Low-silicon magnesium-containing pellets and production method thereof

A production method, the technology of magnesium pellets, applied in the field of low-silicon magnesium-containing pellets and its production, can solve the problems of poor reducibility and droplet performance, blast furnace slag ratio, unfavorable coke ratio, high silica content, etc., to achieve Good droplet characteristics, reducing high magnesium content, improving metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The raw materials for producing low-silicon magnesium-containing pellets are: low-silicon concentrate powder with a silicon content of less than 2%, magnesium oxide powder, lightly burned dolomite, dolomite, olivine, boron mud, etc. Choose bentonite or composite binder. The particle size of the concentrate powder is less than 200 mesh, the content is required to be more than 80%, and the moisture content is 7.0-8.5%.

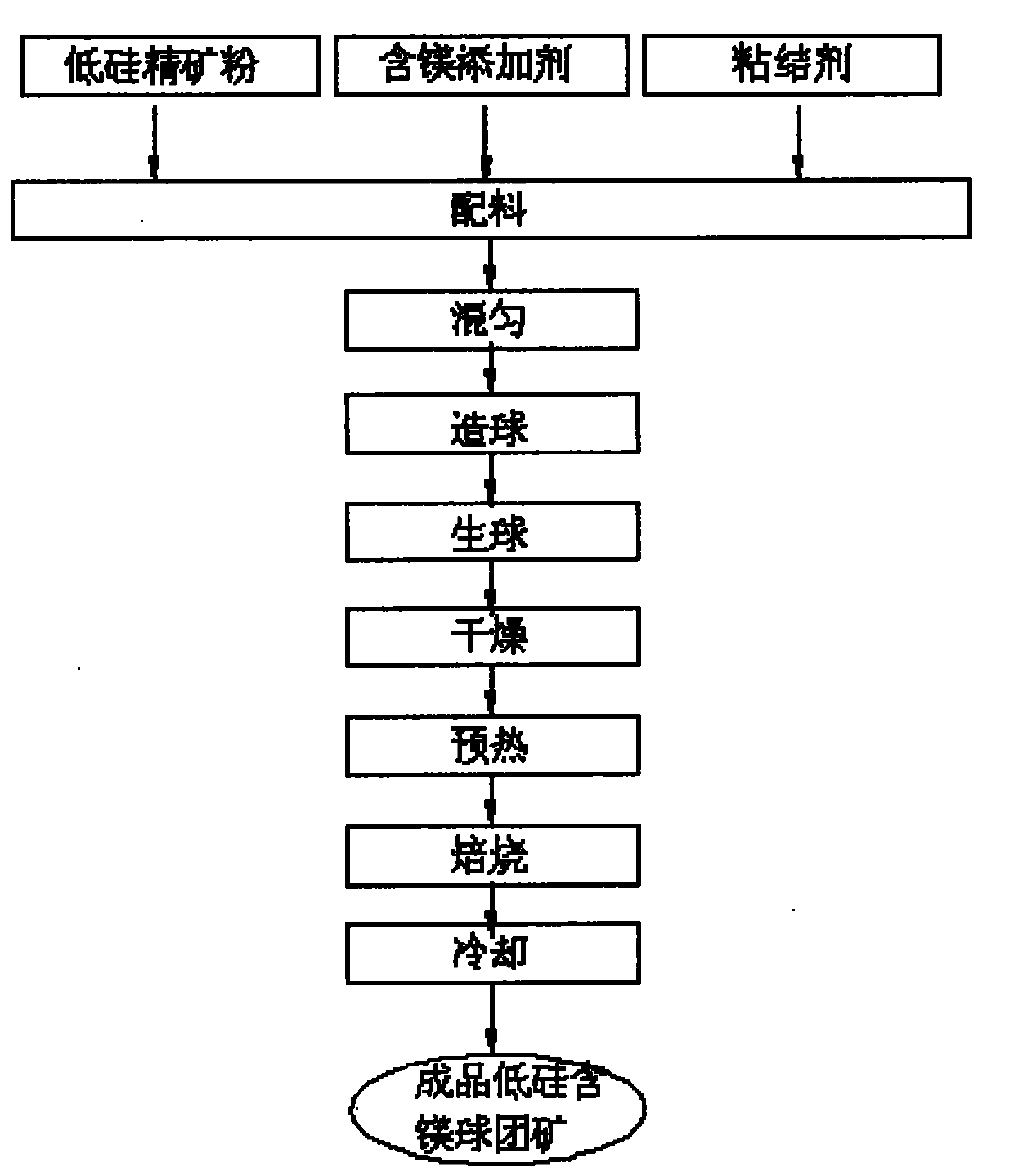

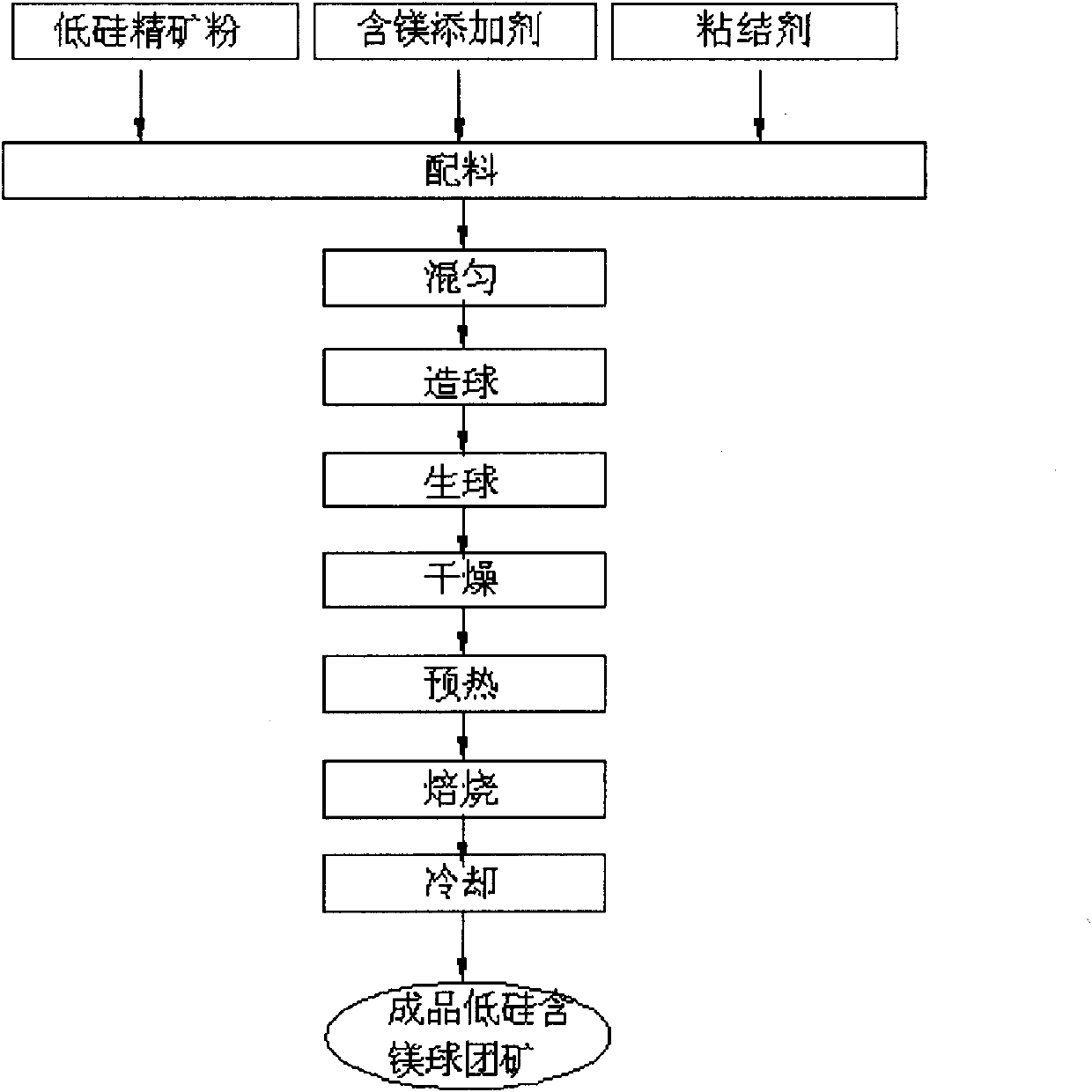

[0011] Such as figure 1 As shown, first, low-silicon concentrate powder, magnesium-containing additives and binders are mixed according to the contents in Table 1. Then use a mixer to mix. If the moisture of the mixture is low, add water to control the moisture of the mixture at 7.0-8.5%.

[0012] The mixed material is pelletized with a disc pelletizer. Ball making method: Put the mixed material into the disc pelletizing machine step by step. During the rotation of the pelletizing disc, the cue ball will be formed first. The cue ball will continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com