Method for processing industrial waste acid solution and preparing drying agent by using dolomite-containing attapulgite clay

A technology of attapulgite clay and industrial waste acid, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as hindering production, production restrictions, etc., to improve product quality and desiccant quality. , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of silica from attapulgite clay and collection of acidic waste liquid

[0021] The attapulgite clay layer is mined in layers, and high-quality ores with attapulgite content greater than 60% and quartz and feldspar content not higher than 5% are selected according to weight percentage. When the water content is too high, first carry out drying treatment. According to the specific production scale and climatic conditions, natural air drying or dryer drying can be considered for drying. It is generally required to make the water content less than 20%. The crushing operation is carried out under the premise that the water content meets the requirements, and the crushing particle size requires 100% to pass 100 mesh to obtain attapulgite clay powder.

[0022] Add 1 ton of dolomite attapulgite clay powder and 2.5 tons of hydrochloric acid solution with a concentration of 100g / L into a reaction kettle or a container, and continue stirring and reacting for 3 hours un...

Embodiment 2

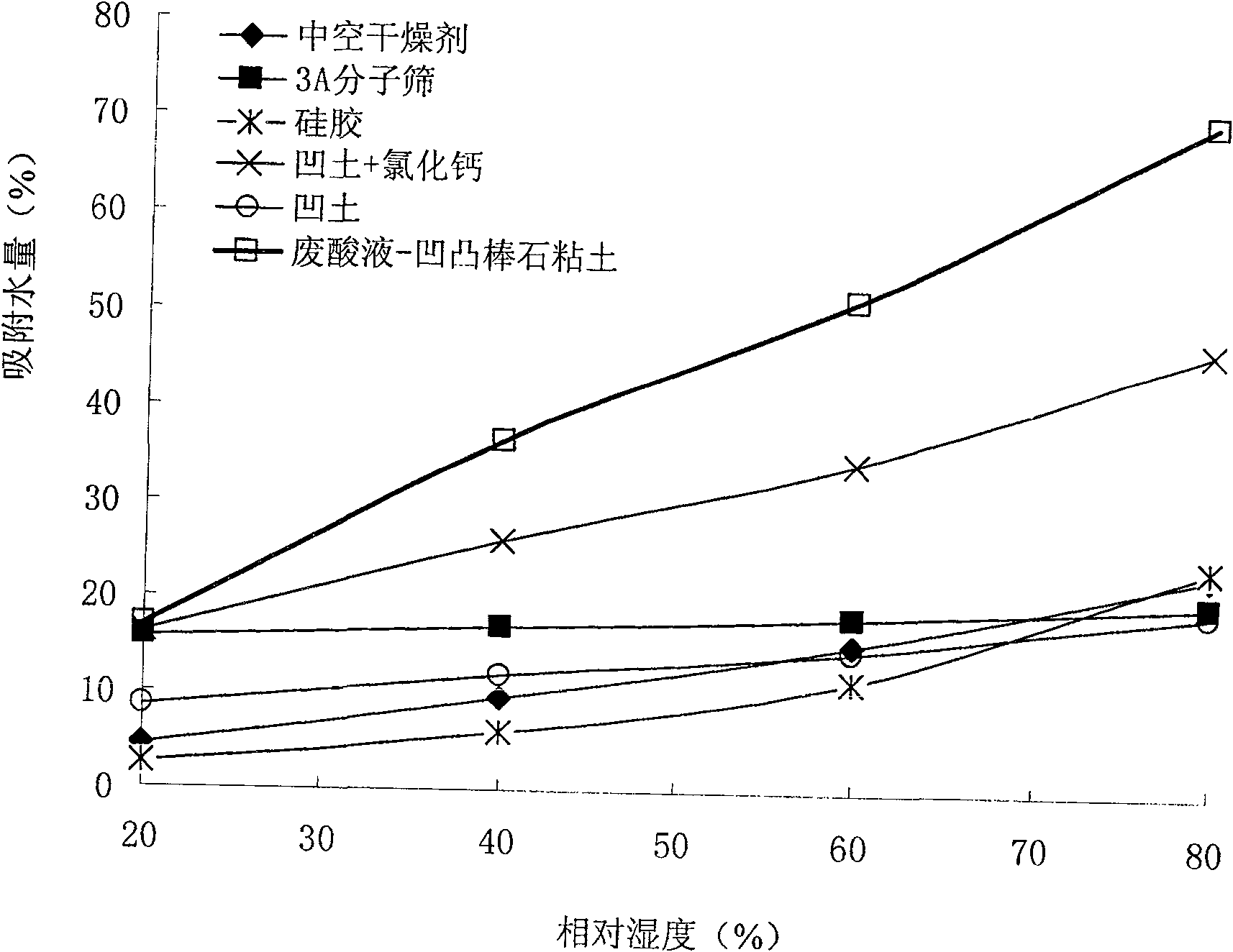

[0029] Mix 70 L of hydrochloric acid acidic waste liquid with an acidity of 100 g / L and 70 kg of attapulgite clay powder containing 50% dolomite evenly. Under the normal temperature condition, the dolomite in the clay reacts with the waste acid solution. After the wet mixture is extruded and uniformly mixed, it is molded into particles with a particle diameter of 3mm, and calcined at 400°C for 1 hour. The solid product is cooled, and packaged under dry conditions to obtain the attapulgite clay composite desiccant product. The attapulgite clay composite desiccant adsorbent prepared according to the above steps is respectively placed in desiccators containing 58.2%, 47.8%, 38.4%, and 26.2% sulfuric acid solutions with a relative humidity of 20%, 40% %, 60% and 80%, the adsorption equilibrium was 48 hours. The water absorption test adopts the gravimetric method. The test results of equilibrium adsorption water under different relative humidity are shown in figure 1 . The des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com