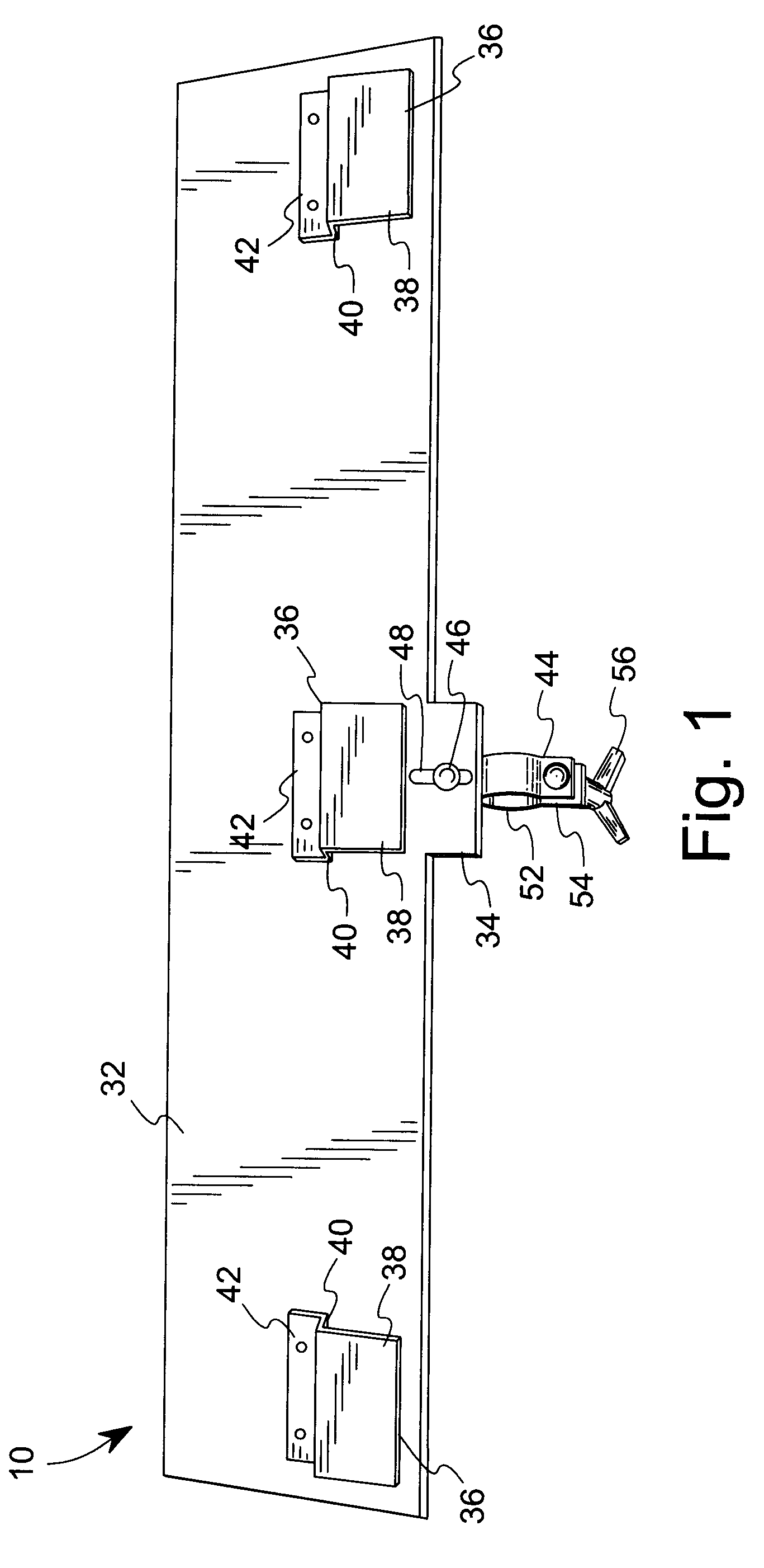

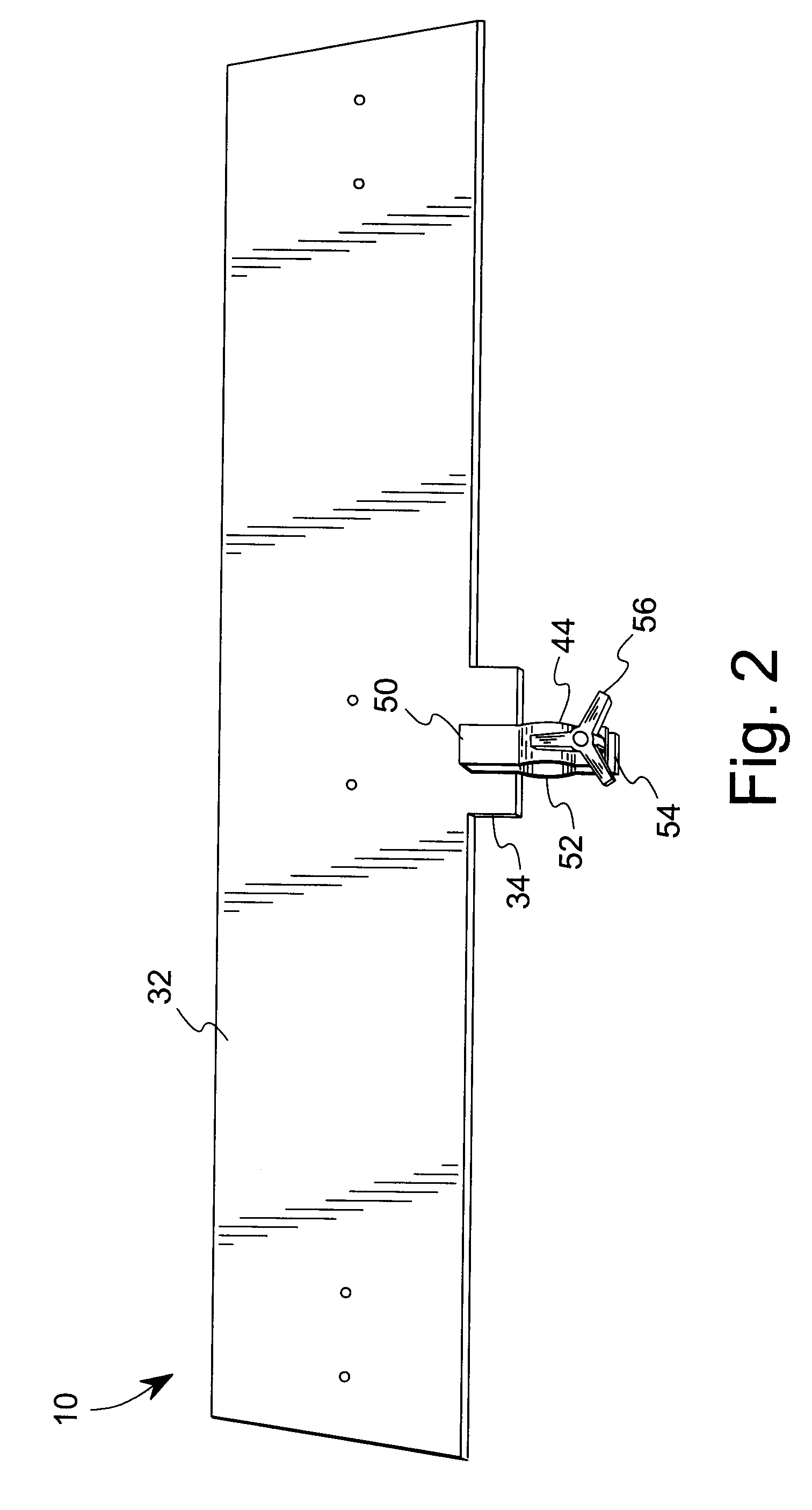

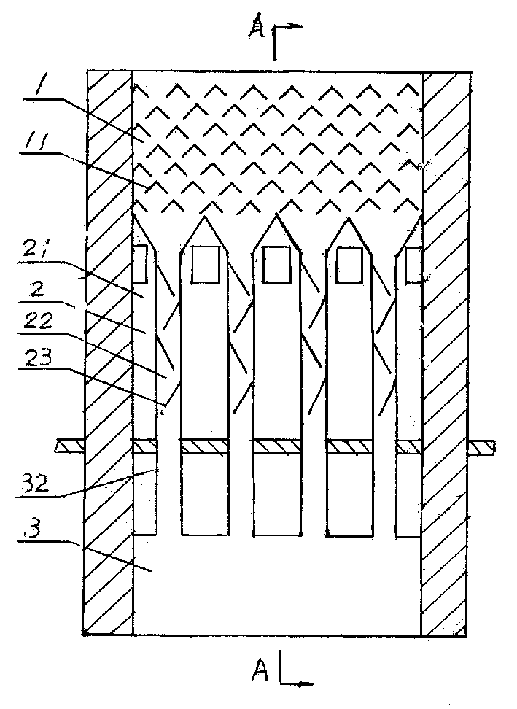

Tool holder and method

A storage device for compactly storing elongate tools includes a plurality of receptacles arranged in a support in at least front and rear substantially linear rows. Each receptacle includes at least a lower receiving port and an upper receiving aperture in which a tool can be held when disposed through the upper receiving aperture and into the lower receiving port. The receptacles of the front row are forwardly splayed at a forward angle with respect to vertical greater than the receptacles of the rear row. The receptacles within each row are laterally splayed with respect to vertical, with receptacles within each row being oriented at progressively increasing lateral angles with respect to vertical from receptacles at a center to receptacles at lateral ends of each row.

Owner:DAMAR ENTERPRISES

Contoured seat and method

A contoured seat generally includes a seat surface for supporting the thighs and buttocks of a sitter and a back surface for supporting the lower back of a sitter. Defined by the seat surface are a pair of bilateral, spaced protrusions that are positioned to extend into performs musculature of the sitter. Preferably, the seat surface is inclined at a 5° to 15°, and more preferably a 7.5°, angle to induce forward pelvic tilt in conjunction with lower lumbar support of a forward angle of the back surface. The seat and back surfaces may define a sacral-coccyx pocket that has a depth that varies, along its proximal-distal path to allow for sacral stabilization. The sacral-coccyx pocket preferably is relatively narrow and deep proximally and flares as it extends in the distal direction. A reinforcing ridge may extend across a top edge of the sacral-coccyx pocket to provide additional support.

Owner:GREGORY MATTHEW WAYNE +1

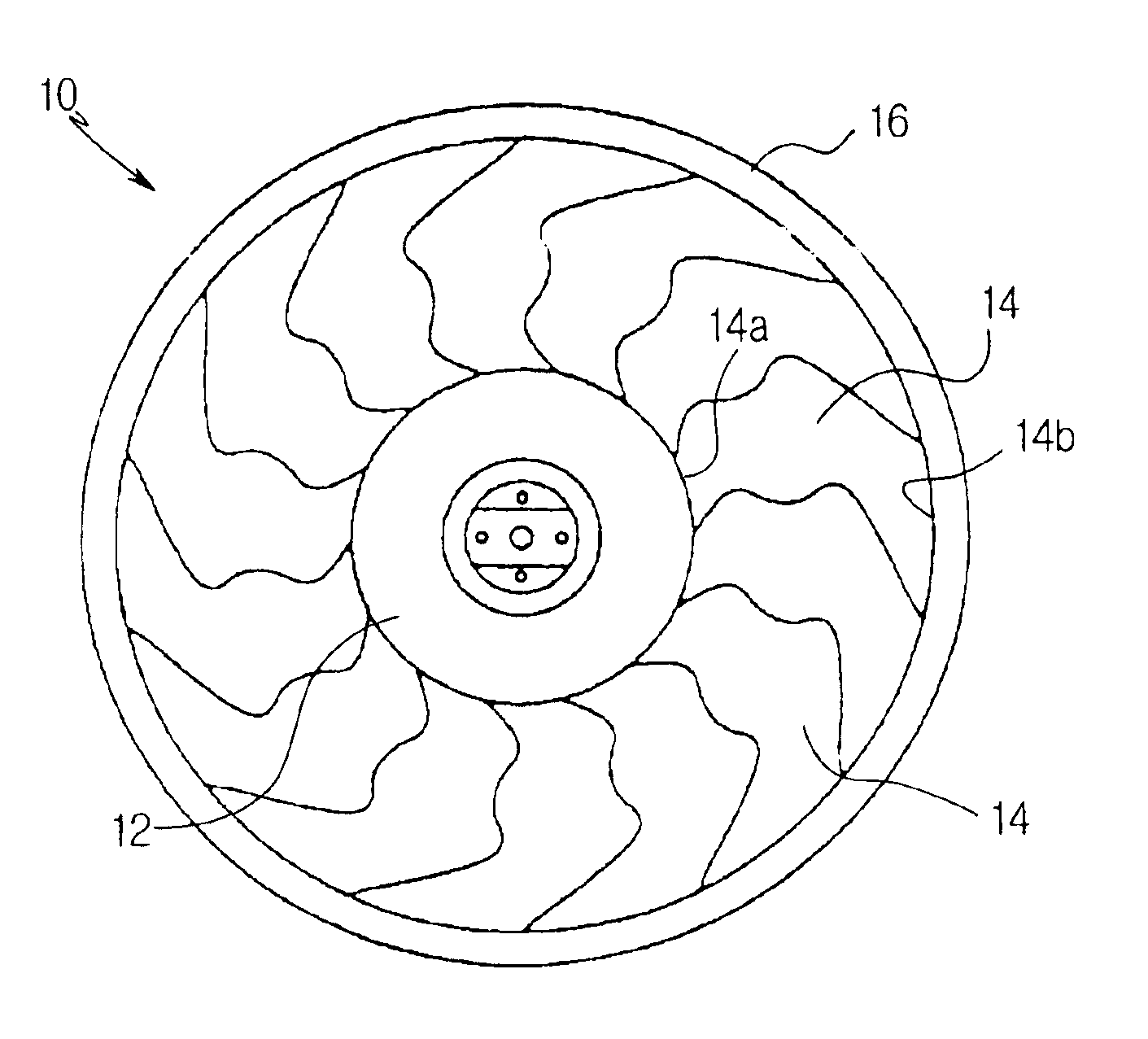

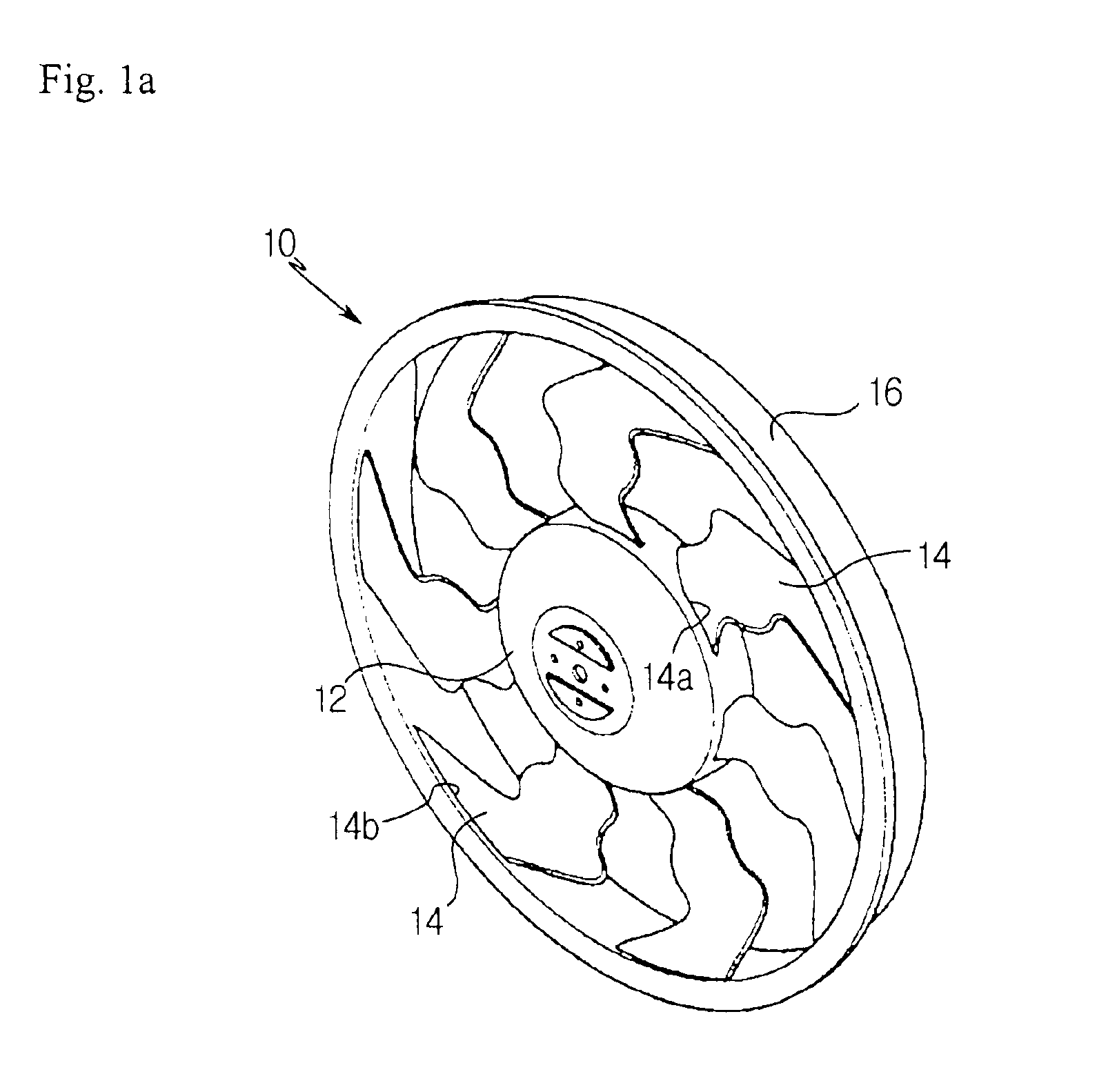

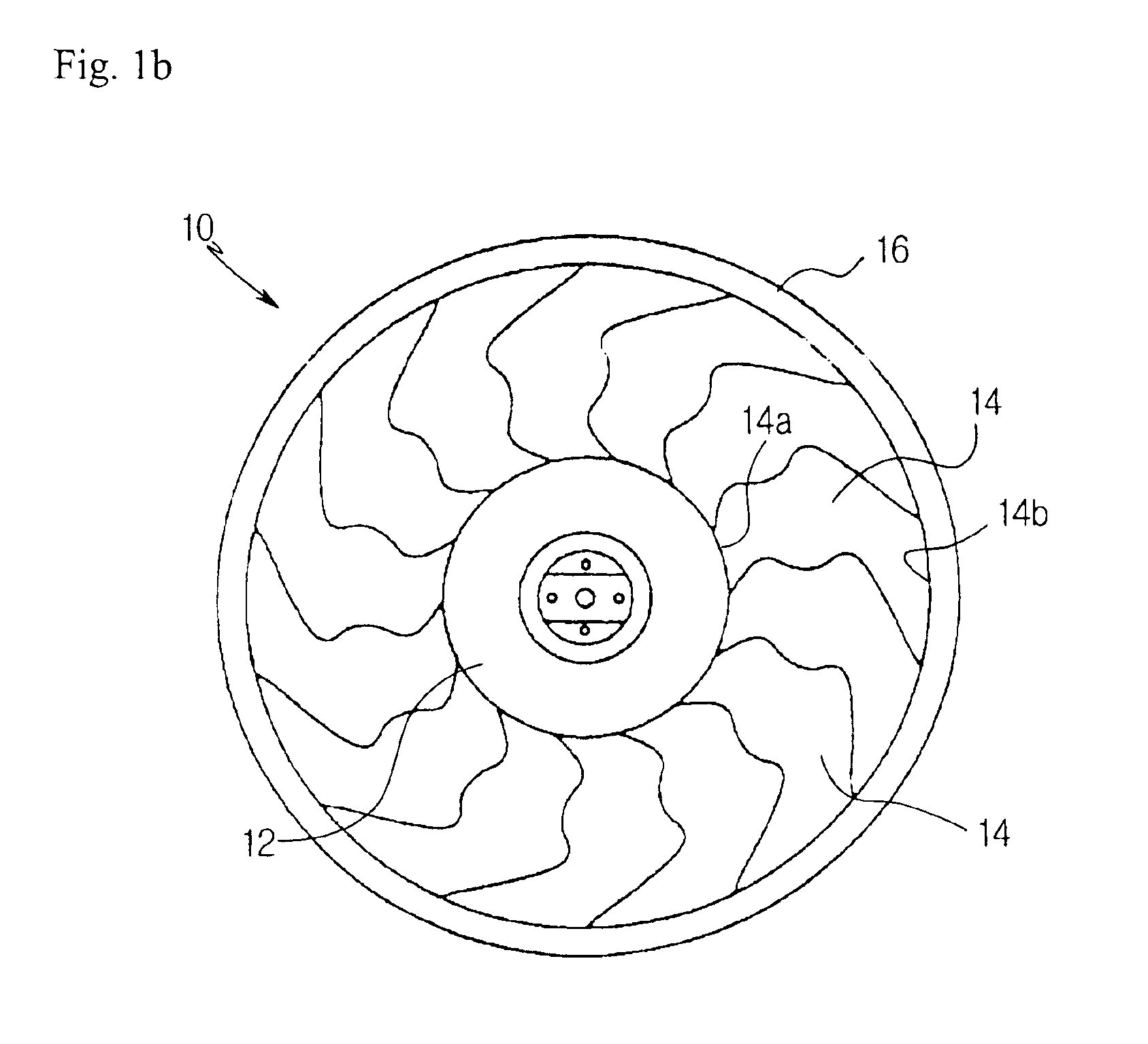

Axial flow fan

InactiveUS6908287B2Reduce blowing noiseImprove blowing efficiencyPropellersRotary propellersLeading edgeWave structure

Disclosed is an axial flow fan capable of achieving reduction of noise while having a high blowing efficiency compared to the power consumption of a motor adapted to drive the axial flow fan. The axial flow fan includes a hub, and a plurality of blades extending radially around the hub. Each blade has a sweep angle varying gradually from a backward angle at a root of the blade connected to the hub to a forward angle at a tip of the blade, while having a flow dispersion region having a plurality of regions where the sweep angle is alternately changed, at a region defined between a backward sweep angle region at the root of the blade and a forward sweep angle region at the tip of the blade. Each blade has a longitudinal cross section curved to have a wave structure between the root of the blade and the tip of the blade. The axial flow fan may further include a fan band connecting tips of the blades. The axial flow fan achieves reduction of blowing noise by receiving air in a dispersed state at the leading edge of each blade, discharging air in a dispersed state at the trailing edge of each blade, and offsetting turbulent flows of air by virtue of the wave-shaped longitudinal cross-sectional structure of each blade.

Owner:HANON SYST

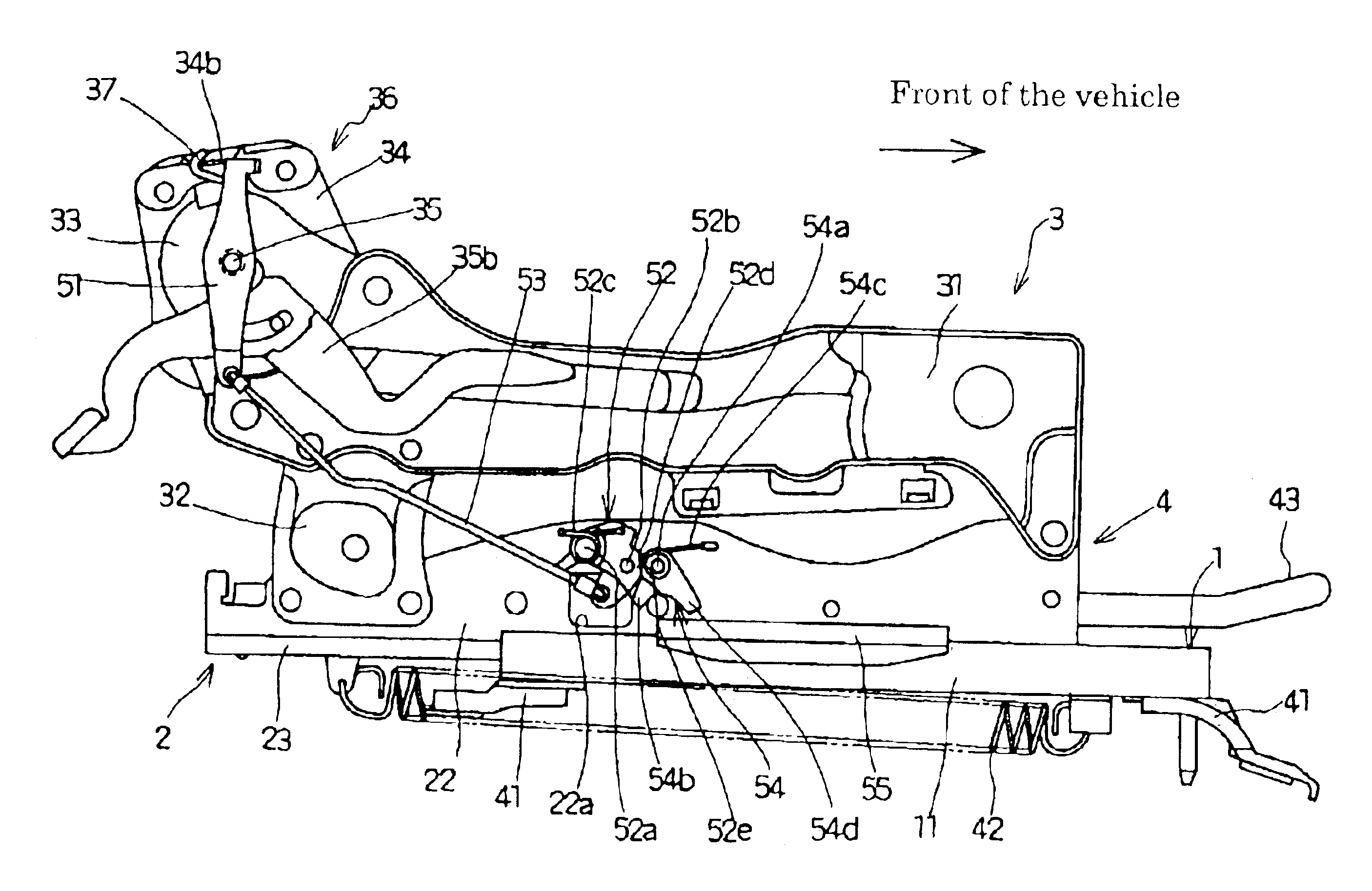

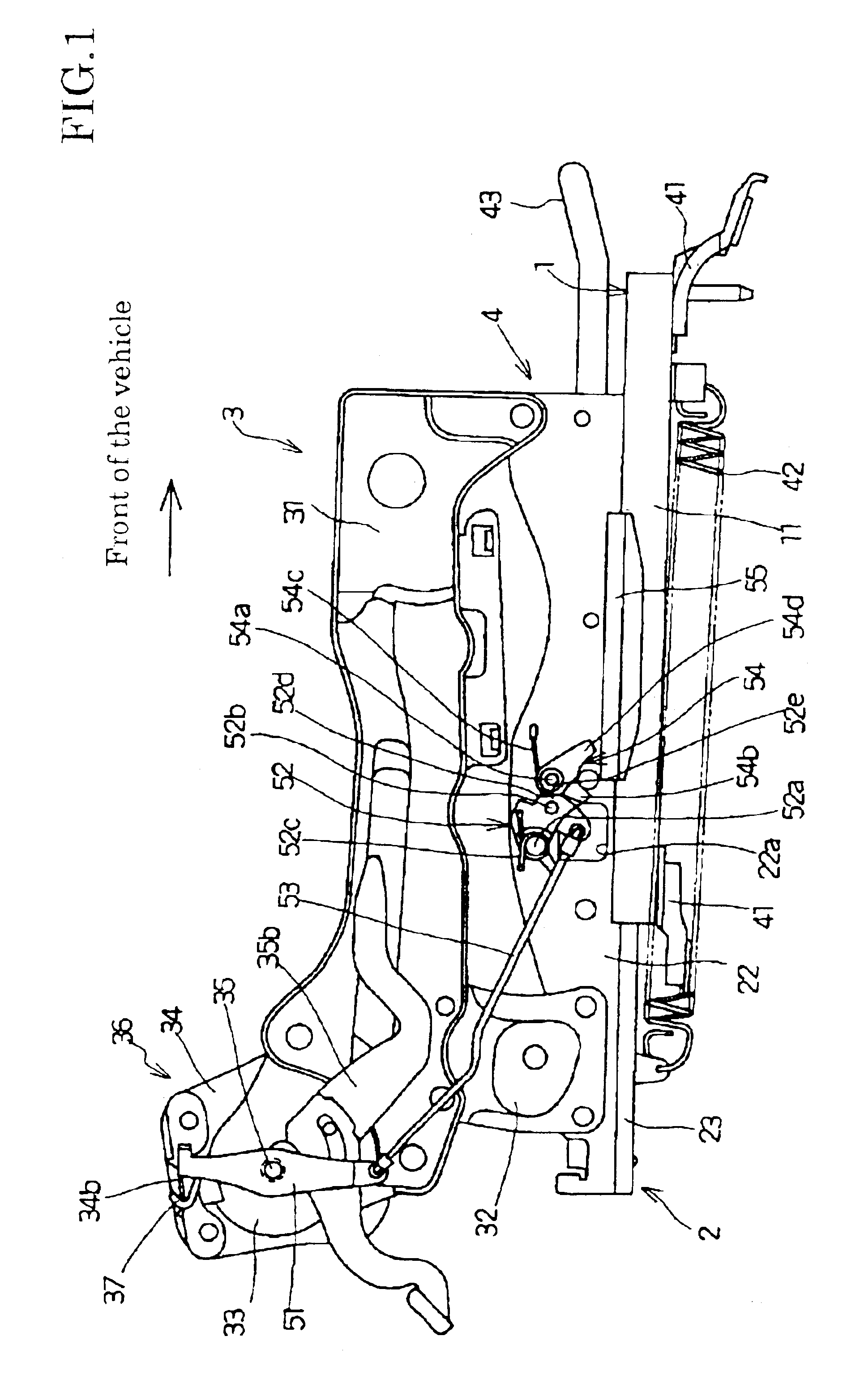

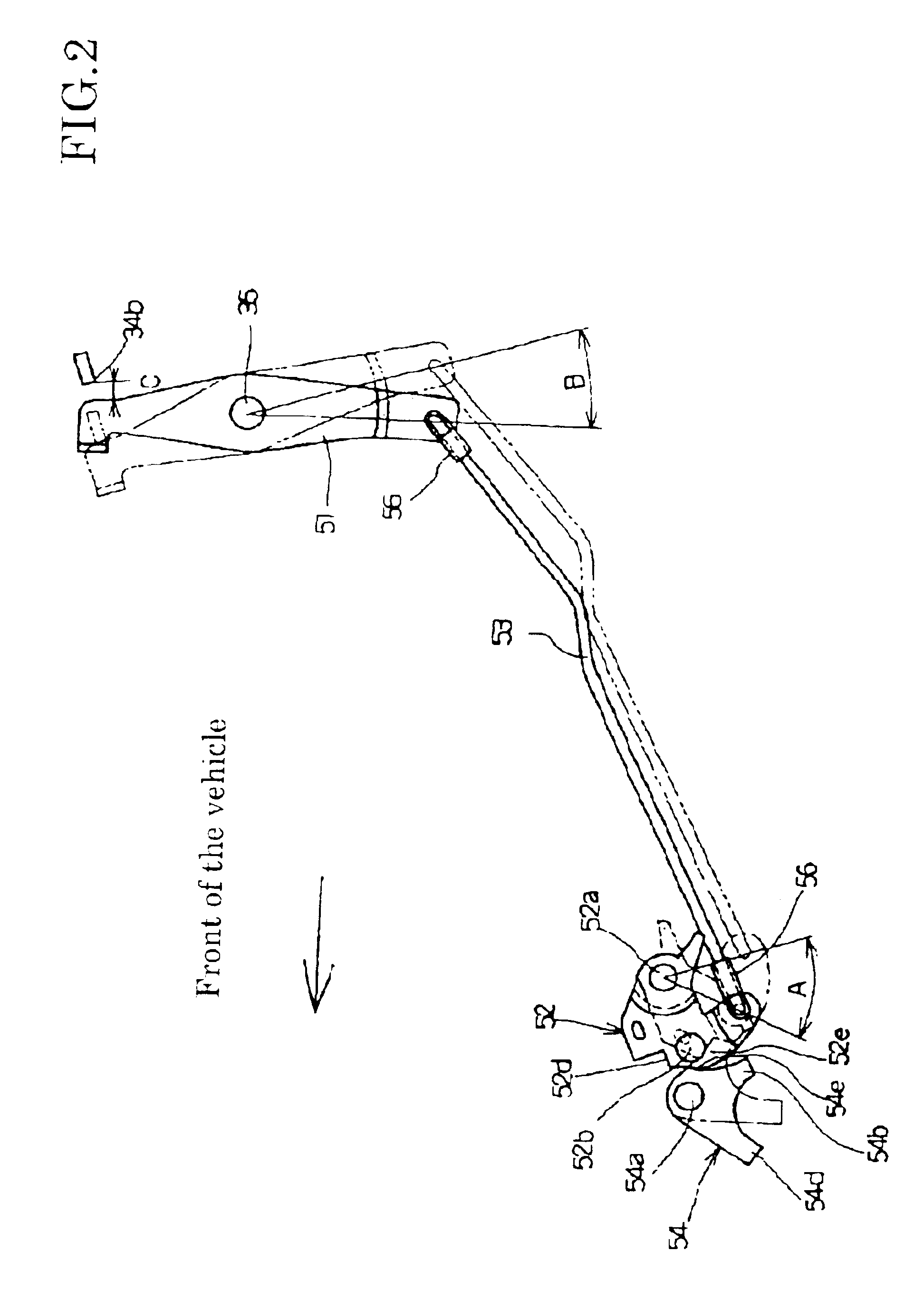

Walk in apparatus for vehicle seat

A walk-in apparatus of a vehicle seat slide includes an upper rail and a lower rail, a lock plate for locking the upper rail position on the lower rail, a release lever engaging with the lock plate for releasing the locking, a supporting lever engaging the release lever, a reclining plate rotating when the seat back rotates more than a predetermined forward angle, a memory plate on the lower rail within a predetermined range, a first supporting portion on the supporting lever for holding the release lever at a first position where the lock plate unlocks when the supporting lever is out of the memory plate range and a second supporting portion provided on the supporting lever for holding the release lever at a second position and waiting for the upper rail to be locked when the reclining plate disengages with the seat back.

Owner:AISIN SEIKI KK

Power below-knee prosthesis-based gait recognition method

The invention relates to a power below-knee prosthesis-based gait recognition method. The method comprises the following steps that: 1) a sensor is arranged at a corresponding position of a power below-knee prosthesis; 2) when H is equal to 1, and simultaneously FH is greater than FPH and the derivative of theta ankle is less than 0, an ankle joint enters a passive plantar flexion stage; 3) when T is equal to 1, the passive plantar flexion stage is finished; the ankle joint enters a passive dorsiflexion stage, and simultaneously the ankle joint rotates forwards until the ankle joint reaches amaximal forward angle or H is equal to 0; 4) when H is equal to 0, Tankle is greater than tau pp, and the derivative of the theta ankle is less than 0, the ankle joint enters an active plantar flexion stage; 5) when theta toe is less than 0, a toe joint enters an active dorsiflexion stage; 6) when FT is greater than FPT, the toe joint enters the active plantar flexion stage and simultaneously thetoe joint starts to rotate downwards; and 7) when the ankle joint and the toe joint reach a specified angle or T is equal to 0, the active plantar flexion stage is finished, and a foot leaves the ground to enter a swinging stage; and in the swinging stage, the ankle joint and the toe joint recover to a balance state respectively. The invention provides a new gait recognition method in which a power ankle joint and a power toe joint are involved at the same time.

Owner:PEKING UNIV

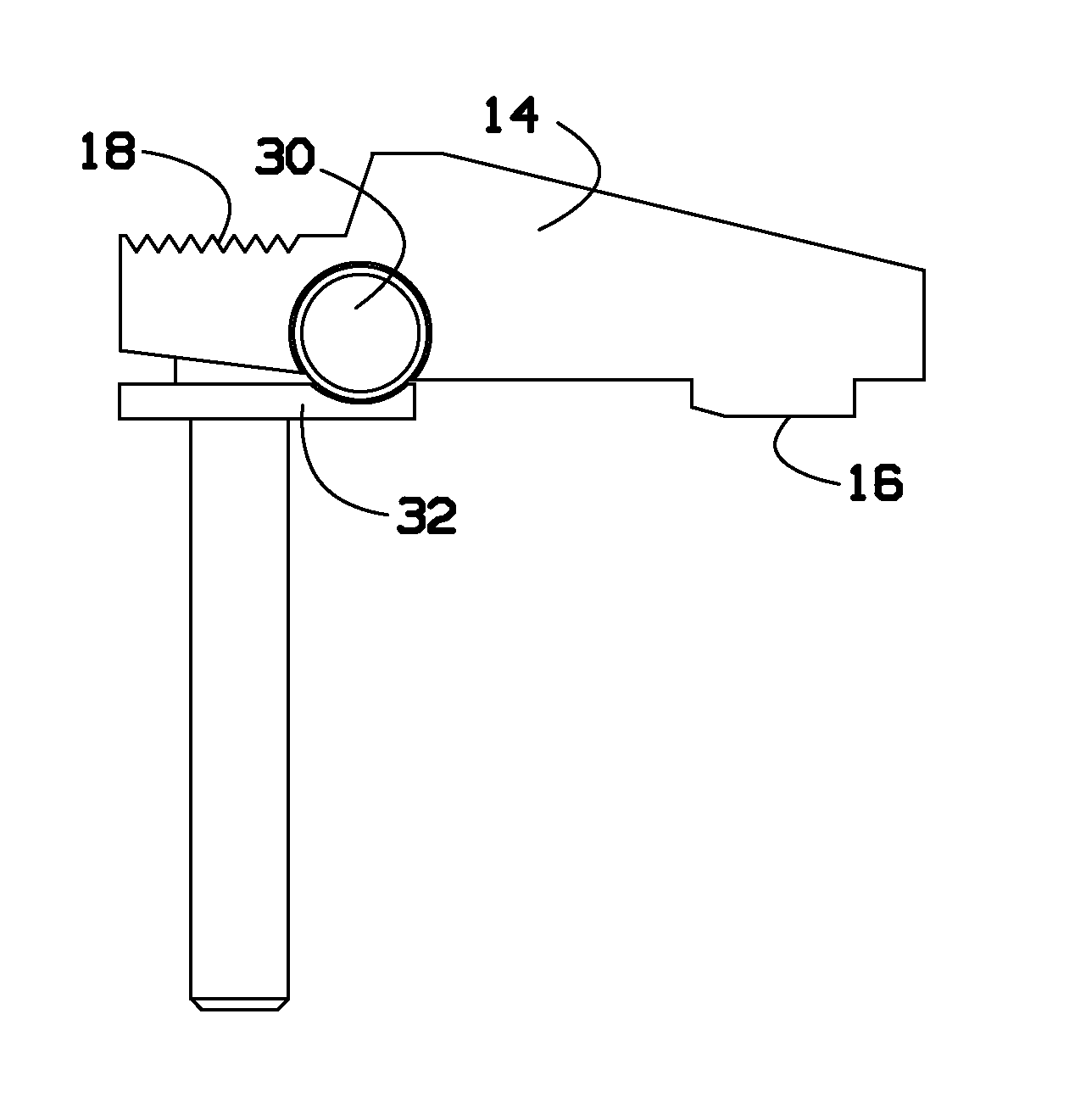

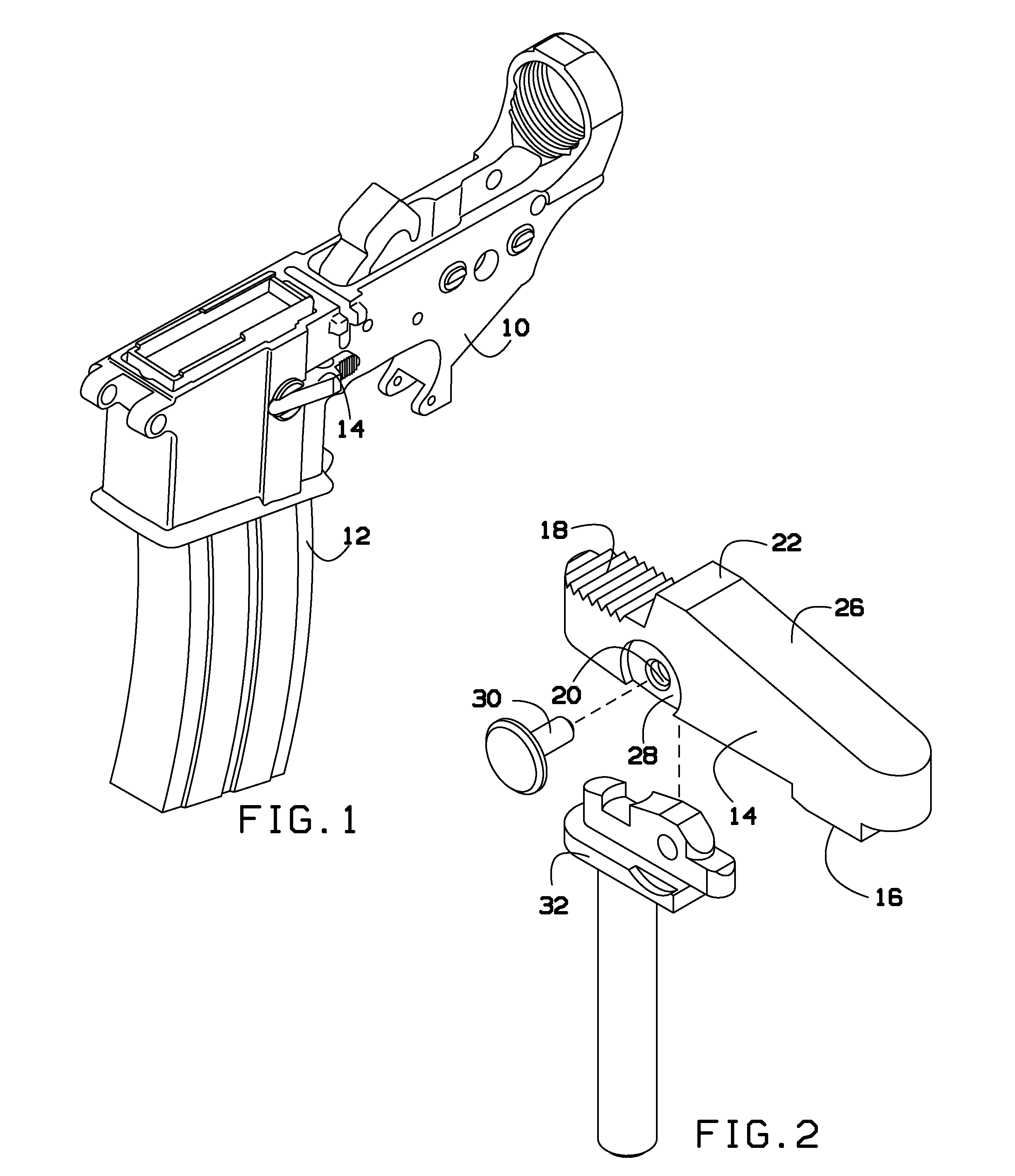

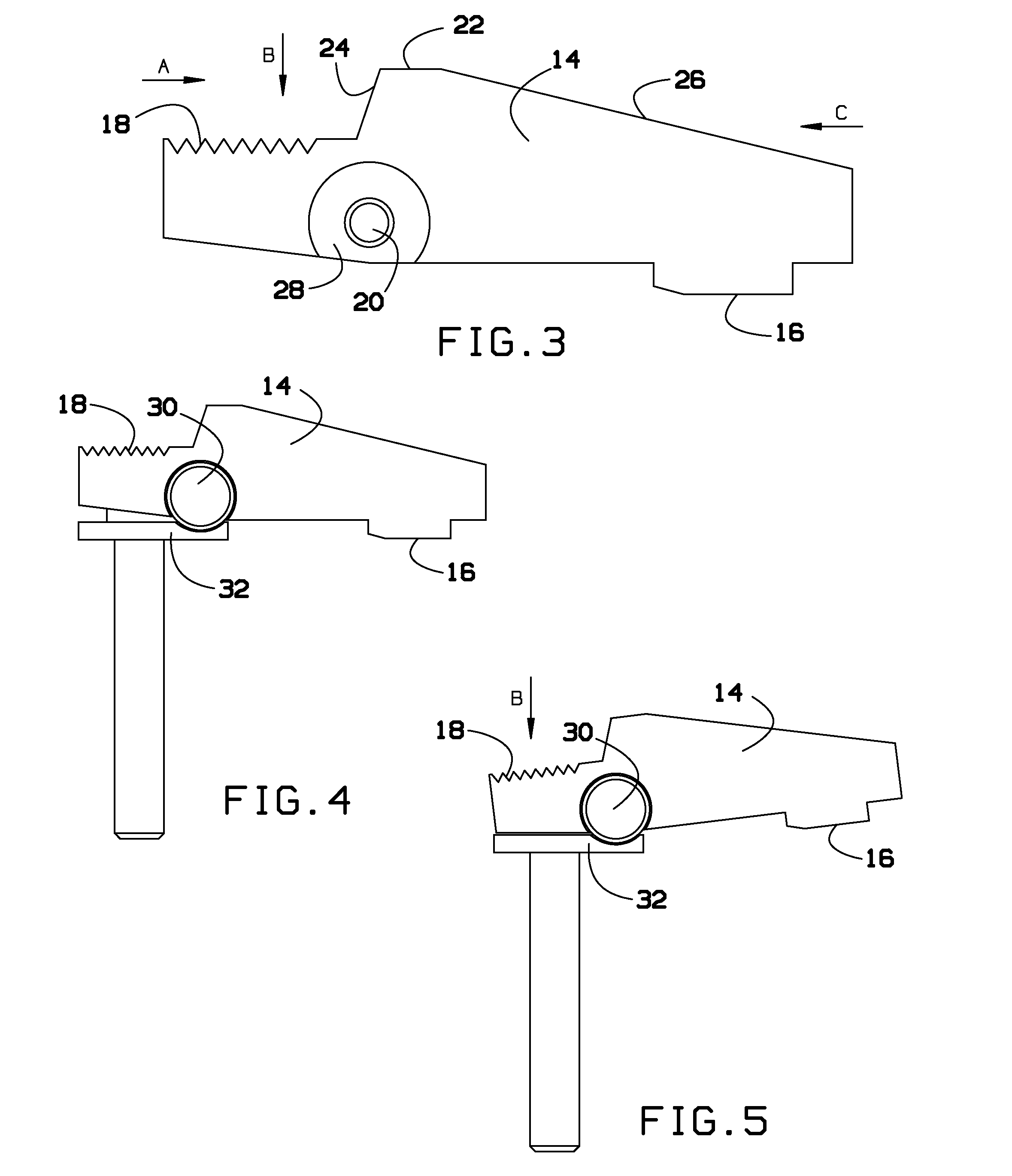

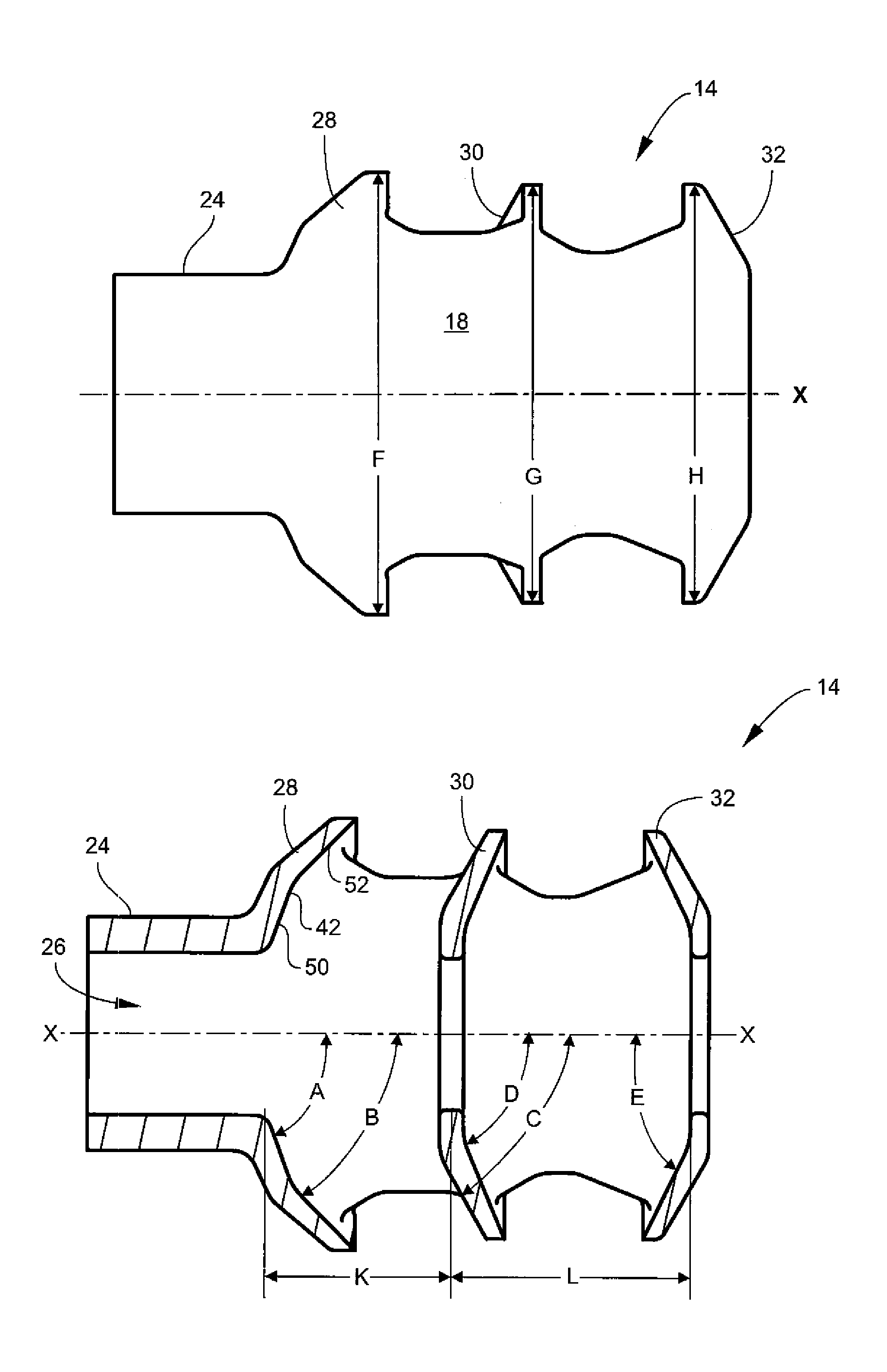

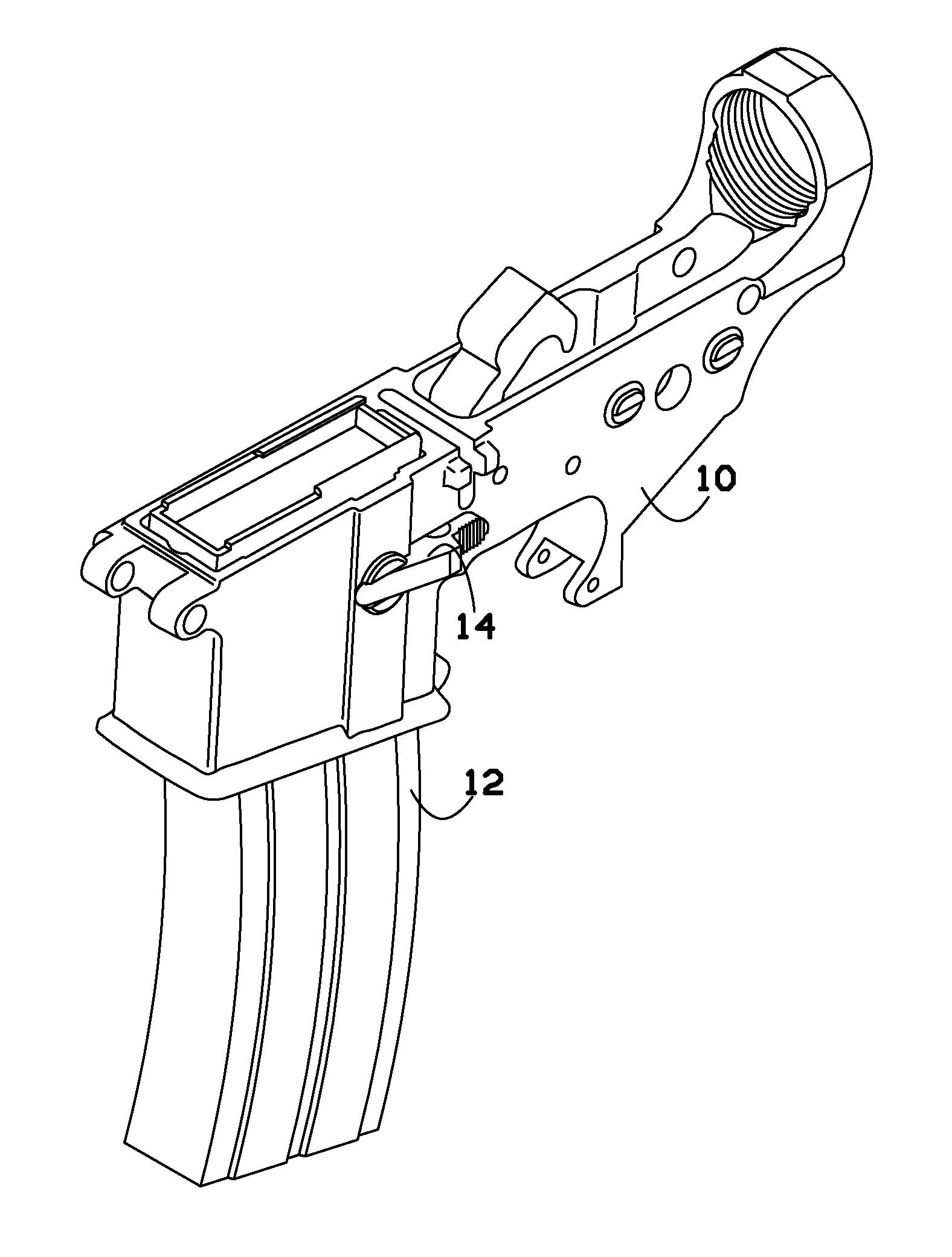

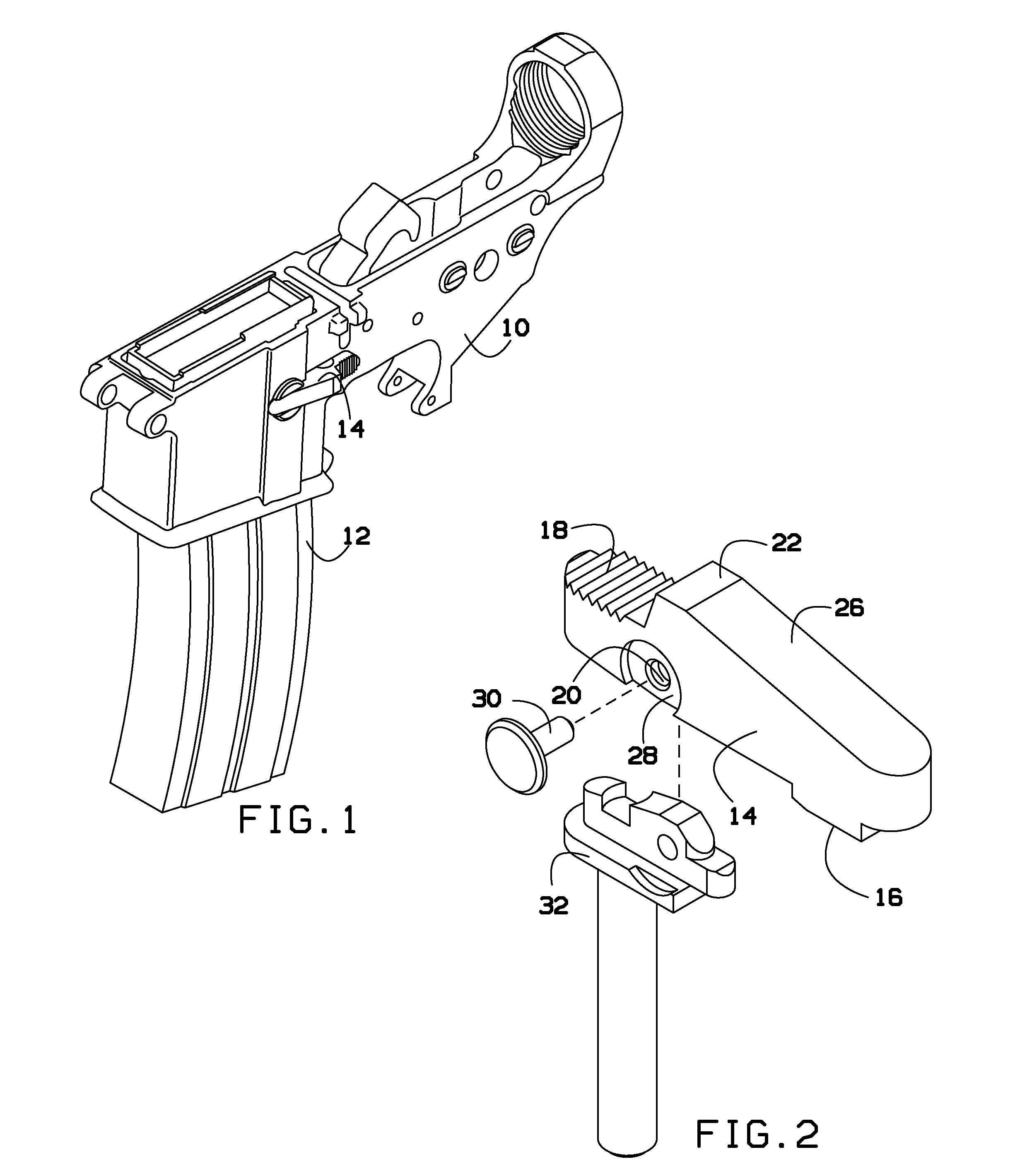

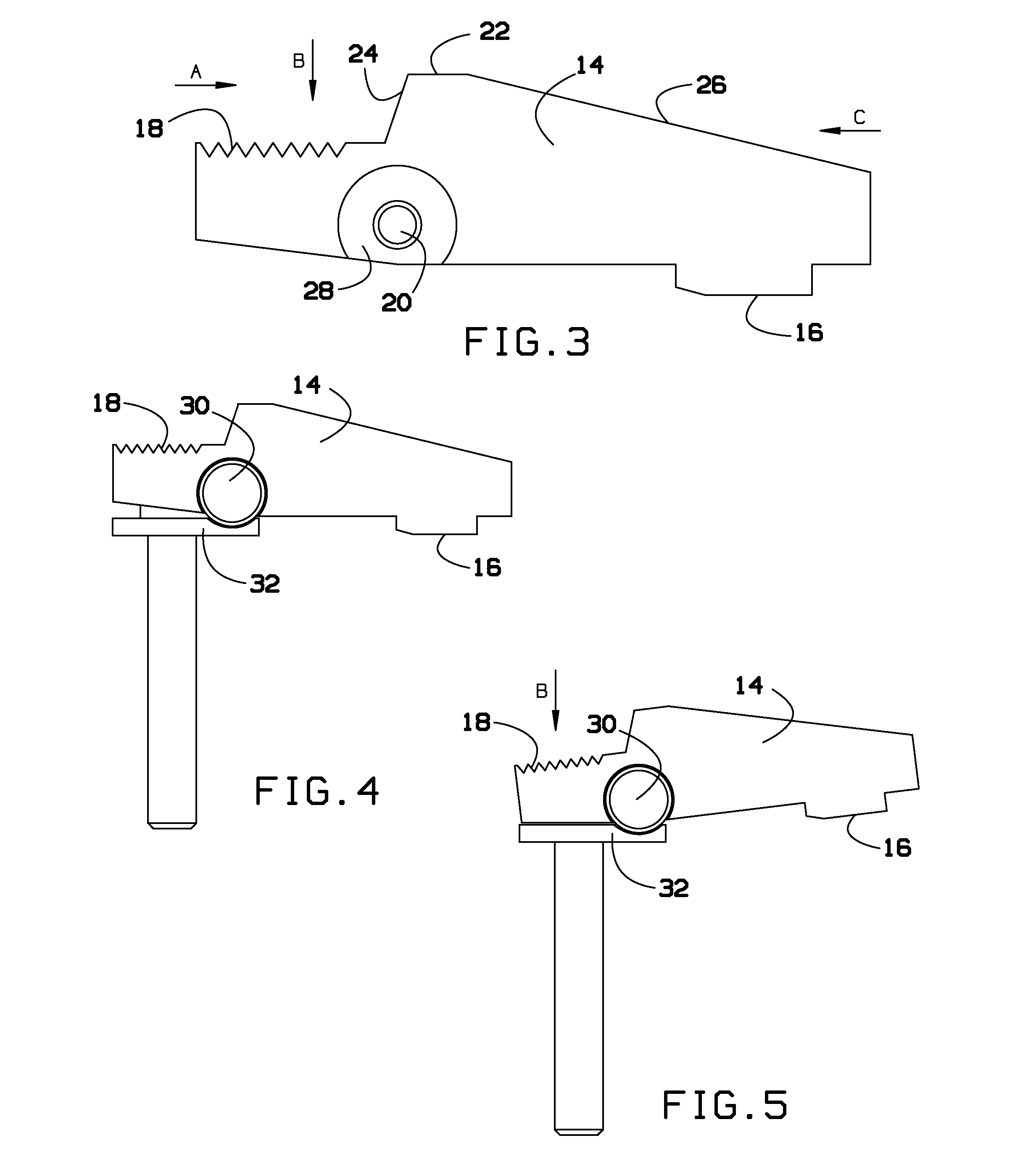

Lever for ambidextrous magazine releases for firearms

A lever protects against inadvertent release of a magazine of a firearm if its ambidextrous release is hit by equipment when the firearm is carried. The lever is made from a projection, above the pivot point, having two opposing angles forward of the depression surface. The projection impacts the equipment before the depression surface is impacted (straight-on impact), which protects the assembly from inadvertent release of the magazine. An impact to the rear angle of the projection (a rear impact) increases the engagement of the lever with the magazine. An impact along the forward angle (from the front or straight-on) of the projection also serves to increase engagement of the lever with the magazine. The lever, with its projection having opposing angles, is specifically designed to protect the lever of an ambidextrous magazine catch from inadvertent release by impact / snag in the field.

Owner:GARRETT ROBERT HUDSON

Low blast overpressure muzzle brake

InactiveUS8424440B1Low BOPAdequate recoil reductionMuzzle attachmentForward angleMechanical engineering

A muzzle brake with reduced blast overpressure may include a body having a top, a bottom, and an attachment hub. Vanes may extend from the top to the bottom. A first vane may be located at a front of the bore in the attachment hub. The first vane may have a forward-angled internal surface. A second vane may be located axially forward of the first vane. The second vane may have a forward-angled rear surface and a forward-angled front surface. A third vane may be located axially forward of the second vane. The third vane may have a rearward-angled rear surface. The forward-angled internal surface of the first vane may include an inner surface adjacent the bore and an outer surface adjacent the inner surface. The inner and outer surfaces may be angled differently with respect to the longitudinal axis.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

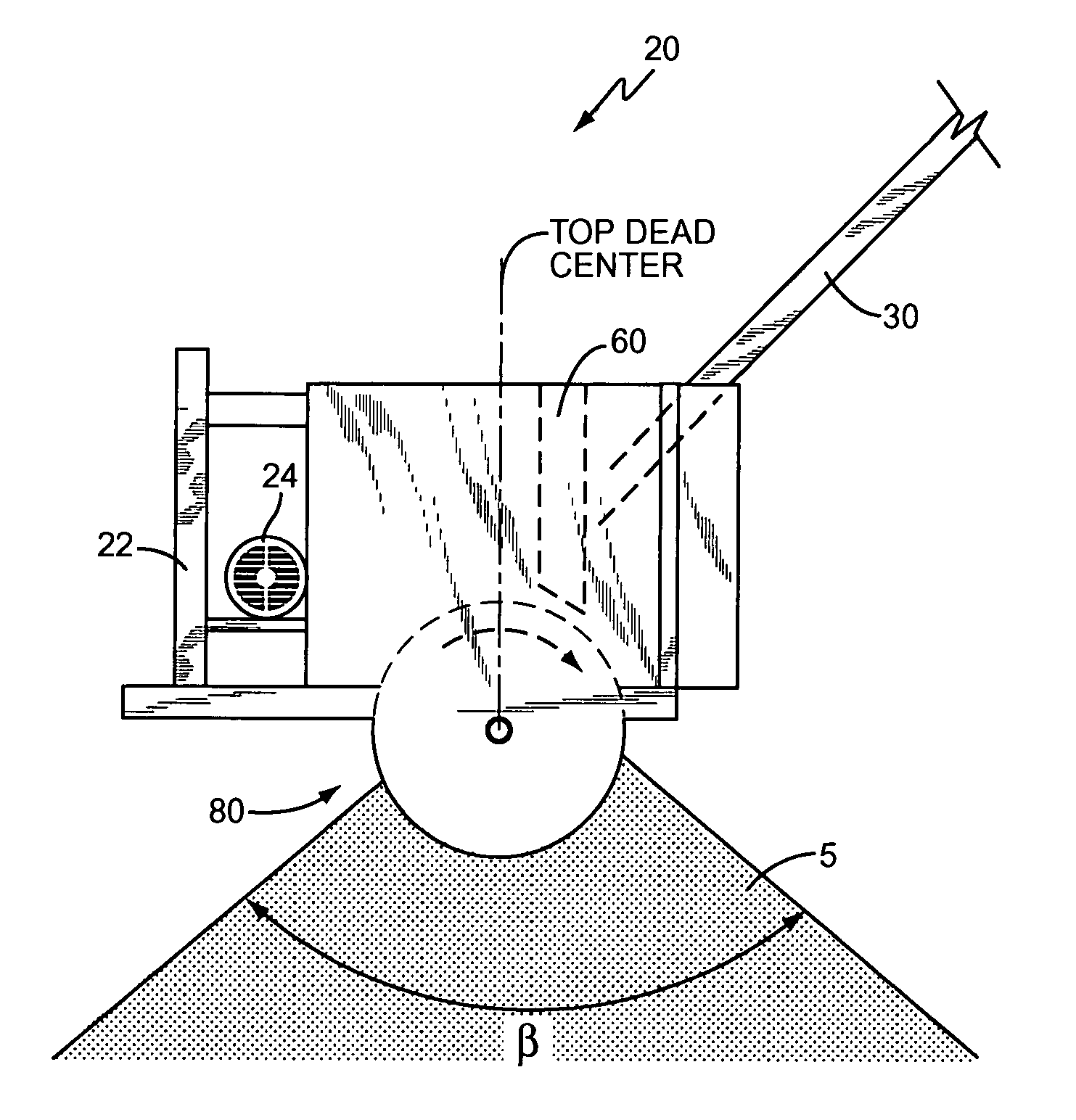

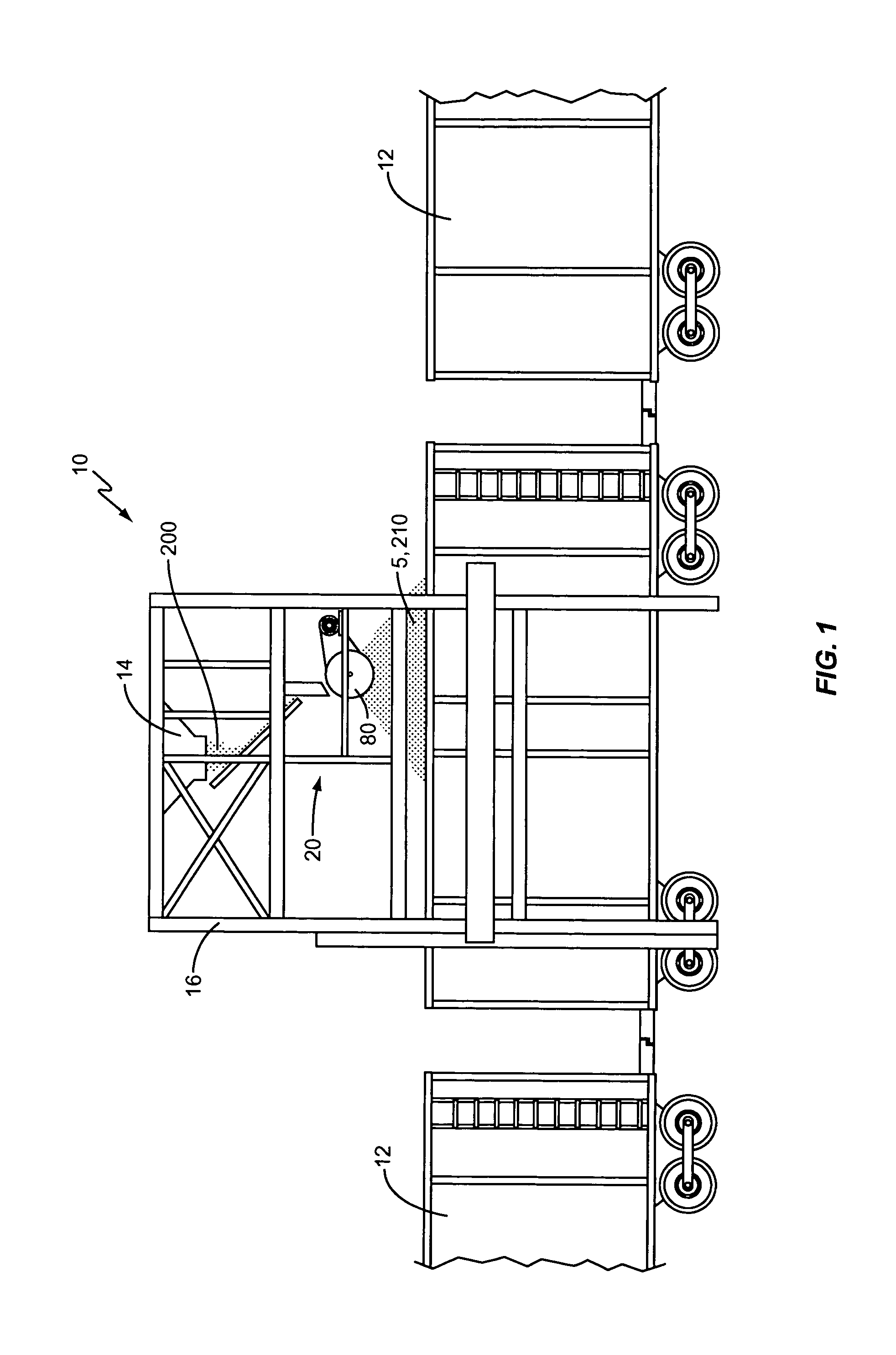

Wood chip flinger and method of densely packing wood chips with large angle output

A handling device packs wood chips with a density greater than that achieved using conventional free-fall techniques by ≧20%-35%. The device includes a drum rotating about a generally horizontal axis that includes a plurality of outwardly extending blades that act to fling the wood chips so as to land with a substantially uniform orientation. The blades may comprise a leading face with at least a first face section that extends in a first direction and at least a second face section extending at a forward angle relative to the first section. The first direction may be generally normal to the drum core's peripheral surface. The output from the drum, when an input stream of wood chips is fed to the drum, covers an arc of at least 90°, typically in the range of 90°-120° and generally downwardly facing, when viewed from the side along the axis.

Owner:BAILEY CONSULTING

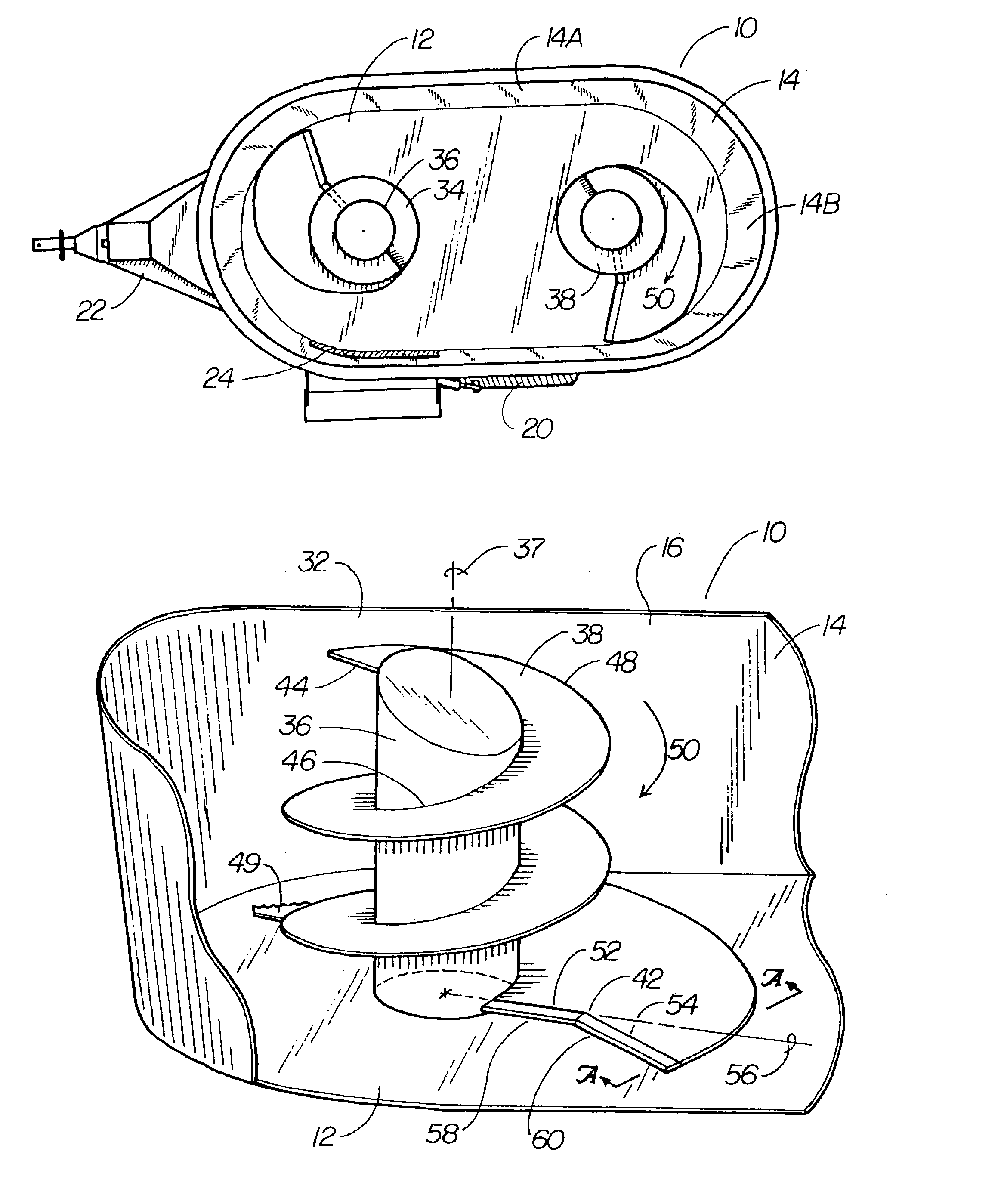

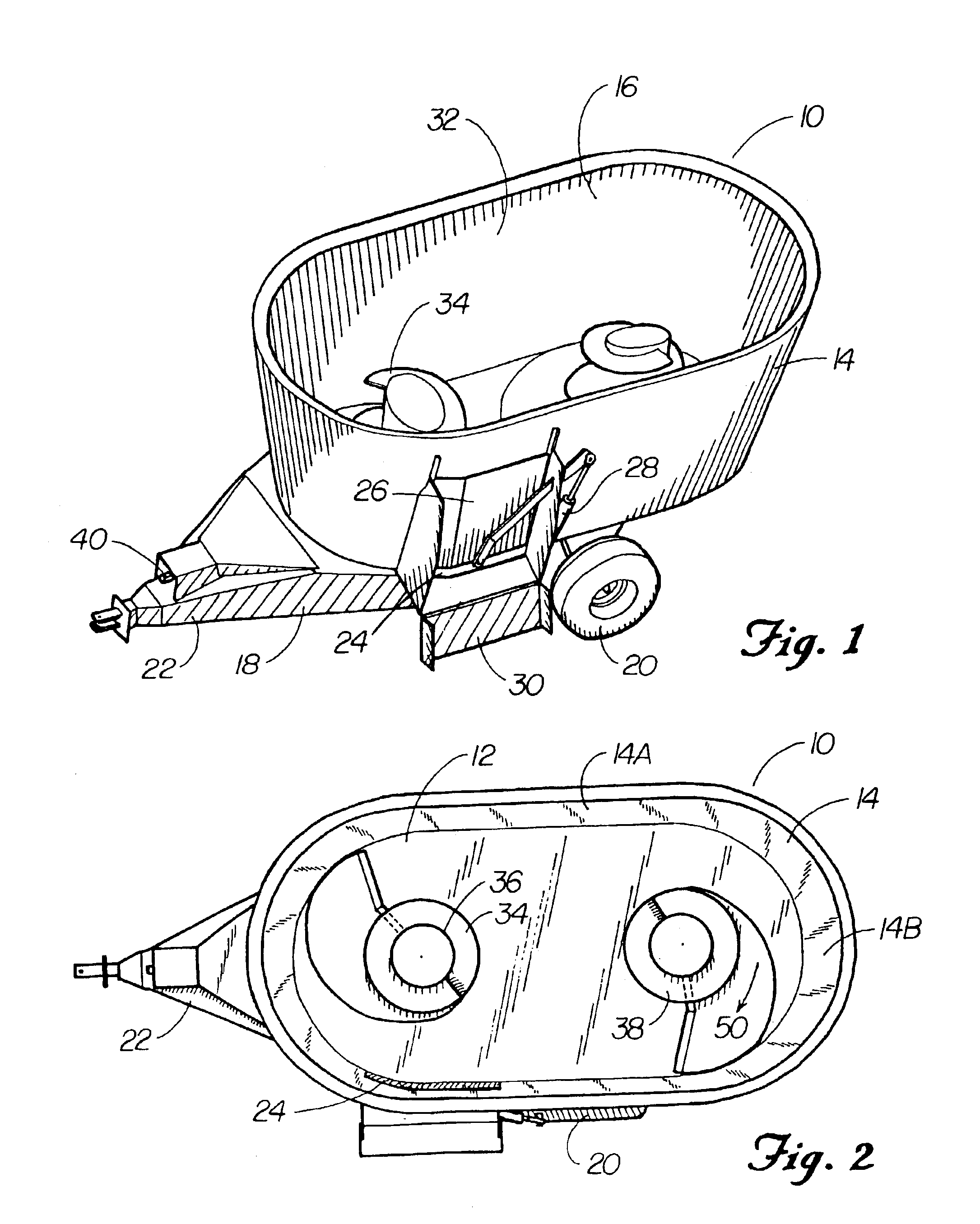

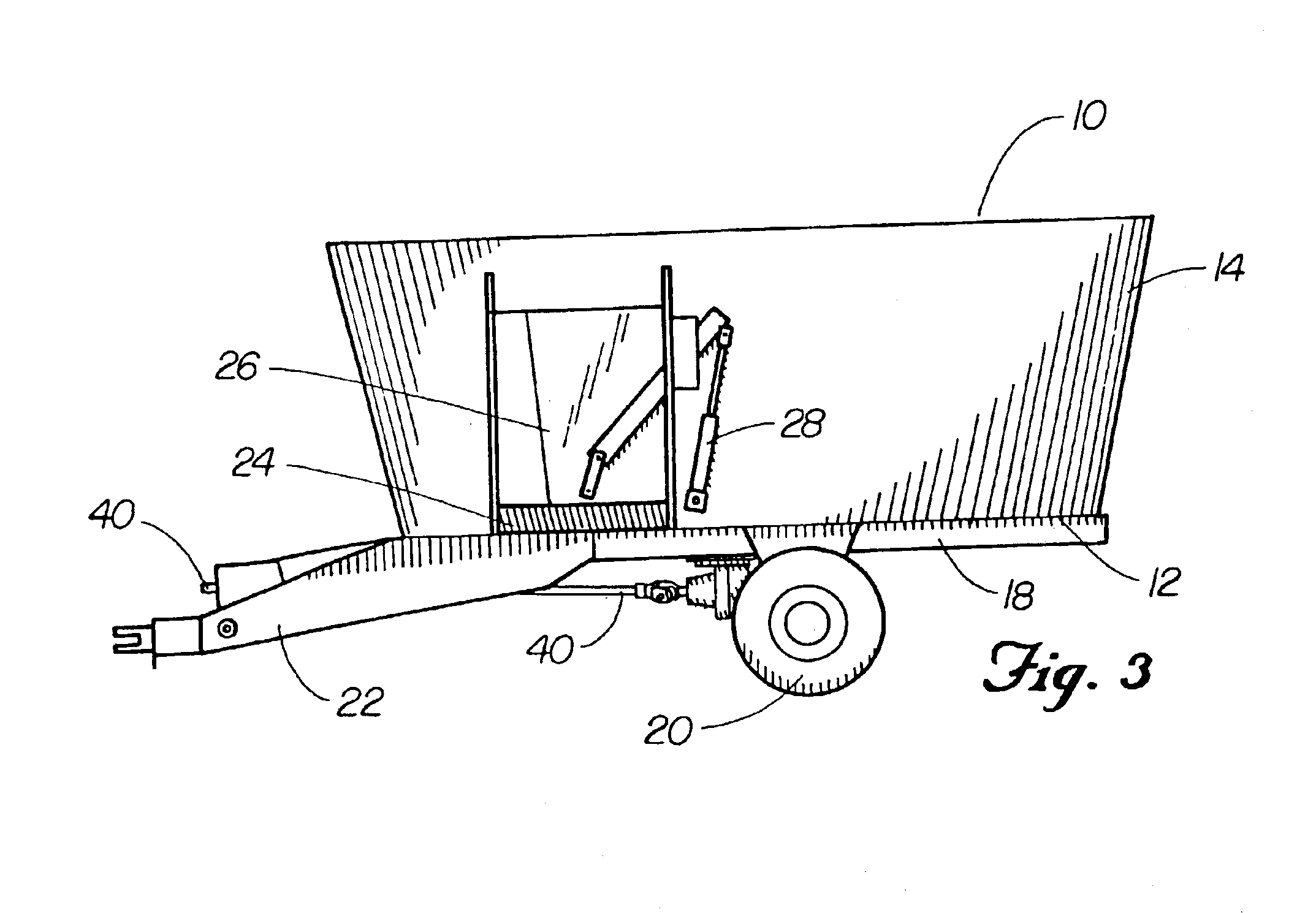

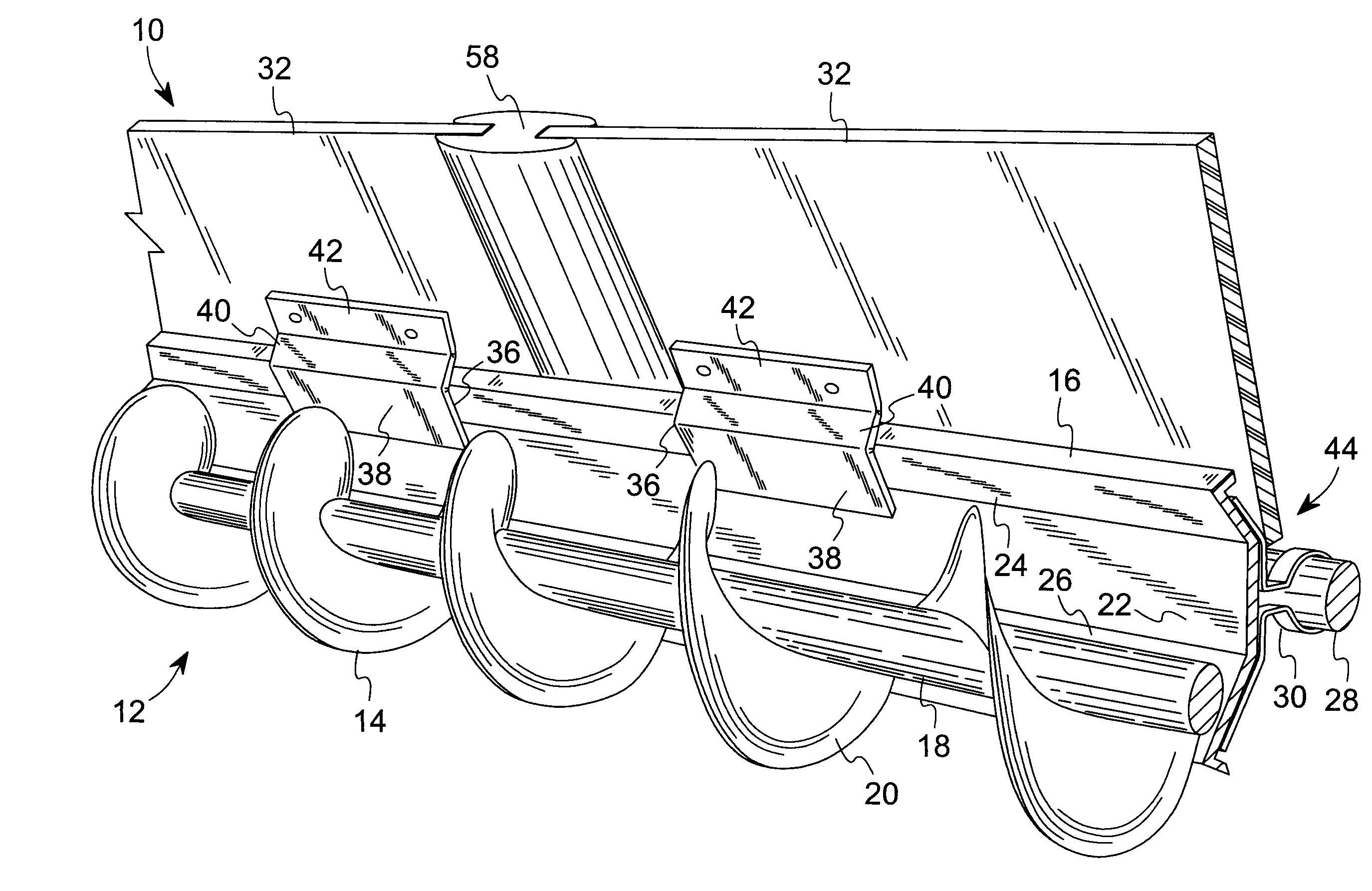

Auger with forward angled leading edge

InactiveUS6863433B2Reduce decreaseImprove productivityGrain huskingGrain polishingLeading edgeForward angle

An auger for vertical mixers includes a forward angled leading edge. The leading edge includes an inner portion, which may or may not be aligned with a radial line extending from the axis of rotation of the auger. The leading edge also includes an outer portion adjacent to the inner portion, which is angled forward of the radial line and extends forward of the inner portion.

Owner:KUHN KNIGHT

Lever for ambidextrous magazine releases for firearms

A lever protects against inadvertent release of a magazine of a firearm if its ambidextrous release is hit by equipment when the firearm is carried. The lever is made from a projection, above the pivot point, having two opposing angles forward of the depression surface. The projection impacts the equipment before the depression surface is impacted (straight-on impact), which protects the assembly from inadvertent release of the magazine. An impact to the rear angle of the projection (a rear impact) increases the engagement of the lever with the magazine. An impact along the forward angle (from the front or straight-on) of the projection also serves to increase engagement of the lever with the magazine. The lever, with its projection having opposing angles, is specifically designed to protect the lever of an ambidextrous magazine catch from inadvertent release by impact / snag in the field.

Owner:GARRETT ROBERT HUDSON

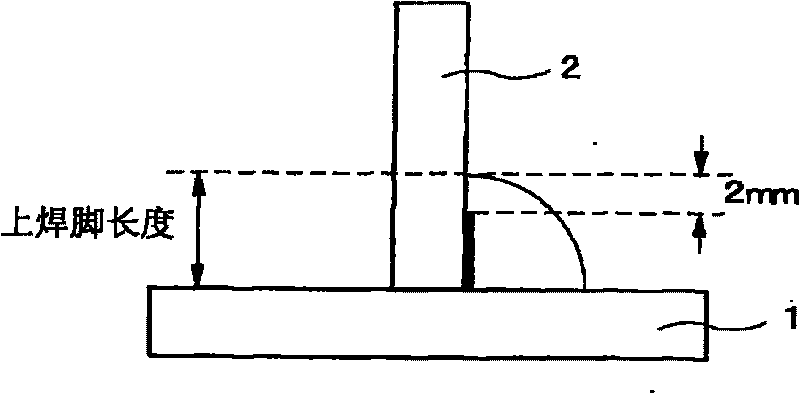

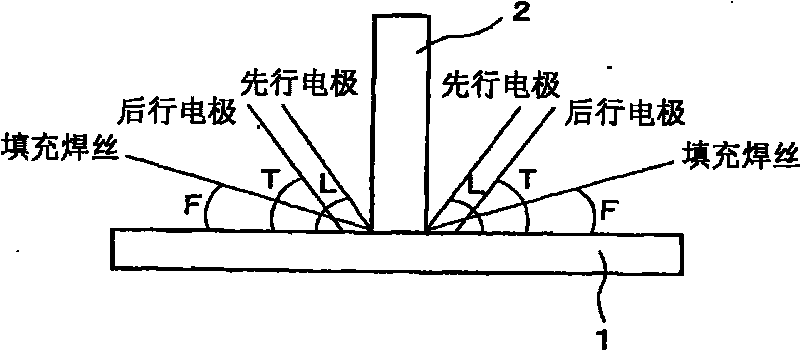

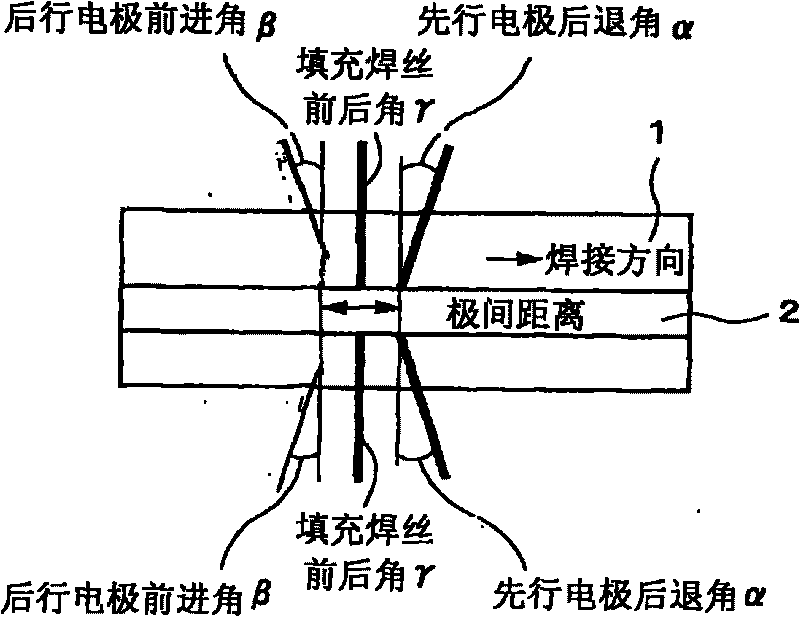

Multielectrode gas-shielded arc welding method

The present application relates to a multielectrode gas-shielded arc welding method in which a filler wire is inserted between leading and trailing electrodes, a distance between the electrodes is 20 to 30 mm. Variables L, T, F, X, Y, alpha, beta, gamma and satisfy the following expressions: 40 DEG <= L<= 60 DEG, 40 DEG <= T <= 60 DEG, X + 5 DEG <= F <= X + 20 DEG or Y - 20 DEG <= F <= Y - 5 DEG, 4 DEG <= alpha <= 14 DEG, 5 DEG <= beta <= 15 DEG, - 5 DEG <= gamma <= 5 DEG, where X represents the larger one of a leading-electrode horizontal angle L and a trailing-electrode horizontal angle T, Y represents the smaller one of the angles, F represents a filler-wire torch angle, alpha represents a leading-electrode backward angle, beta represents a trailing-electrode forward angle, gamma represents a filler-wire torch forward or backward angle. A target position of the filler wire is within a range between a lower end of the vertical plate and a position at a height of (upper leg length - 2 mm) from the lower end. According to the method, the shape of the welding bead can be remarkably improved, the arc noise between the leading and trailing electrodes can be reduced, and the equipment is easy.

Owner:KOBE STEEL LTD

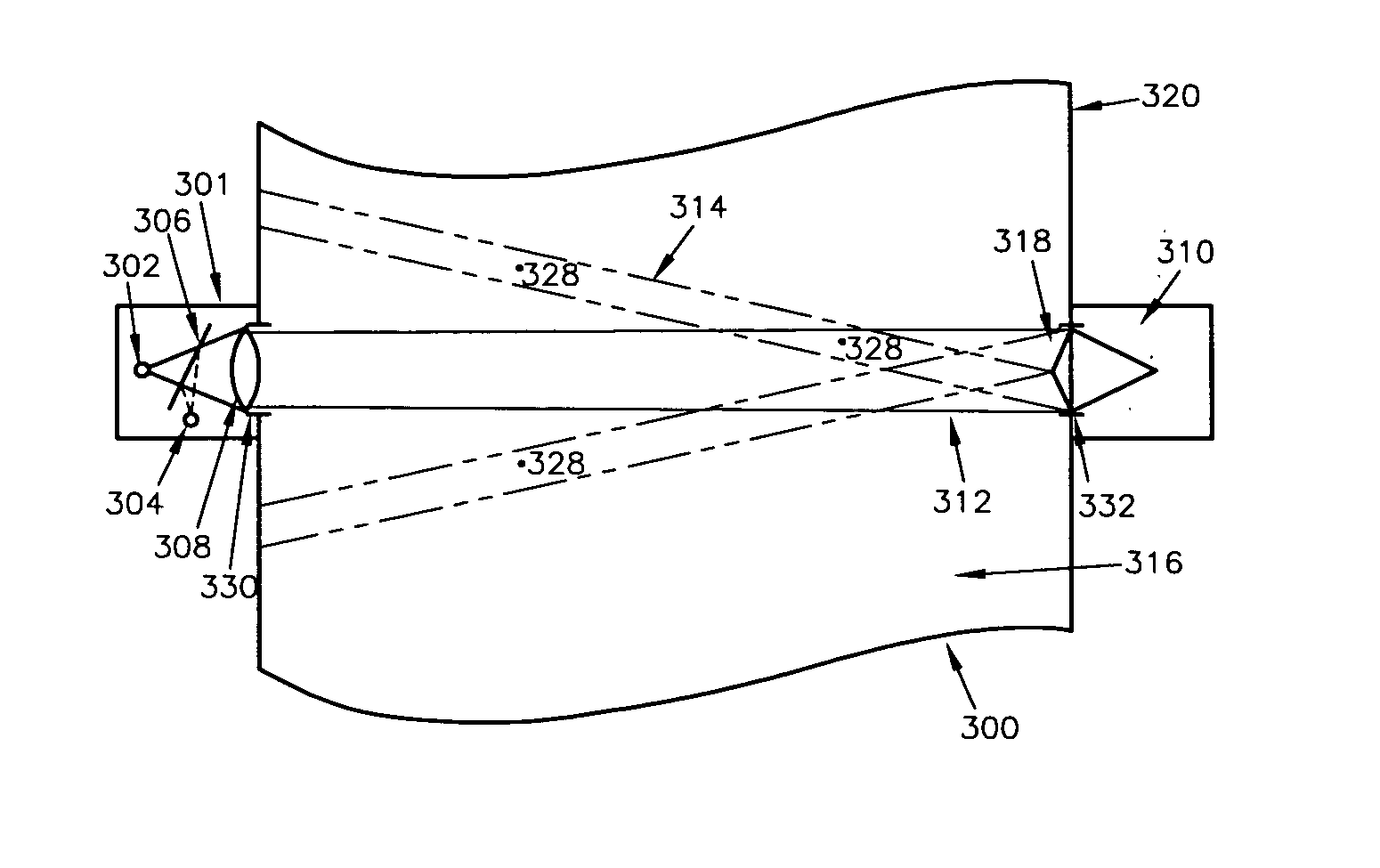

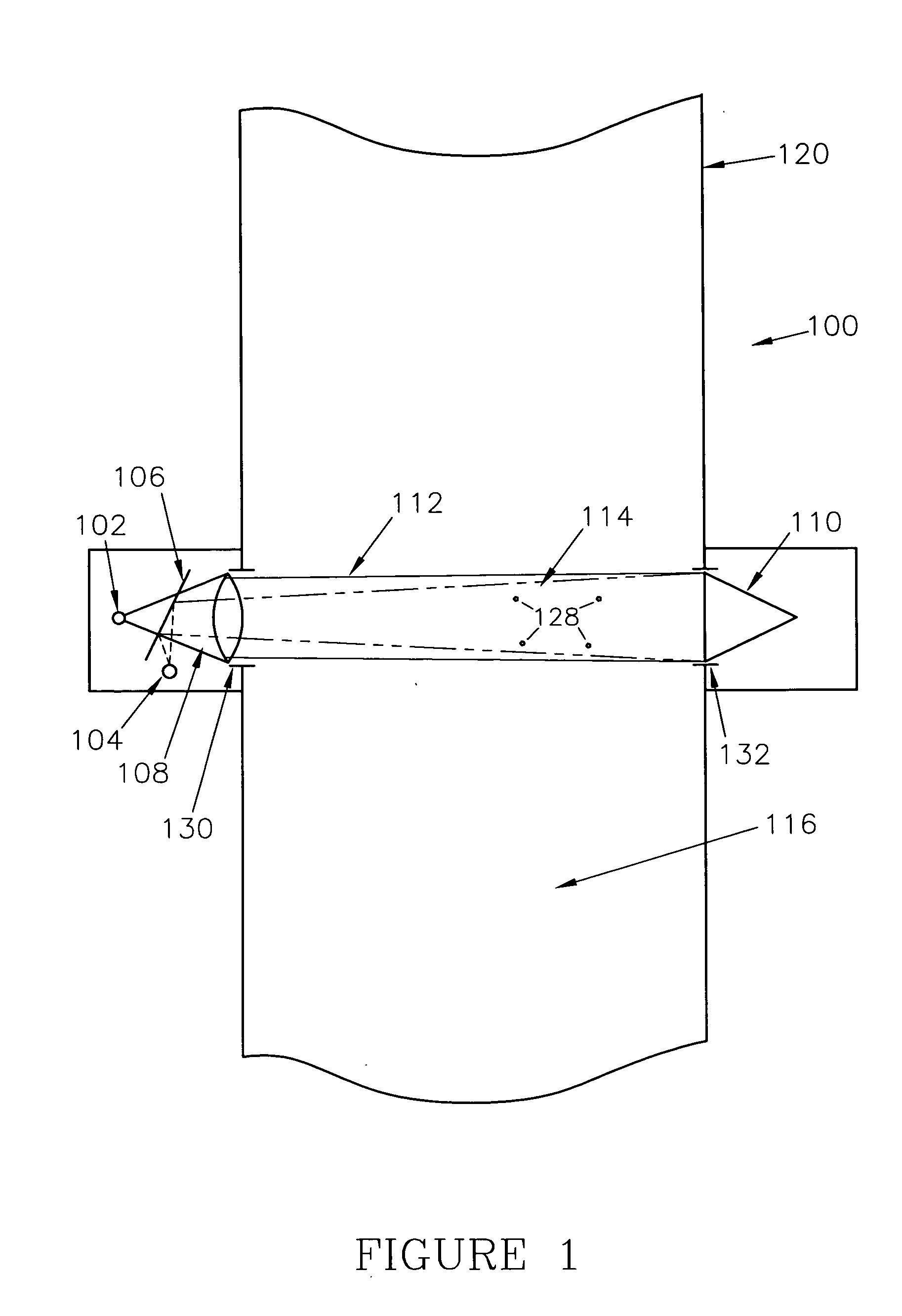

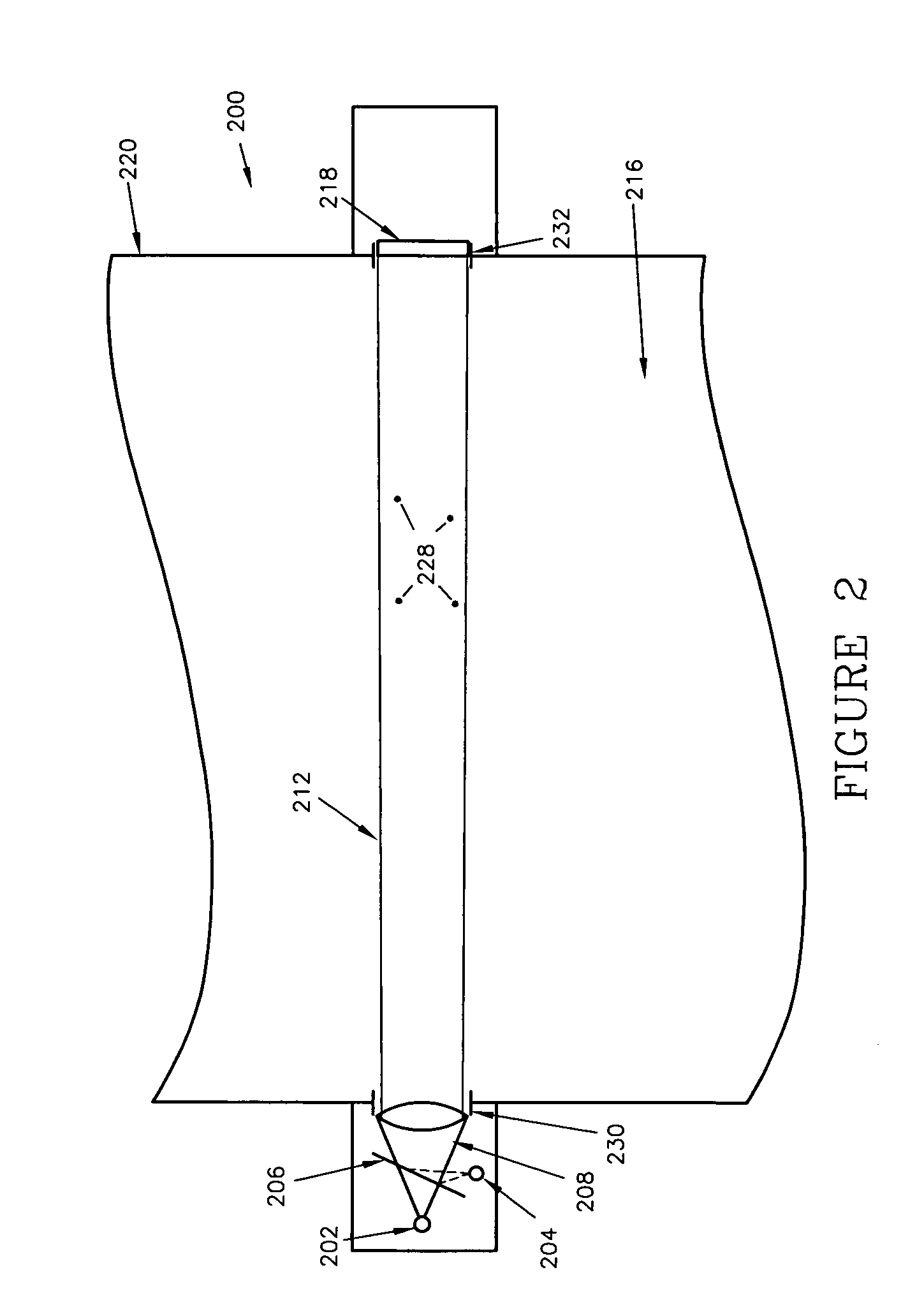

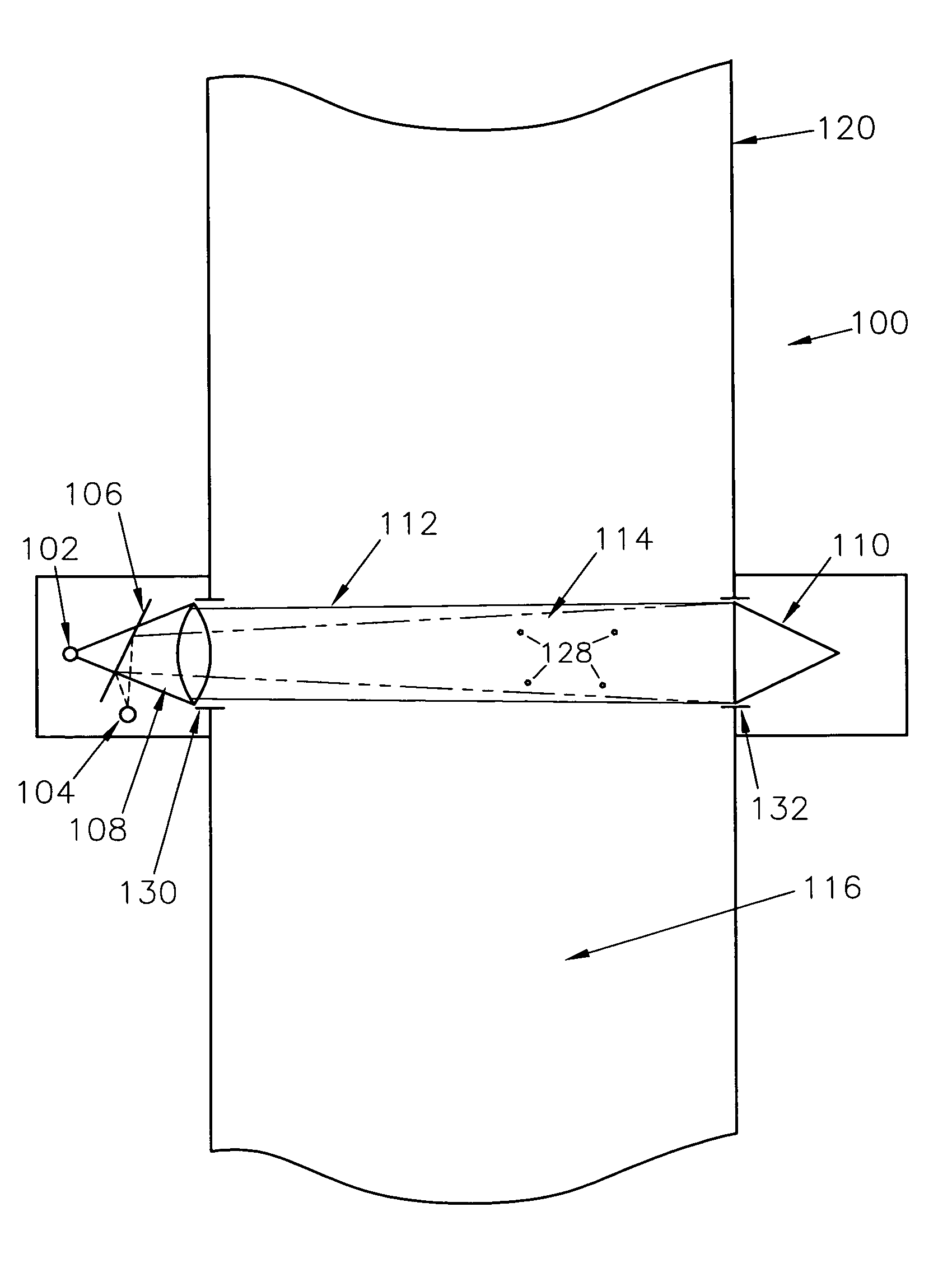

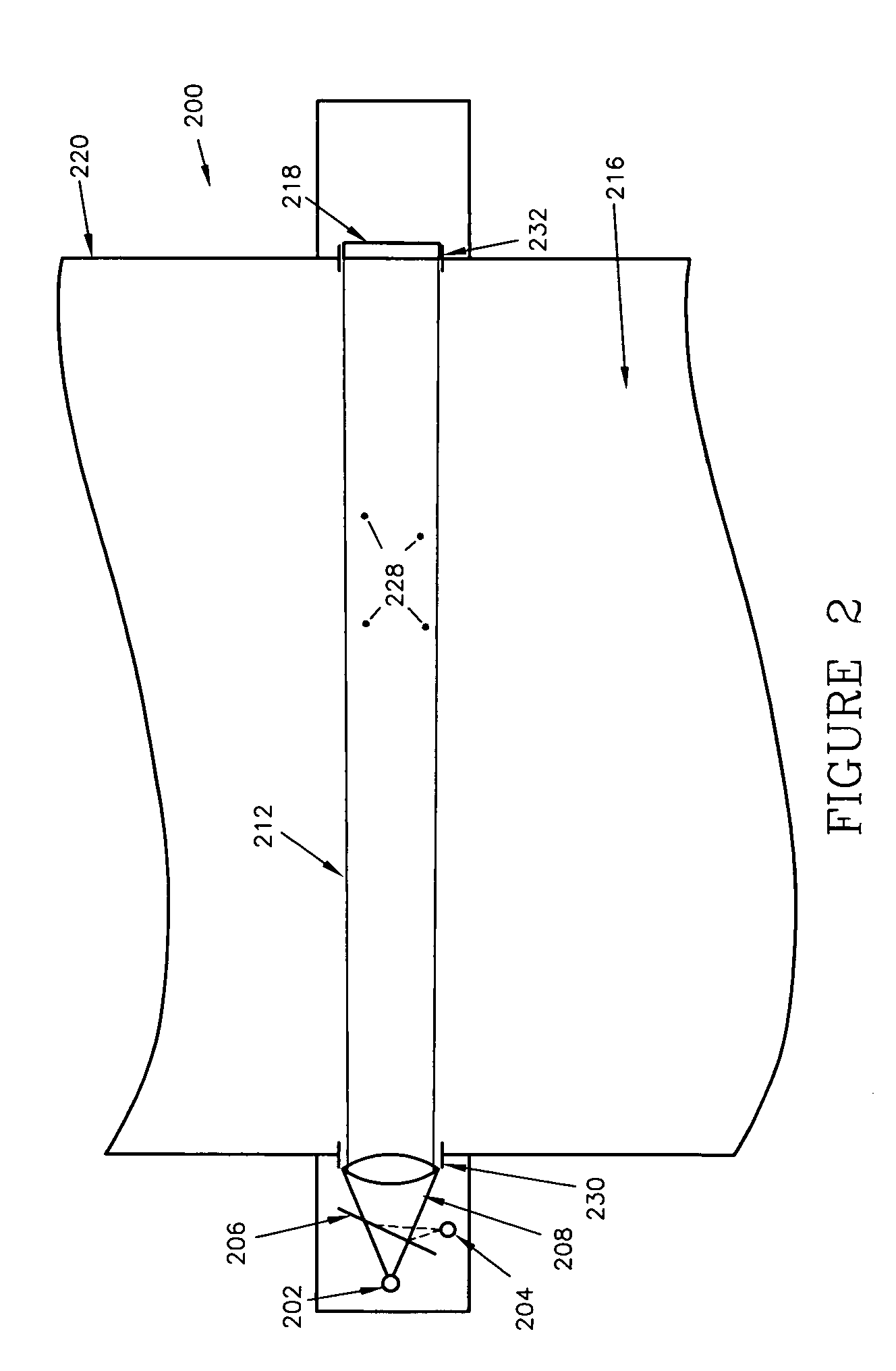

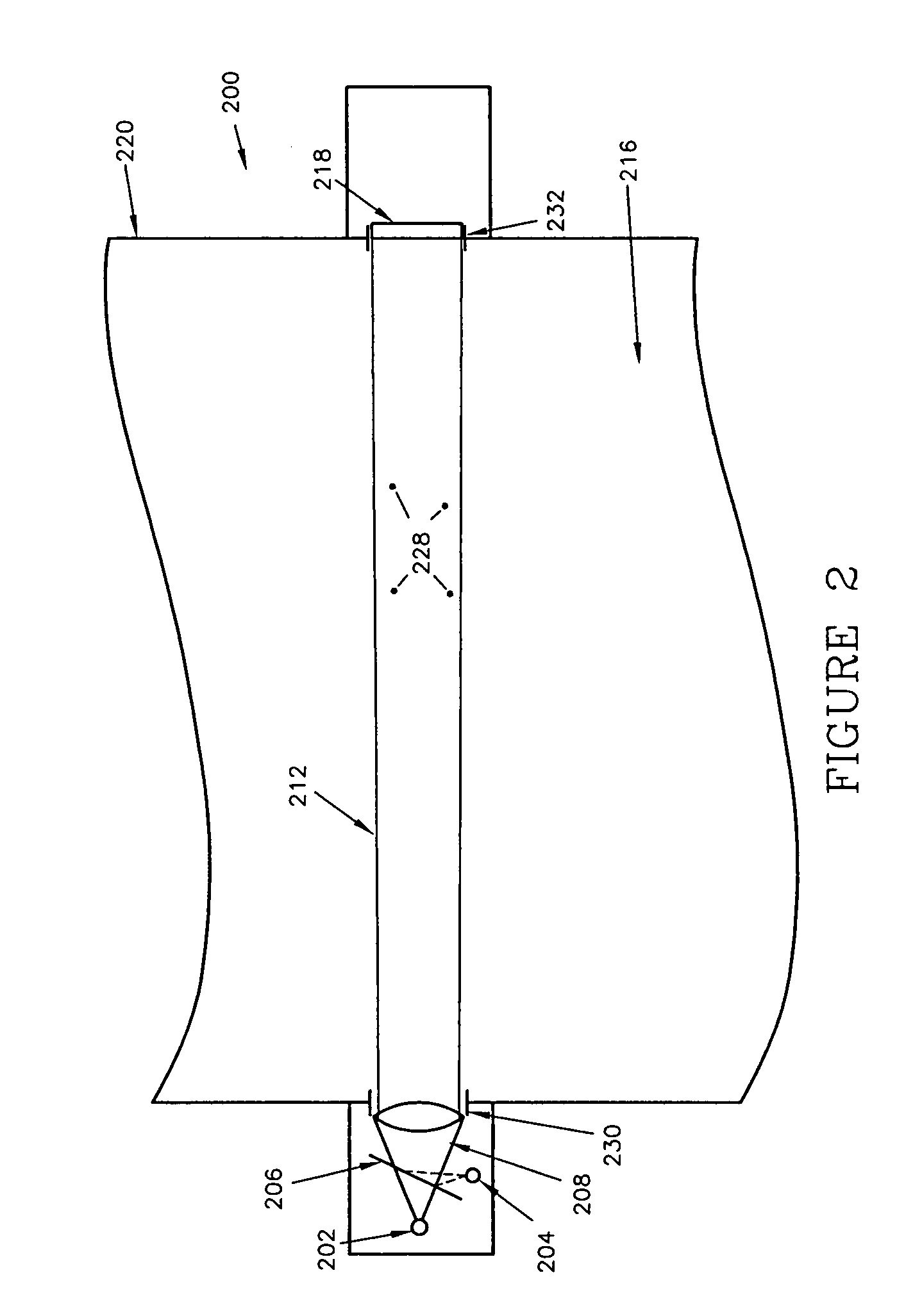

Measuring particulate matter in a fluid

ActiveUS20050264809A1Accurately propertyScattering properties measurementsBundled fibre light guideForward scatterParticulates

A device for measuring near forward scatter caused by particulate matter in a fluid is disclosed. The device comprises, according to various embodiments, a transceiver and a reflector. The transceiver includes a light source and a detector. The reflector is positioned opposite the transceiver so that at least a portion of the fluid is present between the transceiver and the reflector. The reflector includes a front portion facing the transceiver. Optical energy from the light source incident upon the reflector is reflected towards the transceiver as a return beam of optical energy, wherein the detector senses primarily optical energy of the return beam that is scattered over a range of near forward angles by particulate matter in the fluid.

Owner:TELEDYNE

Avalanche preventative shield for sweep auger

InactiveUS7857120B1Improve efficiencyEasy to operatePackagingStorage devicesEngineeringForward angle

A deflector panel or series of such panels are temporarily attached above the containment plate of a grain sweep auger to redirect potentially avalanching grain forward to the auger blade. A front side hook structure holds a predetermined portion of the deflector panel over the top of the containment plate at a forward angle. A rear side clamp on a sliding junction secures the forward angle and adapts the shield to fit auger assemblies with differing distance relationships between the containment plate and stiffening tube. A longitudinal series of deflector panels with interpanel gaps are attached to a sweep auger assembly along the length of the containment plate. A gap-filling bracket closes the gaps and supports the panels in longitudinal alignment.

Owner:PERRING DAVE A +1

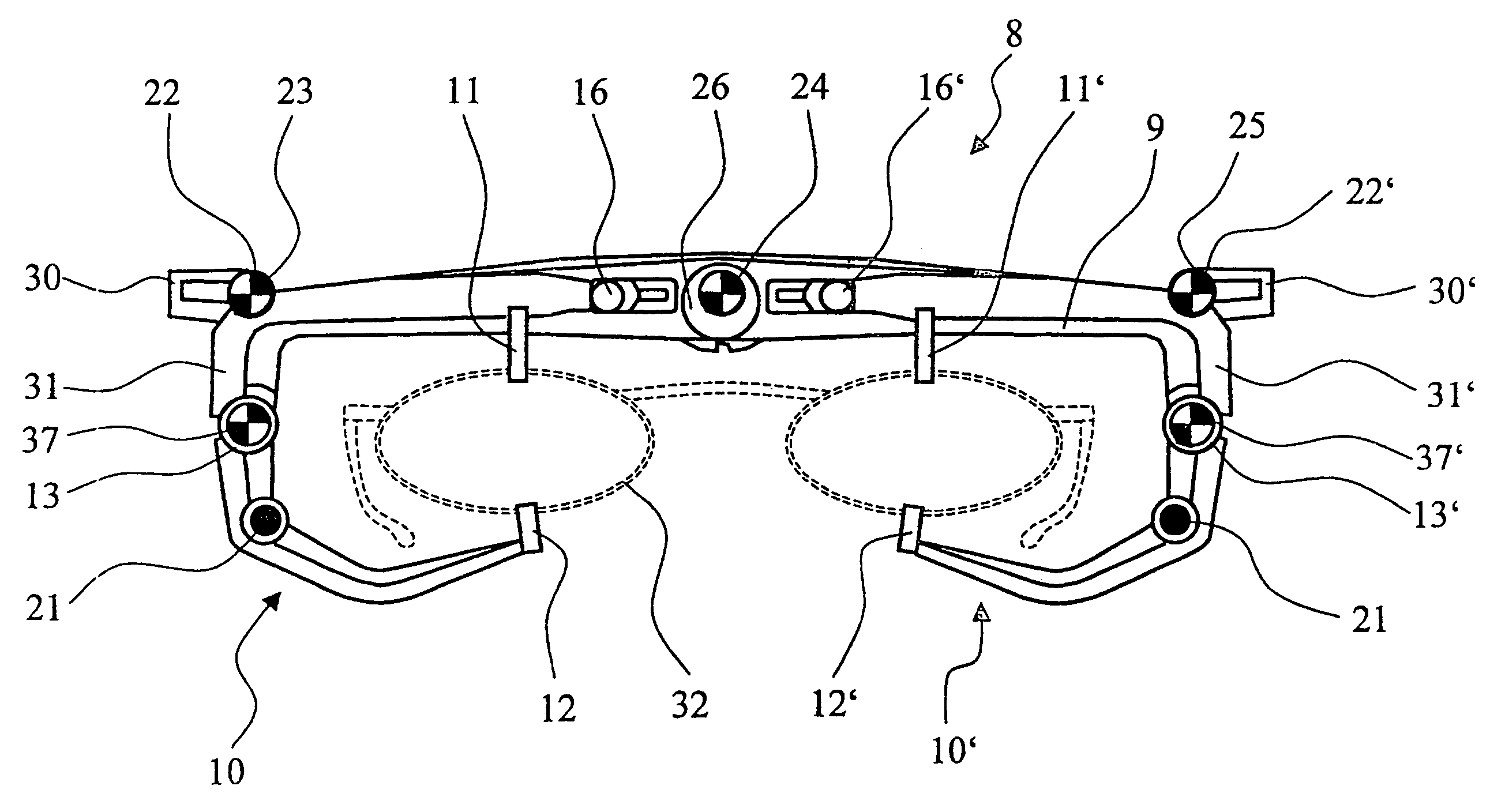

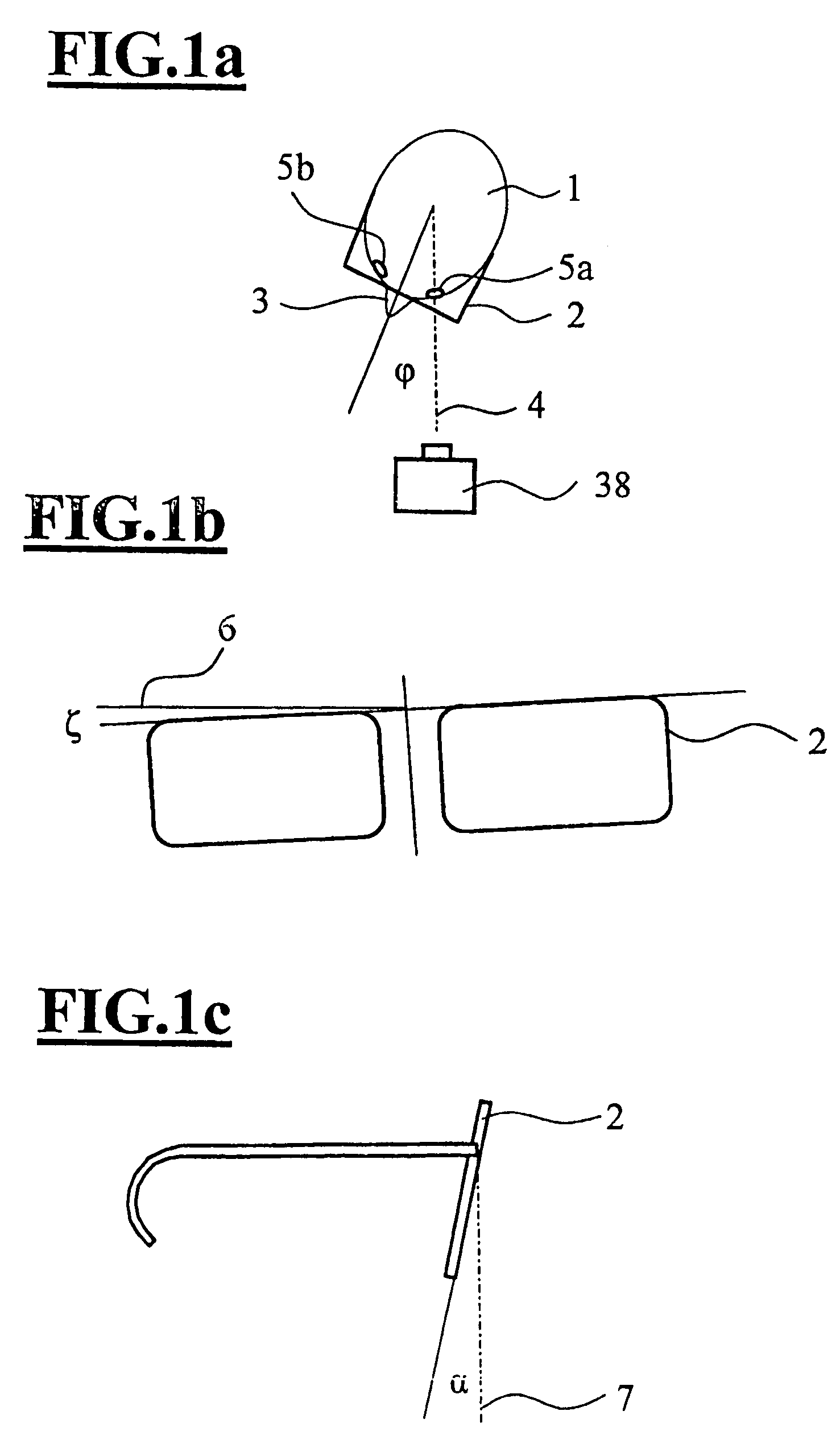

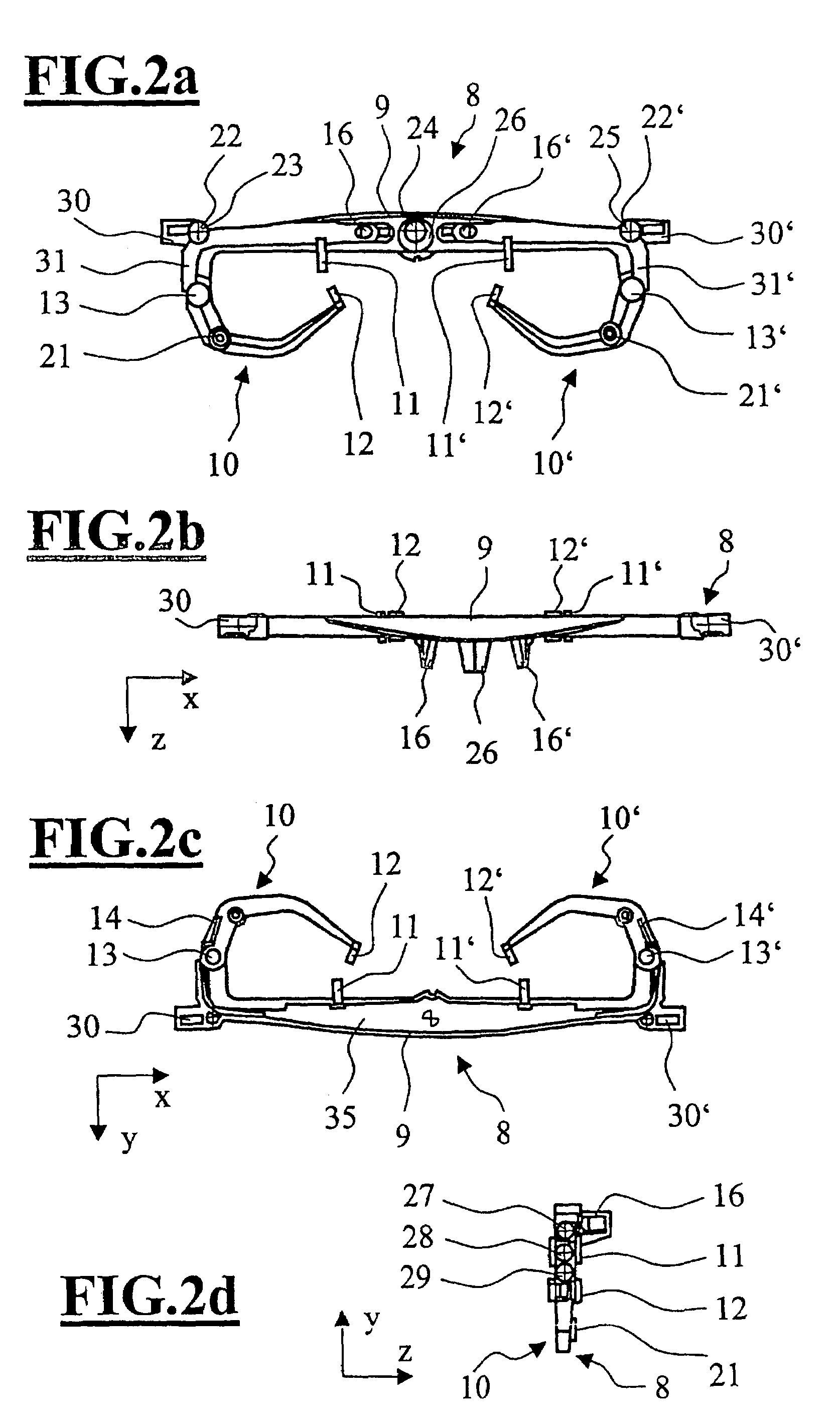

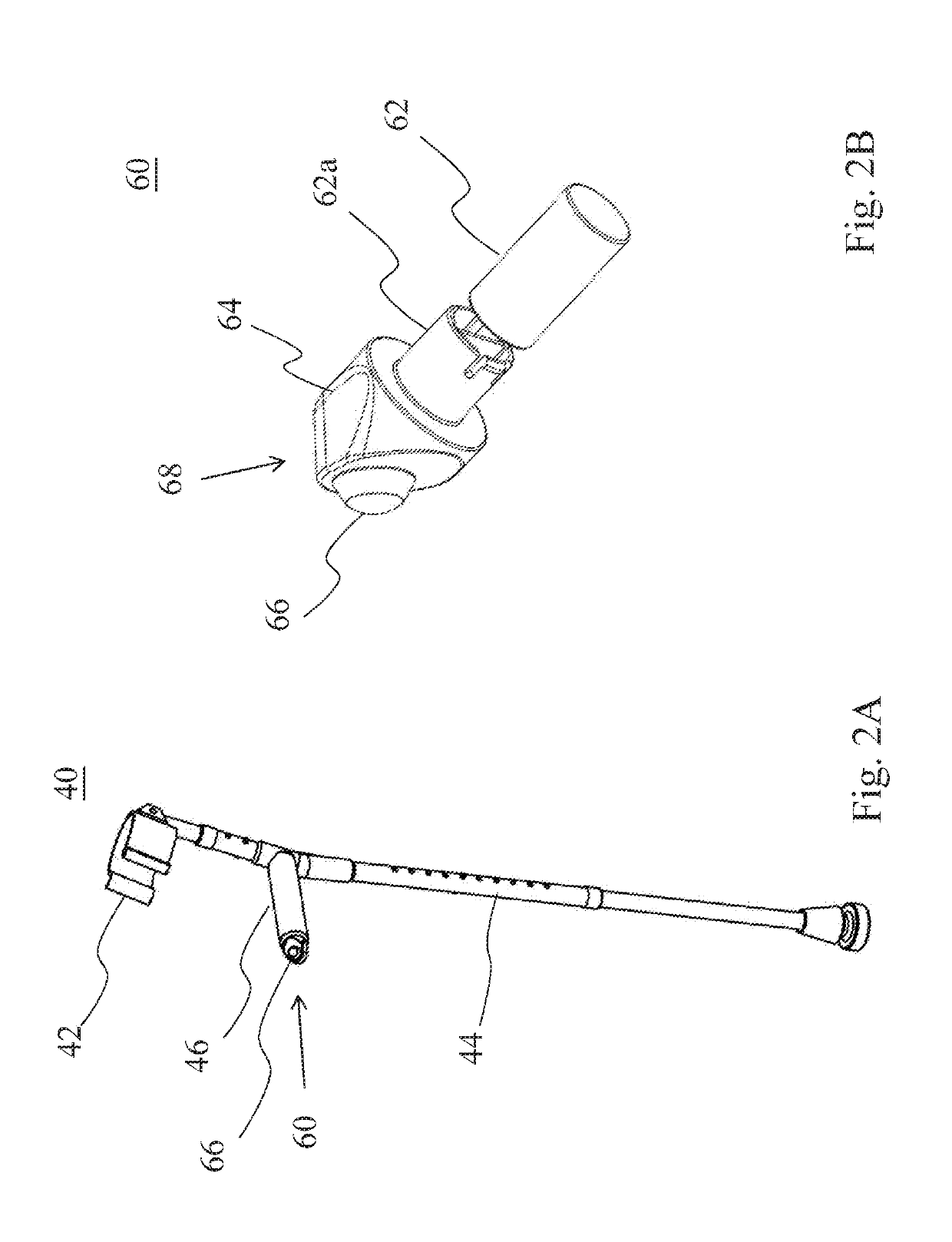

Measuring brace and arrangement and method for determining the forward angle of inclination of a spectacle frame

Owner:CARL ZEISS VISION INT GMBH

Measuring particulate matter in a fluid

ActiveUS7224455B2Accurately propertyScattering properties measurementsBundled fibre light guideParticulatesForward scatter

A device for measuring near forward scatter caused by particulate matter in a fluid is disclosed. The device comprises, according to various embodiments, a transceiver and a reflector. The transceiver includes a light source and a detector. The reflector is positioned opposite the transceiver so that at least a portion of the fluid is present between the transceiver and the reflector. The reflector includes a front portion facing the transceiver. Optical energy from the light source incident upon the reflector is reflected towards the transceiver as a return beam of optical energy, wherein the detector senses primarily optical energy of the return beam that is scattered over a range of near forward angles by particulate matter in the fluid.

Owner:TELEDYNE

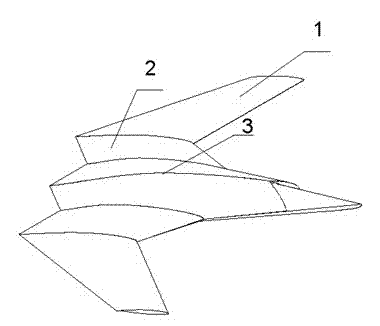

Aerodynamic configuration of aircraft

InactiveCN102826216AMeet the requirements of high subsonic cruiseFlying fastWing shapesJet aeroplaneConfiguration design

The invention relates to the technical field of aerodynamic configuration design of aircrafts, in particular to an aerodynamic configuration of an aircraft. The aerodynamic configuration of the aircraft comprises an aircraft body (3), outer wing sections (1) and inner wing sections, and is characterized in that the surfaces of the outer wing sections (1) and the inner wing sections (2) are laminar flow airfoils; the inner wing sections (2) are wing-body transition sections, adopt back-swept wings with a moderate sweep back angle and a small span-chord ratio and are connected with the aircraft body; the wings and the aircraft body are fused together; and the outer wing sections (1) adopt forward-swept wings with a moderate sweep forward angle and a moderate span-chord ratio. Due to the aerodynamic configuration of the aircraft, not only can the requirement on high-altitude long-endurance high-subsonic-speed cruise of the aircraft be satisfied, but also the flight speed is improved and the problem of trimming difficulty is solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

Radar analog data merging method for navigation simulator simulation

ActiveCN104156527AGuaranteed accuracyReduce data volumeSpecial data processing applicationsRadarForward angle

The invention discloses a radar analog data merging method for navigation simulator simulation. The method comprises the following steps that nautical charts with different measuring scales are screened according to navigation purposes of the nautical charts and the distances between the nautical charts and reference points; radar analog data are cut; the cut nautical charts are ranked according to two principles; redundant data of an overlapping region of every two adjacent nautical charts are screened in sequence; a gap in a merged polygon is filled so as to form a rectangle, and a new mapsheet is constructed; edge matching is conducted on shorelines, from the nautical charts with the different measuring scales, in merged radar analog data. According to the method, due to the fact that the nautical charts involved during navigation are screened according to the reference points of navigational areas and the navigation purposes of the nautical charts, the quantity of the radar analog data is greatly reduced under the premise that the accuracy of the radar analog data is guaranteed. Due to the fact that characteristic rules of forward angles in the radar analog data are worked out, the shorelines and boundaries generated due to chart subdivision are distinguished accordingly, and influences, caused by chart subdivision making, on the accuracy of the radar analog data are eliminated.

Owner:DALIAN MARITIME UNIVERSITY

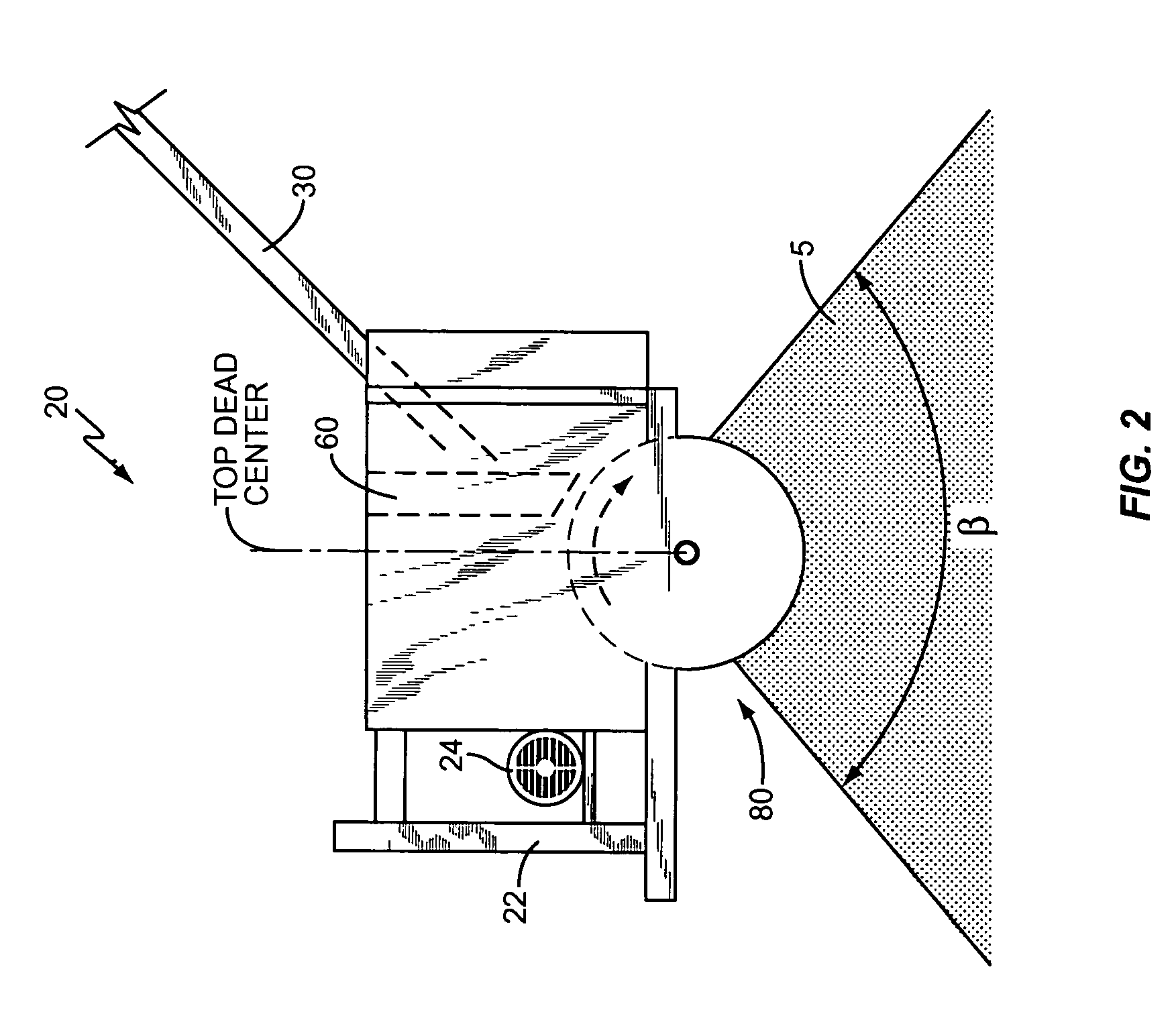

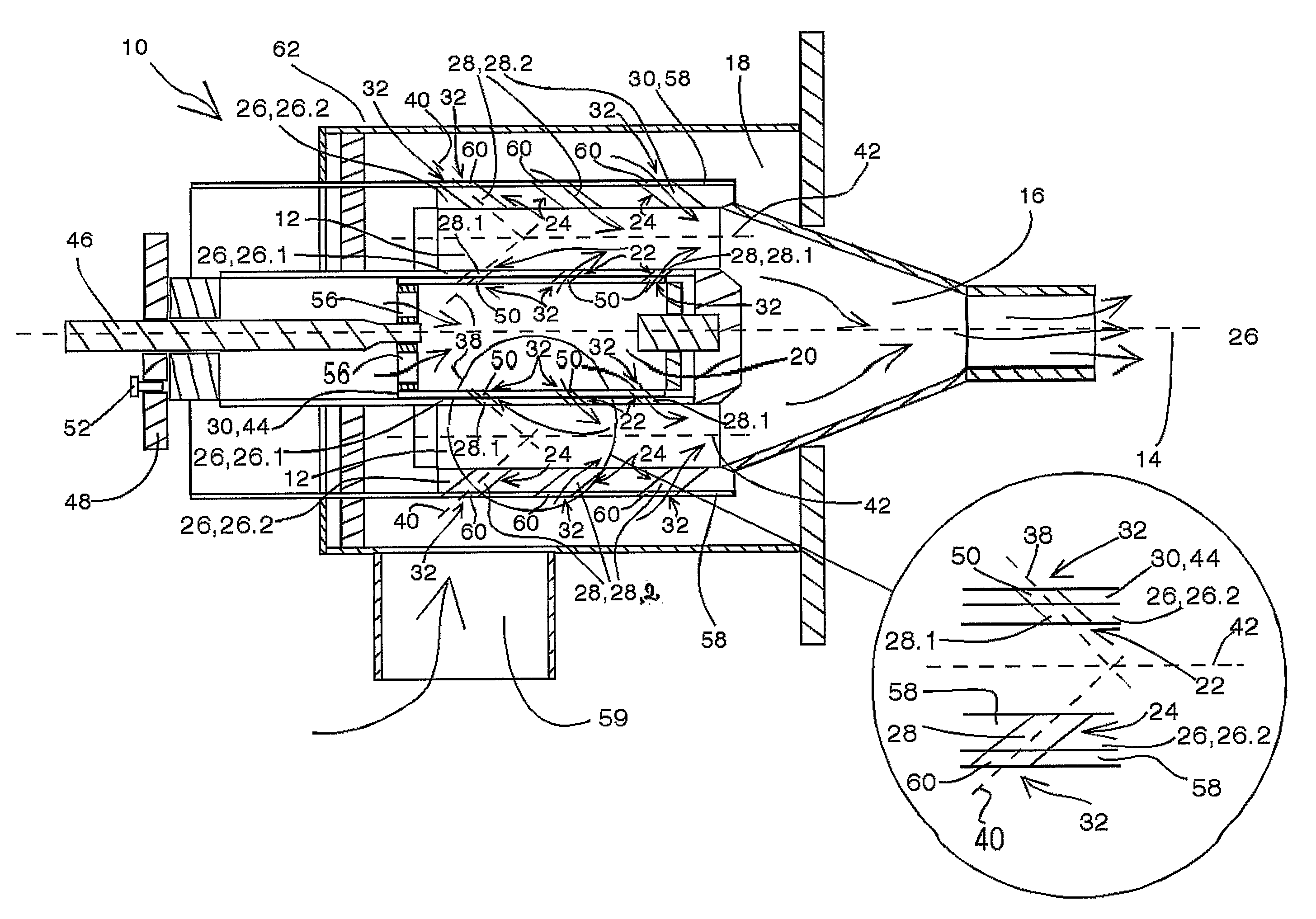

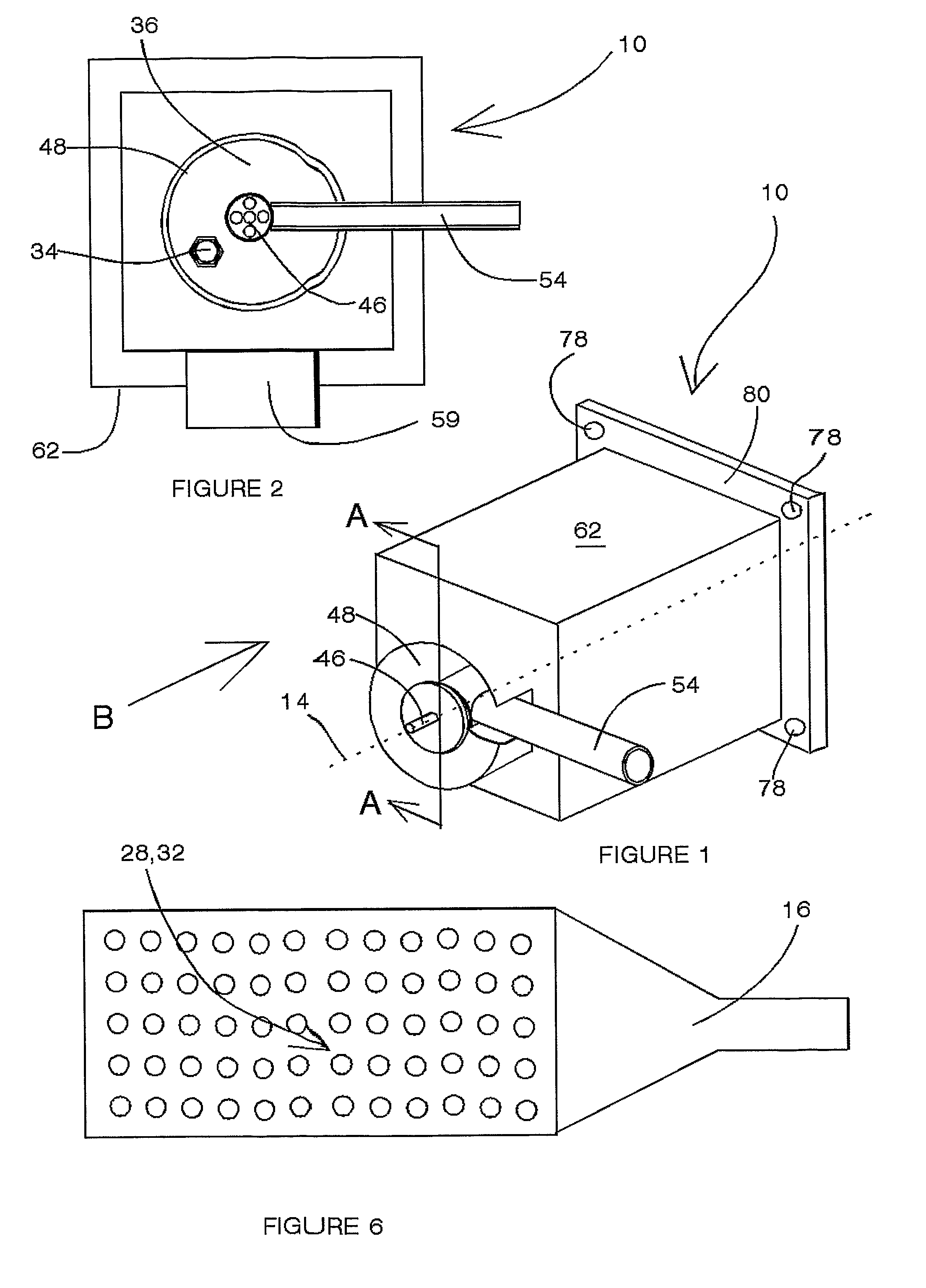

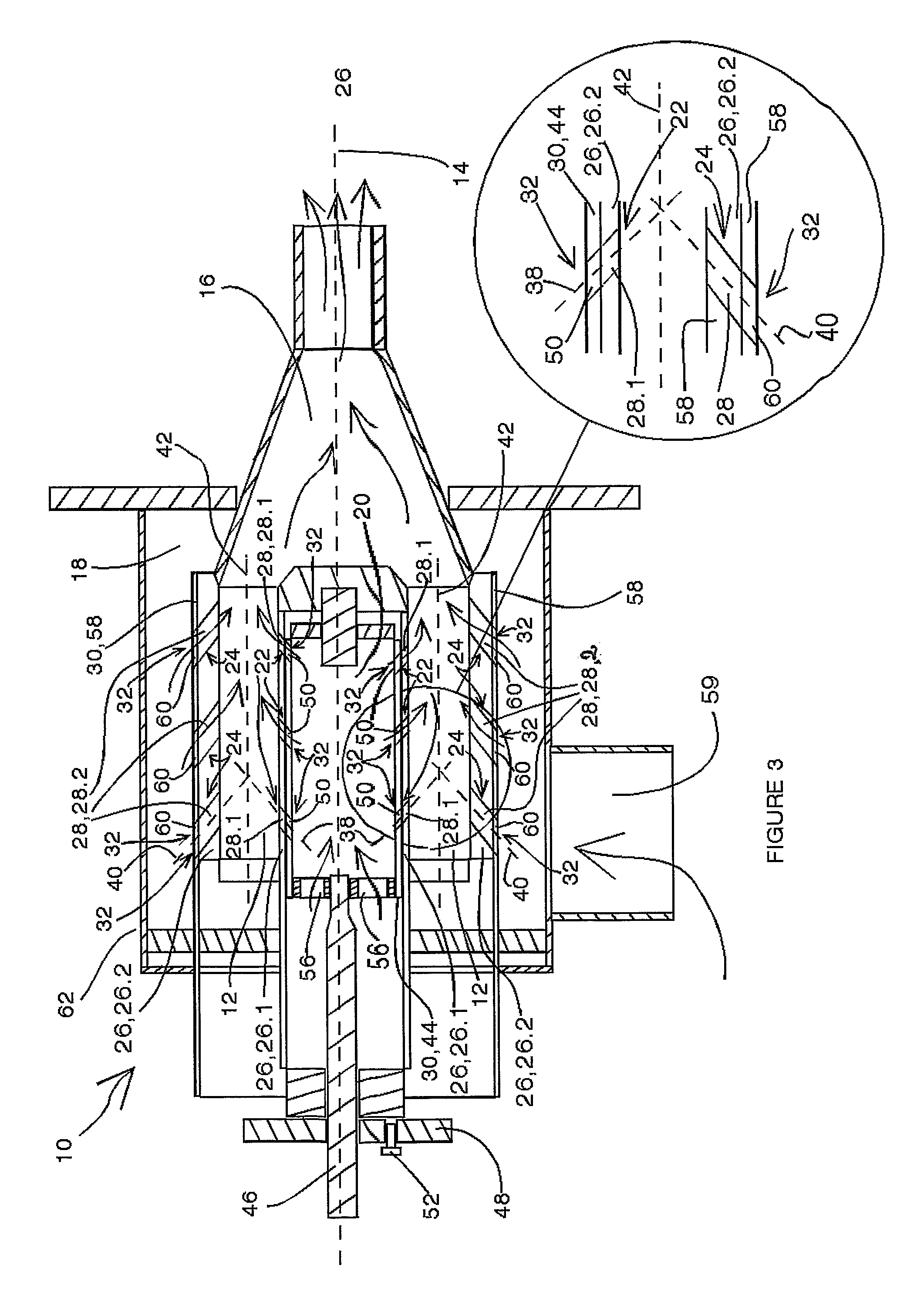

Variable orifice combustor

ActiveUS7566217B2Minimizing developmentMinimal fluctuationCombustion using gaseous and pulverulent fuelFuel supply regulationCombustion chamberCombustor

A variable orifice combustor unit 10 comprises an annular combustion chamber 12 extending about a central axis 14 and ending in a discharge nozzle 16. Charging of the chamber 12 takes place from combustion fuel and air supply chambers 18 and 20 via a fuel charging orifice array 22 and an air charging orifice array 24. The orifices 28.1, 28.2 of the orifice arrays 22, 24 are positioned and slanted at the same forward angle in the direction of the nozzle 16 to the effect of their central axes 38, 40 cutting along the longitudinal centre of the combustion chamber 12. The cross sectional sizes of the orifices 28 are adjustable by means of an orificed displaceably mounted cyndrically shaped covering body 44 for the fuel charging side and an orificed cylindrical body 58 for the air charging side both being displaceable in the direction of the axis 12.

Owner:STRIJDOM MR JOHANNES GERHARDUS 11 ASSIGNMENT +3

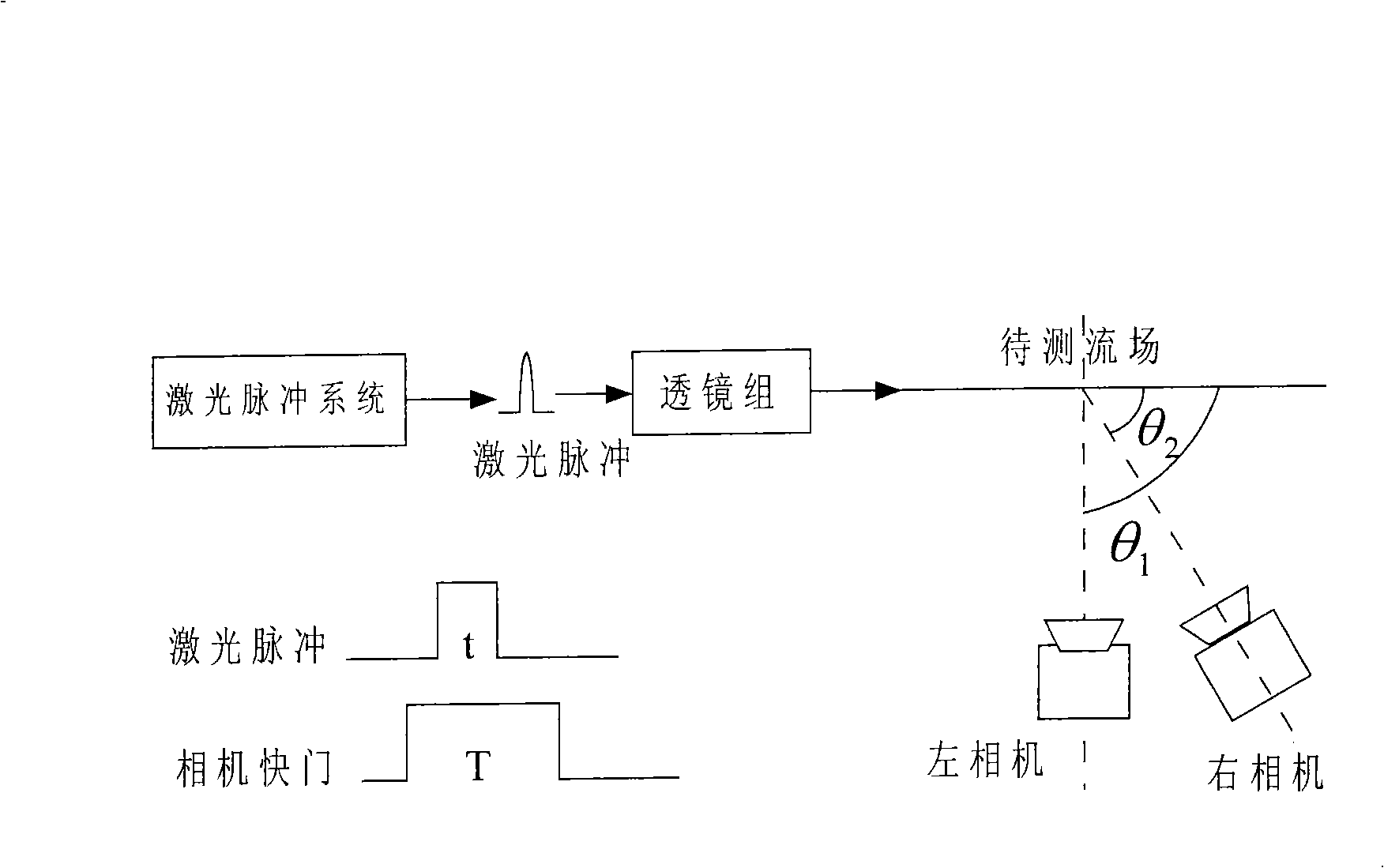

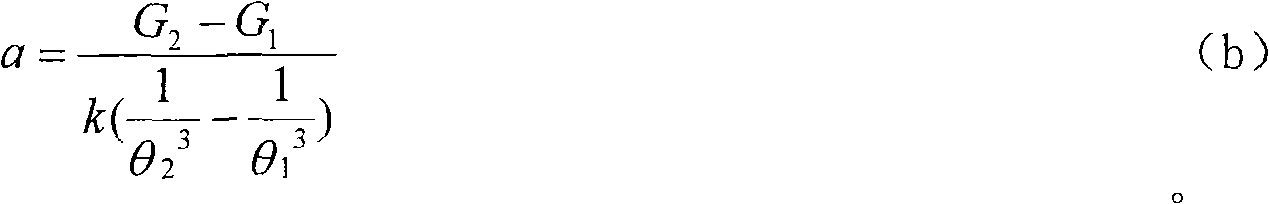

Method for measuring particle grain diameter

InactiveCN101295024ALaser Intensity Stability LimitationsImprove accuracyPhotogrammetry/videogrammetryRadiation particle trackingOptical measurementsForward angle

The invention relates to a method for measuring grain diameter by utilizing binocular vision matching and particle picture gray scale difference, pertaining to the technical field of optical grain diameter measurement. According to the characteristic that different forward angle scattered lights have light intensity differences and by utilizing a digital particle image velocimetry (DPIV) imaging system provided with dual-cameras, the method obtains two particle pictures with gray scale difference, the flow fields of which are formed by single exposure; after the particle pictures are pre-treated by an image processing technique, the mating of a same particle corresponding to two particle image points on the two particle pictures is realized according to a binocular vision matching principle; the grain diameter of the particle is obtained by substituting the gray scale value summation of the two particle image points into a grain diameter solving formula, thus obtaining the particle size information of the whole flow field; the method has the reduced requirement to the light intensity and the stability of laser and the particle mating method is simple and convenient, thus reducing the influence of system errors, the digital graphic processing technique and laser diffraction on the measurement result of the particle size, overcoming the deficiencies and defects in the prior art and having substantial characteristics and prominent advancement.

Owner:TONGJI UNIV

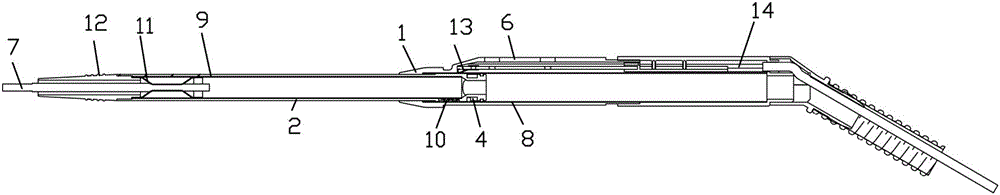

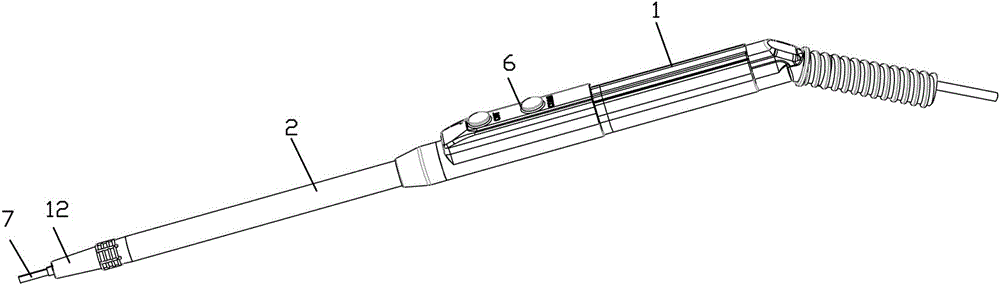

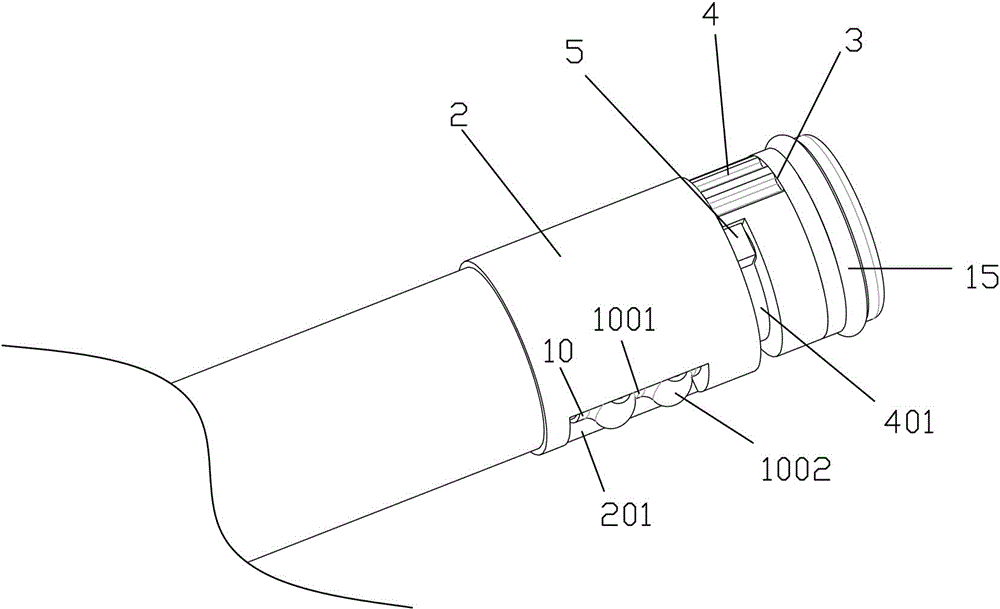

Smoke suction pipe connecting structure and smoke suction electrotome

ActiveCN104434301AImprove deformationGuaranteed structural strengthSurgical instruments for heatingEngineeringForward angle

The invention discloses a smoke suction pipe connecting structure and a smoke suction electrotome. The smoke suction pipe connecting structure comprises a smoke suction pipe, a locking ring slot, an elastic eccentric sleeve and a projection part, wherein the smoke suction pipe is inserted into a housing handle of the electrotome, the locking ring slot is arranged in the outer circumference of the smoke suction pipe, the elastic eccentric sleeve is arranged in the locking ring slot, and the projection part is arranged on the locking ring slot and matched with the elastic eccentric sleeve. When the smoke suction pipe in the housing handle of the electrotome forwardly rotates by a preset forward angle, the projection part and the elastic eccentric sleeve are matched, so that the smoke suction pipe is radially and axially locked with the housing handle of the electrotome; when the smoke suction pipe in the housing handle of the electrotome reversely rotates by a preset reverse angle, the projection part and the elastic eccentric sleeve are matched so as to unlock the radial and axial locking of the smoke suction pipe and the housing handle of the electrotome. The smoke suction pipe connecting structure and the smoke suction electrotome have the advantages of simple structure, convenience in operation and convenience in replacement and adjustment.

Owner:ZHEJIANG MEDSTAR TECH CO LTD

Measuring particulate matter in a fluid

InactiveUS20070201028A1Accurately propertyScattering properties measurementsBundled fibre light guideForward scatterParticulates

A device for measuring near forward scatter caused by particulate matter in a fluid is disclosed. The device comprises, according to various embodiments, a transceiver and a reflector. The transceiver includes a light source and a detector. The reflector is positioned opposite the transceiver so that at least a portion of the fluid is present between the transceiver and the reflector. The reflector includes a front portion facing the transceiver. Optical energy from the light source incident upon the reflector is reflected towards the transceiver as a return beam of optical energy, wherein the detector senses primarily optical energy of the return beam that is scattered over a range of near forward angles by particulate matter in the fluid.

Owner:TELEDYNE

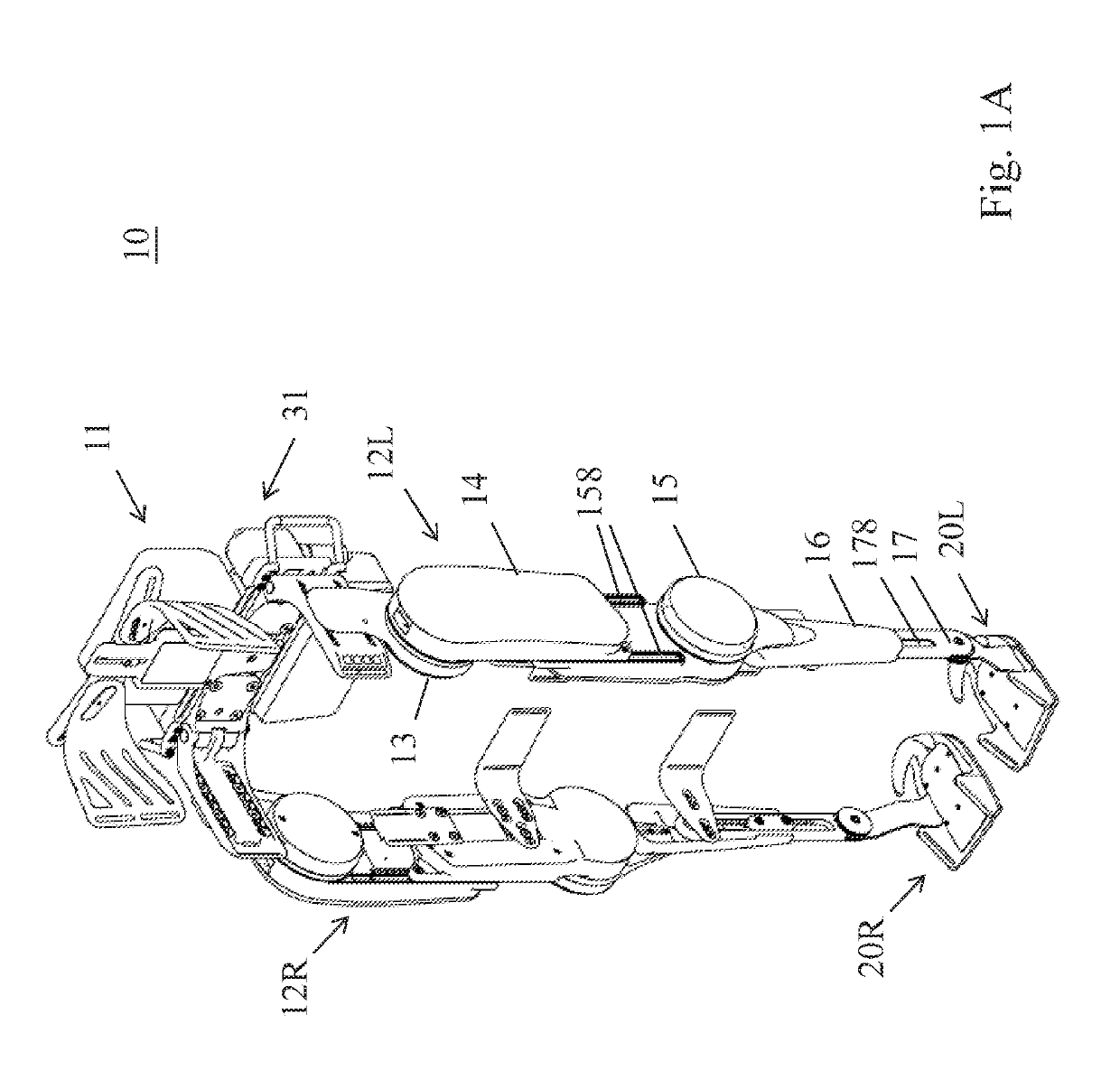

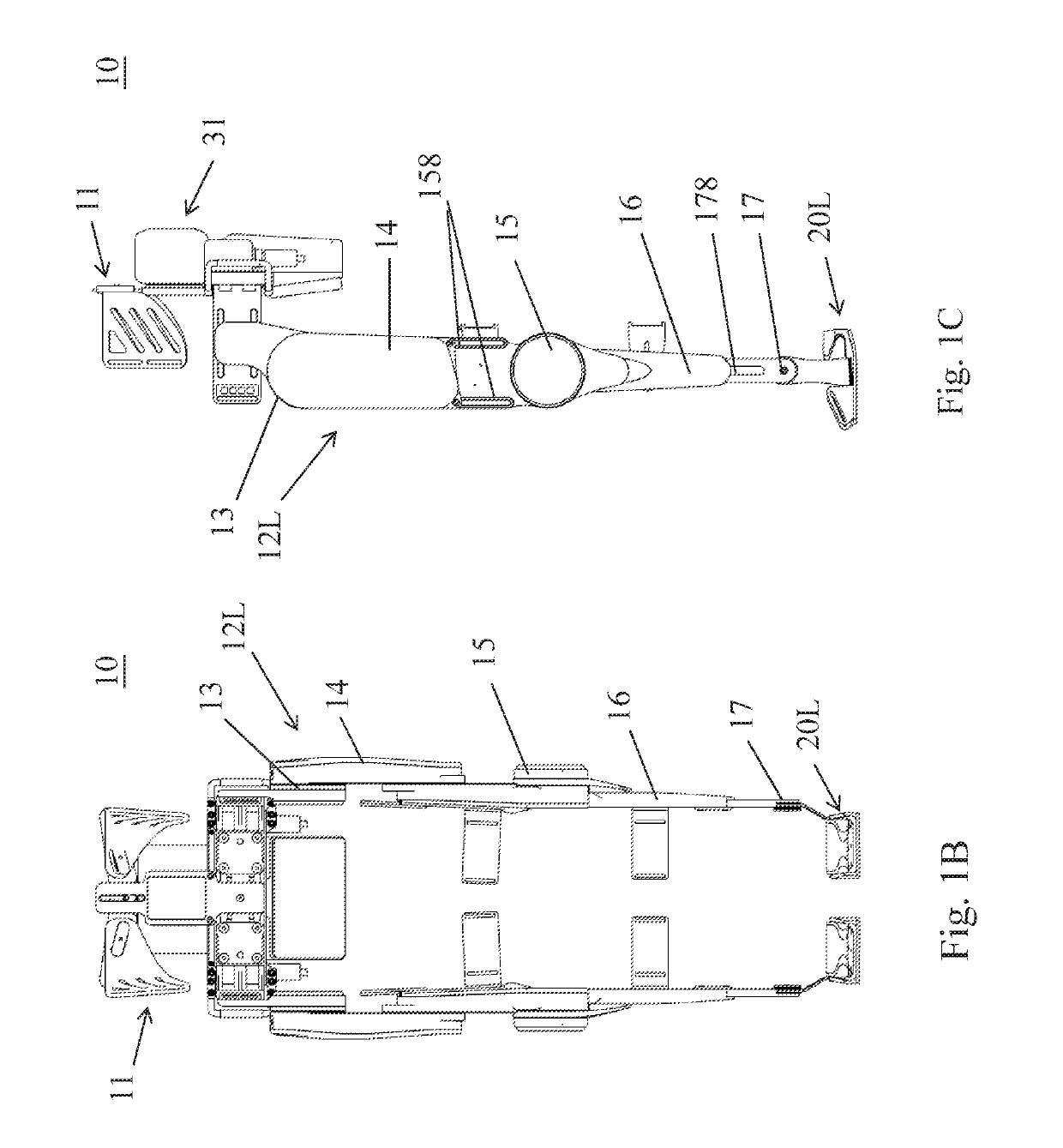

Exoskeleton robot and controlling method for exoskeleton robot

ActiveUS20190133866A1Facilitates user controlReduce riskProgramme controlProgramme-controlled manipulatorExoskeleton robotForward angle

The present disclosure provides a method for controlling an exoskeleton robot. The method comprises checking that a first signal is triggered by a first button, checking a tilt angle after the first signal is triggered, setting an action based on the tilt angle, and executing the action to move the exoskeleton robot. The first signal indicates to change the exoskeleton robot from a standing posture to another posture, and the tilt angle is a leaning-forward angle of a waist assembly of the exoskeleton robot relative to a line vertical to ground. The method utilizes the tilt angle to judge the intent of the user, and thus can simplify the controlling buttons to one or two buttons. Further, the controlling method also monitors the tilt angle to choose a suitable action.

Owner:FREE BIONICS TAIWAN INC

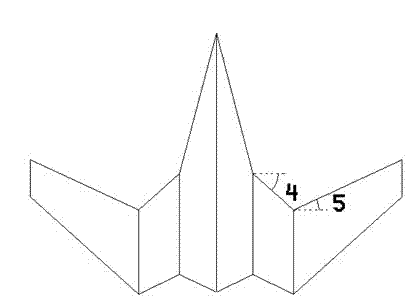

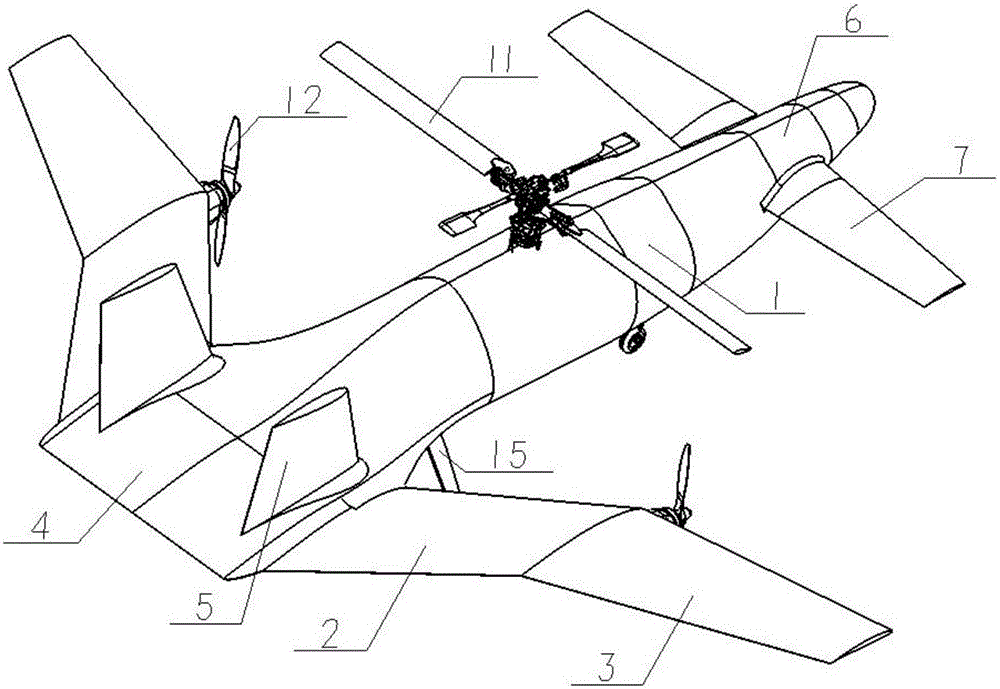

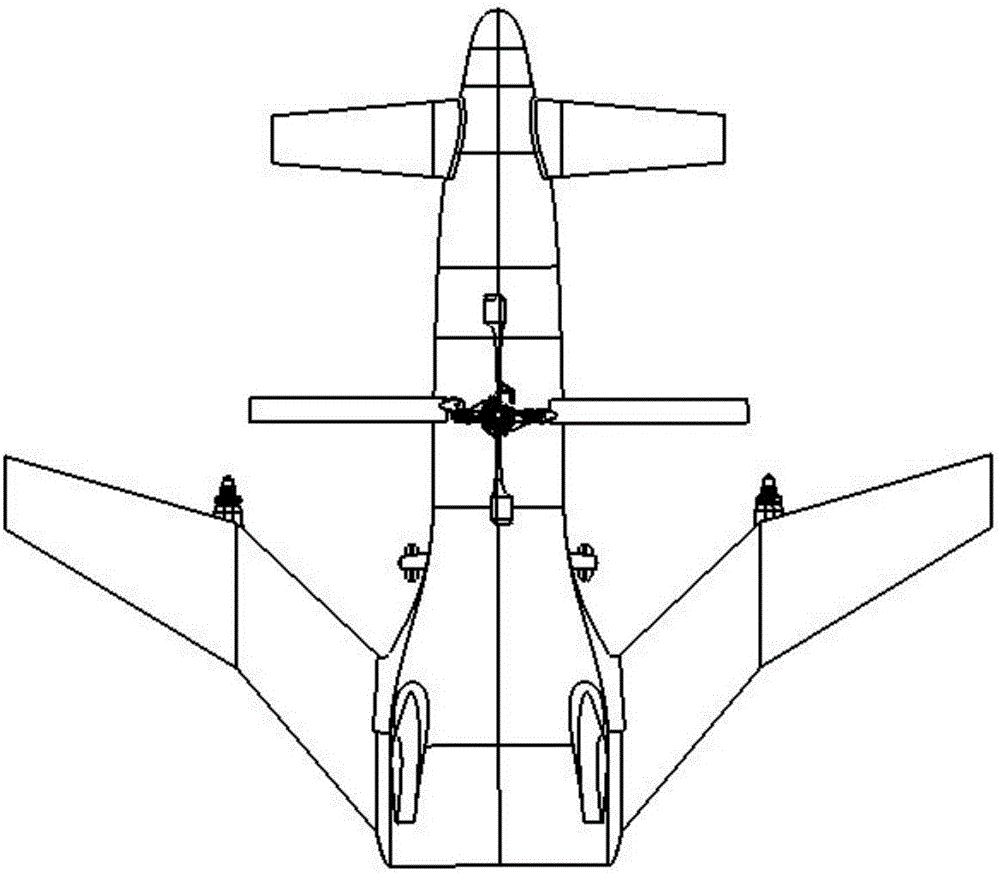

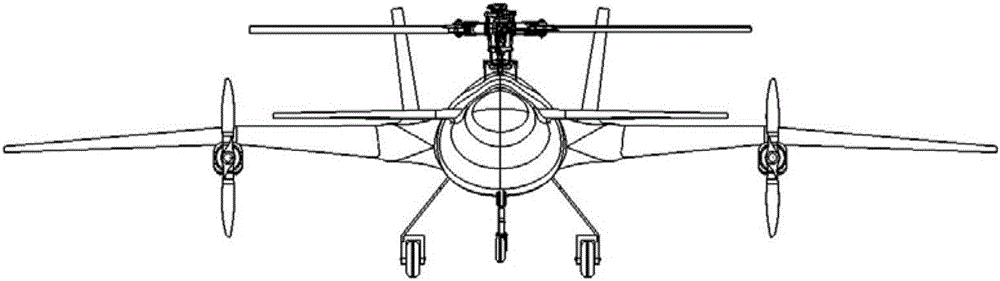

Novel large-lift-force vertical take-off and landing aircraft

InactiveCN105818980AReduce nose down momentBow moment balanceVertical landing/take-off aircraftsRotocraftJet aeroplaneLow speed

The invention discloses a novel large-lift-force vertical take-off and landing aircraft. The aircraft comprises an aircraft body and main wings arranged on the two sides of an aircraft tail of the aircraft body. Each main wing is jointly formed by an inside main wing body and an outside main wing body. Each inside main wing body is a sweep-forward wing, and a sweep-forward angle ranges from 10 degrees to 75 degrees. Two vertical tails are arranged above the aircraft tail of the aircraft body. Canards are arranged on the two sides of an aircraft head of the aircraft body. A rotor wing is arranged above the aircraft body. A power device is arranged between each inside main wing body and the corresponding outside main wing body. An undercarriage is arranged at the lower portion of the aircraft body. By the adoption of the novel large-lift-force vertical take-off and landing aircraft, the flight properties of vertical take-off and landing, the high speed, the long navigation time and the large voyage are considered, the characteristic of a large task load is achieved, and the lift-drag characteristic in the high-speed flight process and the propelling efficiency of a power system are higher than those of a helicopter and those of a tilt rotor, a flight envelope is wider; and meanwhile decoupling is controlled through lift force and horizontal thrust, so that the aircraft is in transition from a low-speed flight state to a high-speed cruising state stably.

Owner:刘行伟

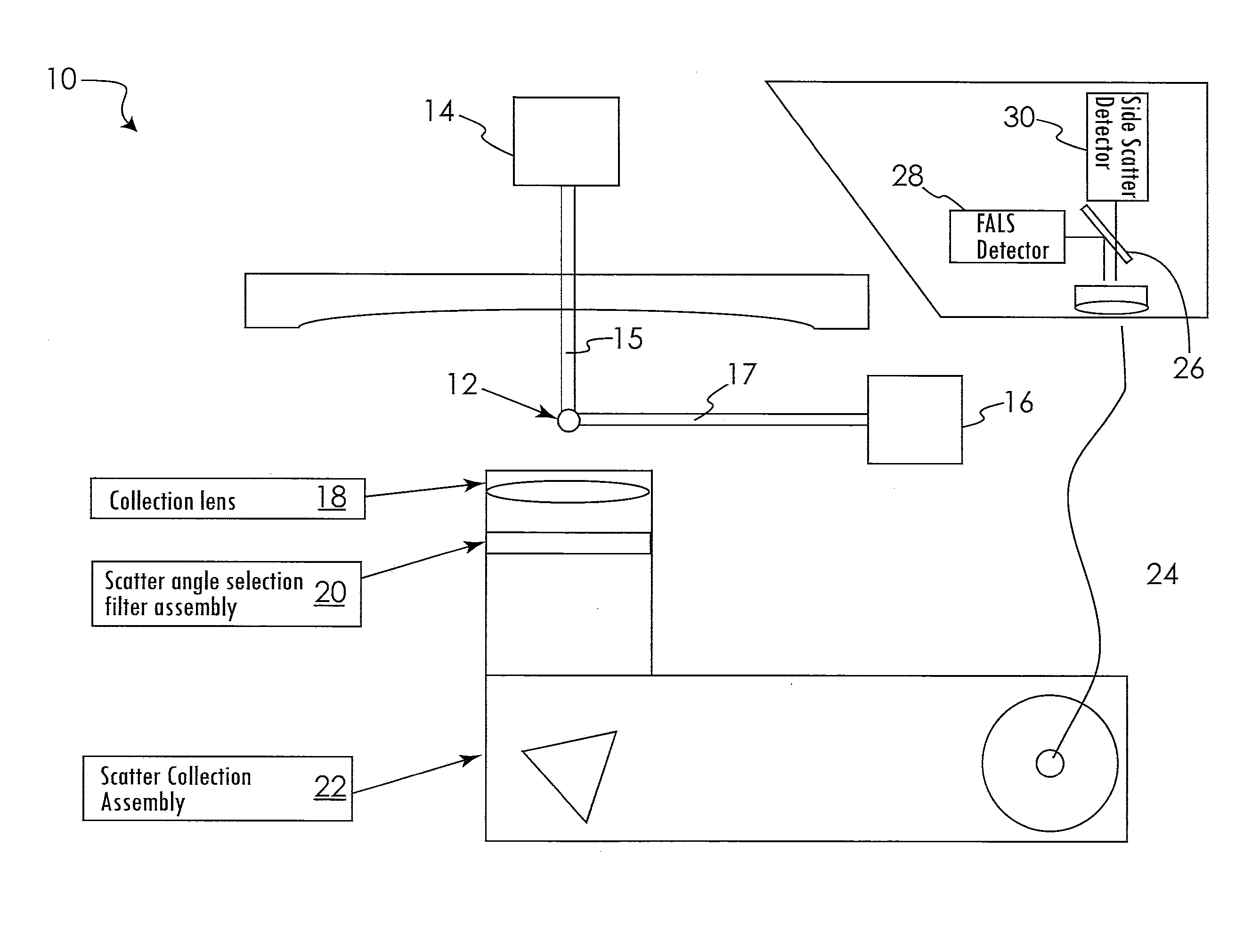

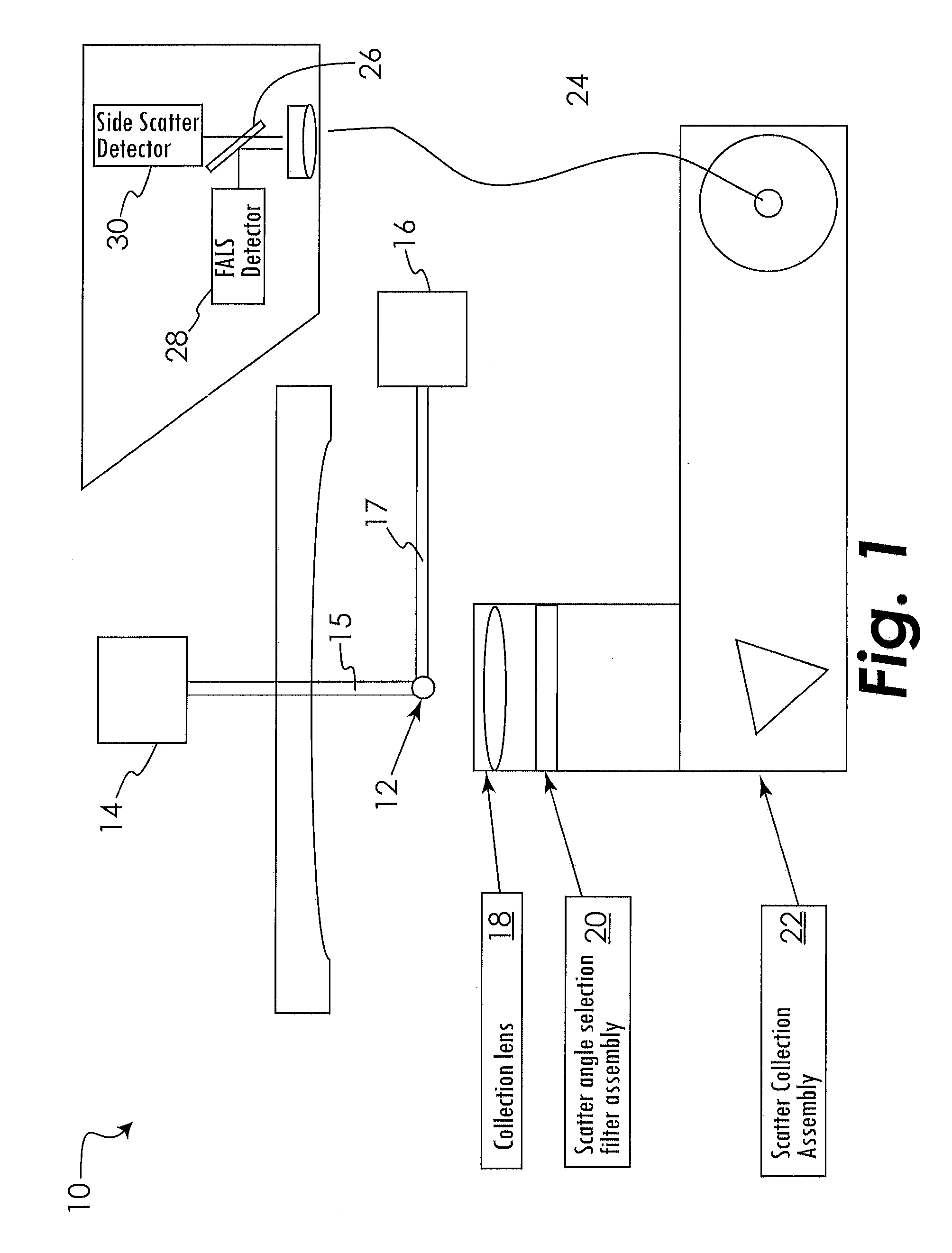

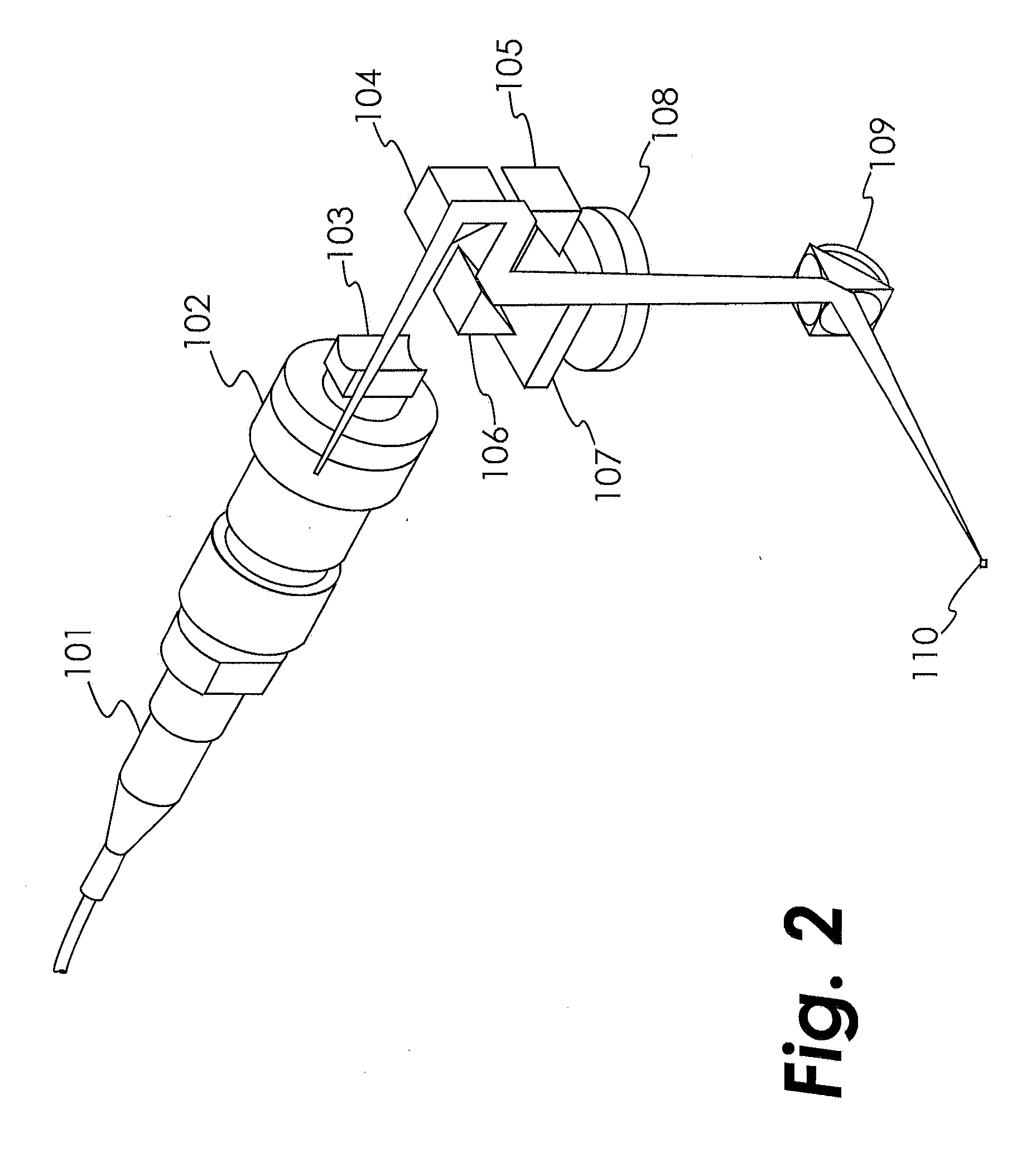

System and method for measuring narrow and wide angle light scatter on a high-speed cell sorting device

ActiveUS20130169953A1Reduce distortion problemsDiffusing elementsScattering properties measurementsFrequency spectrumForward angle

The various embodiments disclosed herein utilize multiple lasers that have different wavelengths and a single detection path. The lasers are mounted orthogonal to one another so that one laser will provide a forward angle light scatter (FALS) signal in the detection path, and one laser will provide a side scatter signal in the detection path (i.e., the single detection optics are approximately in-line with the FALS laser and approximately orthogonal to the side scatter laser). The single detector path spectrally separates the forward and side scatter signals prior to applying them to their respective detectors for measurement.

Owner:SONY CORP +1

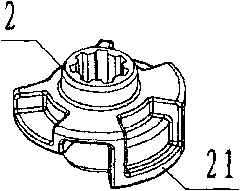

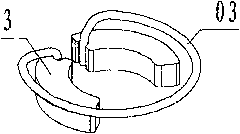

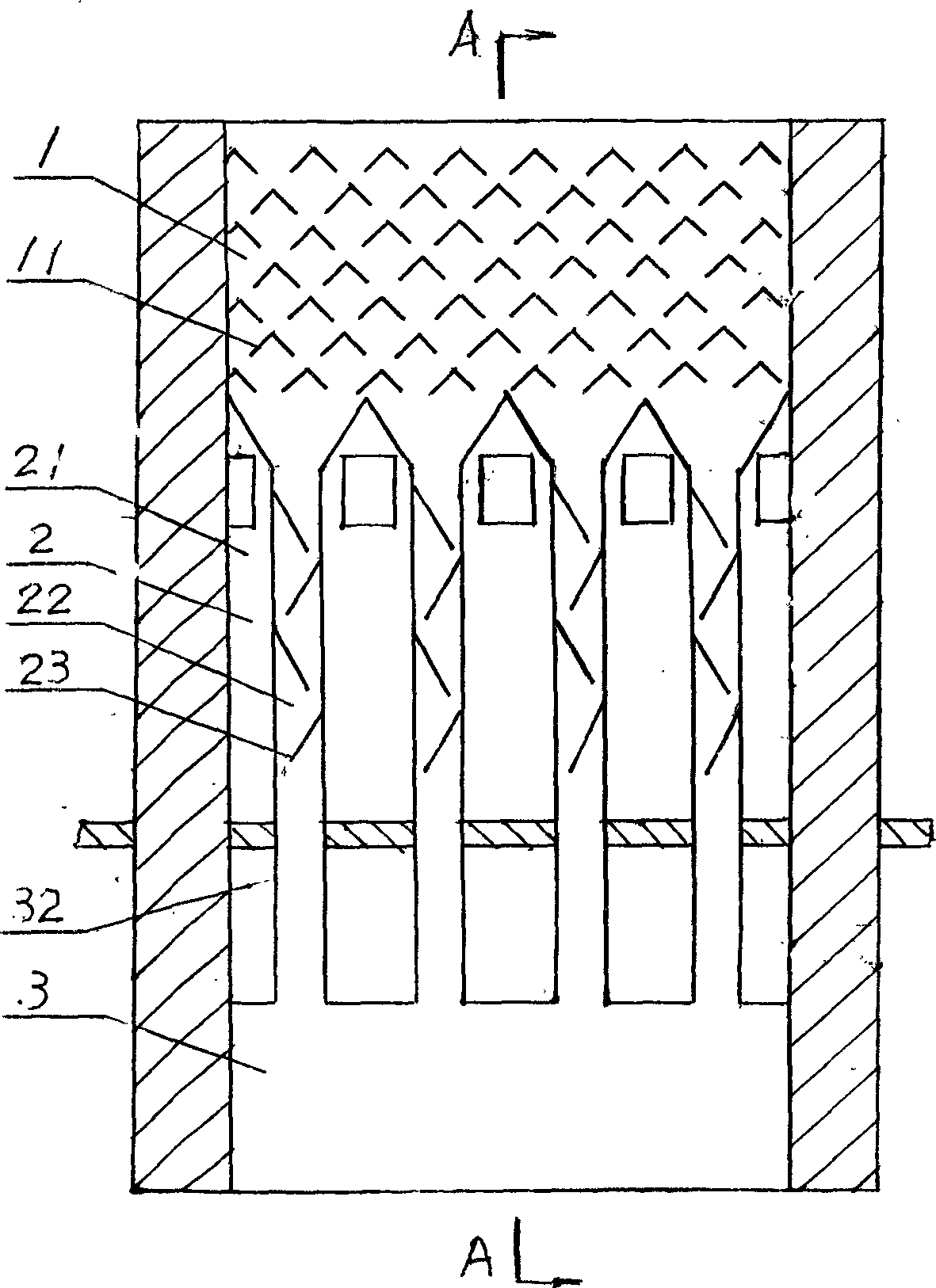

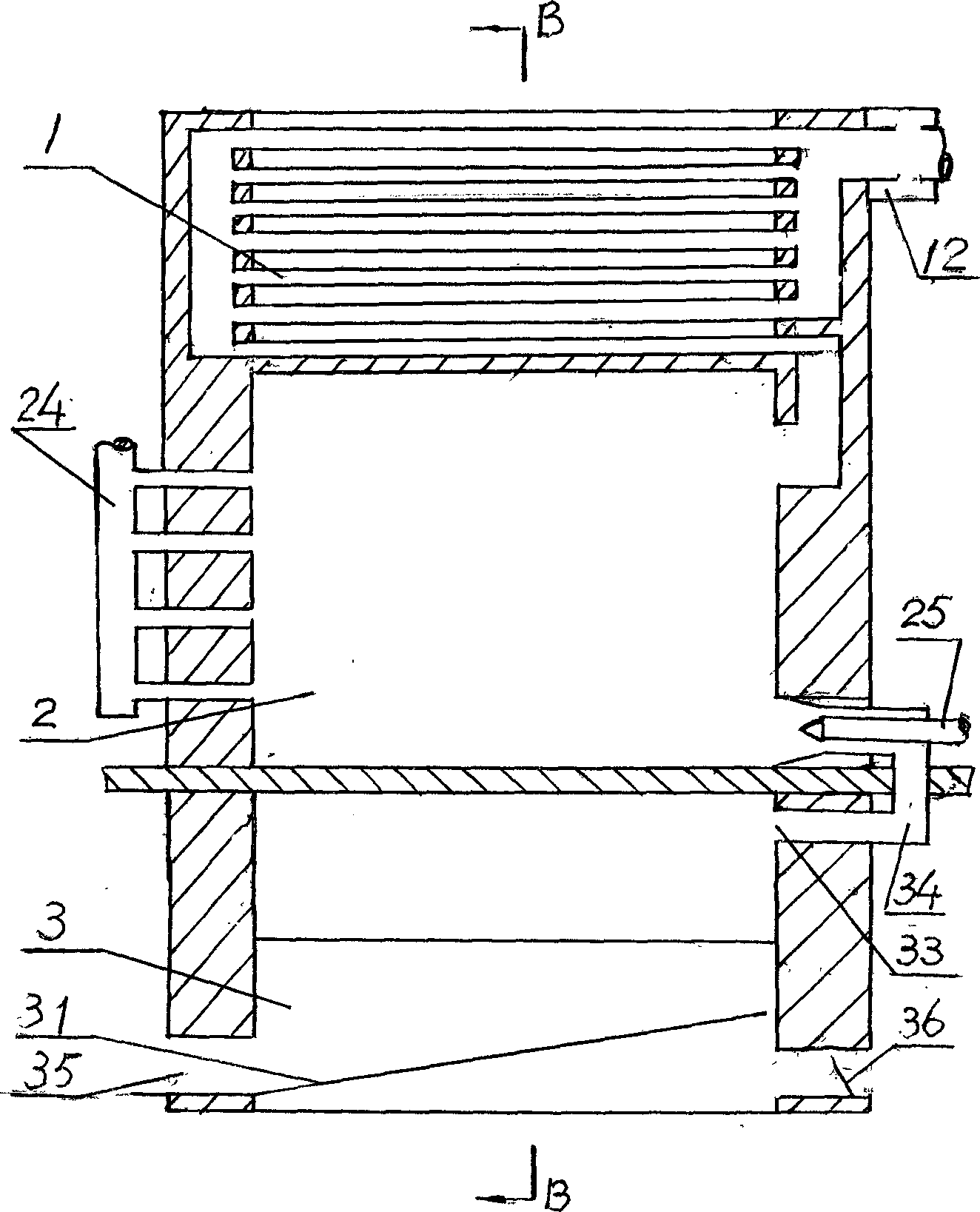

Built-in inversion-stopping self-locking device of angle adjuster

InactiveCN101797900AOvercoming structural complexityOvercoming structural costsMovable seatsSelf lockingEngineering

The invention discloses a built-in inversion-stopping self-locking device of an angle adjuster, comprising a clinching spring (1), an internal spline shaft (2), a cuneatic arch (3), an internal toothed plate (4) and a tension spring (03). The invention adopts the following technical scheme: the clinching spring is arranged on the outer wall of a central axle of the internal toothed plate; the principle that the diameter of the clinching spring is expanded when the clinching spring is stressed opposite to the winding direction and the diameter is contracted when the clinching spring is stressed in the winding direction is adopted; when a convex plate of the internal spline shaft touches a horizontal arm of the clinching spring in the forward angle of the clinching spring, the clinching spring loosens the outer wall of the central axle, and when the cuneatic arch touches the horizontal arm of the clinching spring in the backward angle of the clinching spring, the clinching spring enclasps and locks the outer wall of the central axle, thus overcoming the defects of complex structure, high cost and extra occupation of the inside space in the prior art. The built-in inversion-stopping self-locking device ensures inversion-stopping self-locking of the angle adjuster to achieve the aims of simple and reliable structure, low cost and no extra occupation of the inside space.

Owner:NINGBO SHUANGLIN AUTO PARTS

Technology for roasting magnesite and its special apparatus

InactiveCN1485291AIncrease profitReduce the greenhouse effectLime productionDecompositionMineral particles

A process of roasting magnesite is characterized in taking mineral particles with the size smaller than 10mm as the raw material, experiencing three steps of preheating, roasting and cooling by automatic subsidence of the mineral particles in the upright roaster oven, the preheating temperature is 450í½500degree C, the roasting temperature is 700í‚50degree C, then CO2 is produced. The special device of the process is an upright roaster oven for heating magnesite which could recycle CO2. In the preheating zone of the kiln there have angle irons with forward angles, which are horizontally arranged in rows, a dust catcher is on the top layer. In the decomposition zone, firerooms and material rooms are arranged alternately, there have stock guides in material rooms, a discharging flashboard or a discharging machine or an air channel is at the bottom of the cooling zone. There have flashboards at the bottom and the discharge gate in the same level.

Owner:吴太洲

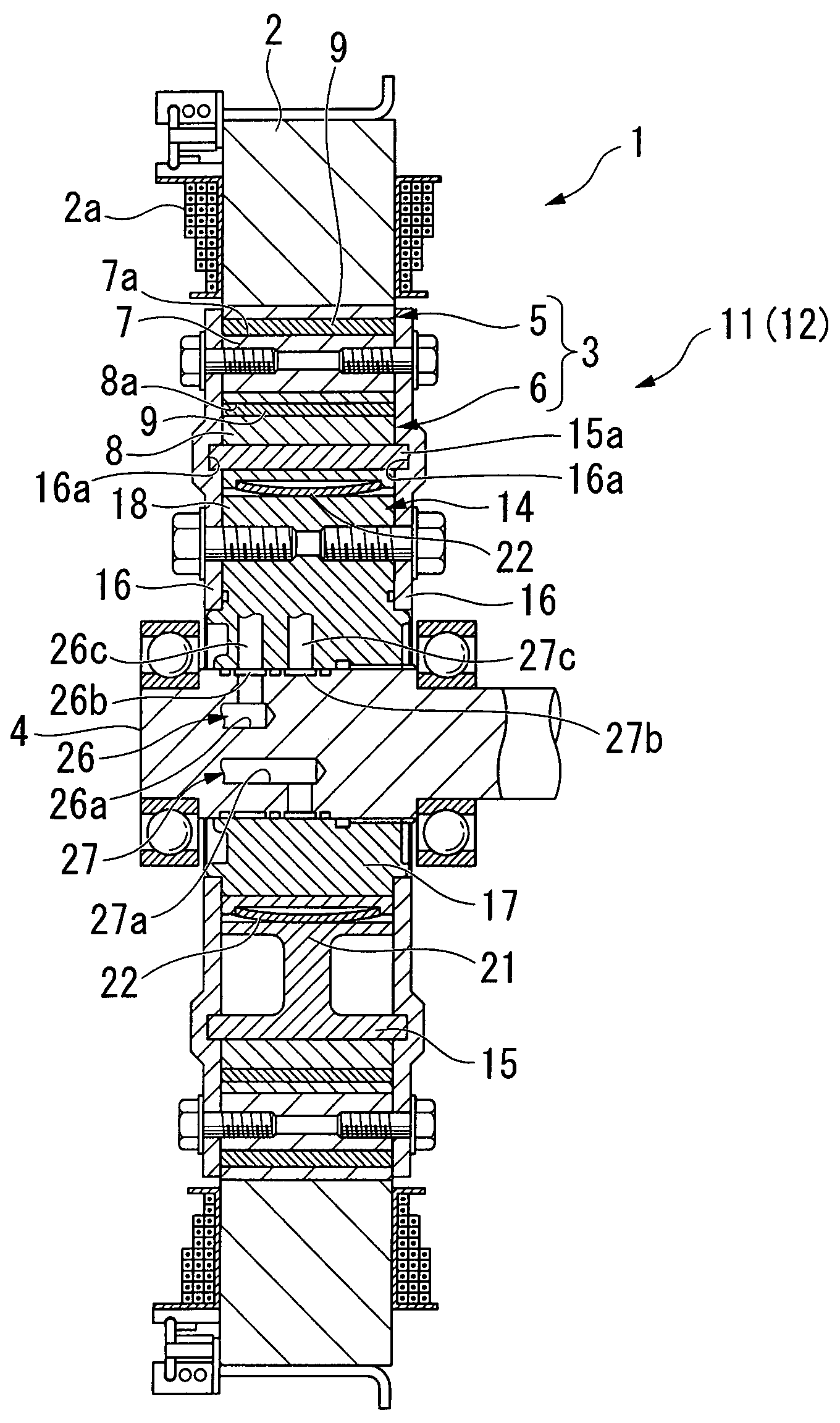

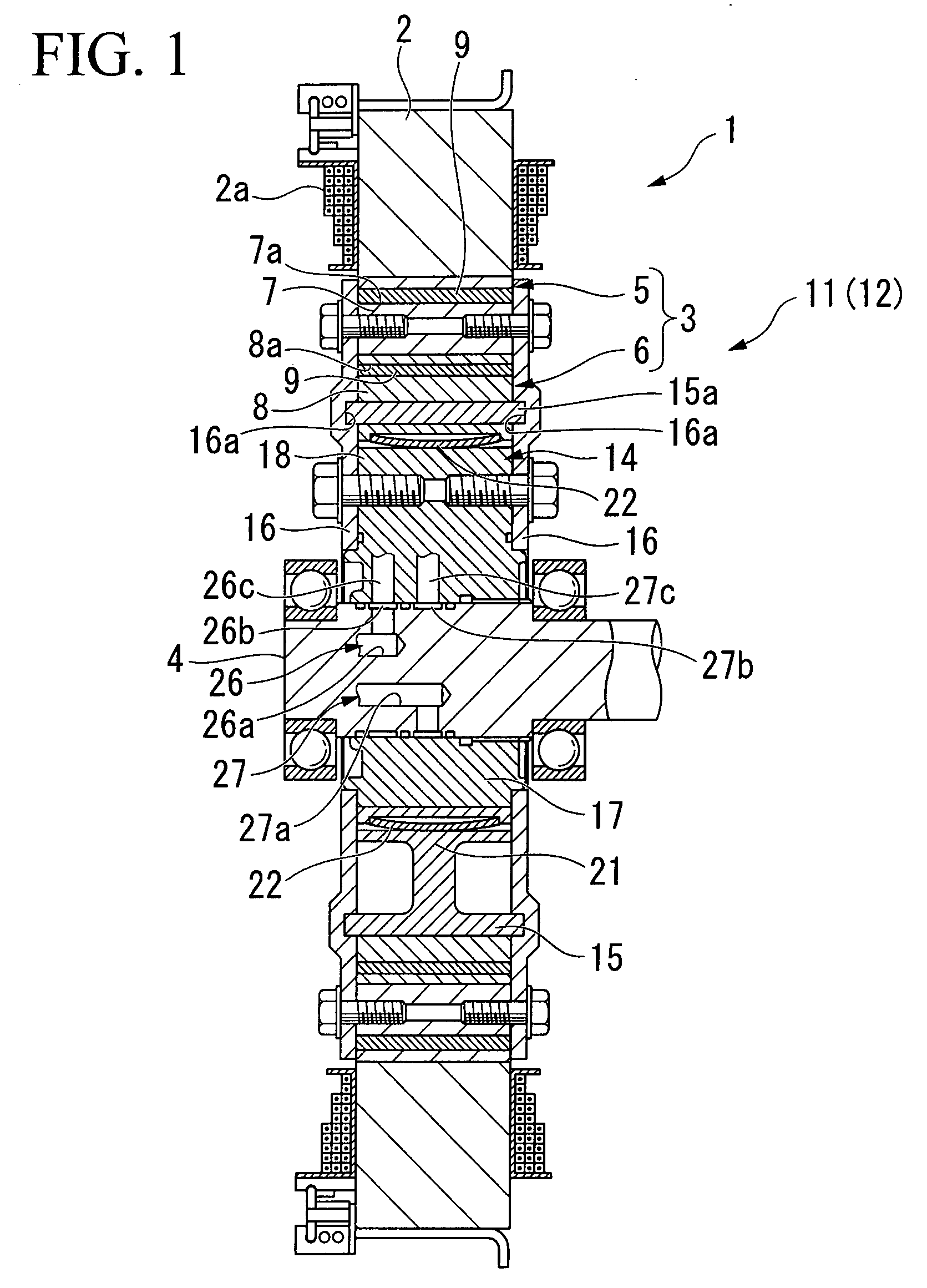

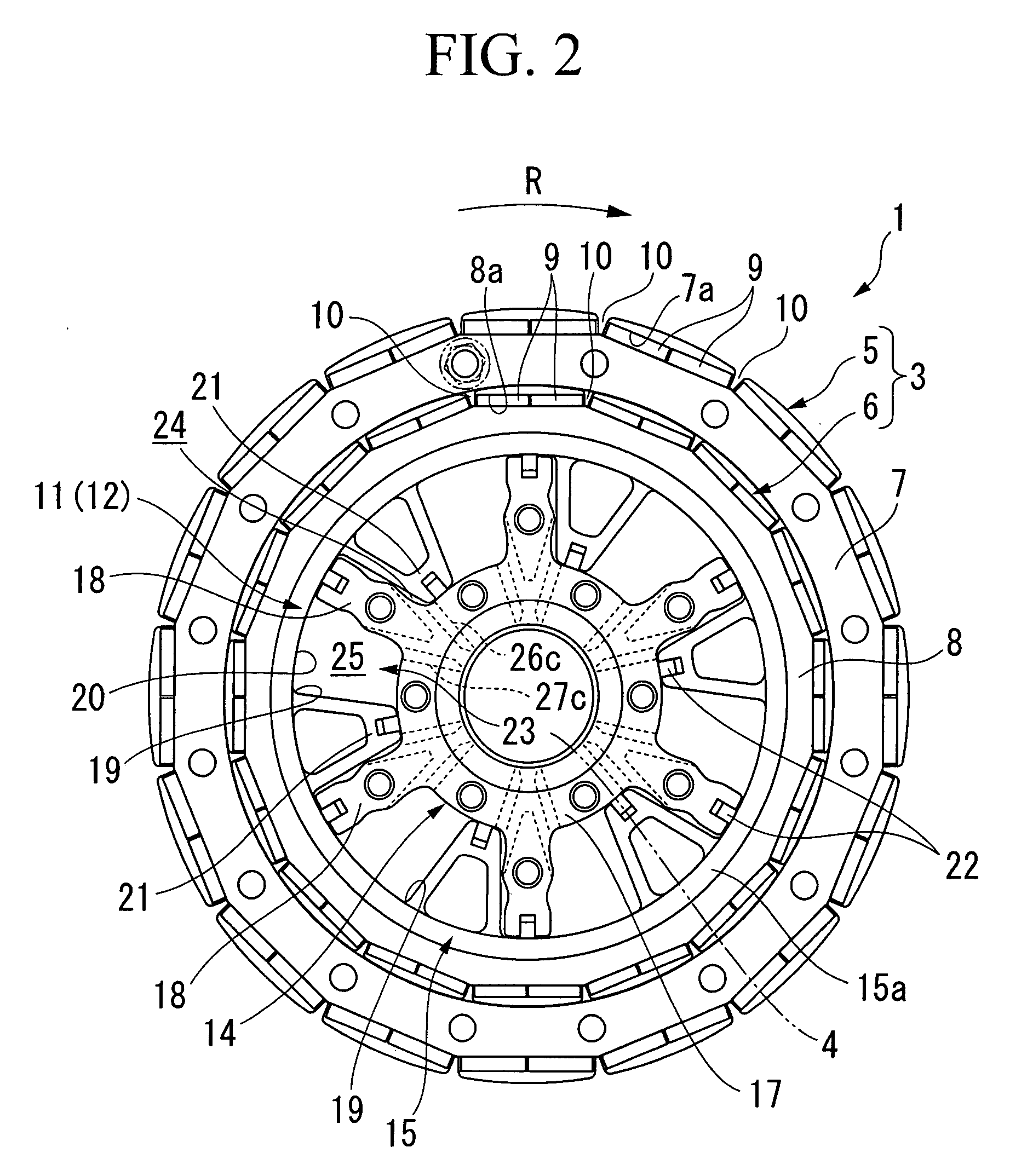

Motor using working fluid distributed into chambers, which are provided for rotating rotors in opposite relative rotation directions

InactiveUS20070296296A1Reduce manufacturing costIncrease flexibilityRotary/oscillating piston combinations for elastic fluidsCombination enginesWorking fluidRelative phase

A motor includes inner-peripheral and outer-peripheral rotors which rotate coaxially and have permanent magnets along a circumference of each rotor; and a phase varying device for relatively rotating the rotors so as to vary a relative phase therebetween. The device has a forward-angle working chamber for relatively rotating the inner-peripheral rotor forward with respect to the outer-peripheral rotor, by using pressure of supplied working fluid; a backward-angle working chamber for relatively rotating the inner-peripheral rotor backward with respect to the outer-peripheral rotor, by using pressure of supplied working fluid; a passage switching valve for performing distribution with respect to supply and drainage of the working fluid between the working chambers in accordance with the position of a spur; and an electromagnetic pressure control valve for controlling pressure of the working fluid, and for controlling the position of the spur in the passage switching valve based on the controlled pressure.

Owner:HONDA MOTOR CO LTD

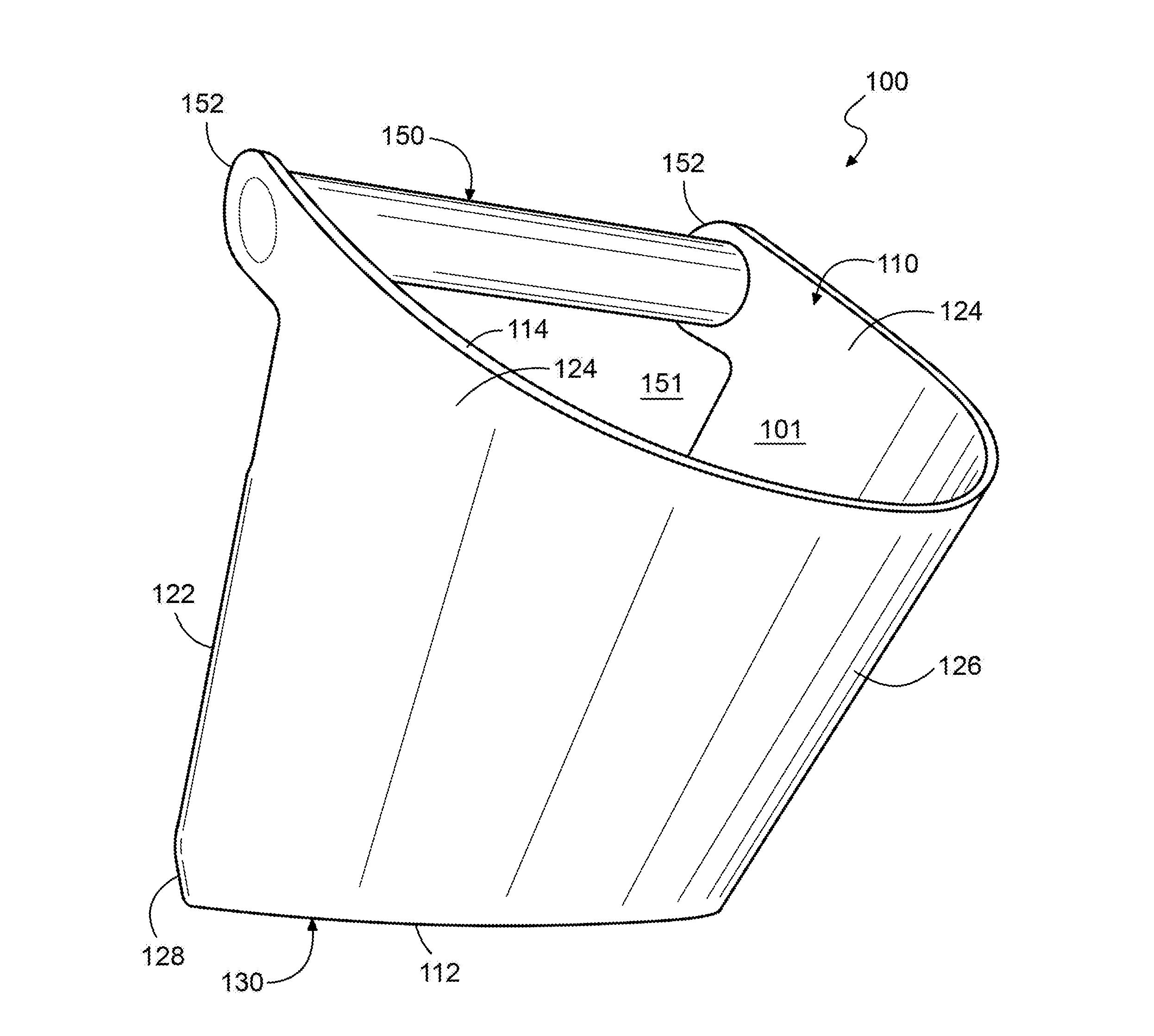

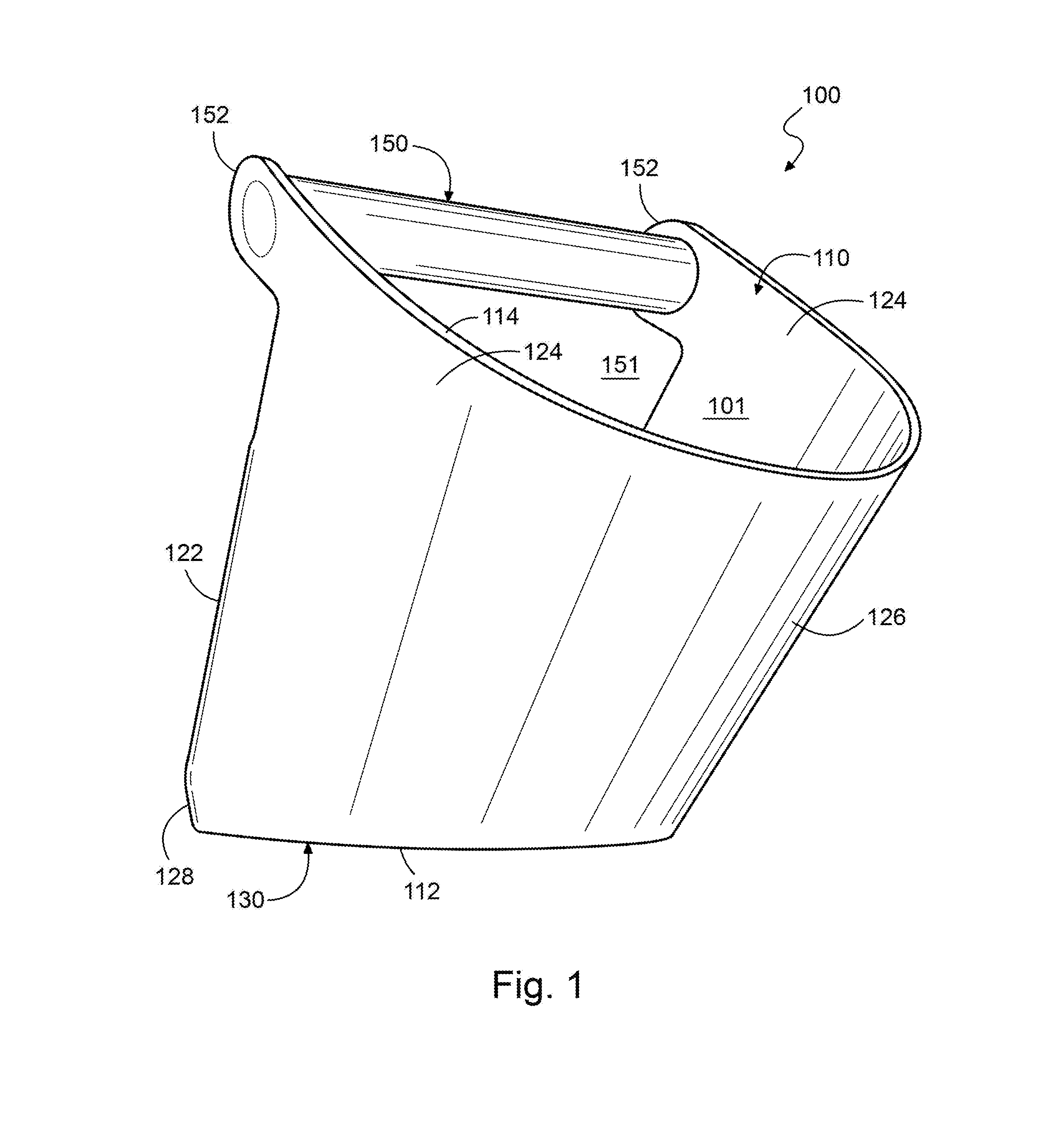

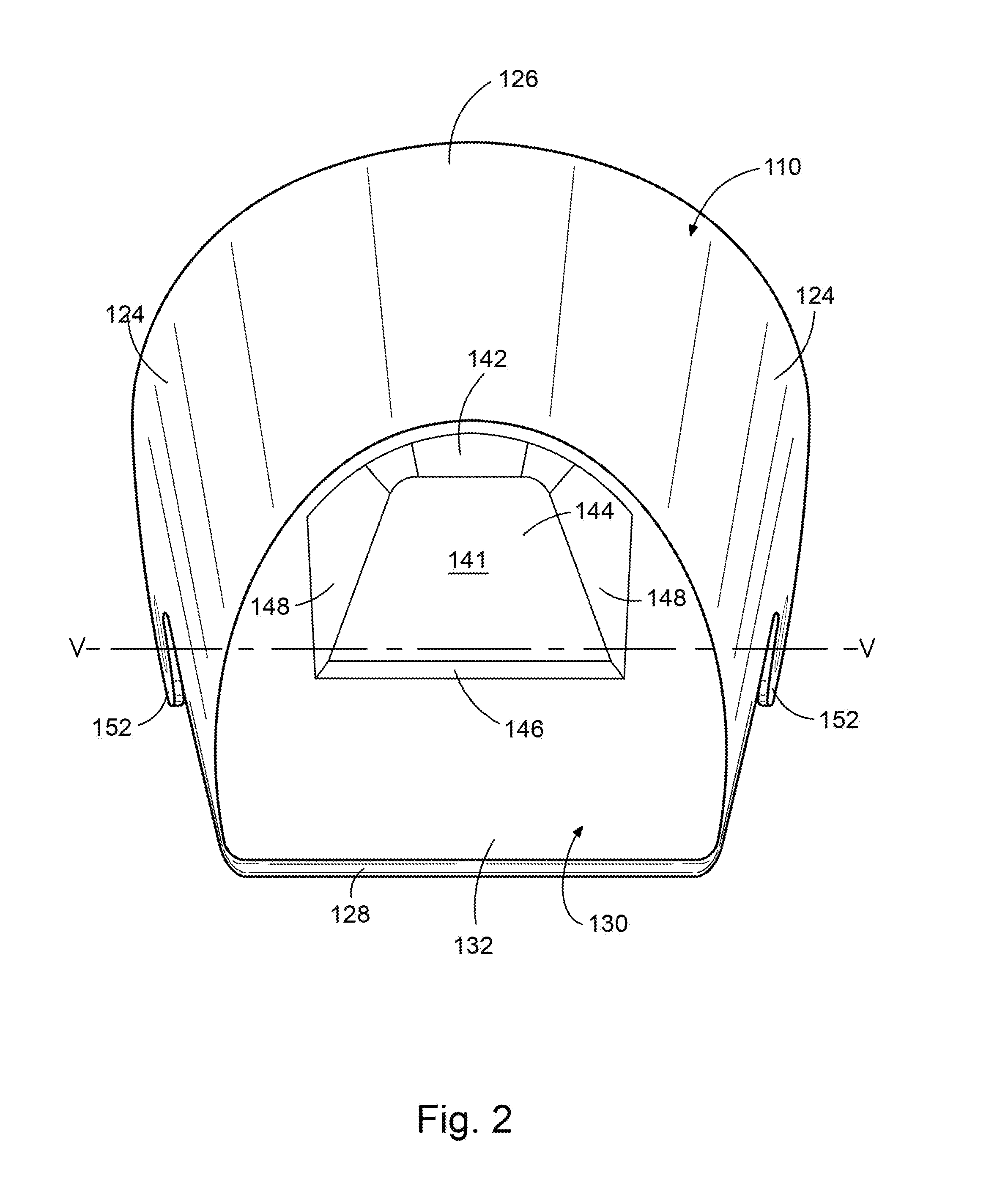

Handheld Fluid Container

ActiveUS20160229591A1Reduces handReduce wrist fatigueRemovable lids/coversCans/barrels/drumsHand heldEngineering

A handheld fluid container shaped and configured so that the majority of the fluid volume is carried near the rear of the container where the container is held and supported. In various embodiments, the containers have handle parts and / or handle openings that allow the containers to be manually supported from the rear of the containers. The container bodies also have forward angled front and rear walls and container bottoms shaped so that the majority of the interior volume of the container is located at the rear of the container rather than at the front. The center of gravity of the containers when partially or fully filled with fluid is located near the rear of the container where it is manually supported by the user.

Owner:BAJUYO ANTONIO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com