Method for measuring particle grain diameter

A technology of particle size and particle size, which is applied in the field of particle size optical measurement, can solve problems affecting particle image point size, comparison result error, and affecting the determination of the real size of particle diameter, so as to eliminate the influence of system error, improve accuracy, The effect of improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

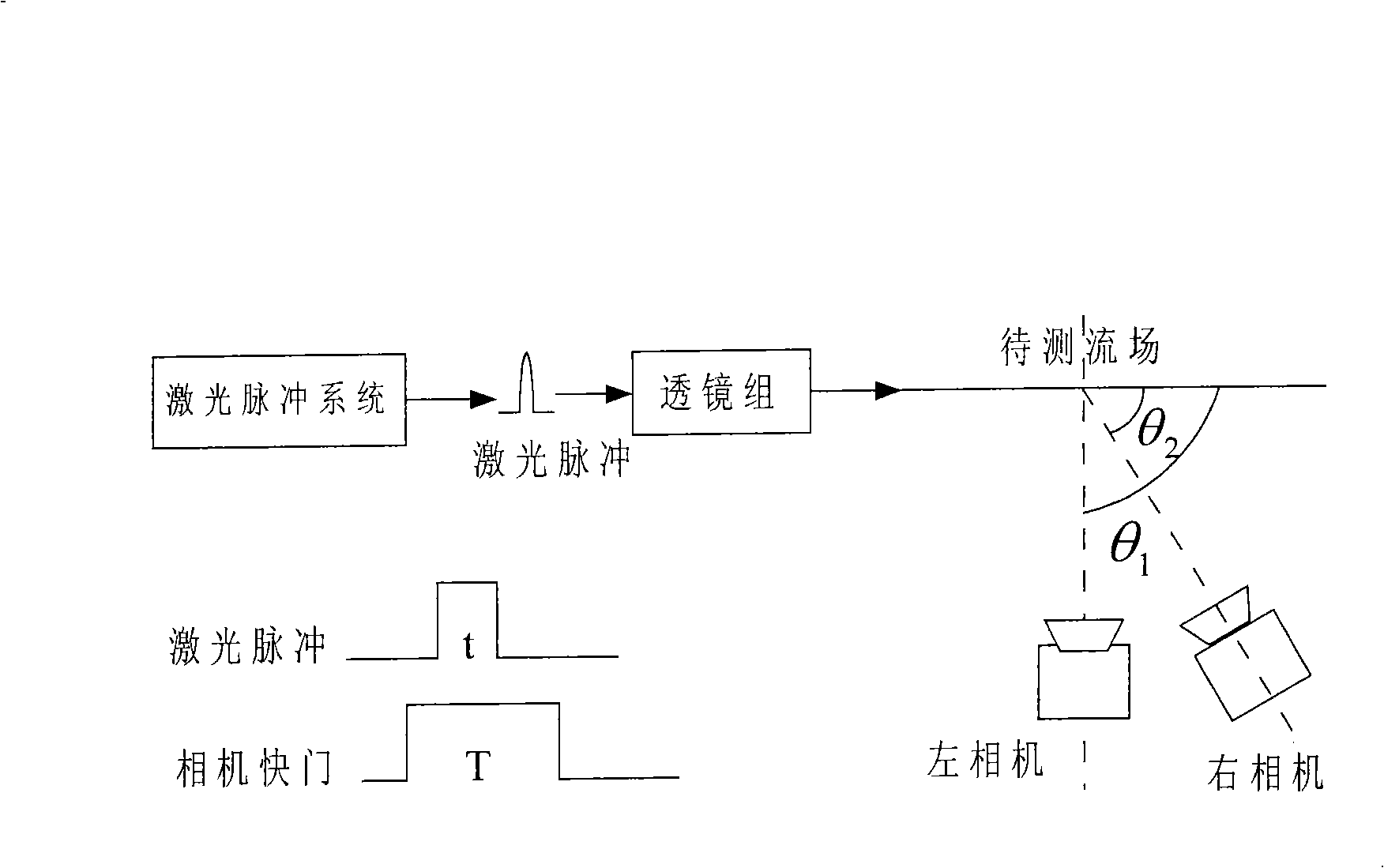

[0020] Below in conjunction with the embodiment and the attached figure 1 The present invention is described in further detail:

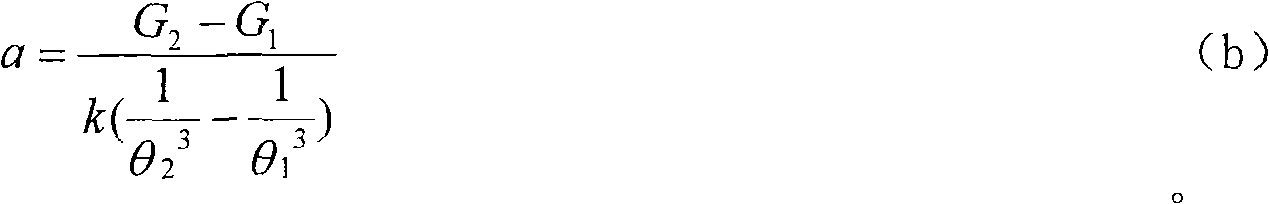

[0021] (1) Since the flow velocity of the flow field in the tank is relatively slow, the particles in the flow field are relatively large and sparse, and the measurement resolution is not high, so the parameters of the particle image velocity field instrument imaging system equipped with dual cameras are set as follows: laser emission The wavelength of the laser is λ=532nm, the side length of the square hole of the orifice plate installed in front of the camera lens used is b′=14mm, the included angle between the laser light path and the optical axes of the two cameras, that is, the forward angle is θ respectively 1 = 90° and θ 2 = 60°, the distance d from the center of the camera lens to the intersection point of the camera optical axis and the laser light path 1 =500mm, the laser sheet light pulse width is the camera exposure time t=5ms, the cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com