Patents

Literature

280results about How to "High quality raw material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

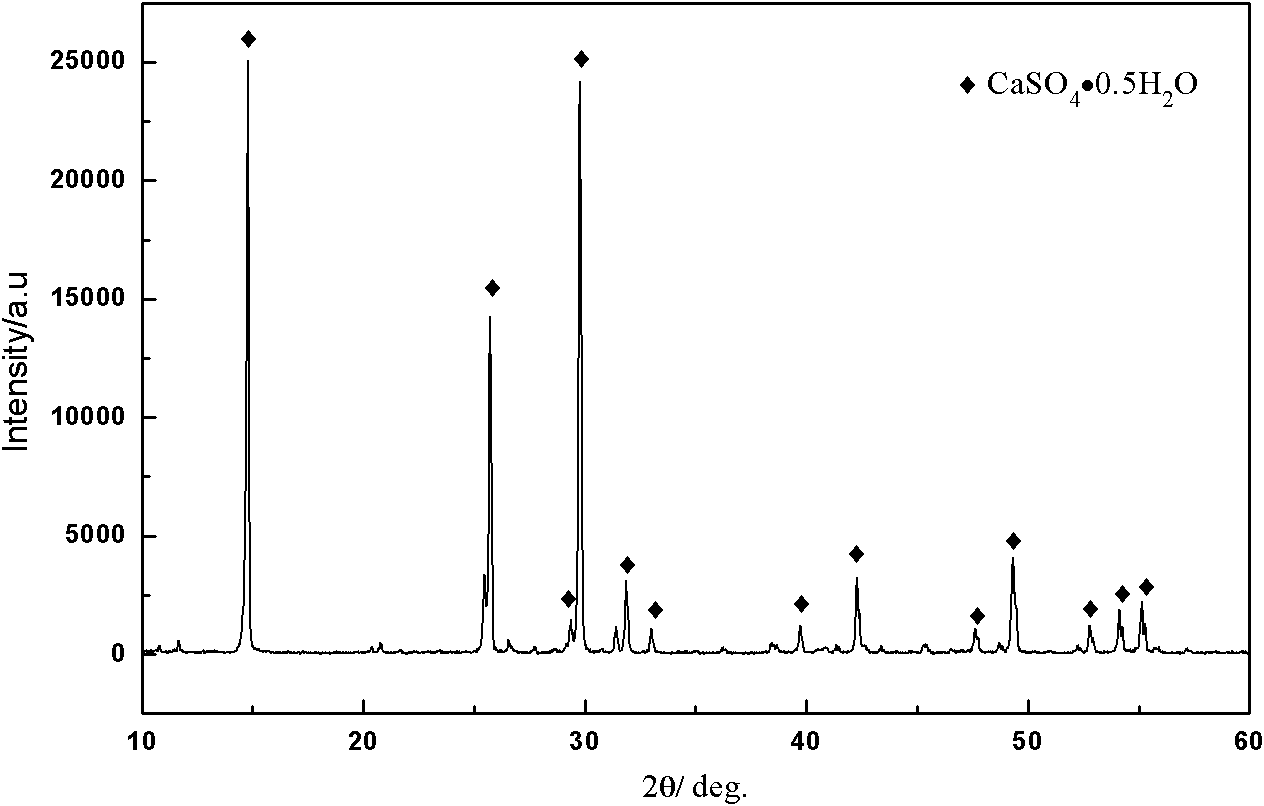

Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

ActiveCN102021329AReduce lossesLow costCalcium/strontium/barium sulfatesProcess efficiency improvementPhosphoric acidSeed crystal

The invention provides a method for extracting tungsten from scheelite and producing high-quality calcined gypsum, comprising the following steps: adding a mixed acid of phosphoric acid and sulphuric acid to decompose scheelite; and after decomposition, adding hydrated gypsum seed crystals to finish the dewatering conversion process of dihydrate gypsum to obtain hydrated gypsum with good properties. The invention has the following advantages: the efficient atmospheric pressure leaching of scheelite is realized, the resource and energy consumption is saved, and the decomposition rate of scheelite can reach over 98%; the serious problems of Cl<-> corrosion and HCl volatilization in the traditional acid decomposition process can be overcome; the recycling of phosphoric acid is basically realized, and the leaching cost and the wastewater discharge are greatly reduced; the leaching device is simple, the operation is convenient and industrialization is easy to realize; the obtained byproduct gypsum has pure quality and can be used to produce gypsum boards, and can be used in retarder, plaster and the like produced by using cement; and due to the recrystallization process, the P2O5 content in gypsum is further reduced to below 0.5%.

Owner:CENT SOUTH UNIV

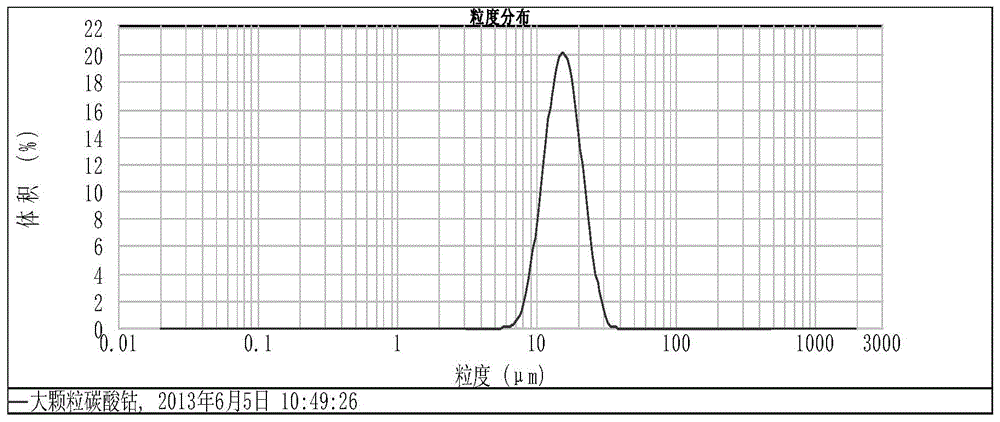

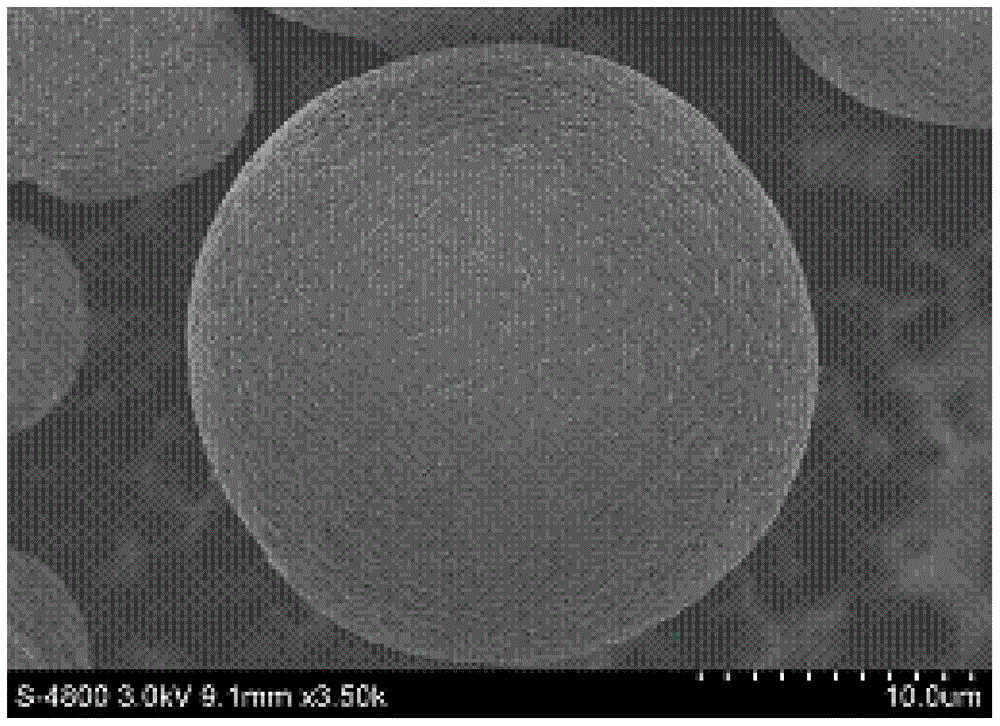

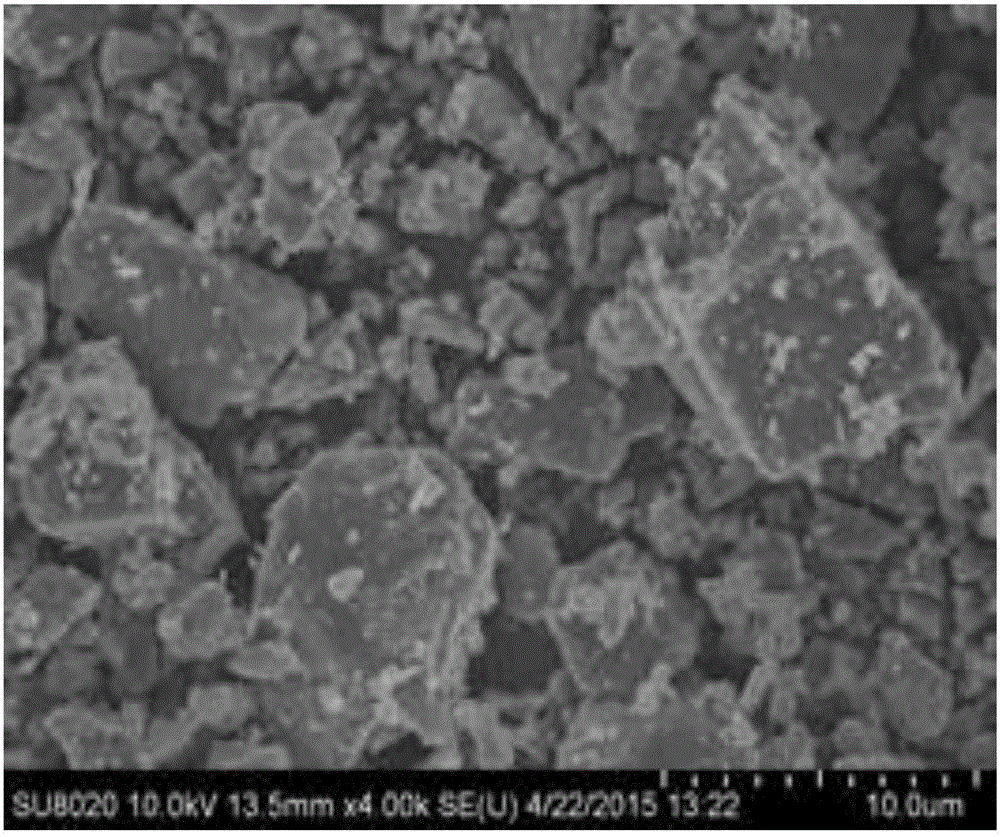

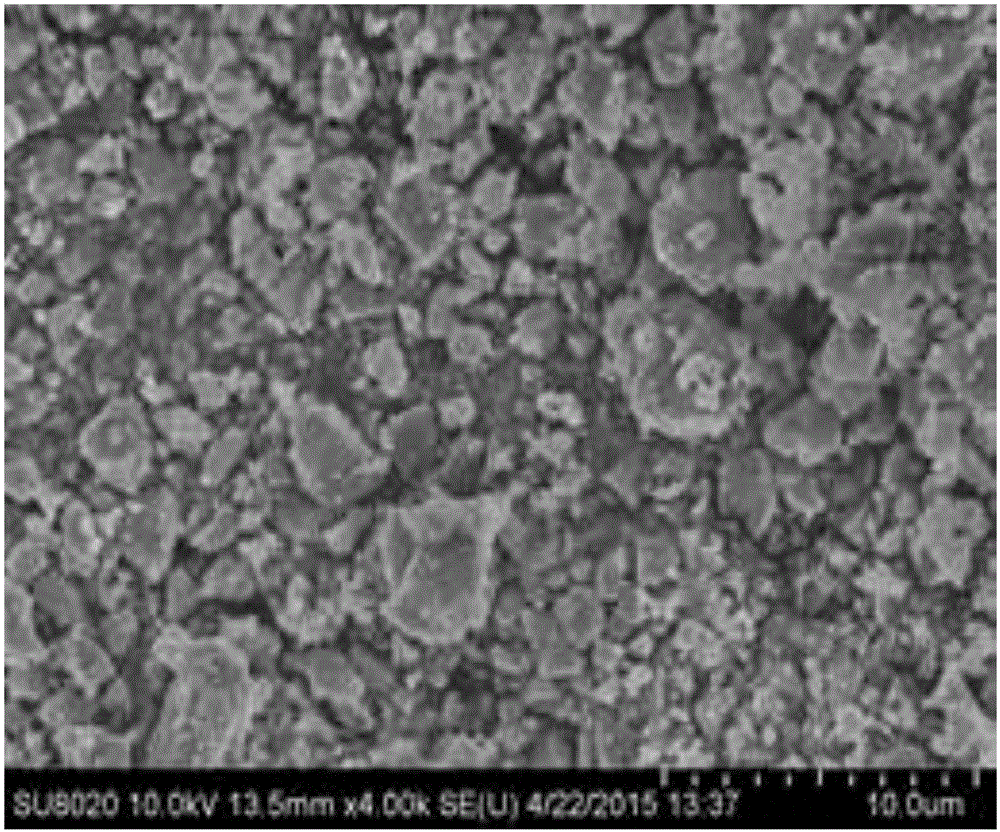

Method for continuously producing large-particle spherical cobalt carbonate

The invention relates to a method for continuously producing large-particle spherical cobalt carbonate. The method comprises the following steps: manufacturing a turbid liquid containing small-particle-size cobalt carbonate seed crystal and manufacturing a turbid liquid containing large-particle spherical cobalt carbonate, stirring the turbid liquid containing the small-particle-size cobalt carbonate seed crystal and the turbid liquid containing large-particle-size cobalt carbonate to form a mixed liquid, carrying out solid-liquid separation, washing and filter pressing to obtain a filter cake as a large-particle cobalt carbonate filter cake, drying the filter cake, and repeatedly operating to obtain the large-particle cobalt carbonate powder. According to the method disclosed by the invention, the small-particle-size cobalt carbonate seed crystal is adopted to control the particle size of the large-particle cobalt carbonate in reaction mother liquor, so that the degree of sphericity of cobalt carbonate produced by continuous production can be ensured to be high, the particle size can be stably controlled within the range of 15+ / -0.5 microns, and the consistency and the stability of the particle size of the large-particle spherical cobalt carbonate through large-scale continuous production can be realized; the method is simple in process, easy to operate and low in cost, and can provide the high-quality raw material for producing high-end lithium cobalt oxide; the carbonate is used as a precipitant, so that the environment can be optimized; the production efficiency can be improved, and the wide application prospect can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

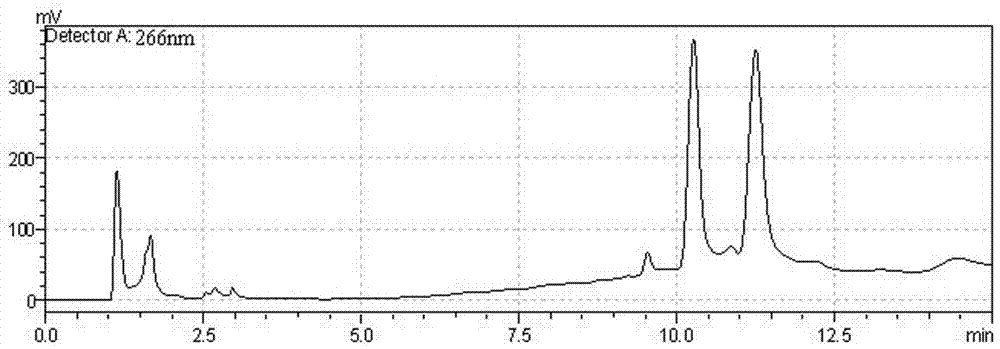

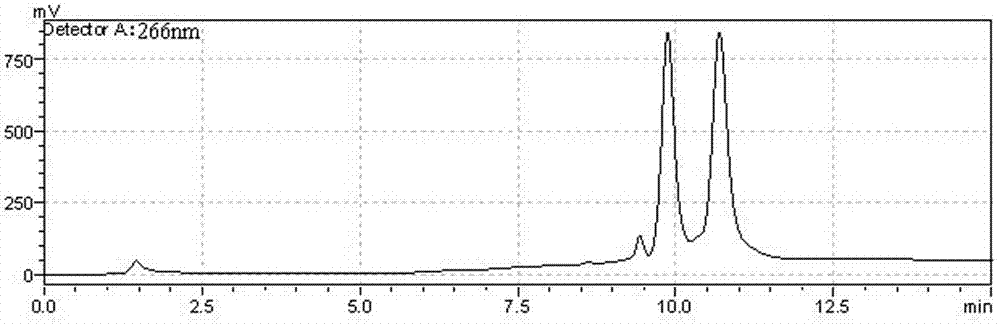

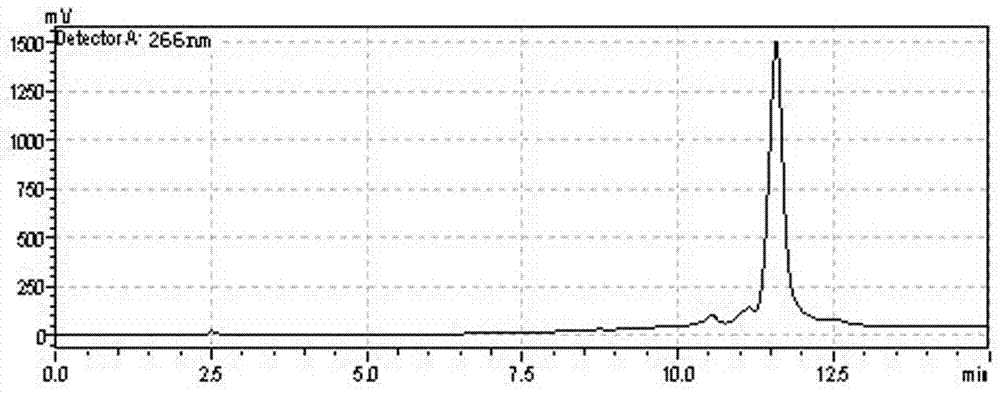

Functional peanut small molecule mixed polypeptide, preparation method and application thereof

ActiveCN101748180AHigh purityImprove solubilityHydrolysed protein ingredientsFermentationSolubilityTotal nitrogen

The invention relates to functional peanut small molecule mixed polypeptide, a preparation method and application thereof, belonging to small molecule mixed polypeptide generated by peptide chain hydrolysis.The invention is characterized in that the functional peanut small molecule mixed polypeptide is prepared by adopting the following raw material components by weight part: 100 parts of defatted peanut cake, 6-10 parts of combined enzyme preparations, 6-12 parts of active carbon, 3-8 parts of diatomite, 3-8 parts of pearlite and 100 parts of water; and the following technical indexes are achieved: the molecular weight distribution range Dalton (D) is less than or equal to 3000, the content of the small molecule mixed polypeptide is more than or equal to 80wt, the total nitrogen is more than or equal to 12wt%, the water solubility is 90wt%, the water is less than or equal to 5wt%, and the fat is less than or equal to 0.5wt%.The invention provides a product of the functional peanut small molecule mixed polypeptide with high purity, good solubility, average molecular weight of less than 3000D and strong biological functionality and a preparation method of the functional peanut small molecule mixed polypeptide with short production cycle, high product yield and low preparation cost. The functional peanut small molecule mixed polypeptide is suitable for a raw material of medicines, health food and beverage and functional nutritious food.

Owner:SHANDONG SHIJICHUN FOOD

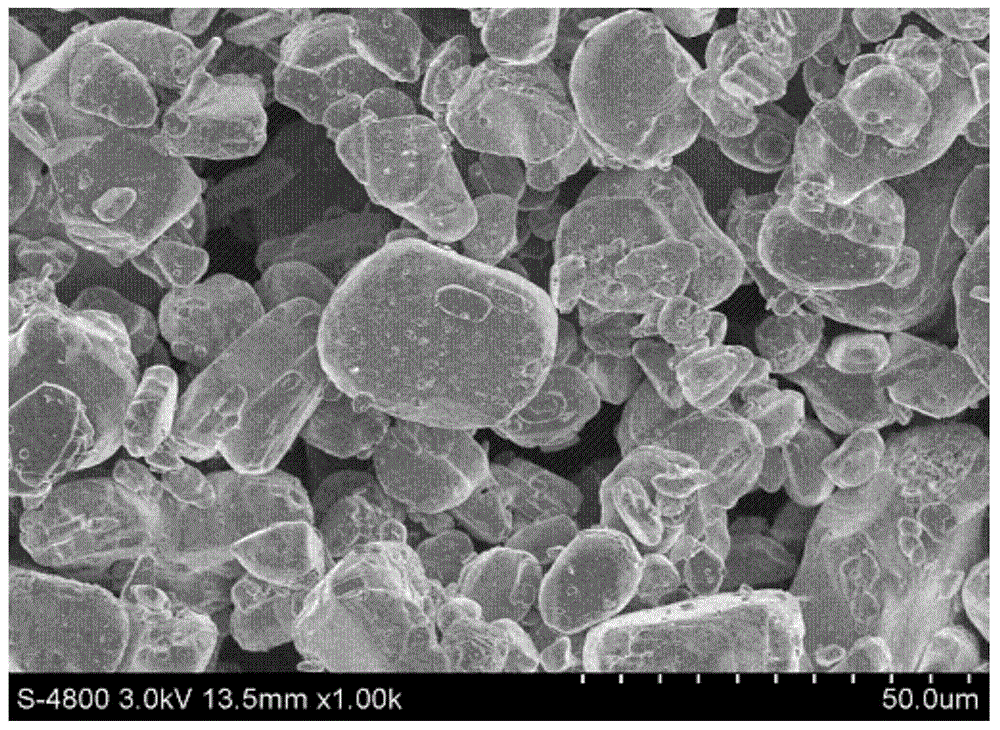

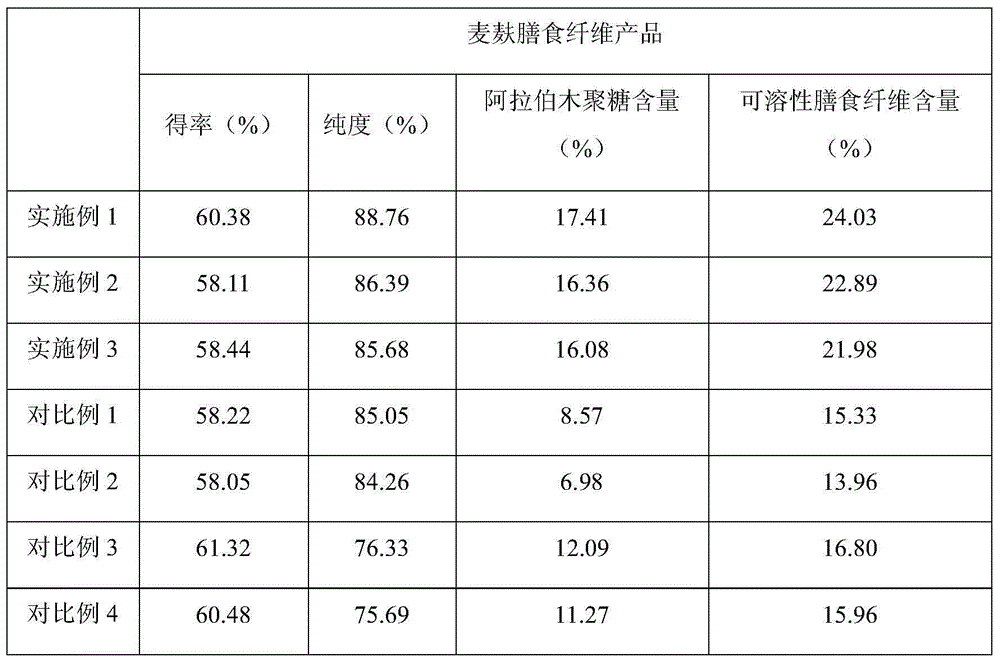

Novel method for preparing wheat bran dietary fibers by taking wheat bran as raw material

ActiveCN104544137AHigh yieldIncrease soluble dietary fiber contentFood preparationArabinoxylanEthanol precipitation

The invention discloses a novel method for preparing wheat bran dietary fibers by taking wheat bran as a raw material. The wheat bran dietary fibers are dietary fibers enriched with araboxylan and the content is more than 16.08%. The novel method takes the wheat bran as the raw material and sequentially comprises the following process steps: pre-treating the raw material; rapidly extracting with an alkaline solution; carrying out ethanol precipitation; adding water to suspend again and blasting by steam; hydrolyzing compound protease; hydrolyzing compound amylase; carrying out secondary alcohol precipitation; and sieving. The dietary fiber product has high wheat bran dietary fiber yield and dietary fiber purity, and also has high content of araboxylan and high content of soluble dietary fibers; the product has good functional properties including water binding capacity, viscosity and the like, and has a plurality of physiological functions of relaxing bowel, controlling blood glucose, lowering blood fat, adjusting human immunity and preventing colon cancer and the like, so that high-quality raw material guarantees are provided for widely applying the wheat bran dietary fibers to foods.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

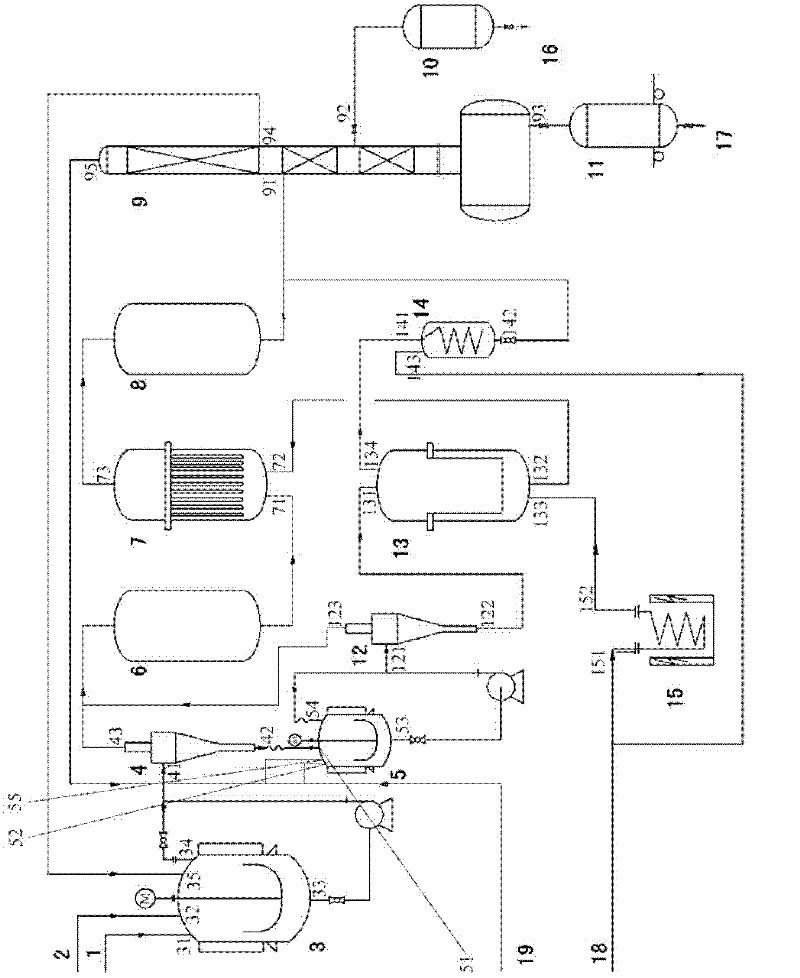

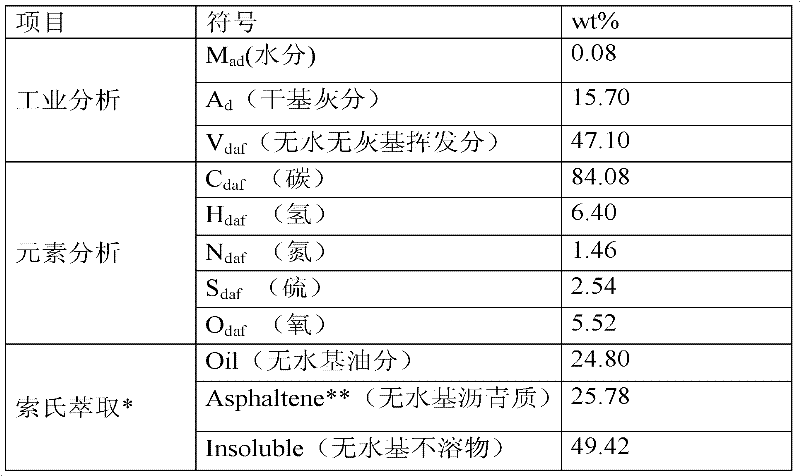

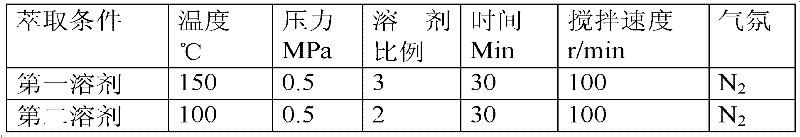

Method for extracting heavy liquefied oil and kerite substance from residue of direct coal liquefaction

ActiveCN102399566AHigh extraction rateEasy to recycleLiquid hydrocarbon mixture productionFiltrationDistillation

The invention provides a method for extracting heavy liquefied oil and kerite substances from residues of direct coal liquefaction. The method comprises steps of: a) adding coal residue powder and a first solvent into an extraction apparatus for extraction; b) carrying out solid-liquid separation on an extraction mixture and a raffinate from step a) by a first cyclone separator to obtain a liquid mixture and an underflow mixture; c) sending the underflow mixture from step b) and a second solvent to a re-extraction apparatus for re-extraction to obtain a mixture; d) carrying out a second solid-liquid separation on an extraction mixture and a raffinate from step c) by a second cyclone separator too obtain a liquid mixture and an underflow mixture; e) carrying out precise filtration on a clear liquid mixture from step b) and a re-extracting clear liquid mixture from step e) in a precision filtering device and sending a filtrate to a distillation separator; f) carrying out pressurizing coarse filtration on the underflow mixture from step d) and sending a filtrate part and a clear liquid mixture treated with precise filtration to a distillation separator; g) separating the extraction mixture in the distillation separator.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

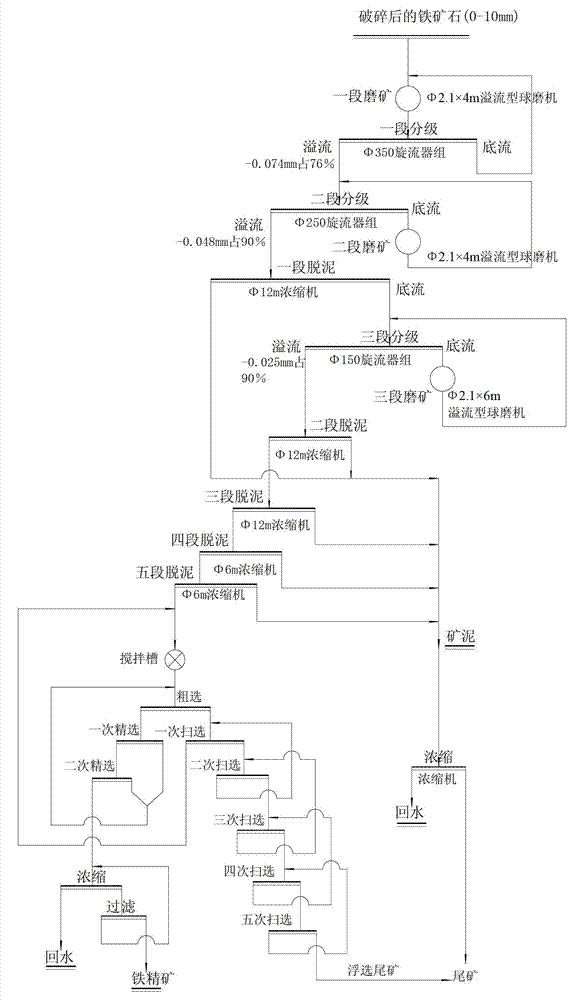

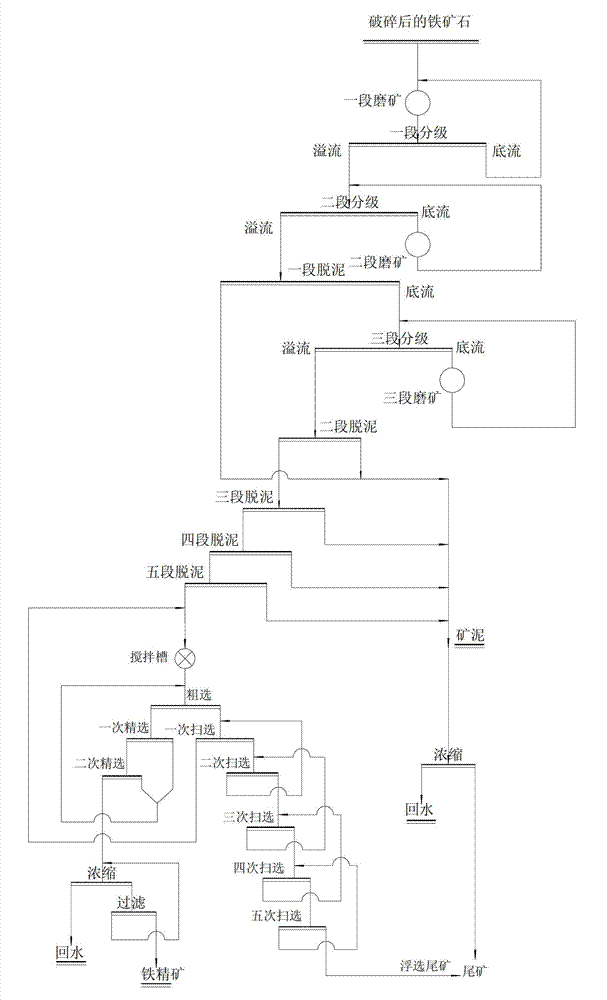

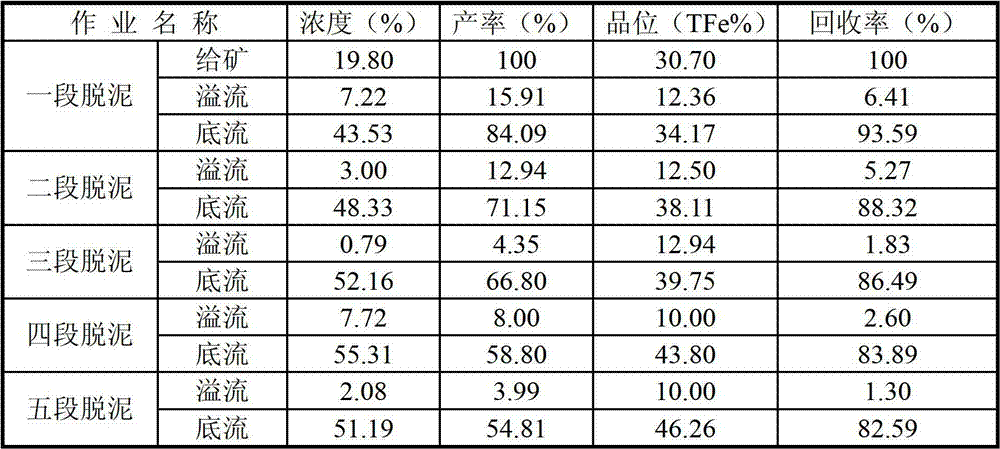

Ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore

ActiveCN102806139AEliminate the effects ofGood desliming effectDifferential sedimentationGrain treatmentsFlocculationThree stage

The invention discloses an ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore. The process comprises the following steps that crushed ore products are firstly subjected to one-stage ore grinding and one-stage grading, underflow after the grading is returned for re-grinding, and overflow is subjected to two-stage grading; underflow after the second-stage grading is subjected to second-stage ore grinding, ore grinding discharge materials are returned to the second-stage grading, and overflow is subjected to one-stage desliming; underflow after the desliming is subjected to three-stage grading and three-stage ore grinding, ore grading discharge materials are returned to three-stage grading, and overflow is subjected to second-stage desliming; next, three-section, four-section or five-section or more-section desliming is sequentially carried out; underflow after the desliming starts to be subjected to reverse flotation after the stirring, rougher flotation is firstly carried out, products in a groove after the rougher flotation are subjected to fine selection, foam products after the fine selection are returned to a rougher flotation groove, and products in a groove after the fine selection are concentrated and filtered to obtain ore concrete; and concentration machines and selective flocculation desliming processes are respectively adopted for each stage of desliming. The process provided by the invention has the advantages that the investment cost is low, the occupied area is small, the production and the maintenance are simple and convenient, the adaptability is high, the fine grinding desliming effect is good, and the like.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Production method of active earthworm protein

ActiveCN102920738ASimple production processReduce manufacturing costAnthropod material medical ingredientsMetabolism disorderChemistryOxygen supply

The invention discloses a production method of an active earthworm protein. The production method comprises the steps of: purging live earthworms, self-dissolving the earthworms, grinding, filtering, centrifuging, carrying out membrane separation and drying to obtain the active earthworm protein. The active earthworm protein has the functions of dissolving thrombus, improving systemic circulation, softening blood vessels, stabilizing plaques, establishing collateral circulation, improving blood and oxygen supply of heart and brain, bi-directionally adjusting blood pressure, reducing blood viscosity and the like. The method disclosed by the invention has the advantages of simple process, high extraction efficiency, low production cost and high production purity and can provide safe and excellent raw materials to foods, health foods, medicines and cosmetics.

Owner:周维官

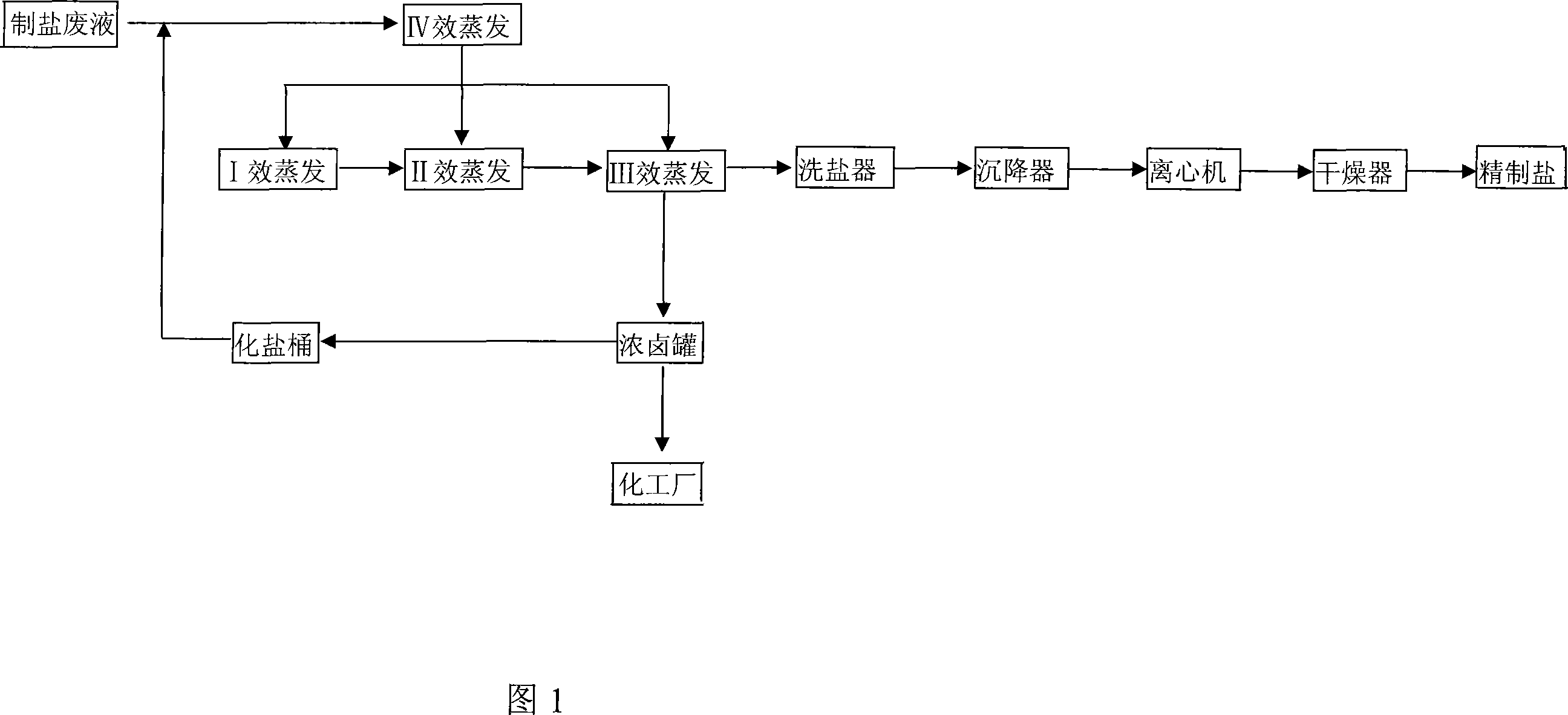

Technique for producing refined salt from salt production waste liquid

ActiveCN101104532AIncrease productionQuality improvementGeneral water supply conservationSeawater treatmentWater desalinationLiquid waste

The present invention provides a refined salt preparation technology by using salt-making liquid waste. The technology comprises the following five steps: evaporation and concentration, mother liquor thickening, bitter salt recovery, washing and dehydration, as well as drying and packaging, and the refined salt will be finally sent to the salt storehouse. The effect of the invention is that the advanced vacuum salt-making technology and salt washing process are adopted in stead of alternative drying to produce high-quality industrial salt so as to improve the yield and quality of industrial salt. Meanwhile, the invention can also help improve the concentration of bittern that enters into the potassium-making work section to reduce the salinity and provide high-quality raw materials for the production of chemical plants; the application of the invention can save the alternative drying area, raise resource utilization rate, increase product yield and reduce the loss of chemical resources to provide a model road for comprehensive utilization of the seawater salt industry as well as the concentrated seawater salt-making after the desalination. The invention achieves organic combination between the new-type salt-making industry and the ocean chemical engineering and realizes zero-discharge of the salt-making waste liquid to make the brine resources be scientifically protected and rationally used. The invention can also protect the marine environment and gradually realize factory salt production.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

Prepn process of alive adult roach extract

InactiveCN1548058AExtract completelyPromote absorptionPowder deliveryAnthropod material medical ingredientsAlcoholTwo step

The preparation process of alive adult roach extract includes the steps of: soaking alive roach in ethanol solution of 60-85 % concentration until death; soaking the roach in ethanol solution of 30-95 % concentration inside a sealed container, filtering the soaked liquid to obtain filtrate, concentrating the filtrate to obtain extractum while recovering ethanol; water extracting soaked roach via decoction for 2 or 3 times, filtering and vacuum concentration to obtain extractum; mixing the extractum obtained in the two steps; vacuum drying, and crushing to obtain powder. The product may be used in preparing some medicine for clinical application.

Owner:FUZHOU JINXIANG CHINESE MEDICINE PHARMA

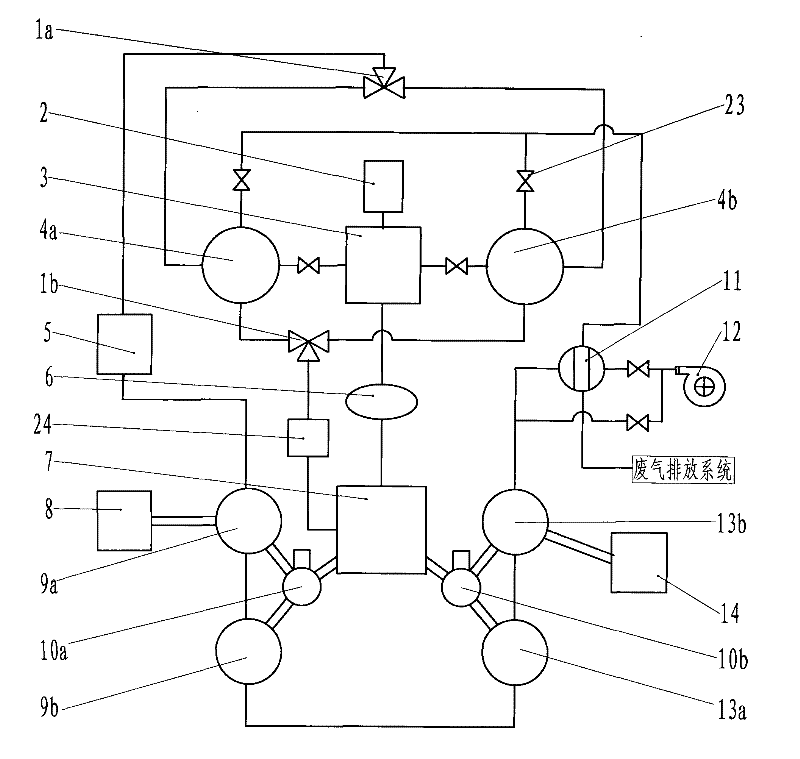

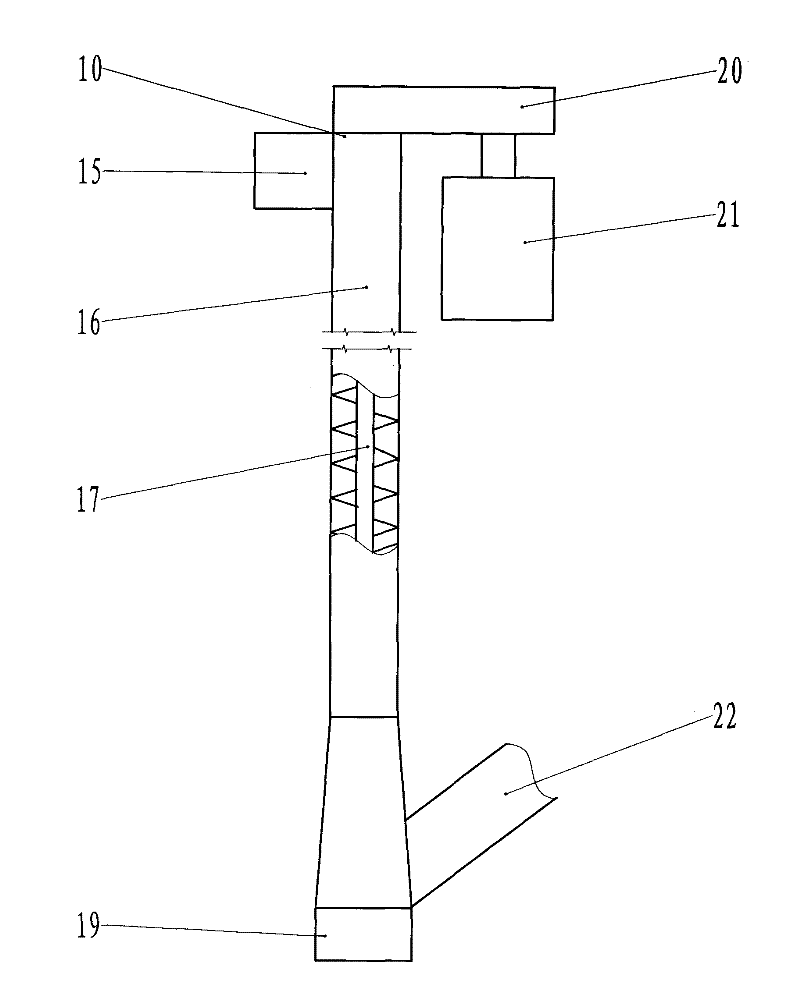

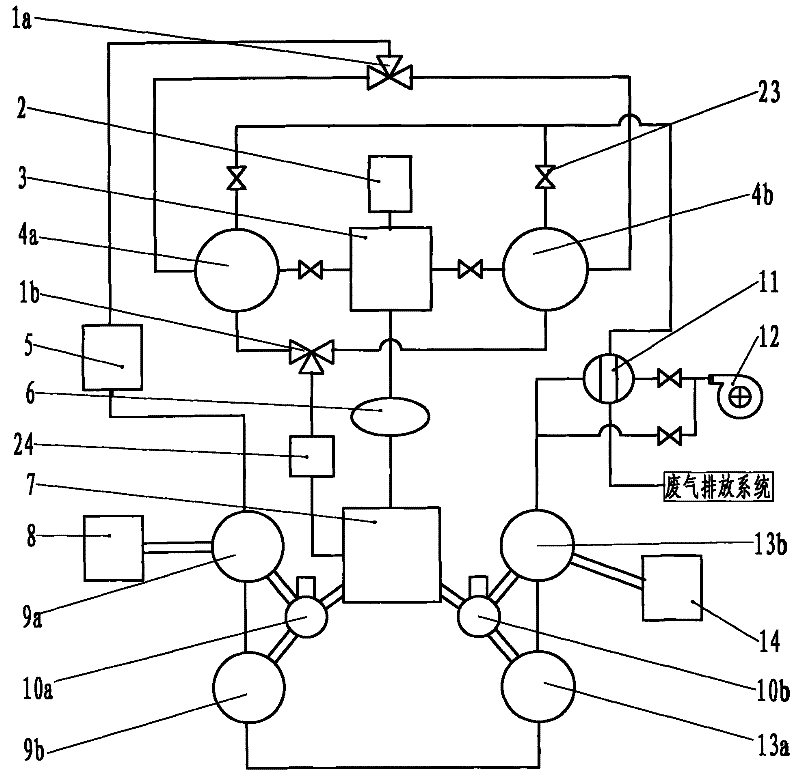

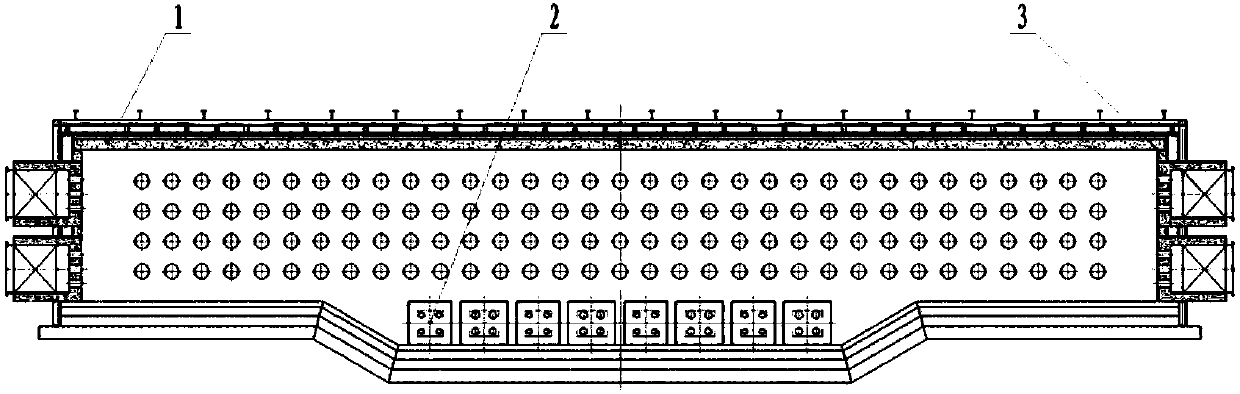

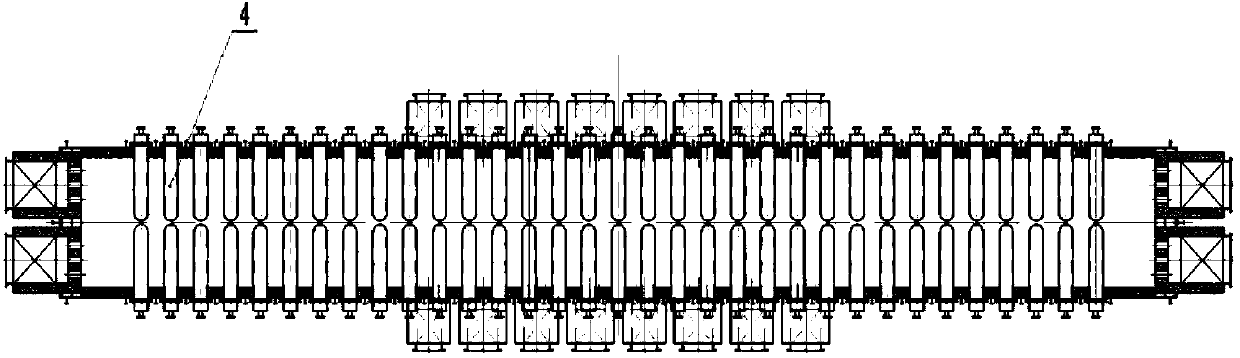

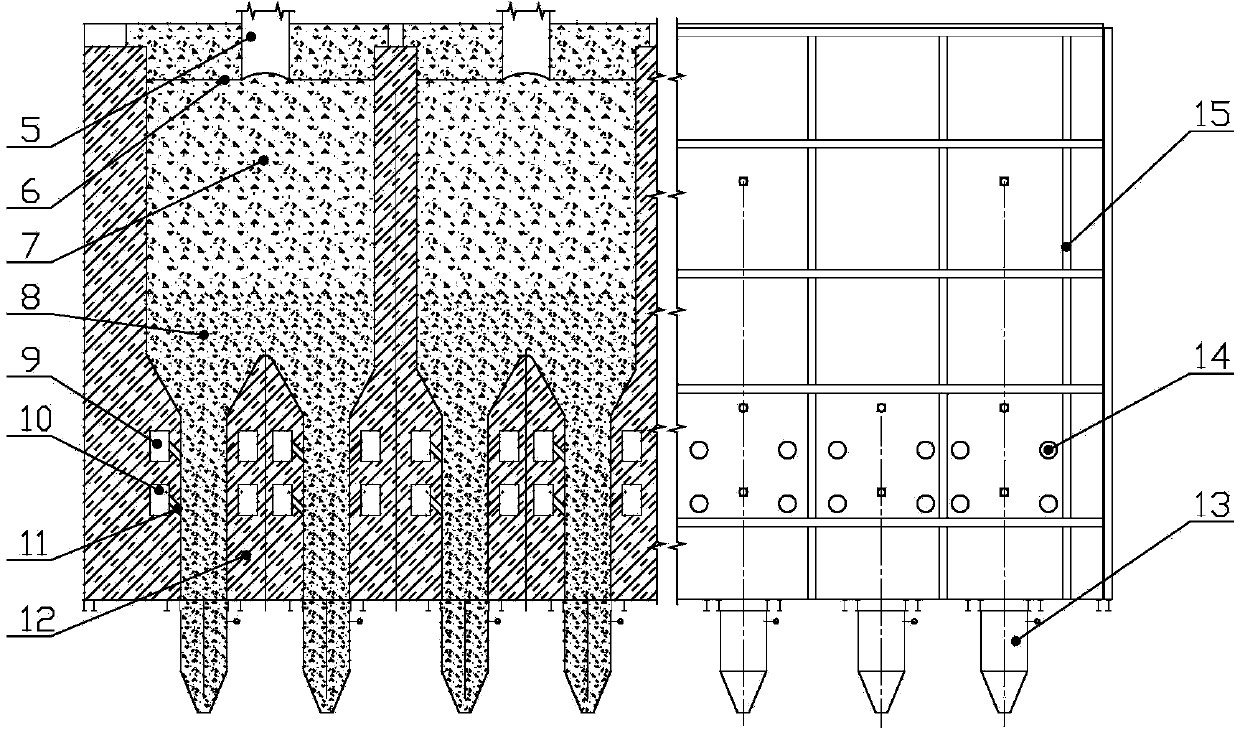

Method and device for calcining materials

The invention provides a method and a device for calcining materials. The device has a splitting type structure comprises a burning chamber, preheating chambers, a calcining chamber, cooling chambers, a heat accumulator, a gas processing unit, a material conveying machine, a feed device, a discharge device and an exhaust gas discharging system. Material to be calcined is conveyed by the material conveying machine between the preheating chambers, between the preheating chambers and the calcining chamber, between the calcining chamber and the cooling chamber and between the cooling chambers. Smoke generated by the burning in the external burning chamber is processed by the gas processing unit, and then enters the burning chamber for calcining the material. Air for cooling lime and preheating limestone material is subject to dust removing by a cyclone separator and is preheated by the heat accumulator, and then enters the burning chamber for supporting combustion. In the invention, the fuel burning and the material calcining are separated, so that the pollution of lime products caused by harmful substances can be avoided, and the quality of the lime product can be improved. The gas is subject to dust removing and then enters the heat accumulator, thus avoiding blocking a gas channel in the heat accumulator. The material conveying machine is used for conveying the material, so that the conveying efficiency is high, and the occupied space is small.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for coproducing sodium chloride, magnesium sulfate and potassium chloride

InactiveCN101591030AHigh extraction rateLong cycleMagnesium sulfatesMultistage water/sewage treatmentDecompositionEvaporation

The invention relates to a method for coproducing sodium chloride, magnesium sulfate and potassium chloride. The method for coproducing the sodium chloride, magnesium sulfate and potassium chloride is characterized in that raw material brine is subjected to processes of primary evaporation, cooling and secondary evaporation to gradually extract and separate the sodium chloride and the magnesium sulfate and prepare carnallite; and the carnallite is performed hydrolytic decomposition, and the potassium chloride is produced after washing and dehydration. The method has the advantages of realizing coproduction of three products, namely the sodium chloride, the magnesium sulfate and the potassium chloride. The extraction yield of the sodium chloride is above 85 percent; the extraction yield of the magnesium sulfate is increased to be between 56.95 and 62 percent; the extraction yield of the potassium chloride is improved by over 7 percentage; the quality of the carnallite is improved; and the content of the potassium chloride is between 19 and 23 percent, which provides good-quality raw materials for the next process.

Owner:天津长芦汉沽盐场有限责任公司

Production technology capable of efficiently separating high-activity hirudin based on anion exchange column

ActiveCN103509105ASimple processHigh extraction ratePeptide preparation methodsLeech-based protease inhibitorsPoecilobdella manillensisBiochemical engineering

The invention discloses a production technology capable of efficiently separating and purifying hirudin based on a novel anion exchange column (DEAE-silica gel separation column). The production technology taking leech powder prepared from Guangxi poecilobdella manillensis as a raw material belongs to the field of traditional Chinese medicine production, relates to extraction of animal effective ingredients and aims at solving the problems that hirudin is complicated to extract, high in cost and difficult to produce industrially. The invention is characterized in that a new hirudin separating and purifying technology is designed aiming at a separating and purifying system of the new DEAE-silica gel separation column with low cost. The technology is simple and speedy and low in cost; besides, the freeze-dried powder of the obtained hirudin is high in activity, recovery rate and purity, and long in storage life, so that safe and good-quality raw materials can be offered for industries of foods, health-care foods, medicines or cosmetics and the like.

Owner:科康生物医药(深圳)有限公司

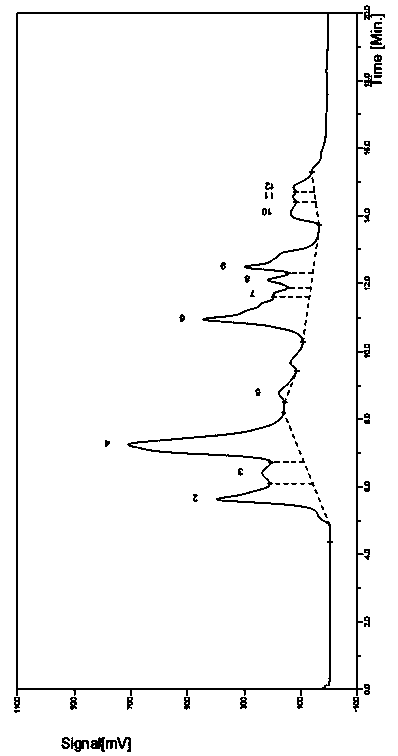

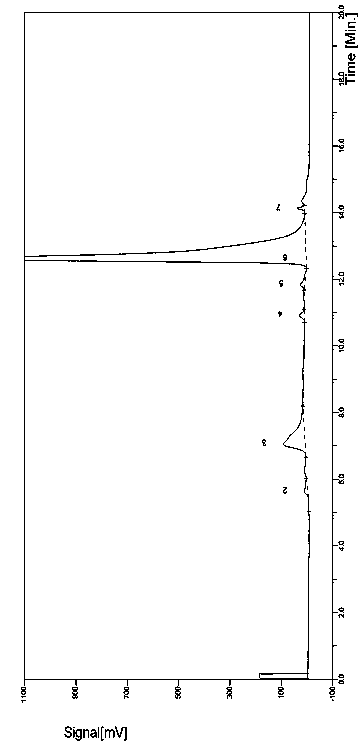

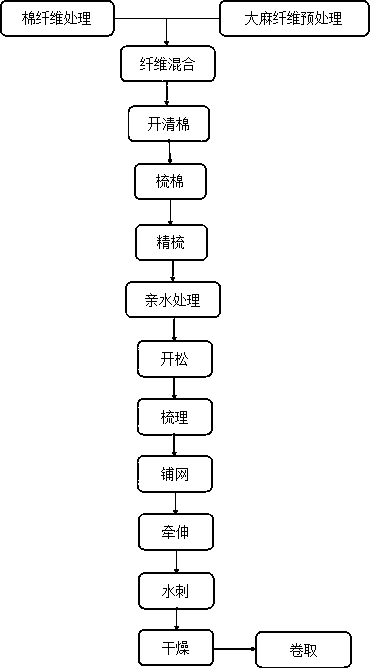

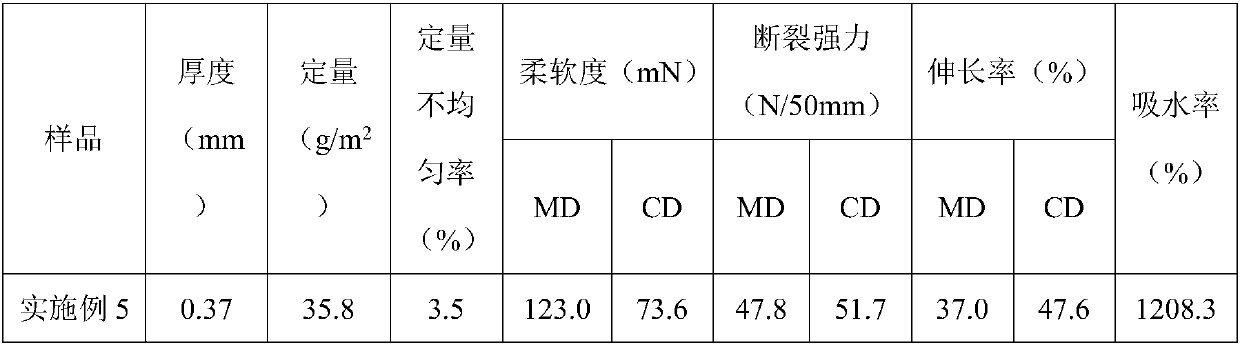

Natural antibacterial fiber spunlaced non-woven fabric and preparation method and application thereof

The invention relates to the field of sanitary articles, and provides a natural antibacterial fiber spunlaced non-woven fabric and a preparation method and application thereof. The natural antibacterial fiber spunlaced non-woven fabric comprises hemp fibers and cotton fibers. The preparation method includes the following steps that the hemp fibers and the cotton fibers are pretreated respectively;the pretreated hemp fibers and the pretreated cotton fibers are mixed; the mixed fibers are subjected to opening and picking, carding and combing in sequence to form fine silvers, the fine silvers are pull apart to form fine webs, and then hydrophilic treatment, opening, carding, lapping, drawing, spunlacing, drying and reeling are carried out to obtain the natural antibacterial fiber spunlaced non-woven fabric. According to the method, damage to the hemp fibers is small, the loss is low, and the antibacterial property of the hemp fibers is well retained; the natural antibacterial fiber spunlaced non-woven fabric is good in evenness and combines the advantages that the cotton fibers are soft and comfortable and the hemp fibers are natural antibacterial, dry and breathable; the fabric truly has the advantages of being good in evenness, soft and comfortable, natural antibacterial, dry and breathable, can be widely used in the fields of sanitary napkins, wet wipes, cotton wipes and the like, and has broad application prospects.

Owner:ZHUZHOU QIANJIN PHARMA +1

Phase-changing temperature-adjusting energy storage floor

InactiveCN1864957AHigh quality raw materialFormulation ScienceWood working apparatusFlat articlesFiberSolvent

The invention relates to a phase-change temperature-adjust energy-storage floor and relative production. Wherein, the inventive floor extracts wood from broken wood, wood wool, and chip, to be added with fiber extracted from waste paper; the wood cell wall is formed by the cellulose and hemicellulose of amylase and the wood with aromaticity. It uses the polymerization process and special extruder to make the temperature-adjust energy-storage floor at 180-280Deg. C, which will not be corrupted by general solvent, acid and alkali. The inventive production will not discharge waste and harmful gas, and it only uses wood powder, macromolecule synthetic material and agent, to save the energy and resource.

Owner:王方怡雪

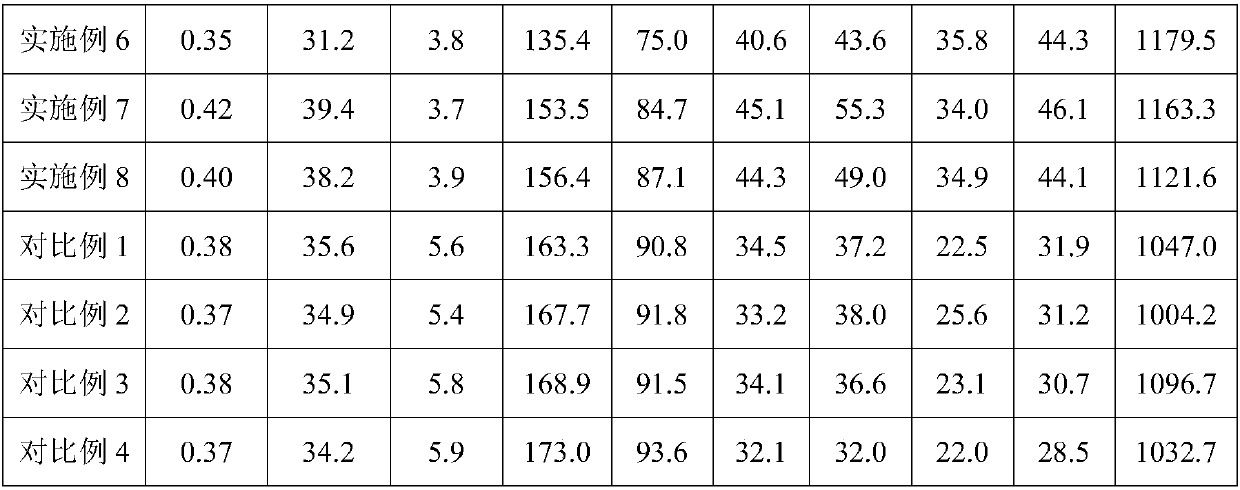

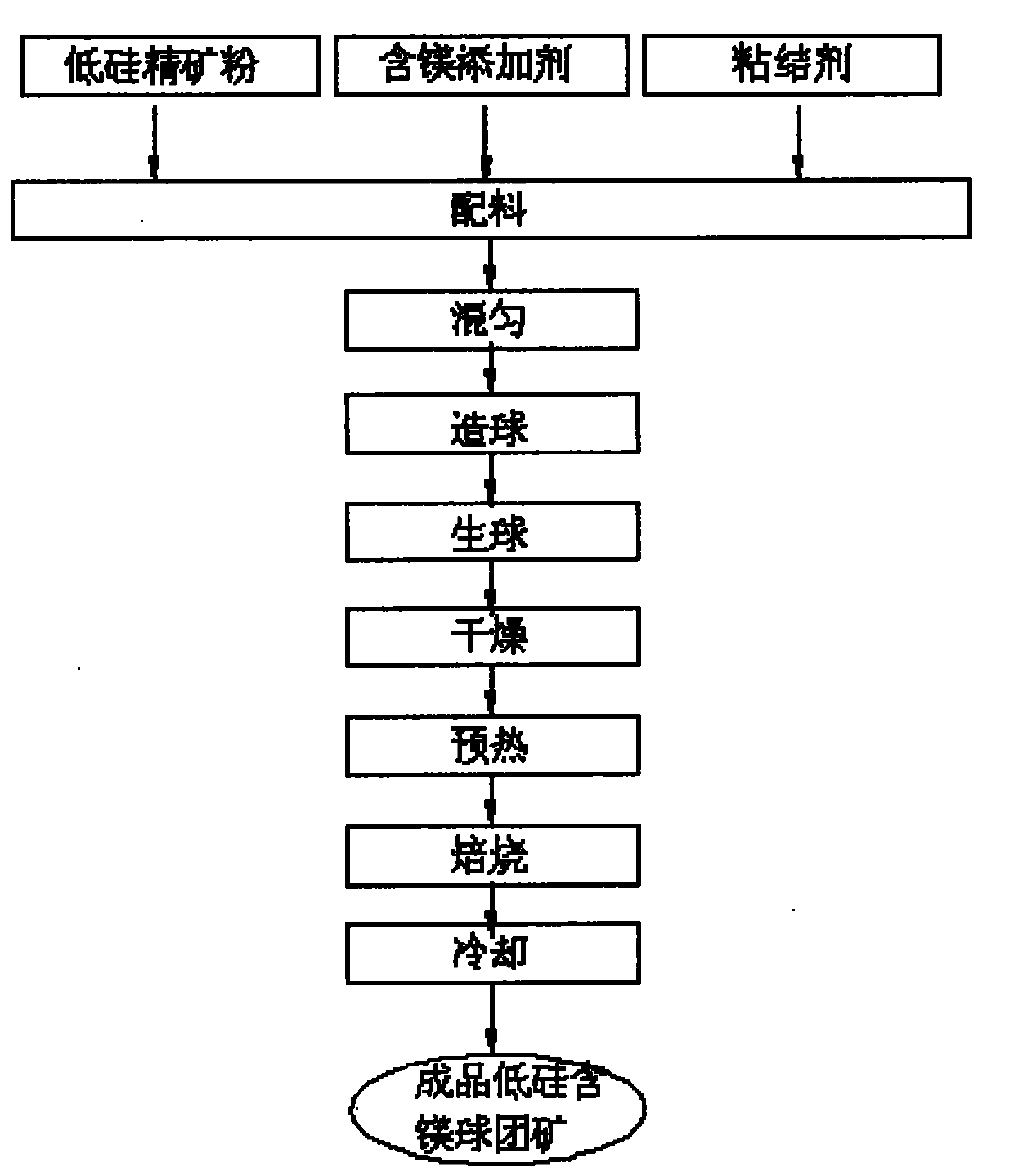

Low-silicon magnesium-containing pellets and production method thereof

ActiveCN101906533AImprove reducibilityGood droplet characteristicsBlast furnace detailsBLENDER/MIXERTO-18

The invention discloses low-silicon magnesium-containing pellets and a production method thereof. The method comprises the following steps of: proportioning 95 to 98.5 mass percent of low-silicon ore concentrate powder, 1 to 4 mass percent of magnesium-containing additive and 0.5 to 1.0 mass percent of binder, uniformly mixing the low-silicon ore concentrate powder, the magnesium-containing additive and the binder by using a blender mixer, adding an appropriate amount of water and controlling the water content of the mixture to be between 7.0 and 8.5 percent, wherein the magnesium-containing additive can be selected from magnesia powder, caustic calcined dolomite, dolomite, olivine and boric sludge and the binder can be selected from bentonite or a composite binder; pelletizing the mixture in a pan pelletizer, forming a mother pellet, adding materials and water gradually to allow the mother pellet to grow bigger and denser, screening green pellets of between 9 and 16 millimeters and performing a continuous roasting process consisting of drying, preheating, roasting and cooling; drying the pellets at the temperature of between 200 and 450 DEG C for 8 to 10 minutes, preheating the pellets at the temperature of between 700 and 1,050 DEG C for 10 to 15 minutes and roasting the preheated pellets at the high temperature of between 1,280 and 1,350 DEG C for 12 to 18 minutes; and cooling the roasted pellets to be less than 100 DEG C after roasting is finished so as to obtain the low-silicon magnesium-containing pellets serving as finished products.

Owner:SHOUGANG CORPORATION

Pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw

InactiveCN106701836APromote degradationLarge specific surface areaBiofuelsSolid fuelsPretreatment methodBiofuel

The invention discloses a pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw, and relates to the field of comprehensive utilization of all components of plant straw, wherein the pretreatment method comprises the steps: plant straw after being cut into sections is successively subjected to washing treatment for two times before and after steam explosion, steam explosion treatment, extrusion treatment, crushing treatment, pre-enzymolysis treatment, cracking treatment, and enzymolysis treatment, and finally a pre-product for preparing the biomass fuels is obtained; a straw washing liquid obtained after washing treatment and an extrusion liquid obtained after extrusion treatment are used for producing marsh gas, and a liquid, gas and solid biomass fuels can be obtained after the pre-product is treated. The method realizes separation and high-valued complete utilization of the all components of the plant straw, namely hemicellulose, cellulose, lignin and a small amount of components, can achieve no pollutant emission, and has the advantages of easy industrialization operation, good economic benefits, and remarkable comprehensive social benefits.

Owner:北京利晟新能生物科技中心(有限合伙)

Method for quickly preparing flavonoid glycoside from oil-tea meal

ActiveCN105440092AEfficient separationReduce lossesSugar derivativesSugar derivatives preparationCamellia oleiferaActive component

The invention discloses a method for quickly preparing flavonoid glycoside from oil-tea meal. The method comprises the following steps of firstly obtaining total flavonoid crude extracts from the oil-tea meal through ethanol extraction, performing enrichment and purification operation by utilization of macroporous adsorption resin, performing low pressure column chromatography refinement, and separating flavonoid glycoside monomers from the oil-tea meal. The method disclosed by the invention has the advantages that large precision equipment is unnecessary, the operation steps are simple and easily mastered, and the effects of simplicity, strong stability, strong repeatability, high yield and low loss of effective components are achieved; active components, namely flavonoid monomers, can be effectively separated from the oil-tea meal, and an important evidence is provided for further scale-up experiment and industrialized production, and excellent raw materials are provided for the development of flavonoid glycoside drugs and healthcare products from the oil-tea meal.

Owner:信阳学院

Method for preparing zirconium tetrachloride through fluidizing chlorination of zircon sand with silicon tetrachloride as byproduct

ActiveCN105565377AEmission reductionReduce manufacturing costCarbon monoxideHalogenated silanesTetrachlorideCollection system

The invention relates to a method for preparing zirconium tetrachloride through fluidizing chlorination of zircon sand with silicon tetrachloride as a byproduct. The method is a preparation method of zirconium halide. A system for realizing the method comprises a zircon sand fluidizing chlorination system, a zirconium tetrachloride condensation and collection system and a silicon tetrachloride rectification system, and also comprises a tail gas recycling system; the tail gas recycling system comprises a tail gas storage device, a chlorine separation and recovery device and a CO recovery and storage device; chlorine in separated and collected tail gas is used as a raw material of a zircon sand fluidizing chlorination reaction, and can be recycled; and the chlorine separated tail gas is used as a raw material of an industrial production apparatus for carrying out a CO participated synthesis reaction. The method for preparing zirconium tetrachloride through fluidizing chlorination of zircon sand with silicon tetrachloride as a byproduct, provided by the invention, has the advantages of effective utilization of Cl2 and CO resources, reduction of discharge of the greenhouse gas CO2, reduction of the product production cost of a zircon sand fluidizing chlorination apparatus, and improvement of the productivity of the apparatus.

Owner:山东广通新材料有限公司

Activation treatment method of oil shale distillation slag

The invention relates to an activation treatment method of oil shale distillation slag, which mainly comprises the following four steps: oil shale crushing, dry distillation activation, acid leaching, and calcination treatment. The invention is characterized in that the step of dry distillation activation of oil shale is carried out twice, and inorganic components are fully activated and removed through temperature adjustment, so as to finally obtain acid leaching residue in which carbon and silica are main components. The invention has the advantages as follows: the dry distillation and the activation of the oil shale are carried out simultaneously, and removed ash residue has higher reactivity and doesn't need second activation treatment, so that the activation energy consumption is greatly reduced; part of organic matters in the oil shale is transformed into shale oil, and the rest components are all burned fully to be converted into heat energy, so that all the organic matters are fully used; the low-consumption preparation of shale oil from oil shale is realized, useful components such as aluminium iron and the like are extracted, and high-quality raw materials for preparing cement and silica from ash residue with silica are obtained.

Owner:上海森永工程设备股份有限公司

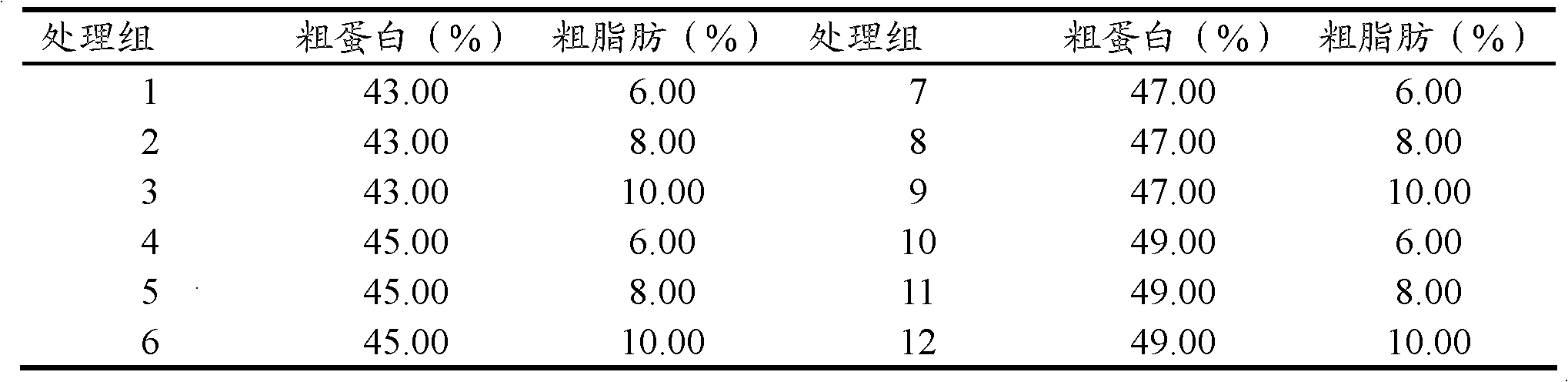

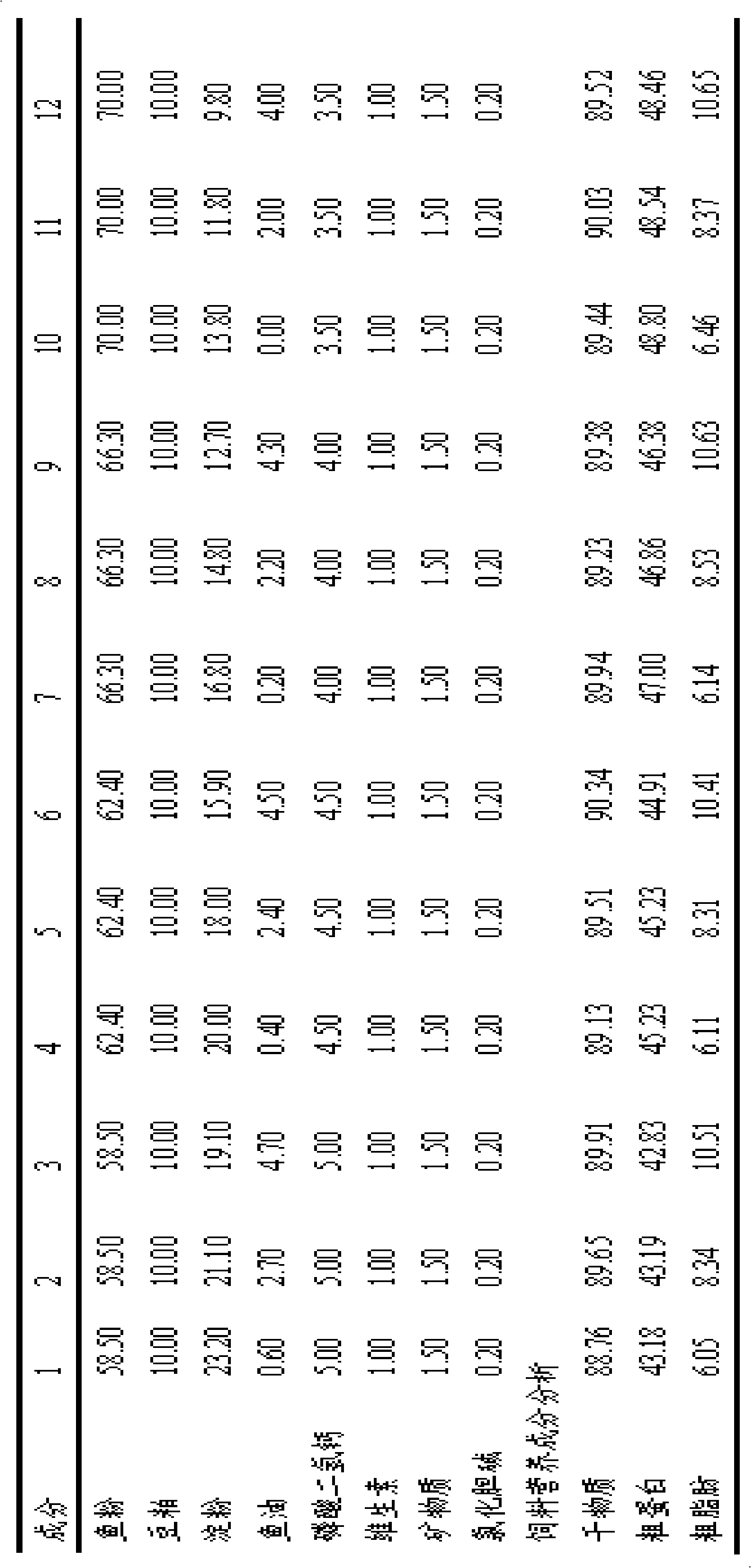

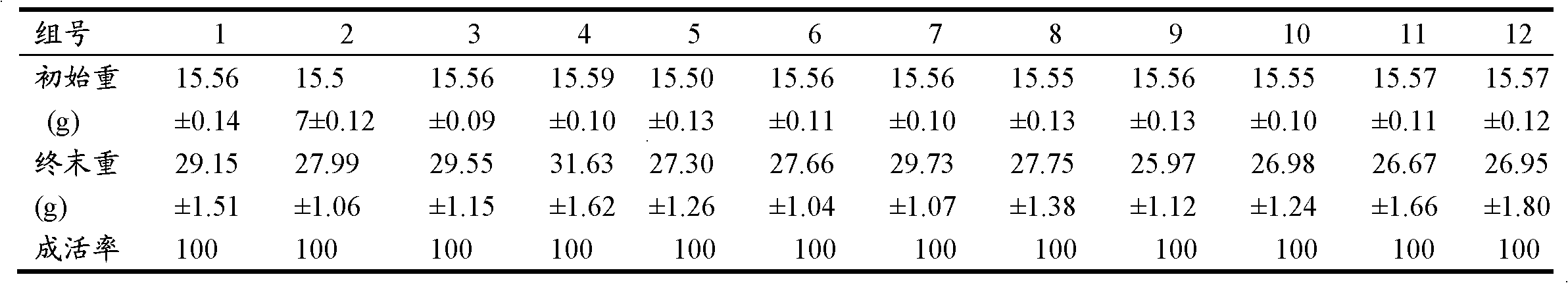

Special feed for juvenile alligator snapping turtle

InactiveCN101971930AHigh quality raw materialNutritional formulation scienceClimate change adaptationAnimal feeding stuffFish oilMonocalcium phosphate

The invention discloses special feed for a juvenile alligator snapping turtle, which comprises the following components in percentage by weight: 49 percent-70 percent of fish meal, 8 percent-30 percent of bean pulp and / or meat and bone meal, 9.8 percent-23.2 percent of starch, 0.2 percent-4.7 percent of fish oil, 0 percent-6 percent of monocalcium phosphate, 0.5 percent-1 percent of vitamin, 1 percent-2 percent of mineral substance and 0.1 percent-0.3 percent of choline chloride. In the invention, the special feed for the juvenile alligator snapping turtle has the advantages of excellent raw materials and scientific nutrition preparation and can ensure that the raw materials are completely ingested by the juvenile alligator snapping turtle without generating aquaculture pollution caused by waste feed, wherein the crude protein is more than or equal to 45 percent, the crude fat is more than or equal to 6 percent, the water content is less than or equal to 10 percent, and the floating time is up to 8-10 hours; after the part of fish meal is replaced by the bean pulp and / or the meat and bone meal, the survival ratio of the alligator snapping turtle is not influenced, but various indexes, such as terminal weight, specific growth ratio, weight growth ratio and the like are obviously improved, and the production cost is greatly reduced.

Owner:GUANGZHOU XIANBU AGRI TECH

Alkoxy silicon resin intermediate and preparation method thereof

ActiveCN102887916AImprove heat resistanceGood weather resistanceGroup 4/14 element organic compoundsEnvironmental resistanceAlcohol

The invention relates to an alkoxy silicon resin intermediate and a preparation method of the alkoxy silicon resin intermediate. The alkoxy silicon resin intermediate contains 8-15% of alkoxy; and the alkoxy silicon resin intermediate is of 10-500mm<2> / S based on the viscosity. The preparation method of the alkoxy silicon resin intermediate comprises steps as follows: (1) adding alcohol to organosilane for alcoholysis reaction; (2) adding a catalyst to a product generated in the alcoholysis reaction for condensing for 1-8 hours at 50-200 DEG C, so as to obtain a condensation product; (3) adding water to the condensation product for hydrolyzing at 30-100 DEG C; and (4) neutralizing until reaching pH (Potential Of Hydrogen) of 6-8, removing methanol in the product, and discoloring and filtering to obtain the alkoxy silicon resin intermediate. The alkoxy silicon resin intermediate provided by the invention is applicable to modified organic resin with active hydroxyl functional group, and also can be directly mixed with a curing agent; the alkoxy silicon resin intermediate is applied to coal coating, appliance paint and other high-temperature resistant products; and with adoption of the preparation method of the alkoxy silicon resin intermediate, less by-products are produced and the preparation method is economic and environment-friendly.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Removing method of boron impurities in metalluragical silicon

The invention discloses a removing method of boron impurities in metallurgical silicon, comprising the following steps: immersing the metallurgical silicon powder into acid for 6 hours to 48 hours to carry out acid cleaning, washing the metallurgical silicon powder, drying the metallurgical silicon powder, putting the metallurgical silicon powder subjected to the acid cleaning, the washing and the drying into a reactor, heating the metallurgical silicon powder to the temperature of 300 DEG C-700 DEG C, introducing oxidizing gas to carry out an oxidizing reaction for 6 hours to 72 hours, immersing the metallurgical silicon powder which is heated and oxidized into water or acid for 1 hour to 6 hours, washing the metallurgical silicon powder, and baking the metallurgical silicon powder which is immersed and washed for 6 hours to 24 hours at the temperature of 100 DEG C-300 DEG C. With the purification process of the metallurgical silicon of the invention, because the purification is completed at lower temperature, the operation is easier and simpler, the purification cost is also reduced. Thus, high quality raw materials are provided for later processes so that needs of producing solar-grade polycrystalline silicon at low cost are met.

Owner:JACO SOLARSI

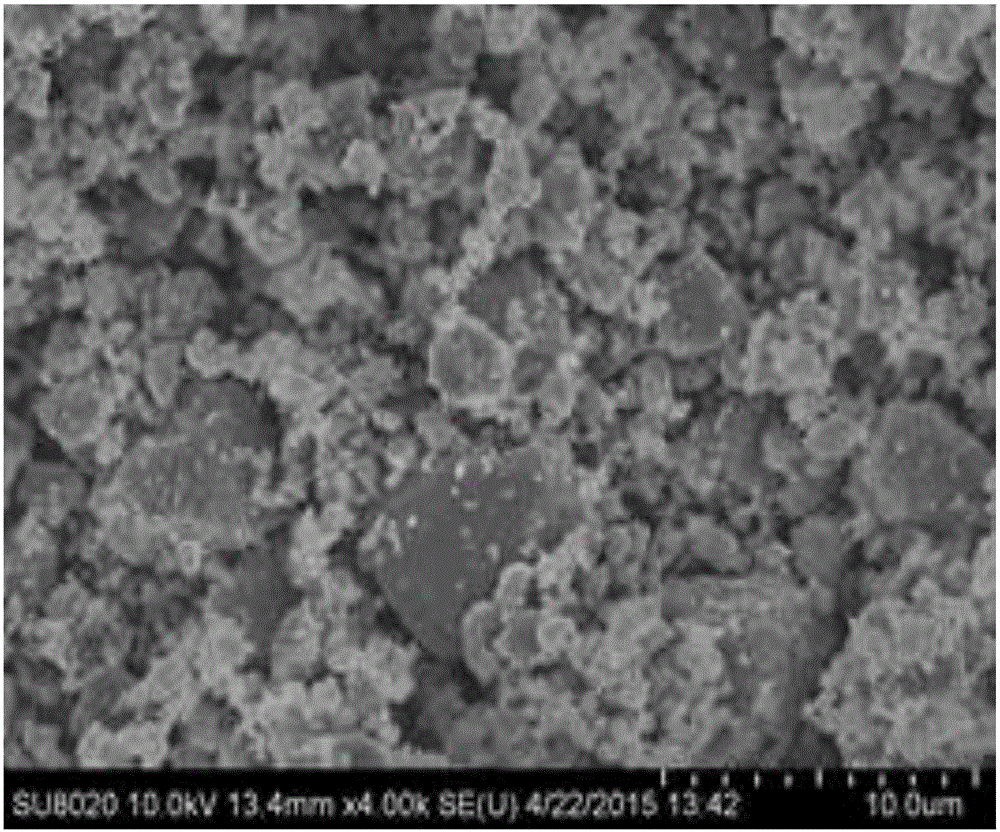

Preparation method of micro low-oxygen titanium hydride powder

InactiveCN105195750AIncrease oxygen contentGood hydrogenation effectHydrogenation reactionOxygen content

The invention relates to a preparation method of micro low-oxygen titanium hydride powder, and belongs to the technical field of powder preparation in a powder metallurgy technology. Hydrogenation treatment and a ball grinding technology are combined; firstly, high-purity hydrogen is fed under a vacuum condition, so that blocky sponge titanium and the hydrogen generate hydrogenation reaction to prepare titanium hydride; then the titanium hydride is crushed by the mechanical ball grinding technology, so that the titanium hydride powder is obtained. The oxygen content of the prepared micro low-oxygen titanium hydride powder is 500 to 900ppm, and the average particle size D50 is 1 to 10 microns.

Owner:BEIJING UNIV OF TECH

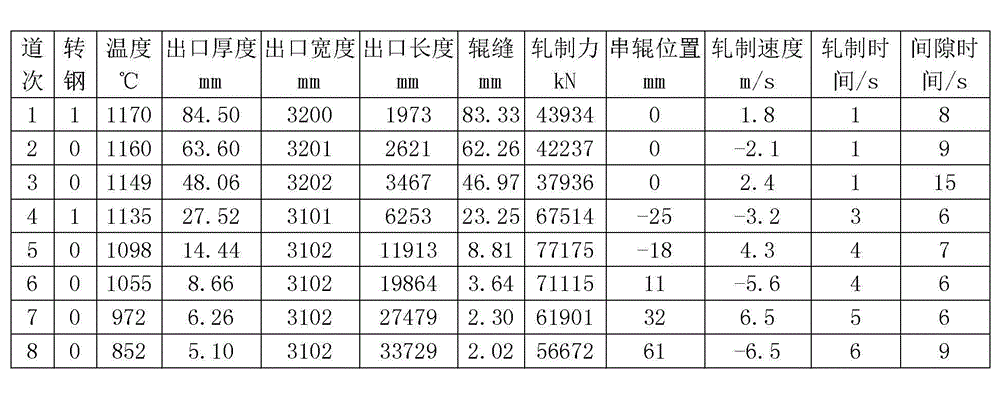

Method for rolling steel plate with heavy and medium plate mill

InactiveCN103331304AReduce vertical and horizontal performance differencesProduct Economic GuaranteeMetal rolling arrangementsSteel platesSheet steel

The invention relates to a method for rolling a steel plate with a heavy and medium plate mill. According to the method for rolling the steel plate with the heavy and medium plate mill, a steel plate with a thickness of 5-6mm is manufactured with the heavy and medium plate mill and is heated with a stepping heating furnace, the steel plate is put into the stepping heating furnace for 180-240 min, and soaking is carried out for 28-35 min at the temperature of 1210-1230 DEG C; the temperature for initial rolling is 1150-1180 DEG C and the temperature for final rolling is controlled between 800 DEG C and 900 DEG C; the cycle of a working roller is 500-800t; the maximum pressing reduction is 48-52mm every single time, and the maximum rolling force is 90000 kN; the roll bending force of the working roller is 1000-2000 kN, and the deviation range of the working roller is -50-+100mm. The method for rolling the steel plate with the heavy and medium plate mill has the advantages that the ultrathin steel plate with the thickness of 5-6mm and with a width more than 3000mm can be rolled, and the difference between the longitudinal performance and the horizontal performance of the steel plate is reduced.

Owner:ANGANG STEEL CO LTD

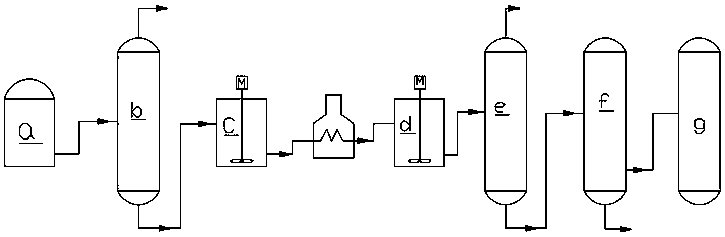

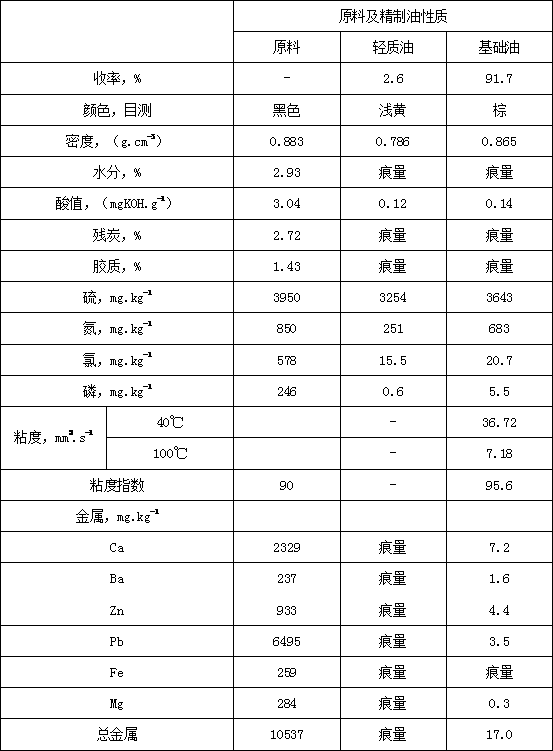

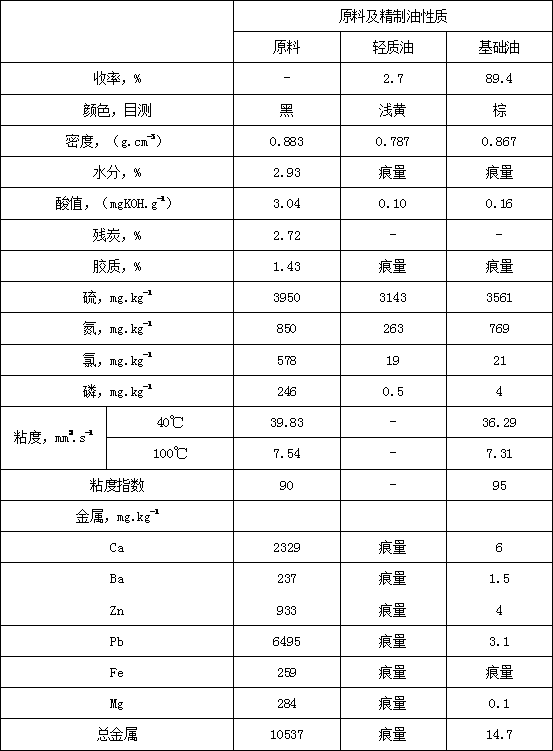

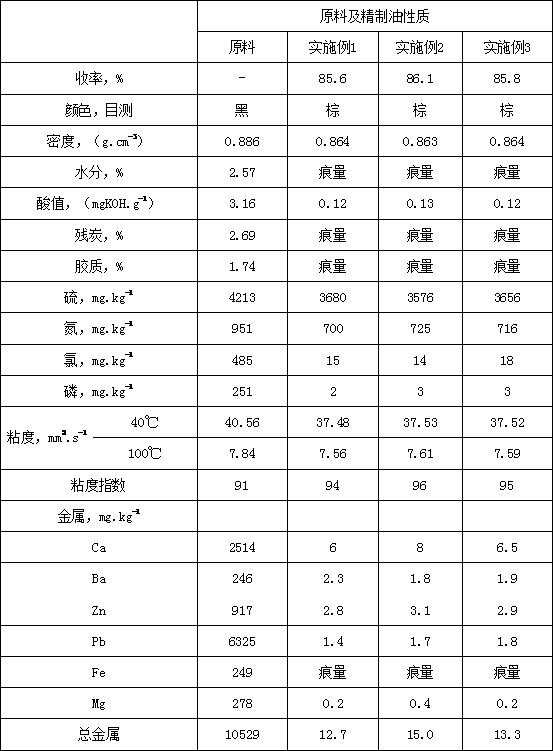

Free-pollution cyclic regeneration pre-treatment technology of waste lubricating oil

The invention provides a free-pollution cyclic regeneration pre-treatment technology of waste lubricating oil. The process comprises the steps of chemical reaction dechloridation, hydrogenation heat treatment, atmospheric flashing, propane refining and reduced pressure distillation. Through the chemical reaction dechloridation, the problems about corrosion of organic chloride to the subsequent devices, pipeline blockage and catalyst poisoning during regeneration can be solved; through hydrogenation heat treatment, additives in the waste lubricating oil can be destroyed, ash formation matter istransformed into residues which can be removed through filtration, and the problems are solved that during propane refining, an interface is not clear and separation is difficult, and during reducedpressure distillation, fractionating tower plates scale. After light oil is drawn out through atmospheric flashing, the additives, metal salt, oxide condensation compounds, colloid and asphaltenes inthe waste lubricating oil are removed through propane refining, and finally, light components are effectively separated from the base oil through reduced pressure distillation. By means of the technology, undesired components in the waste lubricating oil can be effectively removed, high-quality raw materials are provided for subsequent hydrogenation refining, and long-period running of the subsequent hydrogenation device is ensured.

Owner:WUHAN KELIN FINE CHEM

Method and device for low temperature carbonization and pyrolysis of low-rank coal and oil shale

ActiveCN103468281AHigh calorific valueQuality improvementLiquid hydrocarbon mixture productionSpecial form destructive distillationCarbonizationNitrogen gas

The invention relates to a method and a device for low temperature carbonization and pyrolysis of low-rank coal and oil shale. The method comprises the steps of preheating coal gas to 700-800 DEG C with a coal gas preheating device, and then allowing the coal gas to enter an internal thermal vertical retort suitable for hot coal gas carbonization through a pipeline for carbonization and growth into flame coal, non-caking coal and weakly caking coal, wherein the coal gas preheating device consists of a heating system and a preheating system. The method and the device have the advantages that the cooled coal gas is preheated by the coal gas preheating device; high-quality iron alloy coke and calcium carbide coke are produced through a heating mode of the vertical retort and improvement of a retort structure, contents of hydrogen and methane in the coal gas are increased simultaneously, a content of nitrogen is reduced, and a calorific value of the coal gas is increased. The method and the device provide high-quality raw materials for comprehensive utilization of the coal gas for hydrogen, methanol and LNG (liquefied natural gas) preparation, by-product coal tar and the coal gas can be further deeply processed, and a use value is increased.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

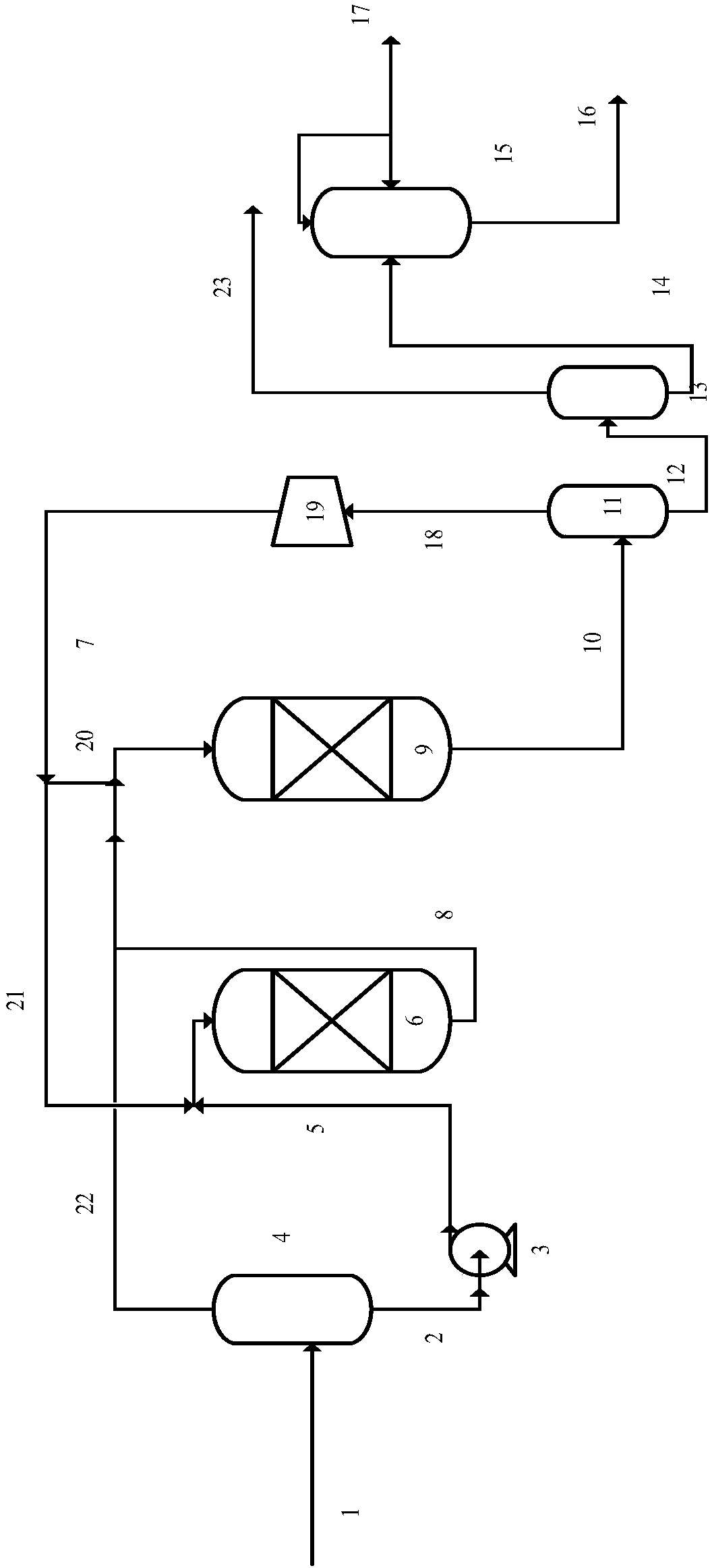

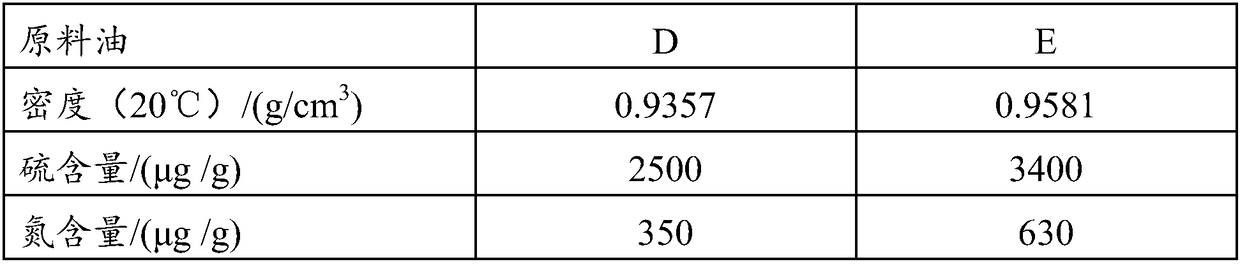

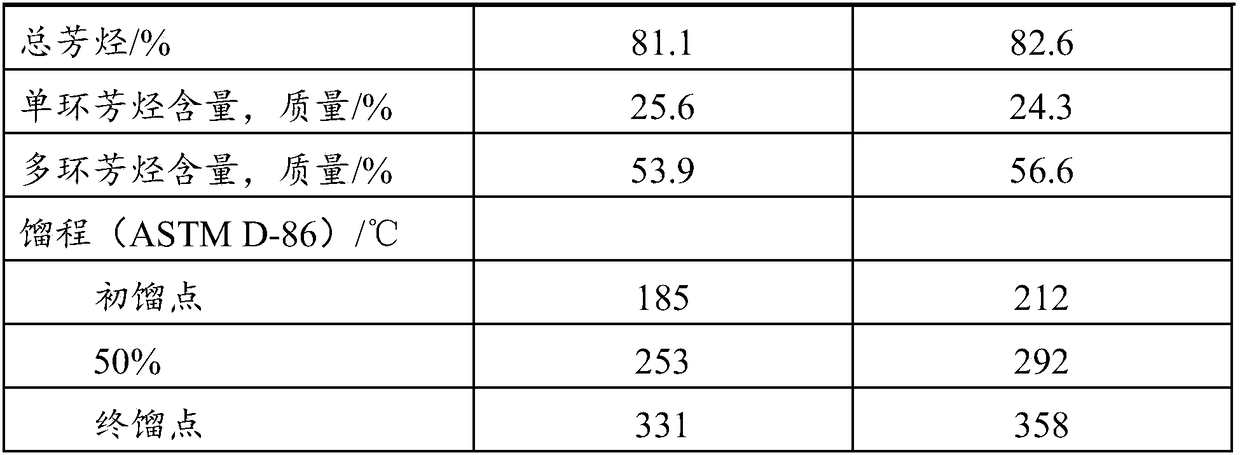

Method for producing raw material rich in monocyclic aromatic hydrocarbons

ActiveCN108728162AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils treatment productsRaw materialPolycyclic aromatic hydrocarbon

The invention discloses a method for producing a raw material rich in monocyclic aromatic hydrocarbons. The method comprises the following steps: diesel feedstock oil is cut into a light diesel oil fraction and a heavy diesel oil fraction, the heavy diesel oil fraction is mixed with hydrogen, the mixture is in contact with a hydrorefining catalyst I in a first reaction zone, and hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are carried out under hydrogenation reaction conditions; the light diesel oil fraction is mixed with an effluent from the first reaction zone, and then the mixture enters into a second reaction zone to be in contact with a hydrorefining catalyst II, hydrodesulfurization, hydrodenitrogenation and selective hydrodearomatization are furthercarried out under the hydrogenation reaction conditions, and the effluent from the second reaction zone is separated to obtain a whole fraction product; based on the diesel feedstock oil, polycyclic aromatic hydrocarbons in the whole fraction product have a saturation ratio of 85% to 90%, and the monocyclic aromatic hydrocarbons have a selectivity of 80% to 85%. The method provided by the invention provides high-quality raw materials for catalytic cracking or hydrocracking to produce high-octane gasoline or BTX components, reduces the hydrogen consumption in a hydrogenation process, and improves the stability of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pretreatment process for regenerating high-quality base oil by using waste lubricating oil

The invention provides a pretreatment process for regenerating high-quality base oil by using waste lubricating oil. The process comprises the steps of chemical reaction dechlorination, hydrocatalyticthermal decomposition, atmospheric flashing, propane refining and NMP or furfural extraction. The chemical reaction dechlorination solves the problems of corrosion, pipeline blockage, catalyst poisoning and the like caused by organic chlorine to a reaction device in the regeneration process by using the waste lubricating oil. The hydrocatalytic thermal decomposition destroys metal-salt additivesin the waste lubricating oil and solves the problem of difficult separation during solvent refining. The waste lubricating oil is subjected to atmospheric flashing, water and light fuel oil are removed, then topped residual oil is subjected to propane refining, additives, metal salt, oxidized condensate, colloid, asphaltene and other impurities in the waste lubricating oil are removed, and the ashcontent can be reduced to 0.02% or below. NMP or furfural is a solvent with high selectivity and low solubility, by utilizing the property, refined oil with less metal, carbon residues, colloid and aromatic hydrocarbon can be obtained, and high-quality raw materials are provided for hydrogenation.

Owner:湖北科润石化科技有限公司

Standardization planting technology of cold-highland-area aconitum vilmorimianum kom

InactiveCN105532237ARipe fullyImprove fertilityPlant cultivationCultivating equipmentsDiseasePest control

The invention discloses a standardization planting technology of cold-highland-area aconitum vilmorimianum kom. The standardization planting technology includes the steps of 1, planting area selecting; 2, soil preparing; 3, seed selecting; 4, standardization cultivating; 5, field managing; 6, disease and pest preventing; 7, harvesting. By means of the planting technology of cold-highland-area aconitum vilmorimianum kom, a regular effect and a reasonable effect are achieved, the yield can be increased, quality can be guaranteed, and high-quality raw materials can be provided.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Method for producing functional biological organic base fertilizer by using chicken manure

InactiveCN104387135APromote sustainable developmentReduce pollutionBio-organic fraction processingExcrement fertilisersFecesOrganic base

The invention provides a method for producing a functional biological organic base fertilizer by using chicken manure. The method is characterized by taking the raw materials such as pig manure, chicken manure and humus as the base, adjusting a best carbon-nitrogen ratio, adopting a deep tank continuous high-temperature aerobic dynamic fermentation process, adding rotten bacteria inoculants capable of facilitating decomposition and rotting of materials and deodorizing into the rotting process, and adding functional bacteria after the materials are rotten to produce high-quality functional biological organic fertilizer. The method has the advantages that an efficient decomposition technology and aerobic fermentation technology system is built, the treatment time of manure of livestock and poultry is shortened, and the production efficiency is improved; the functional bacteria are not mutually antagonized with mutualistic symbiosis; all the microbes can grow and propagate in different temperature zones and mutually exert effects, so that the fermentation effect is ensured fundamentally; the odor of the manure can be effectively removed; the manure of the livestock and poultry can be quickly rotted in 7-10 days.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com