Technology for roasting magnesite and its special apparatus

A roasting process and magnesite technology, applied in lime production and other directions, can solve the problems of high cost, many accidents, large investment, etc., and achieve the effect of improving quality and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

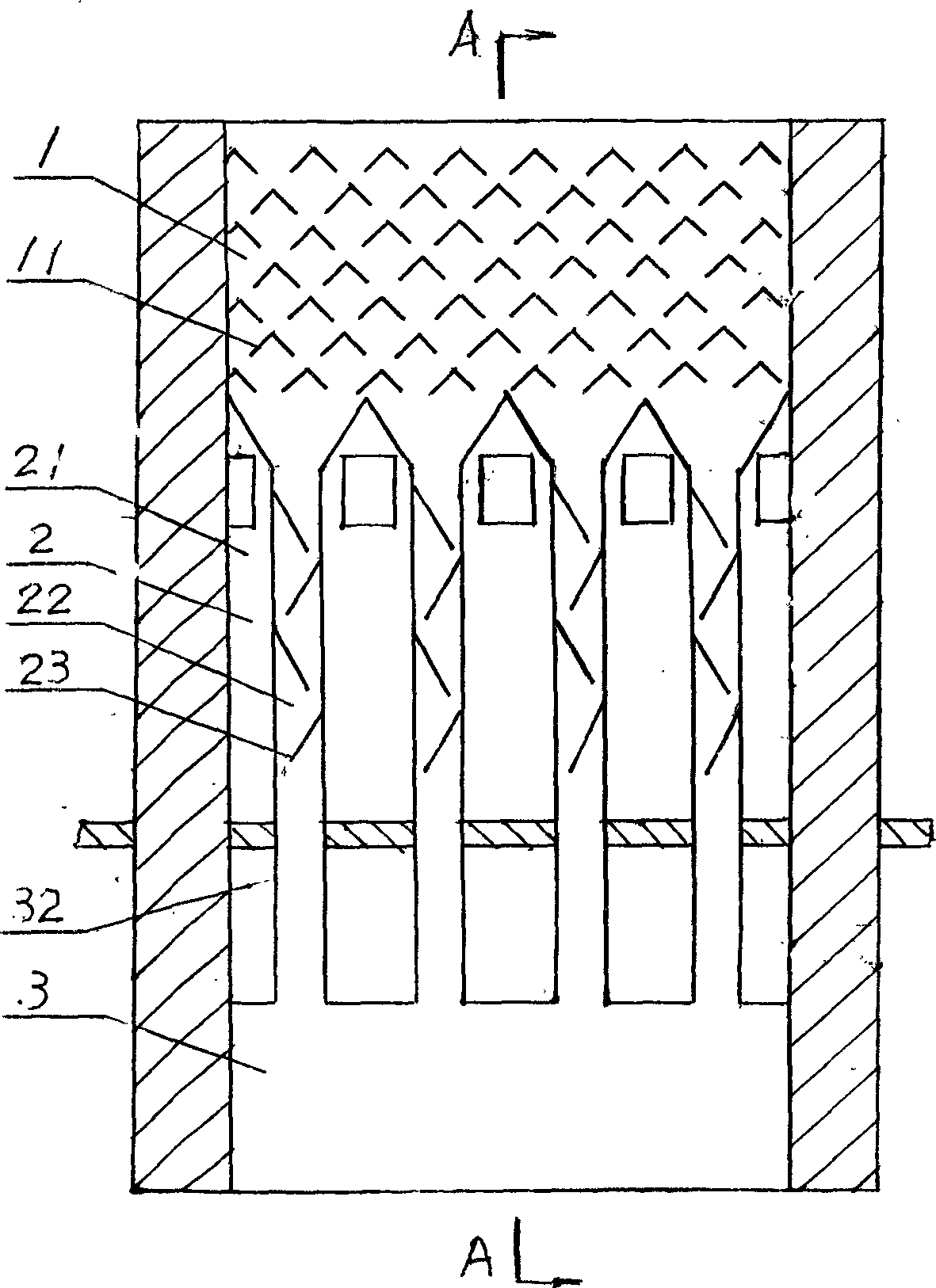

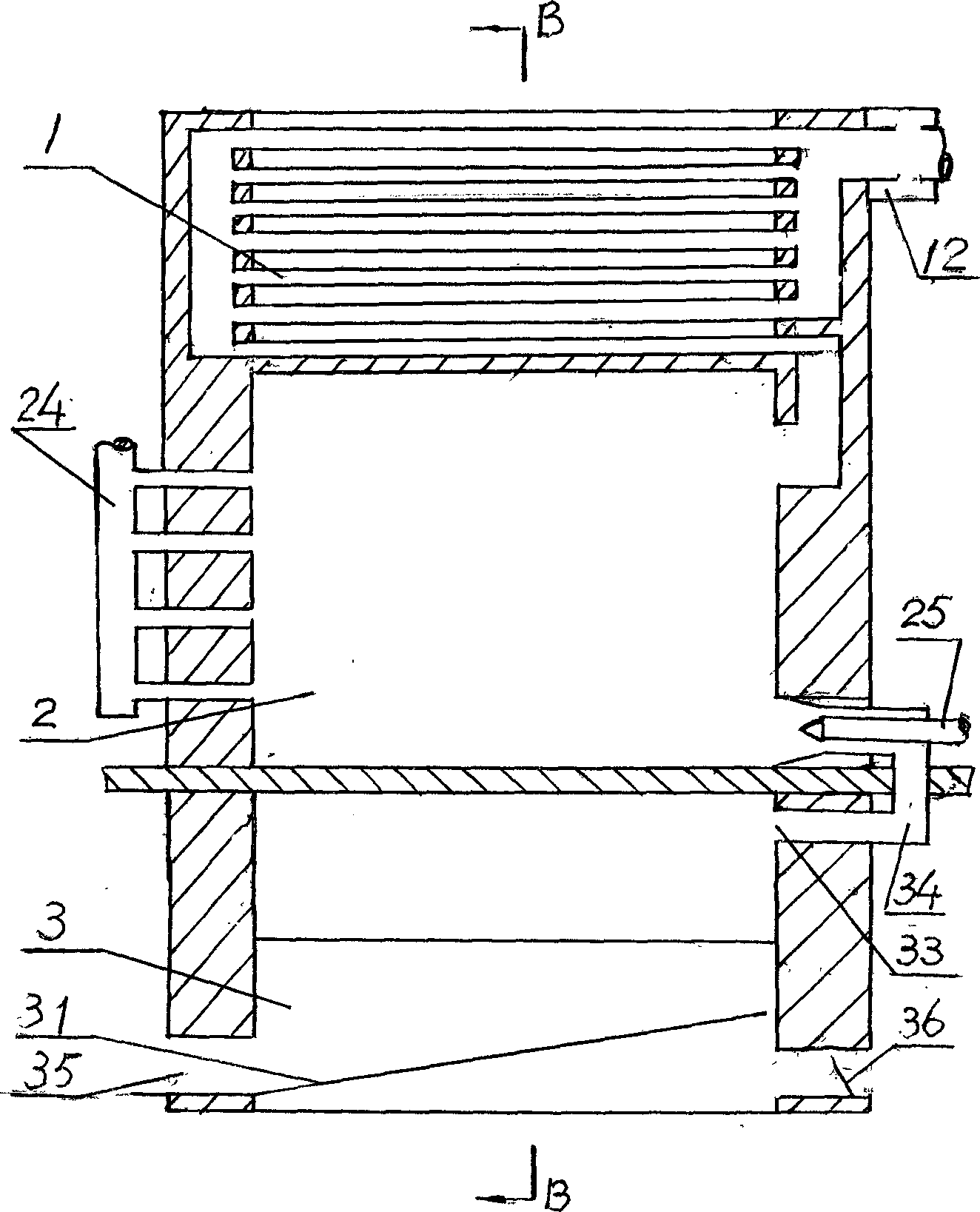

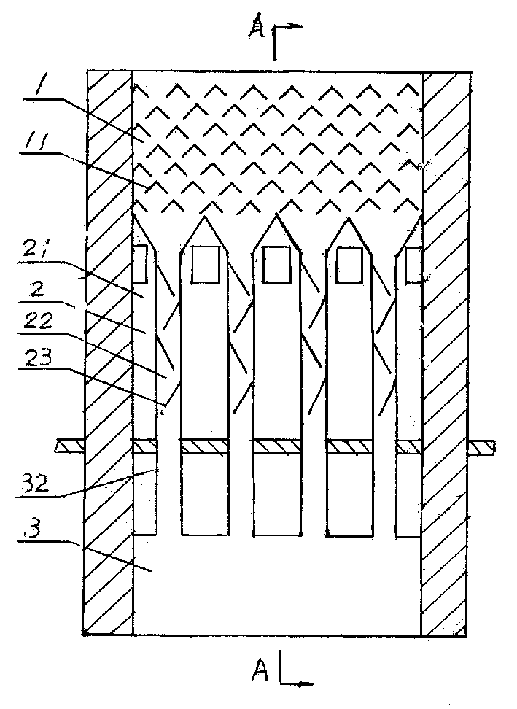

[0028] A recyclable CO 2 The magnesite external heating vertical roasting furnace is divided into three sections: preheating zone (1), decomposition zone (2) and cooling zone (3) from top to bottom according to the roasting process. An angle steel (11) is arranged in the preheating zone (1), and the angle steel is selected to be heat-resistant above 60° C., and the angles are placed horizontally in multiple rows upwards; the top layer is provided with a dust collector (12), so that the flue gas is discharged into the atmosphere after dust removal. In the decomposition zone (2), the fire chamber (21) and the material chamber (22) are alternate, and the material chamber (22) and the fire chamber (21) are made into a rectangular format; the material chamber (22) is equipped with a material guide plate (23), so that the lower space of the material guide plate (23) accommodates the decomposed CO 2 , and then extracted through the discharge hole (24) at one end, the material guide ...

Embodiment 2

[0032] A recyclable CO 2 The magnesite external heating vertical roasting furnace is divided into three sections: preheating zone (1), decomposition zone (2) and cooling zone (3) from top to bottom according to the roasting process. Round steel rods (11) are arranged in the preheating zone (1), and multiple rows are placed horizontally; the top layer is provided with a dust collector (12), so that the flue gas is discharged into the atmosphere after dust removal.

[0033] In the decomposition zone (2), the material chamber (22) is inserted into the fire chamber (fire box) (21) in the form of a rectangular column, and the material chamber (22) is provided with a material guide plate (23) so that the The lower space of the plate (23) accommodates the decomposed CO 2 , and then extracted through the discharge hole (24) at one end, the material guide plate (23) is also to stir the material layer simultaneously, so that it is heated evenly.

[0034] At the bottom of the cooling z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com