Patents

Literature

108 results about "Letovicite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Letovicite (/lɛtoʊˈvɪsaɪt/) is an ammonium sulfate mineral with composition (NH₄)₃H(SO₄)₂ (IUPAC: triammonium sulfate hydrogensulfate, Nickel–Strunz classification 07.AD.20). It is a rare colorless or white monoclinic secondary mineral formed during the burning of waste coal heaps and as a deposit in hot springs. It was first described from the Letovice region of Moravia in 1932.

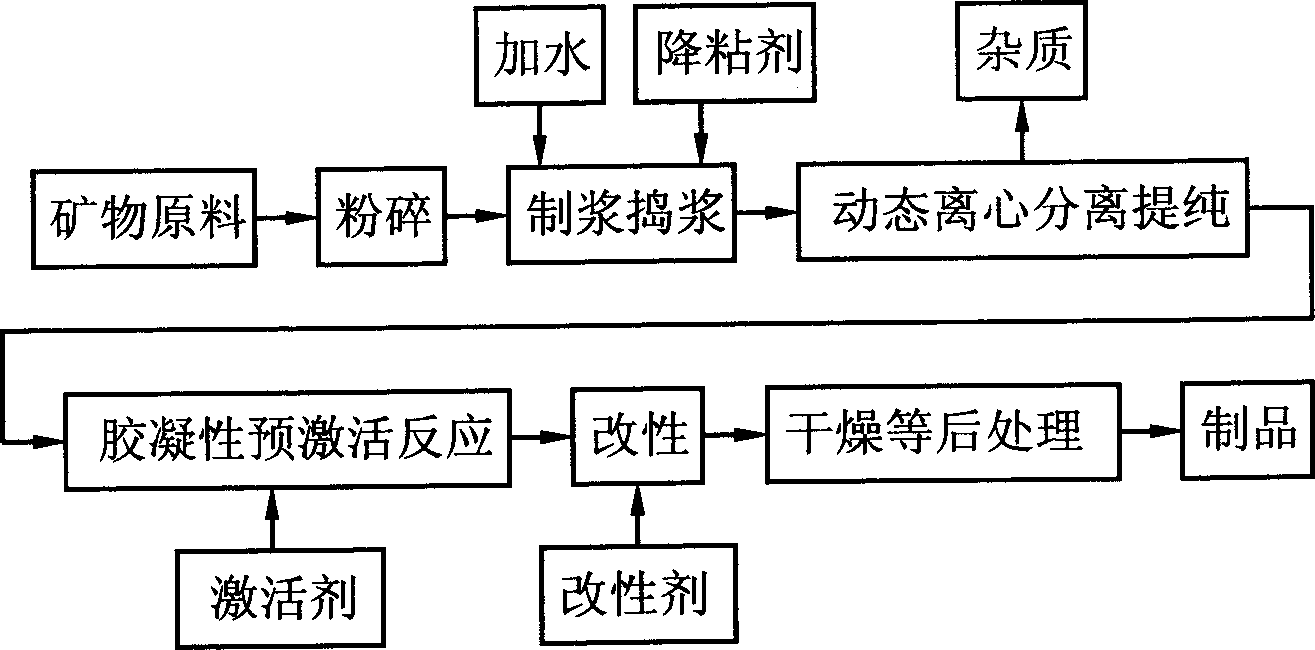

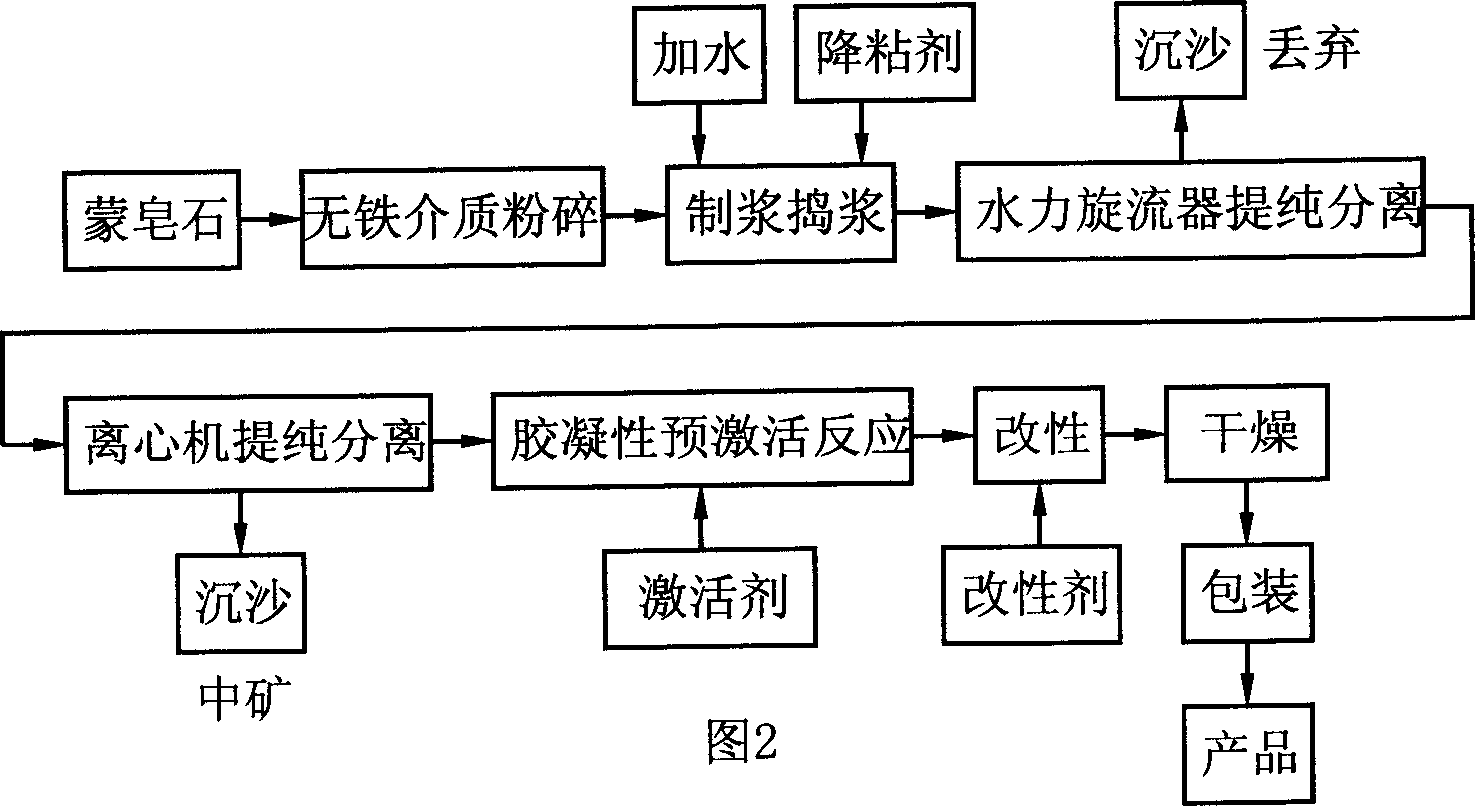

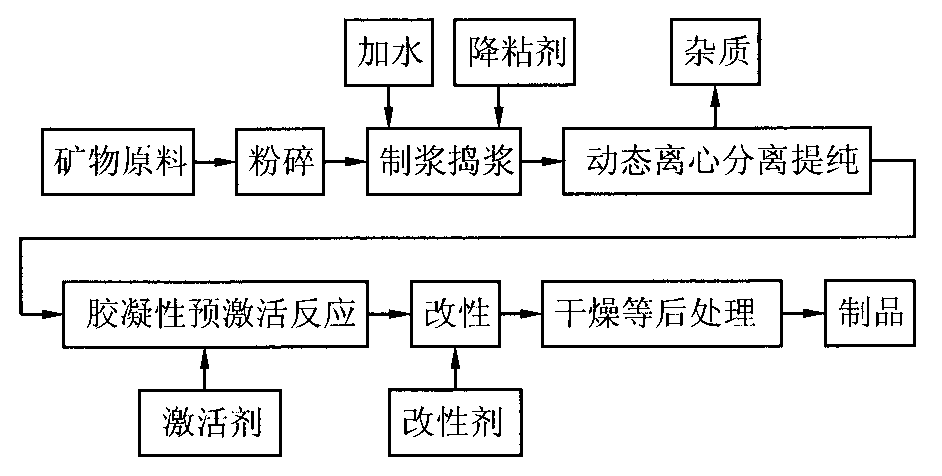

Process for preparing natural magnesium aluminium silicate gel

InactiveCN1363515AAvoid pollutionFe <sub>2</sub> o <sub>3</sub> Low contentAluminium silicatesInorganic saltsSodium Bentonite

A process for preparing natural gel of magnesium aluminium silicate from bentonite, attapulgite, bentone, etc includes such steps as pulverizing, preparing slurry, adding pour depressor, stirring, dynamic centrifugal separation, adding inorganic salt containing one-valence metal ions, stirring, pre-activating, adding organic salt containing at least Na ions, stirring for modifying, and post-treating.

Owner:国家非金属矿深加工工程技术研究中心

Method for prepaing granular profile control agent in copolymerization crosslinking type

This invention describes a process for preparing a new copolymerized and cross-linked granular profile control agent. The process uses two organic monomers, acrylamide and acrylic acid, as the major raw materials, bentonite or montmorillonite as the reinforcing agent, ammonium persulfate or potassium persulfate as the initiator, potassium metabisulfite as the reductant, and N,Ní»-methylene diacrylamide as the cross-linker to synthesize the granular profile control agent. Since the process uses bentonite or montmorillonite as the reinforcing agent, and ammonium persulfate or potassium persulfate / potassium metabisulfite as the oxidation-reduction system, ití»s easy to operate and the PH value is adjustable.

Owner:李松棠

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

Viscous oil emulsion phase-inversion profile control water blockoff

InactiveCN1395024ARealize the function of profile control and water shutoffHigh viscositySealing/packingCarboxylic saltNon ionic

The present invention provides a viscous crude emulsion phase-converting profile control water-plugging method and its phase-converting agent. In the viscous crude system 0.4-1.0% of oil in water emulsion and 3%-10% of phase-converting agent are added, then injected into formation to implement said ivnented method. The oil in water emulsion is a mixturwe of non-ionic surfactants of OP series. Tween series, Span series and sodium carboxylate, etc. and inorganic salts of sodium carbonate, etc. and the phase-converting agent is a mixture of oil-soluble surfactants of OP series or Span series or non-ionic surfactants or organic acid ester, etc. and rosin or asphalt powder or coal powder or bentonite, etc. Said invention developes a effective phase-converting agent, and can implement profile control water-plugging function.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Material of composite modified bentonite and production method

InactiveCN1686794AStructure does not affectRealize the control effectAluminium silicatesIron saltsSodium Bentonite

The present invention relates to a compound modified bentonite material and its production method. The described compound modified bentonite material is prepared by adding first modifying agent and second modifying agent to bentonite. The described first modifying agent is sodium salt, its added quantity is 1-10% of mass of bentonite, and the second modifying agent can be water-soluble iron salt or magnesium salt or aluminium salt or calcium salt or sodium salt different from first modifying agent, and its added quatity is 0.1-10% of mass of bentonite.

Owner:ZHEJIANG UNIV OF TECH

Pyrophillite lost foam casting coating and preparation method thereof

InactiveCN101444827AGood suspensionImprove thixotropyFoundry mouldsFoundry coresSoluble glassOctanol

The invention discloses a pyrophillite lost foam casting coating and a preparation method thereof. The coating comprises the following components by the mass percentage: 90% to 95.8% of pyrophillite refractory powder, 0.2% to 0.7% of sodium carboxymethyl cellulose, 1.9% to 4.4% of swell soil, 1.9% to 5.3% of soluble glass, 0.1% to 0.18% of polyethylene alkyl polyol ether, and 0.05% to 0.1% of N-octanol, and the mass percentage of the components is 100% in total, wherein, pyrophillite refractory powder is pyrophillite or mixture of pyrophillite and other refractory materials. The invention has the advantages that the pyrophillite lost foam casting coating has favorable suspension property and thixotropy, as well as excellent ventilation property and relatively high surface strength; and the preparation technology is simple, the operation is convenient, the raw material is abundant and the production cost is low. The invention is mainly used for producing refractory material on the surface of foam plastic mould of lost foam pieces.

Owner:HAIAN HENGYE SILK

Process for preparing granular pentonite

InactiveCN1382628AImprove water absorptionPure white colorSilicon compoundsPolymer scienceSodium silicate

A process for preparing granular bentone includes choosing white bentone, baking or drying in sun, adding sodium carbonate, pulverizing by 100-200 meshes, adding solution of sodium silicate and water, stirring, squeezing, baking and screening. The resultant bentone particles (0.8-4 mm) features high hydroscipicity, strength and caking performance, and high purity.

Owner:张兴华

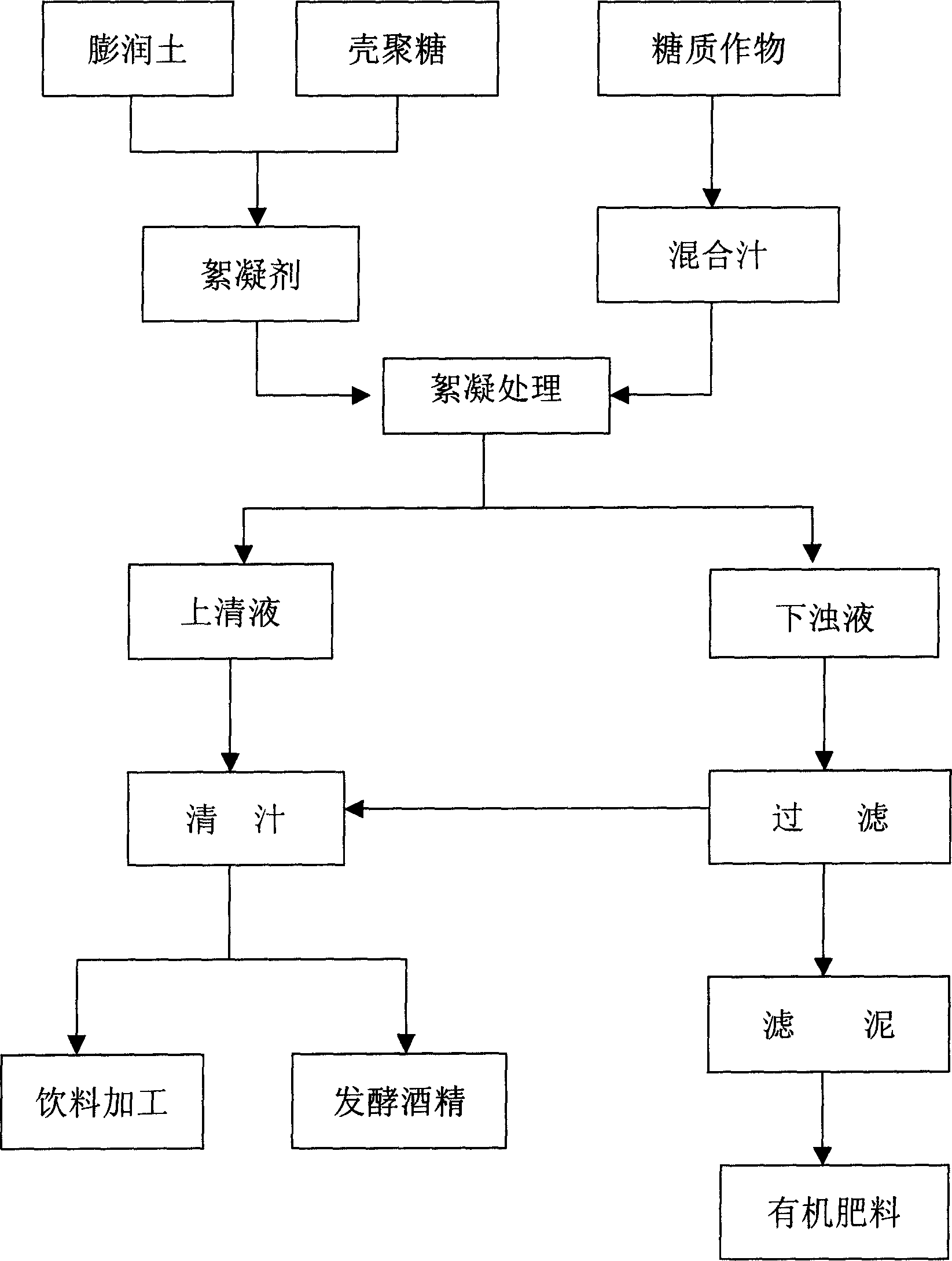

Method of clarifying saccharic crop pressed juice mixture by using bentonite-chitin composite flocculant

A method for clarifying the juice mixture obtained by squeezing the sugar-contained crops (sugar cane, sweet sorghum, etc) features use of the composite bentone-chitosan flocculant. Its filtered mud can be used as organic fertilizer.

Owner:FUJIAN NORMAL UNIV

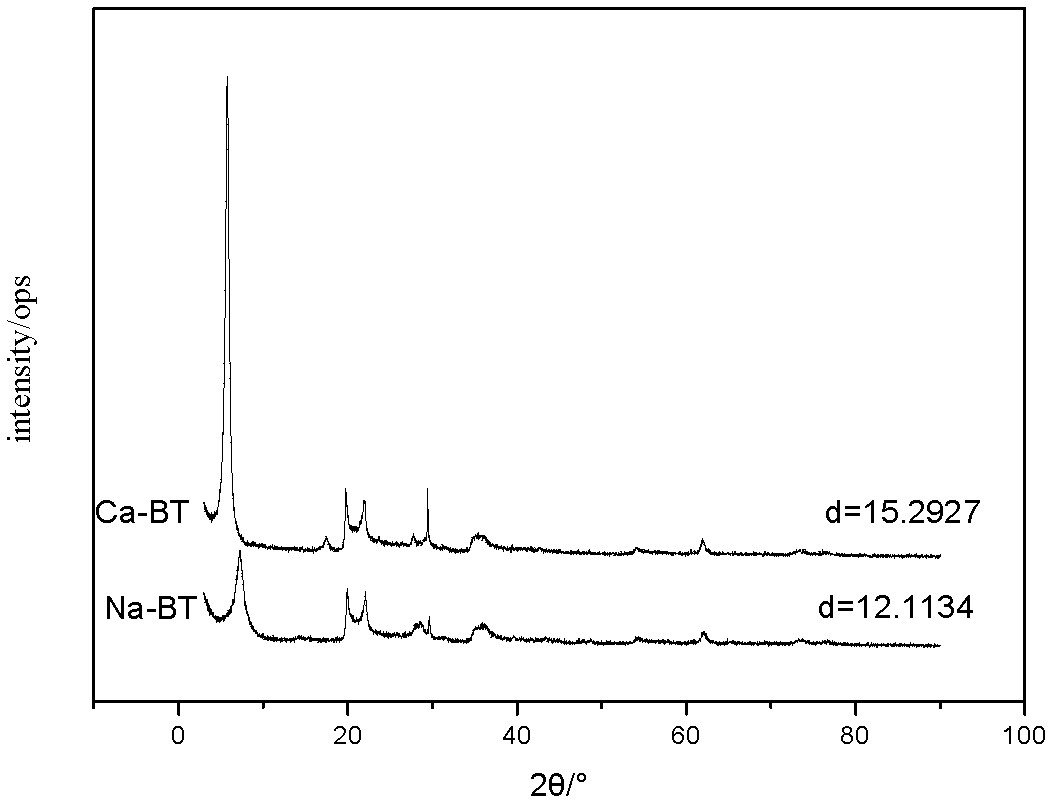

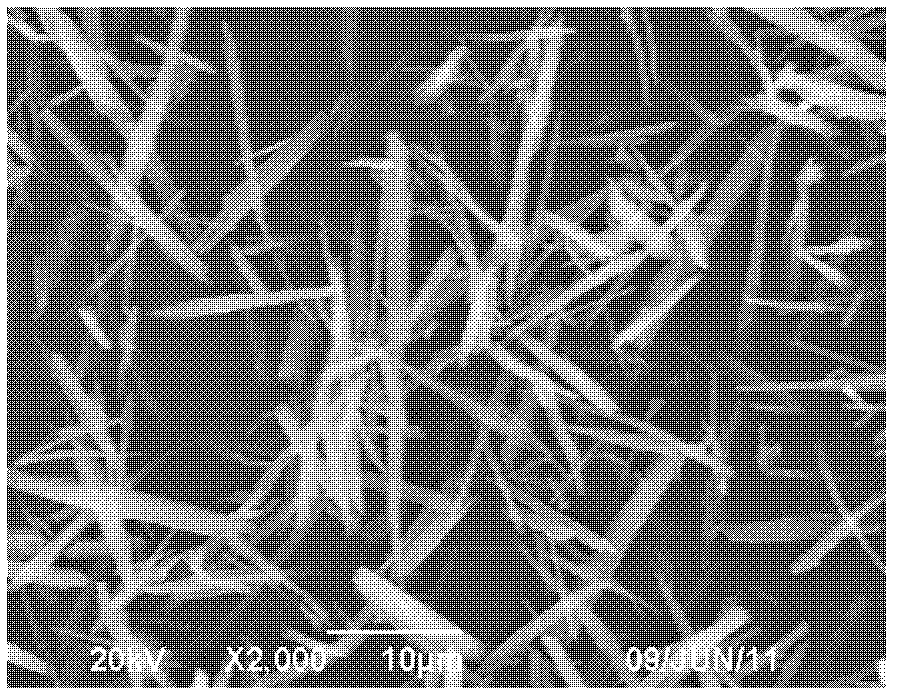

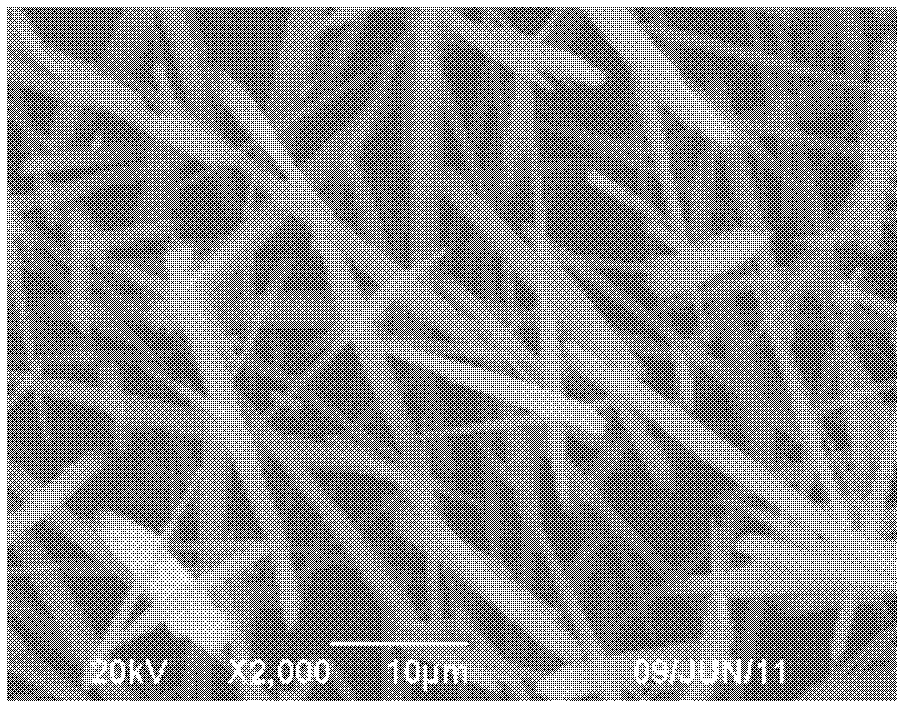

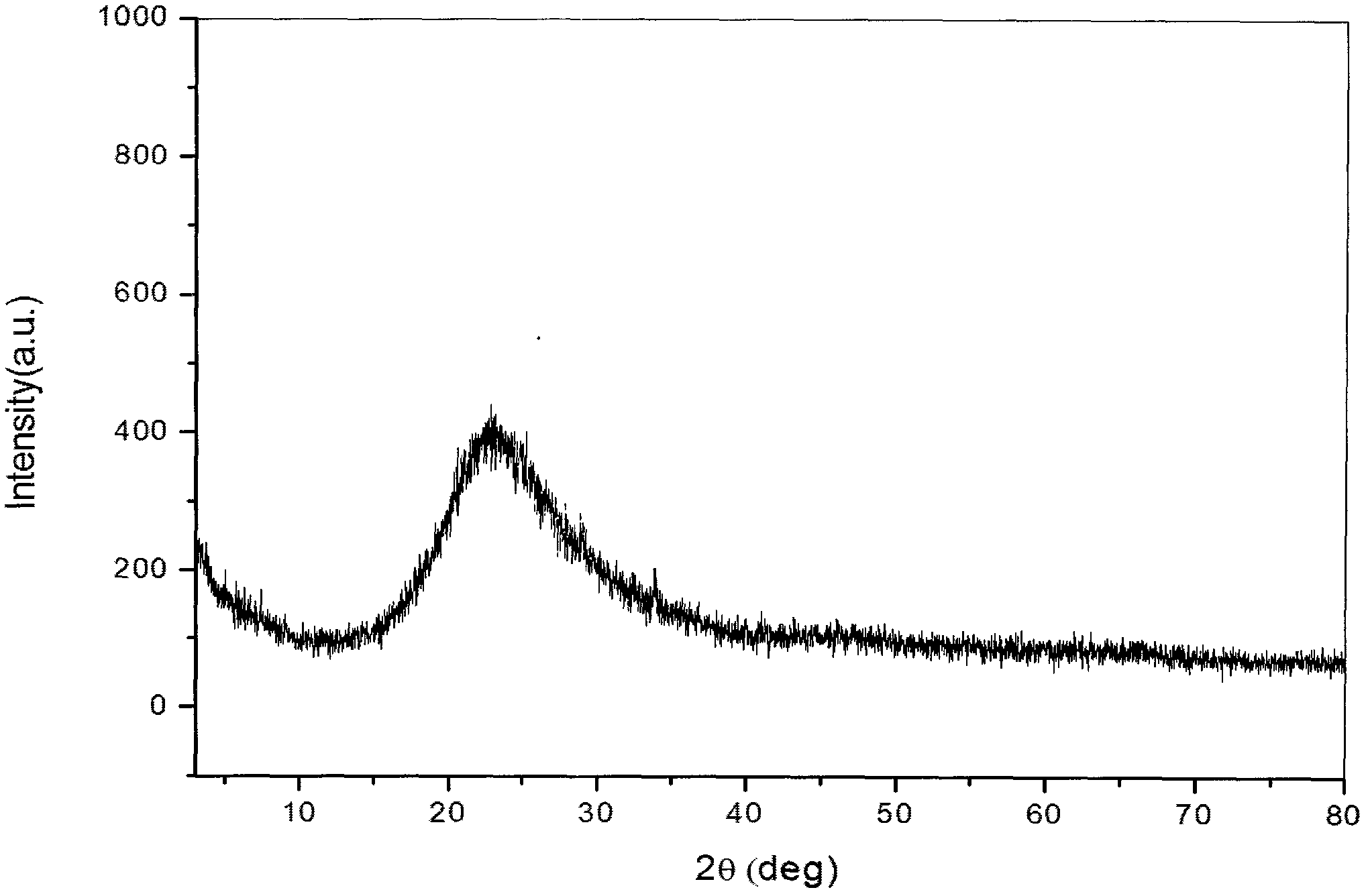

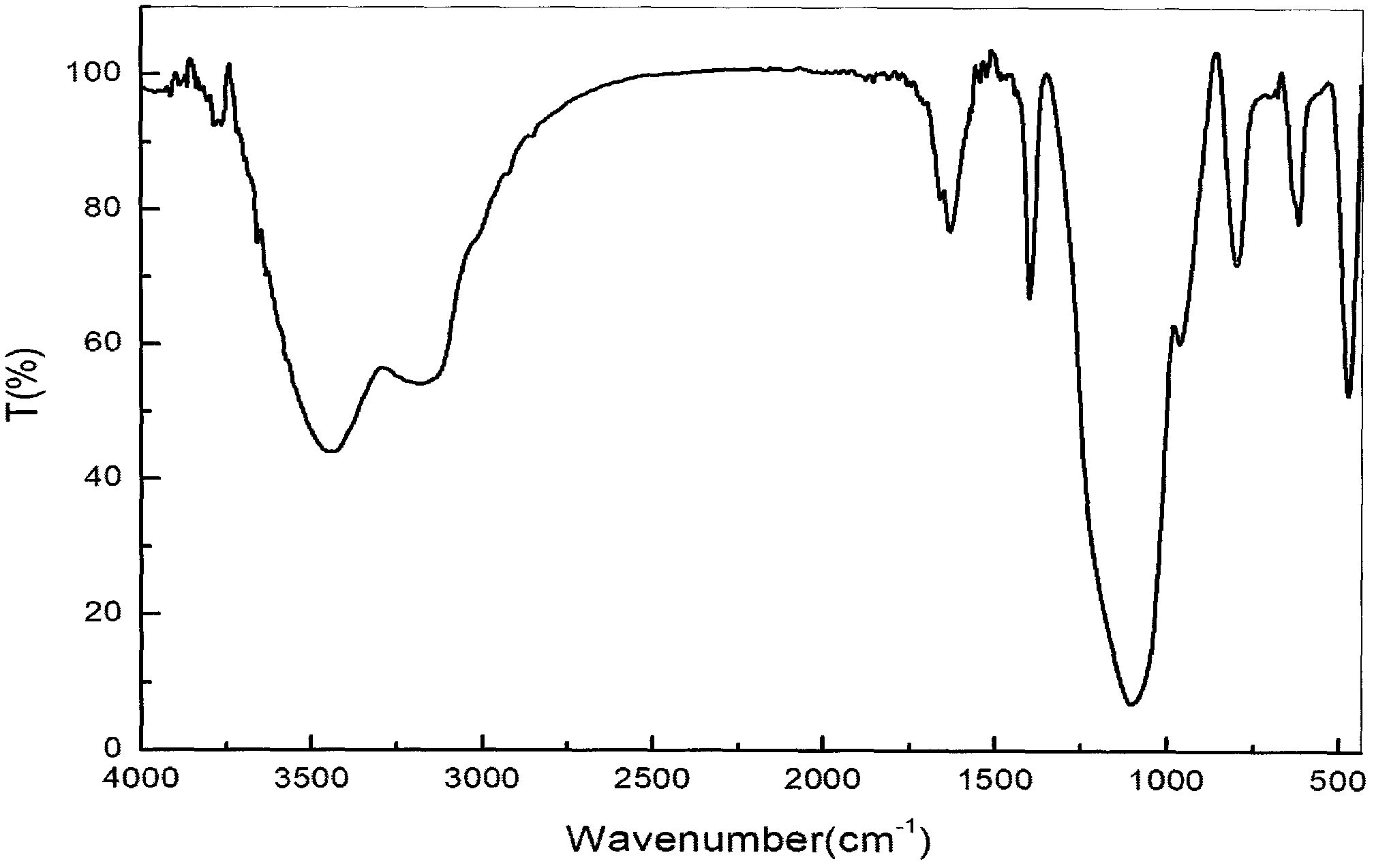

AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof

ActiveCN103897121AHas inclusion functionHigh viscosityDrilling compositionSolubilitySodium Bentonite

The invention relates to a polymer-ionic liquid composite clay stabilizer used for restraining clay hydration expansion in petroleum industry and a synthesis method of the polymer-ionic liquid composite clay stabilizer. The synthesis method comprises the steps of: reacting single 6-allyl amino beta-cyclodextrin, acrylamide and acrylic acid under initiation of ammonium persulfate and sodium hydrogen sulfite in an aqueous solution under the condition of pH of 7 and the temperature of 35 DEG C, purifying by aqueous solution after 8 hours of reaction and drying to obtain a polymer; refluxing quinoline and n-butyl bromide for 48 hours at 60 DEG C to obtain brominated 1-normal-butyl-quinoline salt, stirring for 3 days with sodium fluoborate in acetonitrile, filtering, carrying out rotary evaporation and drying to obtain tetrafluoroborate 1-normal-butyl-quinoline salt ([bquin]BF4); refluxing the polymer and the [bquin]BF4 for 4 hours at 50 DEG C to obtain a polymer-ionic liquid compound. The polymer-ionic liquid compound has good water solubility, stability and clay expansion restraining power and the antiswelling rate to bentonite can reach 90.3%.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of catalyst for synthesis of aniline through catalytic hydrogenation of nitrobenzene

ActiveCN103272601ALow costEasy to makeOrganic compound preparationAmino compound preparationFixed bedNitrobenzene

The invention discloses a preparation method of a catalyst for synthesis of aniline through catalytic hydrogenation of nitrobenzene. The catalyst is obtained through loading nickel into bentonite. The catalyst is prepared by taking the sodium bentonite as the raw material and is prepared into a suspension liquid, the nickel nitrate solution is added into the suspension liquid, the sodium hydroxide or ammonium hydroxide or sodium carbonate is taken as the precipitator to enable the nickel to form hydroxide and load the hydroxide on the bentonite. The suspension liquid and the precipitate are filtered, dried at the temperature of 80 DEG C for 10 hours, and roasted at the temperature of 250 DEG C to 450 DEG C for 2 hours, to obtain the Ni-loaded bentonite catalyst with the content of Ni being 0.001-0.010mol / g in the bentonite. After being reduced through a reducing agent, the catalyst shows excellent activity in the synthesis of aniline through catalytic hydrogenation of nitrobenzene in a fixed bed reactor, and the recycling service life of the catalyst is relatively long.

Owner:GUANGXI UNIV

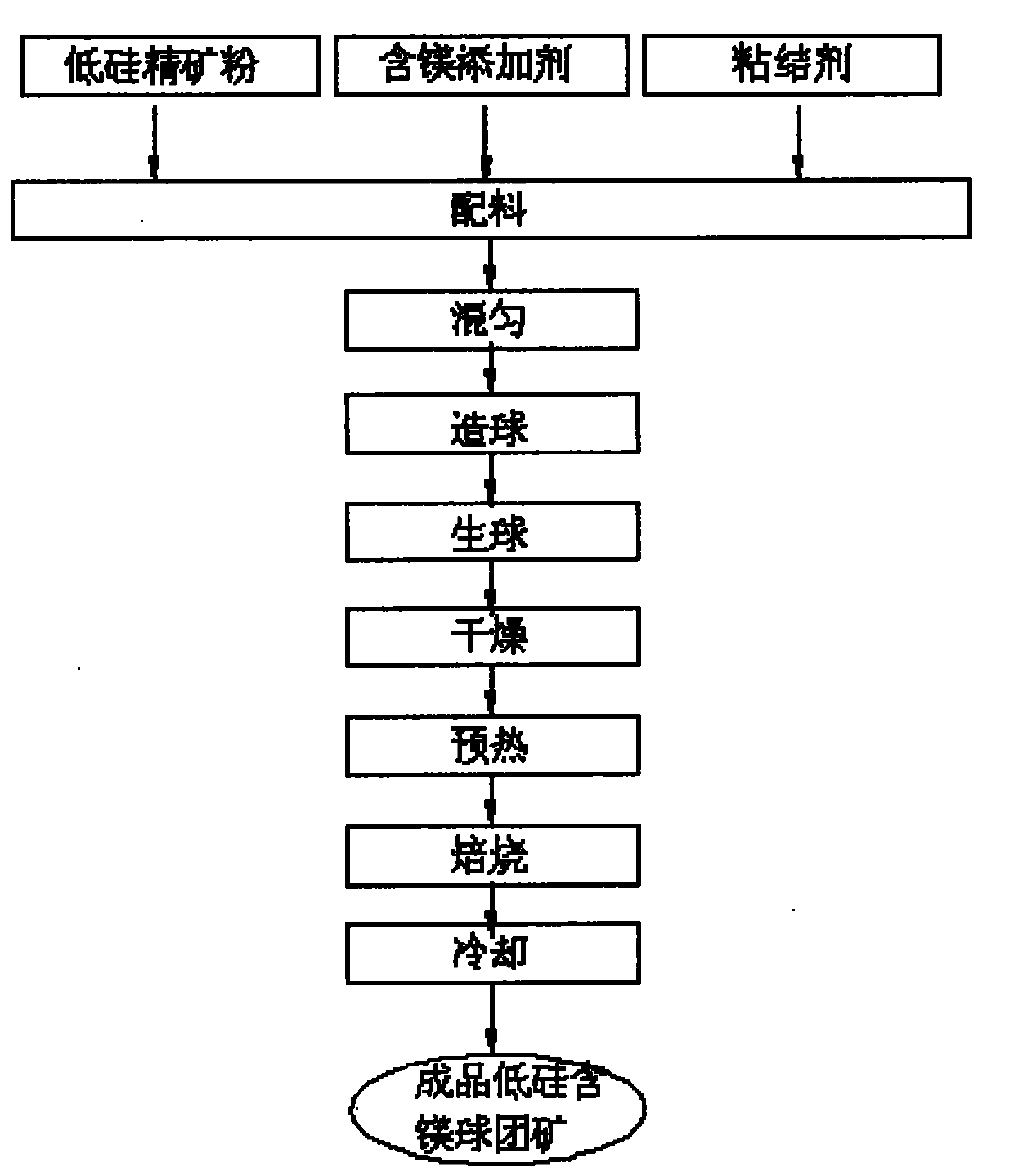

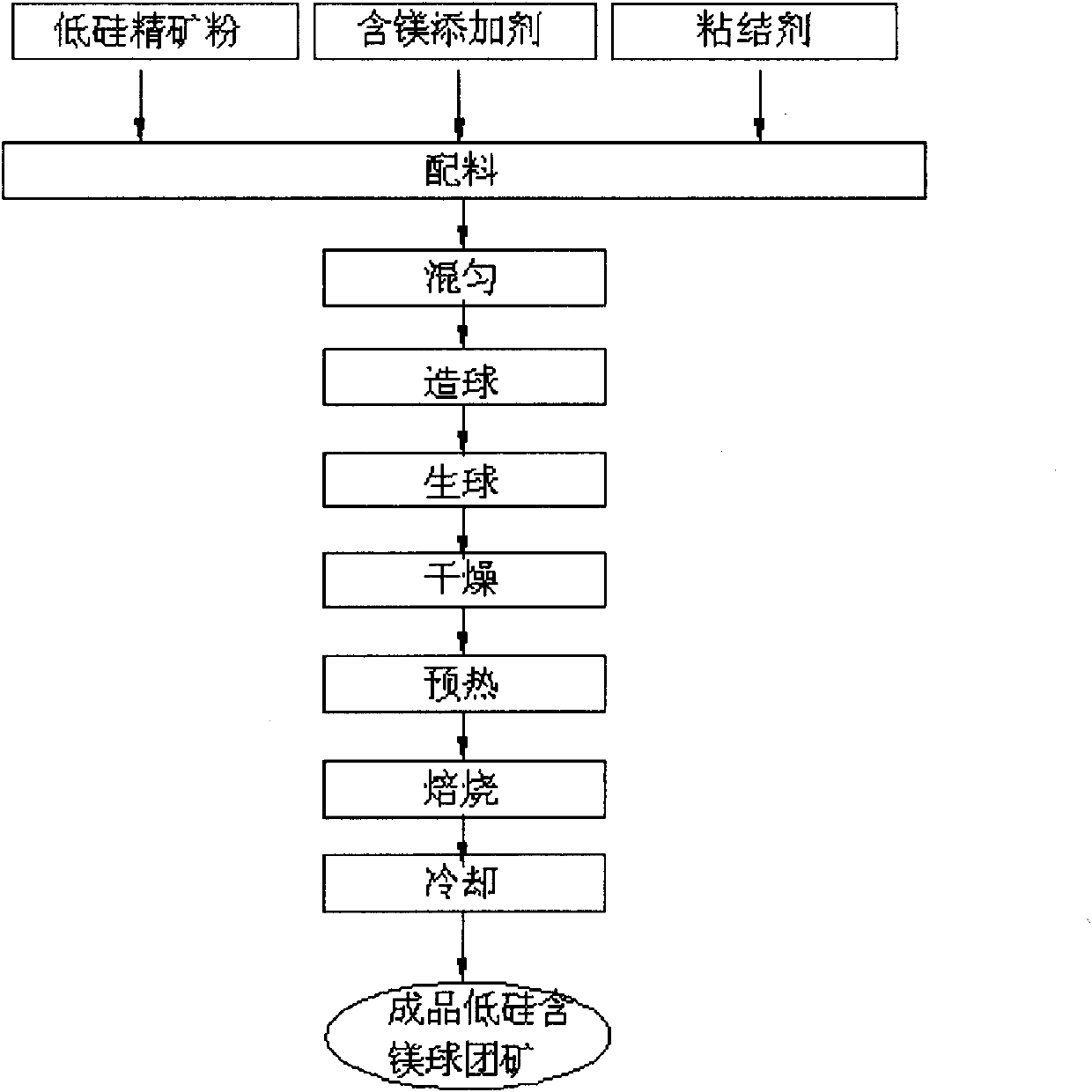

Low-silicon magnesium-containing pellets and production method thereof

ActiveCN101906533AImprove reducibilityGood droplet characteristicsBlast furnace detailsBLENDER/MIXERTO-18

The invention discloses low-silicon magnesium-containing pellets and a production method thereof. The method comprises the following steps of: proportioning 95 to 98.5 mass percent of low-silicon ore concentrate powder, 1 to 4 mass percent of magnesium-containing additive and 0.5 to 1.0 mass percent of binder, uniformly mixing the low-silicon ore concentrate powder, the magnesium-containing additive and the binder by using a blender mixer, adding an appropriate amount of water and controlling the water content of the mixture to be between 7.0 and 8.5 percent, wherein the magnesium-containing additive can be selected from magnesia powder, caustic calcined dolomite, dolomite, olivine and boric sludge and the binder can be selected from bentonite or a composite binder; pelletizing the mixture in a pan pelletizer, forming a mother pellet, adding materials and water gradually to allow the mother pellet to grow bigger and denser, screening green pellets of between 9 and 16 millimeters and performing a continuous roasting process consisting of drying, preheating, roasting and cooling; drying the pellets at the temperature of between 200 and 450 DEG C for 8 to 10 minutes, preheating the pellets at the temperature of between 700 and 1,050 DEG C for 10 to 15 minutes and roasting the preheated pellets at the high temperature of between 1,280 and 1,350 DEG C for 12 to 18 minutes; and cooling the roasted pellets to be less than 100 DEG C after roasting is finished so as to obtain the low-silicon magnesium-containing pellets serving as finished products.

Owner:SHOUGANG CORPORATION

Preparation method of modified bentonite sewage treatment material

InactiveCN105983399AImprove adsorption capacityIncrease utilization uptakeWater/sewage treatment by irradiationOther chemical processesHeat treatedIon

The invention provides a preparation method of a modified bentonite sewage treatment material. The method includes the steps of: 1) adding tetrabutyl titanate to anhydrous ethanol, and adding glacial acetic acid to prepare a solution A; 2) adding a metal nitrate to deionized water and adding anhydrous ethanol and nitric acid to prepare a solution B; 3) adding bentonite to deionized water, and adding glacial acetic acid to prepare a suspension C; 4) slowly adding the solution B to the solution A to form a solution D, and slowly adding the solution D to the suspension C to form gel; 5) drying, grinding, washing, drying and thermal-treating the gel to obtain bentonite modified by TiO2; and 6) adding the bentonite modified by TiO2 to an organic cationic surfactant solution, filtering the mixture, and washing and drying the product to prepare the modified bentonite sewage treatment material. The modified bentonite sewage treatment material has strong adsorption and degradation capability on organic substances, heavy metal ions, nitrogen, phosphorus and the like.

Owner:青岛润国生态科技研究院 +2

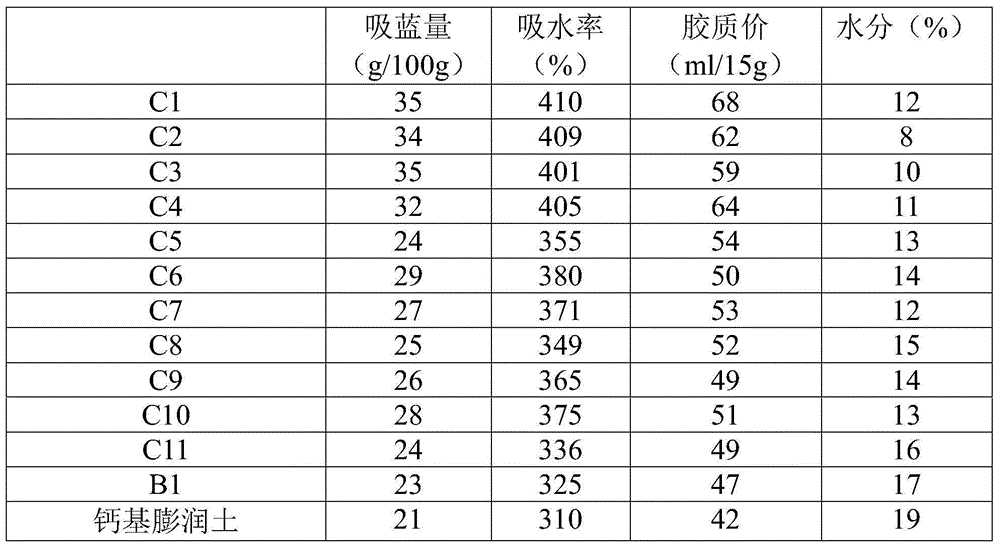

Sodium bentonite and double sodium modifying method for sodium bentonite

ActiveCN104986778ARaise the degree of sodiumImprove sodium effectSilicon compoundsSodium acetateSodium phosphates

The invention discloses sodium bentonite and a double sodium modifying method for the sodium bentonite. The method comprises the steps that 1, calcium bentonite and a sodium salt are mixed and modified in a sodium mode to manufacture first-class sodium bentonite; 2, the first-class sodium bentonite and an addition agent are mixed and inoculated to manufacture second-class sodium bentonite, wherein the addition agent comprises microcrystalline cellulose, silica gel modified by a sodium salt, expanded vermiculite, boric acid, a thickening agent and polyacrylamide; the sodium salt and the sodium salt in the silica gel modified by the sodium salt are independently selected from one or more of sodium carbonate, sodium silicate, sodium fluoride, sodium oxalate, sodium acetate, sodium phosphate, sodium polyacrylate, sodium hydroxide, sodium chloride, sodium thiosulfate and sodium cellulose; the thickening agent is selected from magnesium oxide and / or magnesium hydrate. According to the method, the calcium bentonite is fully modified into the sodium bentonite in the sodium mode, moreover, the sodium bentonite has excellent blue absorption power, a high water absorption rate and large colloid indexes, the steps are simple, and the raw materials are easy to obtain.

Owner:芜湖恒杰膨润土科技有限公司

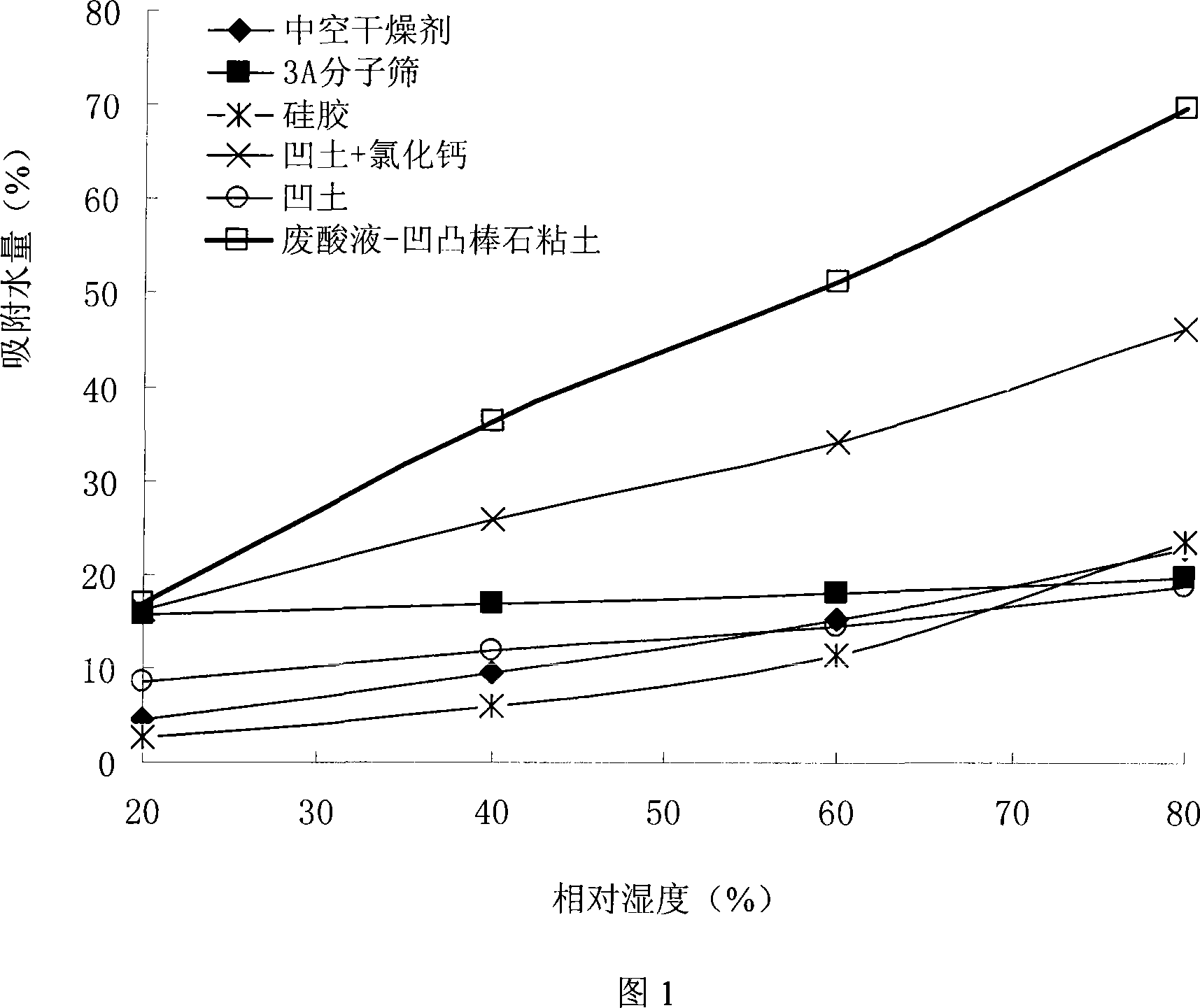

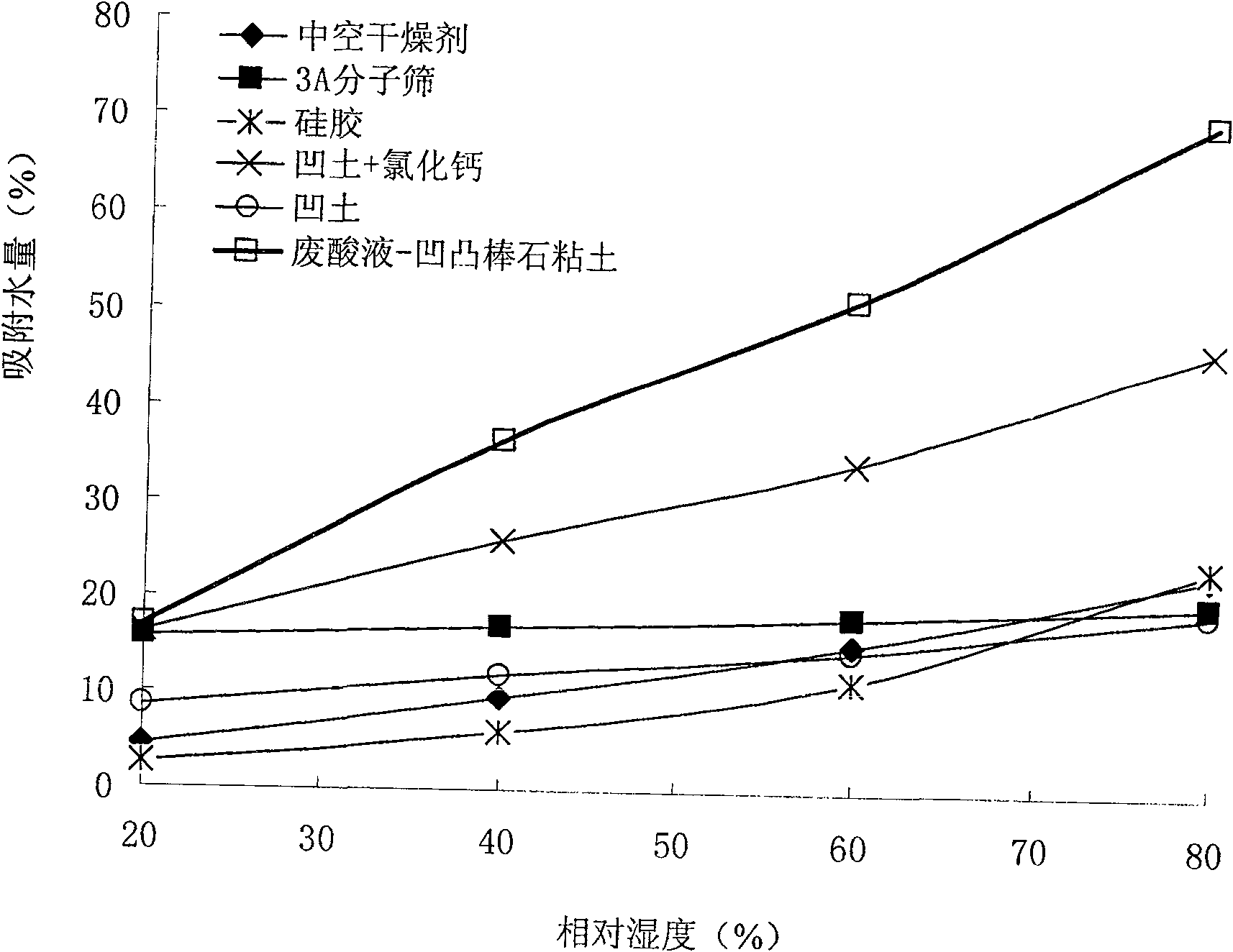

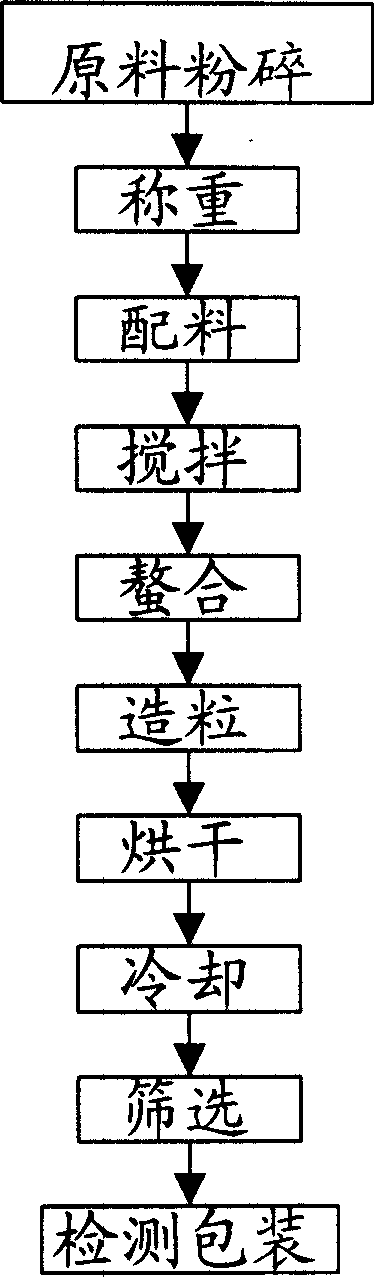

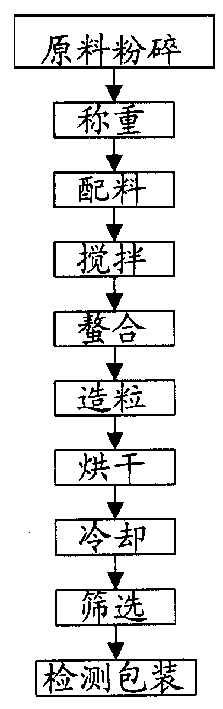

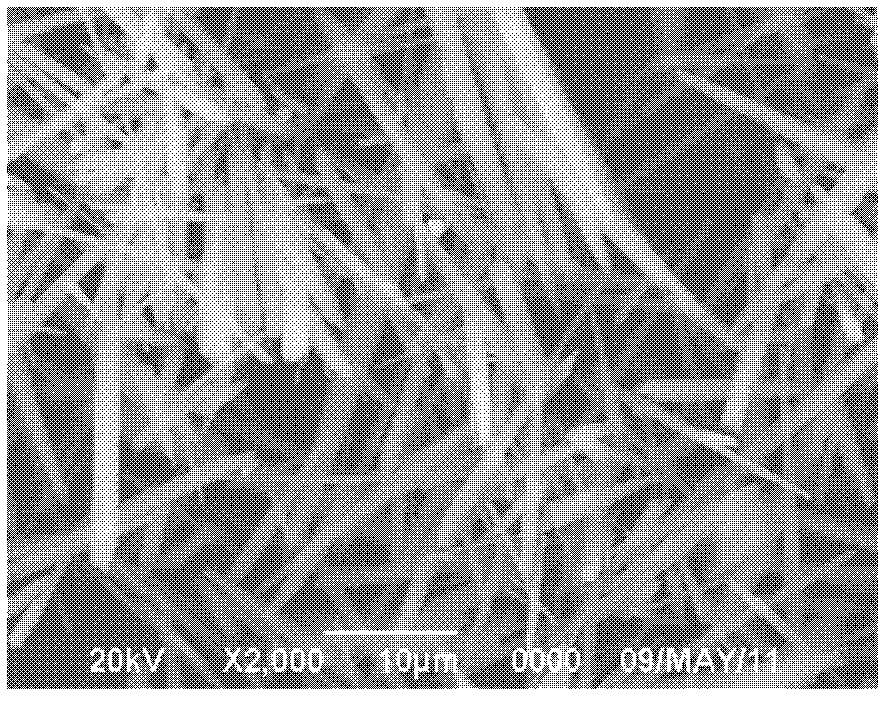

Method for processing industrial waste acid solution and preparing drying agent by using dolomite-containing attapulgite clay

InactiveCN101186351AReduce manufacturing costSimple production processDispersed particle separationWater/sewage treatment by sorptionLiquid wasteDolomite

The invention relates to a method of processing industry waste acid liquid and preparing desiccant with dolomite attapulgite clay, which is characterized in that: according to a volume mass ratio of the waste acid liquid and the dolomite attapulgite clay of 0.4 to 1 L / kg, the dolomite attapulgite clay powder is added in the waste acid liquid; a neutralization reaction occurs between the dolomite in the clay and the waste acid liquid, thereby the pH value of reacted mixture is more than 3, and the water content of the mixture is controlled; an attapulgite clay compound desiccant is obtained after the hydrous mixture is molded and calcined; the industry waste liquid acid comprises acid waste liquid produced by active clay, the acid waste liquid of active silicon dioxide which adopts attapulgite clay or swell soil and hydrochloric acid or sulphuric acid as raw material, etc. The invention not only processes and utilizes the attapulgite clay or swell soil to process the acid waste liquid and realizes the zero draining of the waste water, but also saves materials such as calcium chloride and caking agent, etc. which are required in the preparation of the attapulgite clay desiccant, thereby greatly reducing the production cost of the attapulgite clay compound desiccant.

Owner:HEFEI UNIV OF TECH

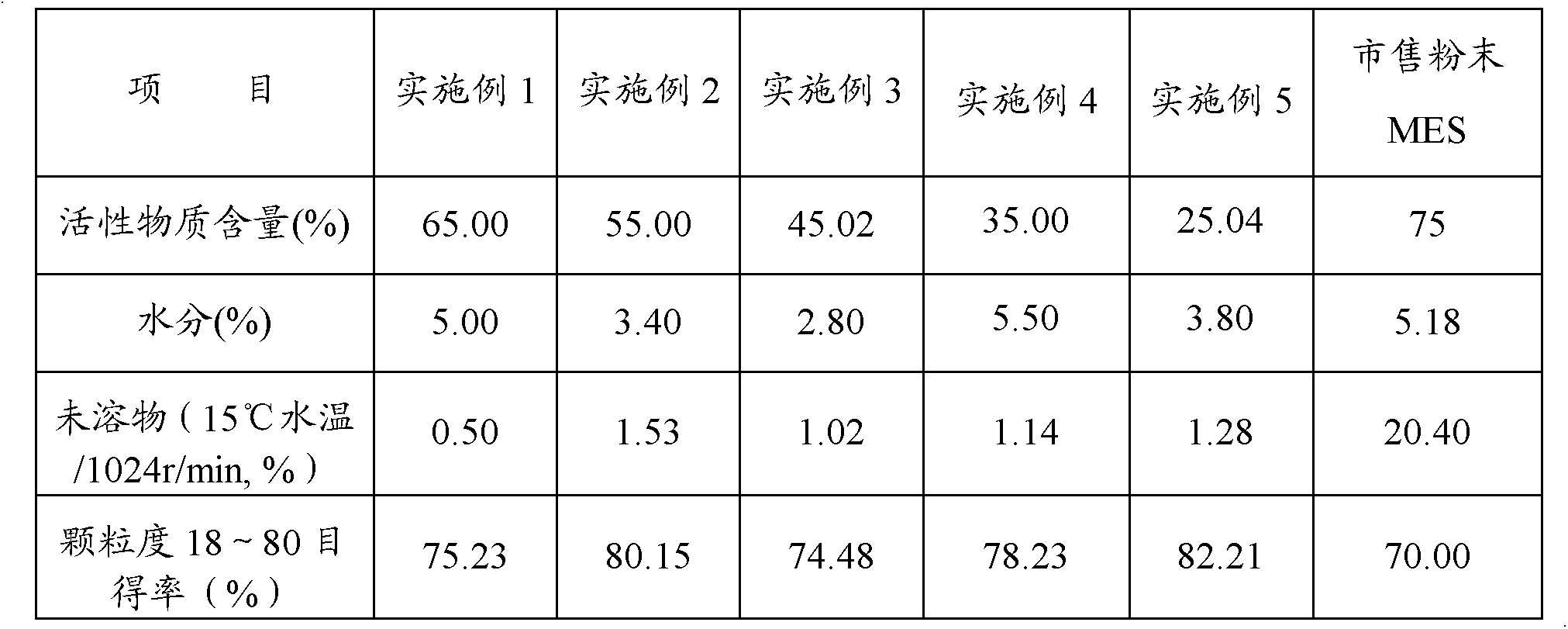

Particles containing sodium fatty acid methyl ester sulfonate and preparation method thereof

ActiveCN103320235AFully packagedIncrease package volumeSurface-active detergent compositionsDetergent mixture composition preparationSolubilitySulfonate

The invention discloses particles containing sodium fatty acid methyl ester sulfonate and a preparation method thereof. The preparation method comprises the following steps: mixing a wrapper and 20-75 parts by weight of paste sodium fatty acid methyl ester sulfonate, granulating by a wet process, drying, and screening. The wrapper is a composition comprising the following components in parts by weight: 1-40 parts of zeolite, 1-40 parts of silicate, 1-30 parts of modified starch and 0-30 parts of bentonite. The mass percent of the sodium fatty acid methyl ester sulfonate in the particles containing sodium fatty acid methyl ester sulfonate can be up to 65%; the particles containing sodium fatty acid methyl ester sulfonate can be used as a raw material for preparing washing powder or directly used as a detergent; and the invention effectively solves the problems of poor stability, high decomposition tendency, high lumping tendency, poor low-temperature solubility and the like in the use process of sodium fatty acid methyl ester sulfonate.

Owner:NICE GROUP

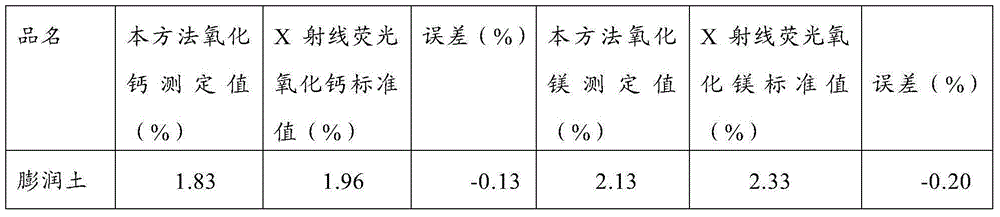

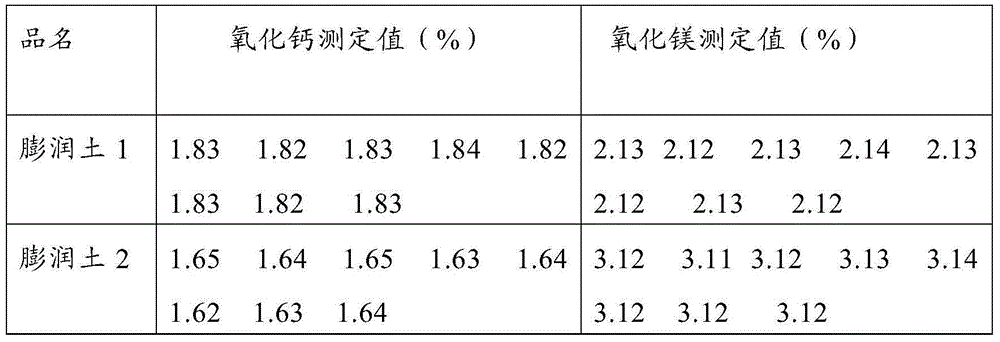

Method for continuously determining content of calcium oxide and magnesium oxide in bentonite

InactiveCN105158405ALow costReduce operating proceduresChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorSodium BentoniteHydroxylamine Hydrochloride

The invention discloses a method for continuously determining the content of calcium oxide and magnesium oxide in bentonite. According to the method, a bentonite sample is added to a polytetrafluoroethylene plastic beaker, another beaker is not filled with the bentonite sample and serves as a blank control, then hydrochloric acid and nitric acid-hydrofluoric acid are added for dissolution respectively, perchloric acid is added for smoking, then hydrochloric acid is added to heat and dissolve salt, test solutions are transferred to large volumetric flasks respectively and diluted to a constant-volume scale, each solution is split into two parts of solutions with equal quantities; triethanolamine, water and hydroxylamine hydrochloride are added sequentially to one of the sample and the blank control, a potassium hydroxide solution and an appropriate amount of calcein are added, an EDTA (ethylene diamine tetraacetic acid) standard solution is adopted for titration until fluorescent green disappearance, the volume is recorded, and the content of calcium oxide is calculated; triethanolamine, water and hydroxylamine hydrochloride are added sequentially to the other one of the sample and the blank control, an ammonia-ammonium chloride buffer solution and an appropriate amount of eriochrome black T indicator are added, the EDTA standard solution is adopted for titration until purple red turns into blue, the volume is recorded, and the content of magnesium oxide is calculated.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Novel sodium bentonite-AM-AA composite lead ion absorbing agent

InactiveCN102580697AIncrease contentUniform and stable structureOther chemical processesWater/sewage treatment by sorptionSodium BentoniteSorbent

The invention relates to a novel sodium bentonite-AM-AA composite lead ion absorbing agent which belongs to the technical field of water treatment. The novel sodium bentonite-AM-AA composite lead ion absorbing agent comprises sodium bentonite obtained subjecting sodium treatment to calcium bentonite and a material A polymerized on the sodium bentonite, wherein the material A accounts for 11-17 percent by mass of the total mass, the sodium bentonite accounts for 83-89 percent by mass of the total mass, the material A is generated by monomer acrylamide and crylic acid and a crosslinking agent for solution polymerization under the action of an initiator. The invention overcomes the problems of large swelling property, difficulty in solid-liquid separation and the like of the bentonite, and realizes final synthesis continuous operation of the sodium treatment of the calcium bentonite to the novel sodium bentonite-AM-AA composite lead ion absorbing agent; and the novel sodium bentonite-AM-AA composite lead ion absorbing agent has less synthesis steps in the whole preparation process, is safe in operation, has lower cost and lead absorbing performance of reaching 157.5mg / g.

Owner:HEBEI UNIV OF TECH

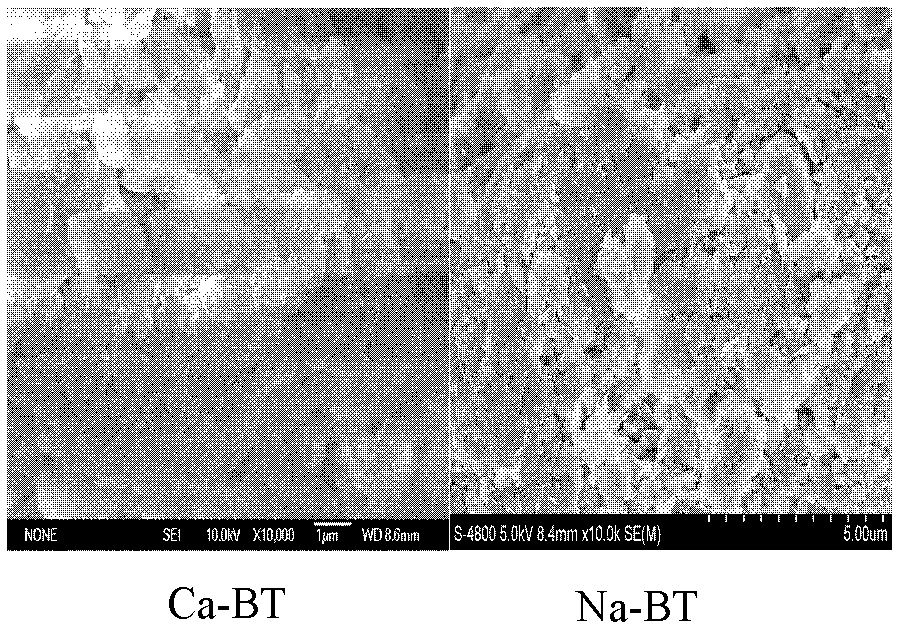

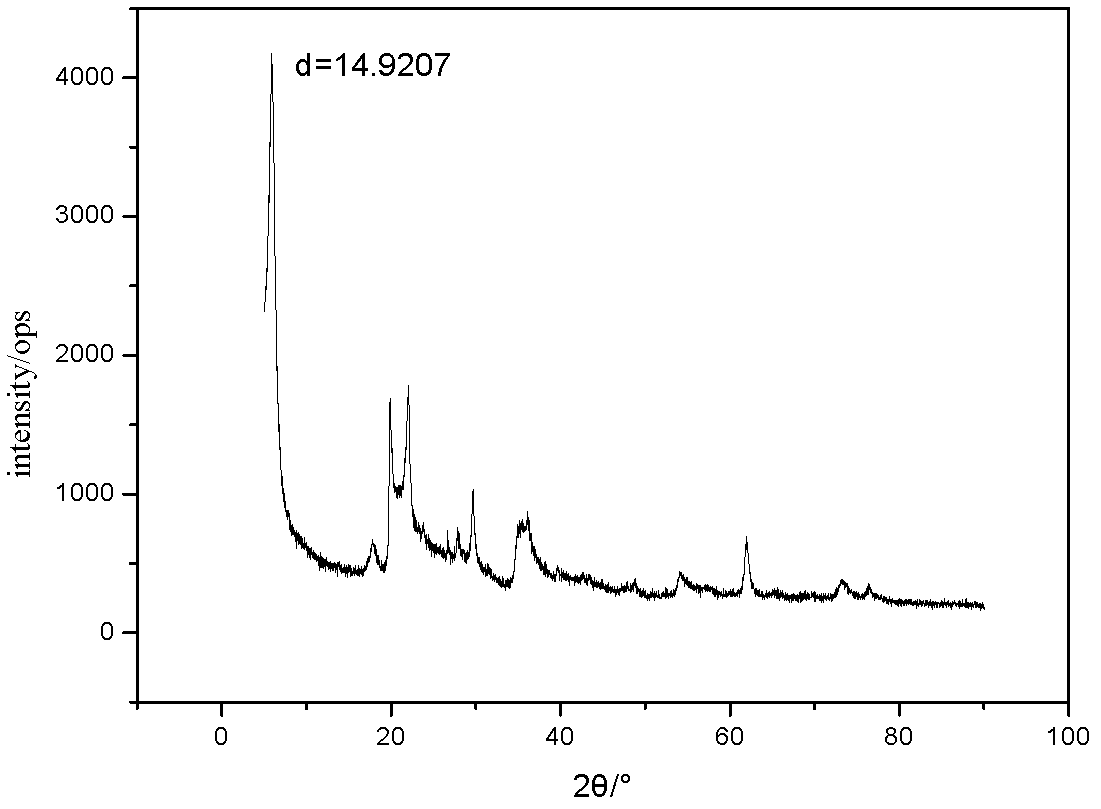

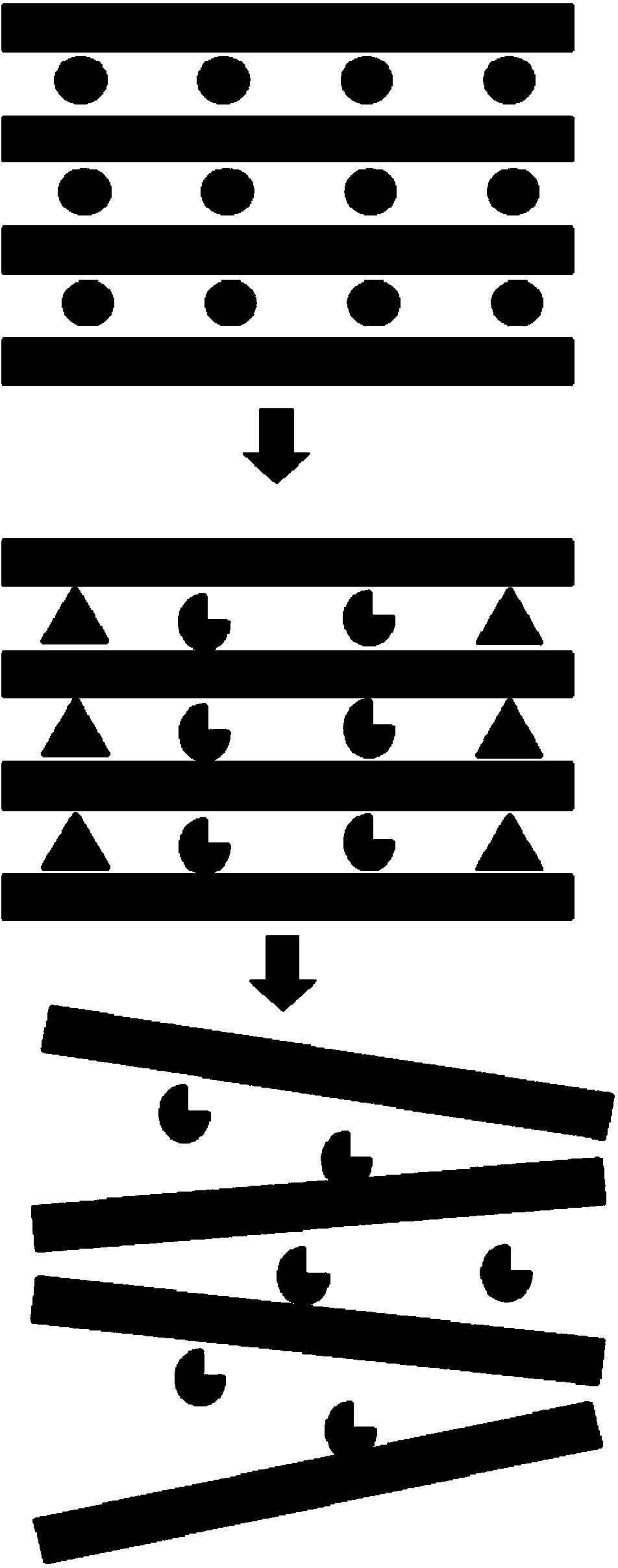

Synthesis method of bentonite loaded iron carbonyl adsorbent

ActiveCN103962093AFast adsorptionReduce dosageOther chemical processesWater/sewage treatment by sorptionWater bathsSodium Bentonite

The invention discloses a synthesis method of a bentonite loaded iron carbonyl adsorbent. The synthesis method comprises the following steps: dropwise adding a NaOH or Na2CO3 solution into a ferric nitrate solution under water bath stirring condition, aging a product after ending the dropwise adding, diluting hydroxyl, then adding bentonite powder, stirring and separating sediment, adding the solid part into a tetramethylammonium chloride solution, stirring, washing and drying; putting the dried product in a microwave oven and irradiating the product for 3-6 minutes by using microwave; and finally adding the product irradiated by the microwave into a lithium chloride solution, stirring, separating sediment, washing and drying to obtain the bentonite loaded iron carbonyl adsorbent. The synthesis method has the advantage that the microwave is used for decomposing interlayer organic matters and breaking a layer structure of the bentonite to form a sawtooth structure, so that hole diameter is increased, thereby effectively increasing the adsorption speed of the iron carbonyl.

Owner:南通豫湖机械有限公司

Method for processing industrial waste acid solution and preparing drying agent by using dolomite-containing attapulgite clay

InactiveCN100562498CReduce manufacturing costSimple production processDispersed particle separationWater/sewage treatment by neutralisationLiquid wasteSodium Bentonite

Owner:HEFEI UNIV OF TECH

Method of producing low viscosity casting parts resin sand core casting paint

InactiveCN101152659ANo pollution in the processLow viscosityFoundry mouldsFoundry coresSodium BentoniteLow speed

The invention provides a preparation method for low viscosity casting resin sand core molding coating. Hydromica powder, sea-foam powder and bentonite is mixed together by the ratio of 1:0.5: 0.5 to form 2 percent of suspension, which is mixed uniformly with 33 percent of water under low speed stirring, and then 2 percent of polyvinyl alcohol is added in the mixture; after dissolving polyvinyl alcohol, the mixture is added with 21 percent of zircon powder, 24 percent of brown corundum, 6 percent of porzite, 6 percent of scale graphite and 6 percent of magnesium olivine, and then is stirred uniformly and continuously, at last, finished product is realized. The invention has the advantages of no pollution, low viscosity, no poison and rapid drying and can improve casting quality and productivity.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

acidified bentonite

ActiveCN103979559BPromotes natural weatheringImprove the disintegration effectAluminium silicatesFiberSodium Bentonite

The invention discloses an acidified bentonite. The technical scheme is as follows: the acidified bentonite is composed of bentonite, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The production method of the acidified bentonite comprises the following steps: inputting acidified bentonite materials into a mill, and milling into powder, thereby obtaining the acidified bentonite. The composite proportioning is performed after acidification, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate, fully displaying the respective characteristics of the raw materials in the formula, and ensuring the inherent quality of the acidified bentonite. The acidified bentonite has favorable adsorbability, high-temperature stability and lubricating property, and the water absorptivity, colloid index, plasticity, expansion coefficient, colloid viscosity and thixotropy are greatly enhanced. The acidified bentonite is suitable for producing products in the fields of paints, aviation, metallurgy, chemical fibers, petroleum, firefighting and the like.

Owner:江苏世澳非金属应用科技有限公司

Organic potassium-added diammonium phosphate

The invention discloses a kind of organic phosphate-adding diammonium phosphate (base manure), which includes potassium chloride adaptable to the foodstuff and oil plants or lemery salt adaptable to the fruits and vegetable, diammonium phosphate, carbamide, weathered coal and bentonite. The former type has the following components by 1000kg: 455 of diammonium phosphate, 100 of carbamide, 167 of potassium chloride, 200 of weathered coal and 78 of bentonite, while the later typer has 410 of diammonium phosphate, 154 of carbamide, 200 of lemery salt, 180 of weathered coal and 56 of bentonite. The effective nutrients in the fertilizer can increase the activity of soil enzyme through humic acid, be transformed by the microbiota and is used in order. In return, the plants absorb the nitrogen, phosphorus, potassium, organic material, microelements and other nutrients.

Owner:张明

Method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite

ActiveCN102618932ANo waste dischargeReduce manufacturing costPolycrystalline material growthAlkali metal silicatesSodium BentoniteSurface-active agents

The invention discloses a method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite, which comprises the following steps of: adding sulfuric acid solution to bentonite mineral powder which is taken as an initial raw material; reacting; then performing filtering separation; collecting an acid-leached filtrate and acid-leached filter cakes; adding salpeter solution and isoamyl alcohol to the acid-leached filtrate; performing liquid separation and collecting an aqueous phase to obtain aluminum salt solution; adding urea and a surface active agent to the aluminum salt solution; reacting; then, separating, washing and drying to obtain basic ammonium aluminum carbonate hydroxide whiskers; and calcining the basic ammonium aluminum carbonate hydroxide whiskers to obtain aluminum oxide whiskers. Aluminum oxide and silicon dioxide which are required by the method disclosed by the invention respectively come from bentonite ore, and other industrial raw materials do not need to be adopted, so that the production cost can be effectively reduced. The method disclosed by the invention has the advantages that the recovery rate is high; the yield of the aluminum oxide in the bentonite can reach at least 90 percent; and the yield of the amorphous silicon dioxide can reach at least 95 percent.

Owner:HEFEI UNIV OF TECH

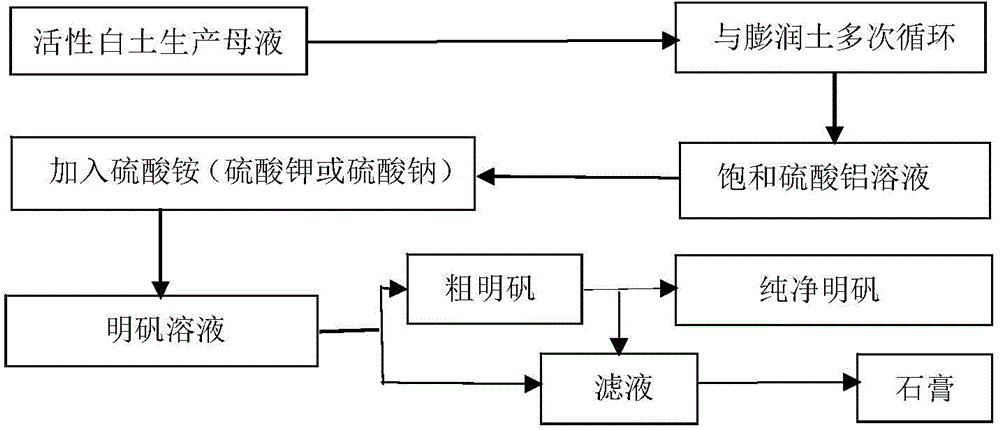

Method for co-production of aluminum potassium sulfate and gypsum through activated clay production mother liquid

InactiveCN105293797AReduce manufacturing costShort cycleCalcium/strontium/barium sulfatesMultistage water/sewage treatmentSodium BentoniteFiltration

The invention discloses a method for co-production of aluminum potassium sulfate and gypsum through an activated clay production mother liquid, and belongs to the technical field of activated clay wastewater treatment and inorganic salt preparation. According to the method, through repeated cycling use of the activated clay production mother liquid and bentonite, aluminum sulphate dissolved in the activated clay production mother liquid is saturated, then the mixture is reacted with ammonium sulfate ( potassium sulfate or sodium sulfate), such steps as purification, crystallization, pressure filtration and water removal are performed to obtain high-purity aluminum potassium sulfate, and the obtained filtrate is subjected to neutralizing treatment through lime to prepare hydraulic and retardant gypsum. Through the method, activated clay wastewater is effectively treated, so that not only are aluminum elements in the mother liquid comprehensively utilized, but also gypsum prepared by wastewater neutralization meets the industrial application requirements, and purposes of energy conservation and emission reduction as well as changing waste into valuable are realized; meanwhile, the production cost of aluminum potassium sulfate is reduced, the production period is shortened, and the enterprise economic benefit is increased.

Owner:GUANGXI LONGAN RUIFENG IND TRADING CO LTD

Compostte artificial board and its preparation method

InactiveCN1623746AImprove performanceImprove adsorption capacityWood working apparatusFlat articlesWood fibreLetovicite

A composite artificial board is prepared from the strew and stalk fibres other than wood fibres, urea-formaldehyde resin and benton through breaking said straw and stalk fibres, making its water content to be 3-25%, proportionally mixing it with benton, ball grinding, proportionally adding urea-formaldehyde resin, stirring, spreading in die, and hot pressing.

Owner:SOUTHEAST UNIV

Method for producing activated clay by circulating use of waste hydrochloric acid

InactiveCN101519211AHighlight substantive featuresSignificant progressSilicon compoundsSodium BentoniteLetovicite

The invention relates to a method for preparing activated clay. The method is characterized in that bentonite and hydrochloric acid are taken as raw materials. The method is as follows: bentonite ore and the waste hydrochloric acid returned from latter processes are ground by a wet method to obtain suspension liquid, concentrated hydrochloric acid is added to the suspension liquid in an agitation reactor to enable the concentration of the suspension liquid acid to reach 10-15 percent, the concentrated hydrochloric acid and the suspension liquid react for 3-6h at the temperature ranging from 75 DEG C to 100 DEG C to obtain reaction suspension liquid, the reaction suspension liquid is filtered to obtain waste hydrochloric acid and filter cakes, the waste hydrochloric acid is returned for recycle, and the activated clay with the activity degree being more than 240 and the rape oil color-removing ratio being more than 90 percent is obtained by filtering and drying the filter cakes. In the method, a waste hydrochloric acid return process is adopted in the activated clay preparing process, thus the use amount of the hydrochloric acid is reduced by 60 percent and the discharge amount of the waste hydrochloric acid is reduced by 80 percent; and the quality of the obtained activated clay is better than that of the activated clay prepared by a sulfuric acid process.

Owner:GUANGXI UNIV

Method for improving dye wastewater adsorptivity of hydroxyl iron pillared bentonite

ActiveCN102219278AImprove processing efficiencyImprove adsorption capacityCombustible gas purificationWater/sewage treatment by sorptionDyeing wastewaterLetovicite

The invention relates to a method for improving the dye waste water adsorptivity of hydroxyl iron pillared bentonite, comprising the following steps of: firstly, acting hydroxyl iron pillared bentonite powder prepared by adopting a traditional method under a magnetic field with the intensity of 3000-4000 gausses for 40-80 minutes; secondly, simultaneously adding the obtained hydroxyl iron pillared bentonite powder acted by the magnetic field and sodium chloride into dye wastewater for treatment, wherein 0.5-1mol of sodium chloride and 1-5g of the hydroxyl iron pillared bentonite powder acted by the magnetic field are added into each liter of dye wastewater; and finally, stirring for 15-30 minutes, precipitating and separating. The adsorbing capacity of the hydroxyl iron pillared bentonite on the dye is improved and the treatment efficiency of the dye wastewater is improved.

Owner:溧阳常大技术转移中心有限公司

Method for preparing superfine aluminium silicate by bentonite

InactiveCN101804992ANo waste dischargeReduce manufacturing costAluminium silicatesSodium BentoniteManganese

The invention relates to a method for preparing superfine aluminium silicate by bentonite, which takes the mineral powder of the bentonite as a raw material and comprises the steps of pickling, purifying, alkaline leaching, synthesizing, washing and drying. In the pickling step, acid liquor is added according to the weight ratio of 1:2.5 to 5.5 of the mineral powder of the bentonite to the acid liquor, and the mineral powder of the bentonite and the acid liquor react for 2 to 6 hours at the temperature of 80 to 105 DEG C; in the purifying step, potassium permanganate and manganese sulfate which have the weight ratio of 0.7:1 are added after the pH value of pickling filtrate is regulated to 3 to 4 by using a sodium hydroxide solution, the adding quantity of the potassium permanganate and the manganese sulfate is 1 to 3 percent of the weight of the pickling filtrate, and an aluminium salt solution is obtained by processing; and in the alkaline leaching step, the sodium hydroxide solution is added into a pickling filter cake according to the weight ratio of 1:2.5 to 5.0 of the pickling filter cake to the sodium hydroxide solution, and the pickling filter cake and the sodium hydroxide solution react below the boiling temperature to obtain water glass. In the synthesizing step, the aluminium salt solution and a water glass solution react to obtain the superfine aluminium silicate by separating, washing and drying. The invention has the characteristics of low production cost, low energy consumption and good economic benefit.

Owner:黄山市恒佳科技有限公司

Novel sodium modification process of bentonite

The invention aims to provide a novel sodium modification process of bentonite. The process comprises the following steps: firstly, mining bentonite raw materials, screening and drying; smashing; sequentially carrying out primary sodium modification on the smashed raw materials; and then carrying out secondary sodium modification on the smashed raw materials in a multilayer treatment gestation manner so as to obtain the bentonite with sodium modification. The process is simple and effective; the drying treatment is not required, thereby saving energy sources. The bentonite raw materials are subjected to sodium modification twice in the multilayer treatment gestation manner, so that the sodium-based bentonite with homogeneous sodium modification and a sufficient sodium modification effect is obtained. The sodium modification homogeneity of the bentonite can reach above 96%.

Owner:芜湖恒杰膨润土科技有限公司

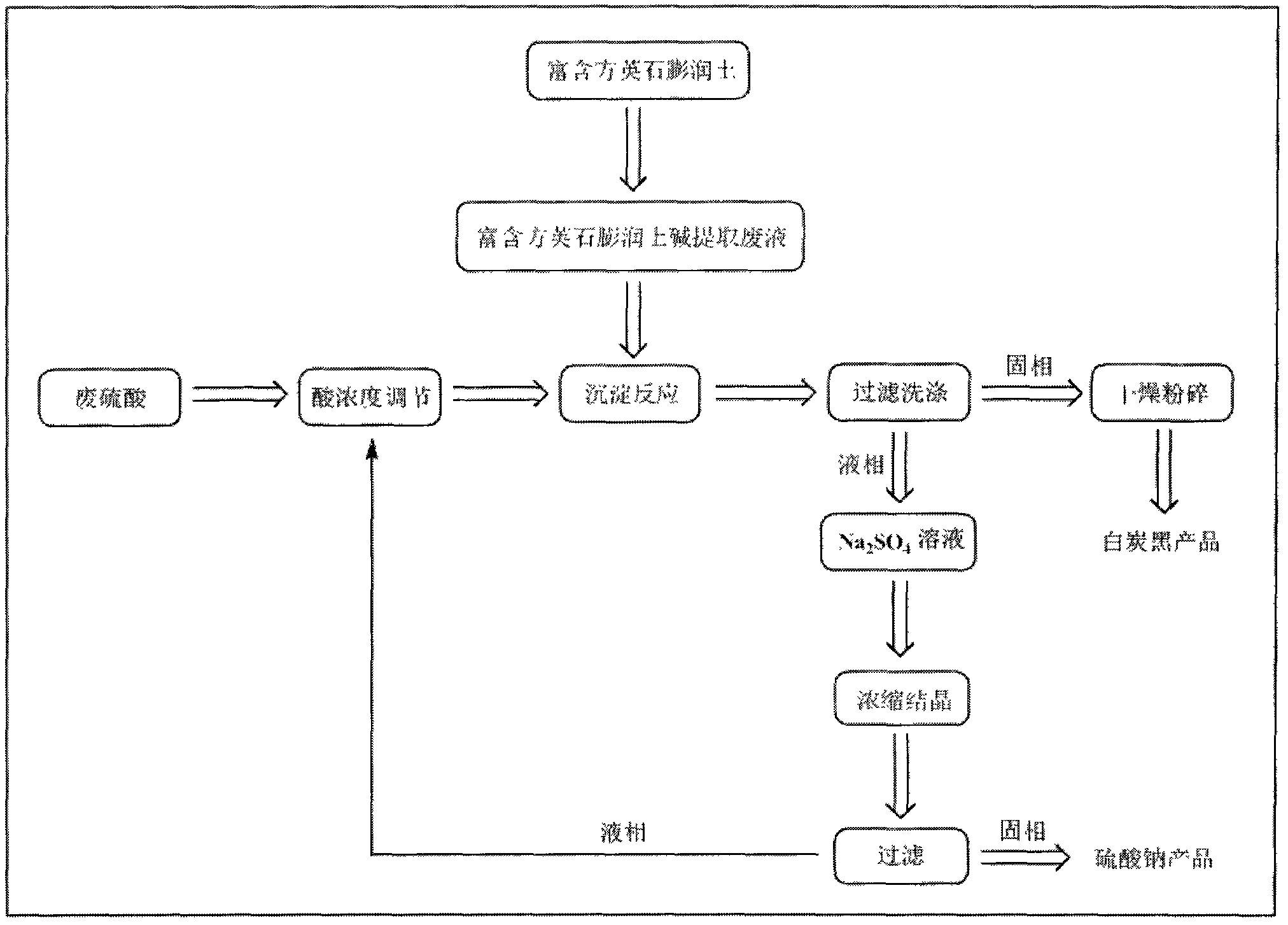

Method for coproducing white carbon black and sodium sulfate from waste sulfuric acid and bentonite alkaline extraction waste liquid rich in christobalite

InactiveCN102351199ARealize cleaner productionSmall modulusSilicaAlkali metal sulfites/sulfatesSodium BentoniteResource utilization

The invention provides a resource utilization method for inorganic wastes. The treatment of waste sulfuric acid and depth processing of bentonite rich in christobalite are combined in a circular economy approach; a characteristic of easiness to conducting a precipitation reaction with sulfuric acid of the bentonite alkaline extraction waste liquid (with a main component of a sodium silicate dilute solution) rich in christobalite is fully utilized to prepare white carbon black through a precipitation reaction, and a mother liquor obtained from the precipitation reaction is further utilized to prepare sodium sulfate. The technology of the invention is easy, practical and with high economic benefits, solves an environmental pollution problem caused by waste sulfuric acid and bentonite alkaline extraction waste liquid rich in christobalite and also produces two products of white carbon black and sodium sulfate with excellent product performances, wherein a white carbon black purity is higher than 99%, and a sodium sulfate purity is higher than 99.5%. The invention realizes waste resource exploitation and utilization with high efficiency, low costs and high added value.

Owner:INNER MONGOLIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/e15dbbf8-c72c-4ab6-bf51-8de551180619/140408101615.PNG)

![AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/e15dbbf8-c72c-4ab6-bf51-8de551180619/140408101620.PNG)

![AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof AM/AA/N-beta-CD polymer-ionic liquid [bquin]BF4 composite clay stabilizer and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/e15dbbf8-c72c-4ab6-bf51-8de551180619/140408101624.PNG)