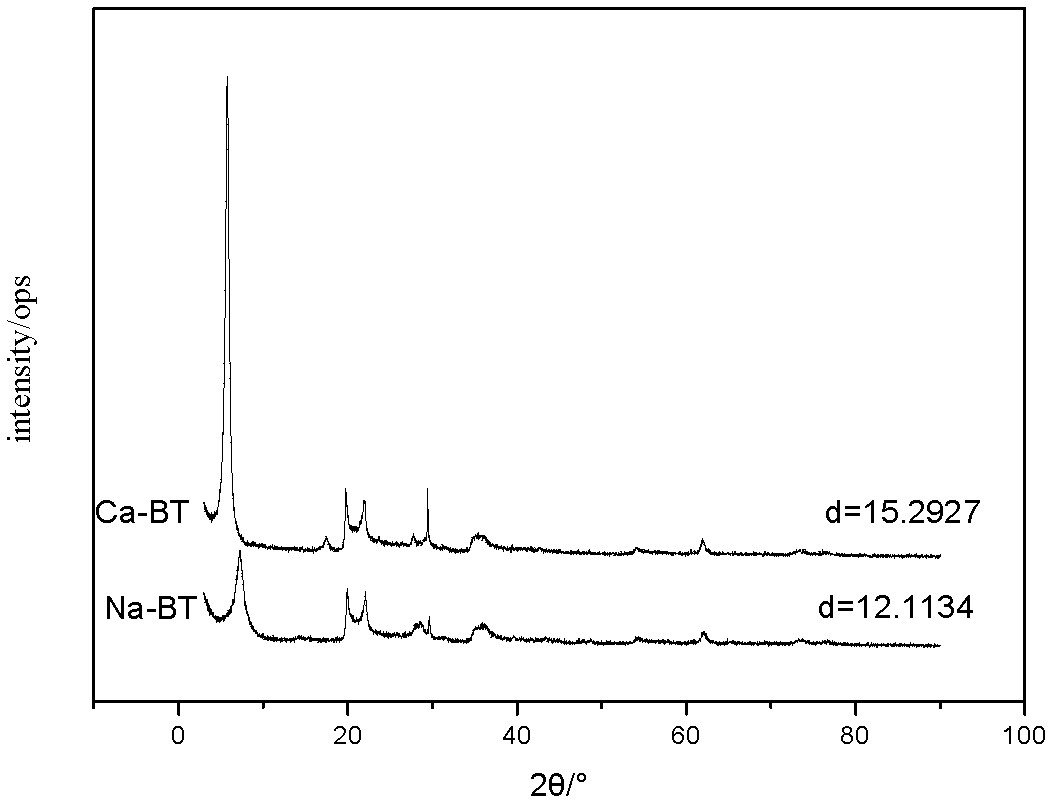

Novel sodium bentonite-AM-AA composite lead ion absorbing agent

A technology of sodium-based bentonite and calcium-based bentonite, applied in the field of water treatment, can solve the problems of high cost of composite bentonite and high cost of organic monomers, and achieve the effects of easy recycling, short preparation period and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

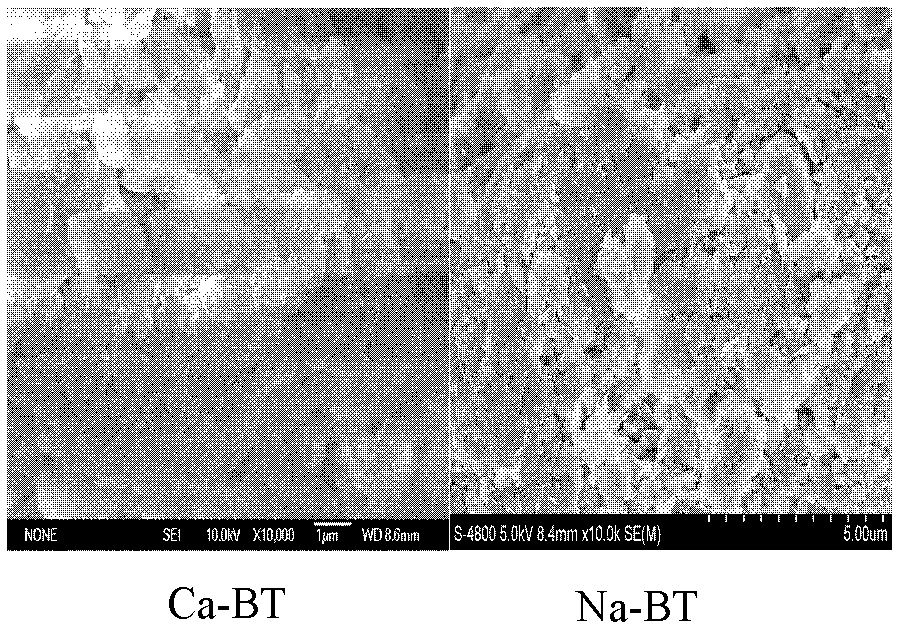

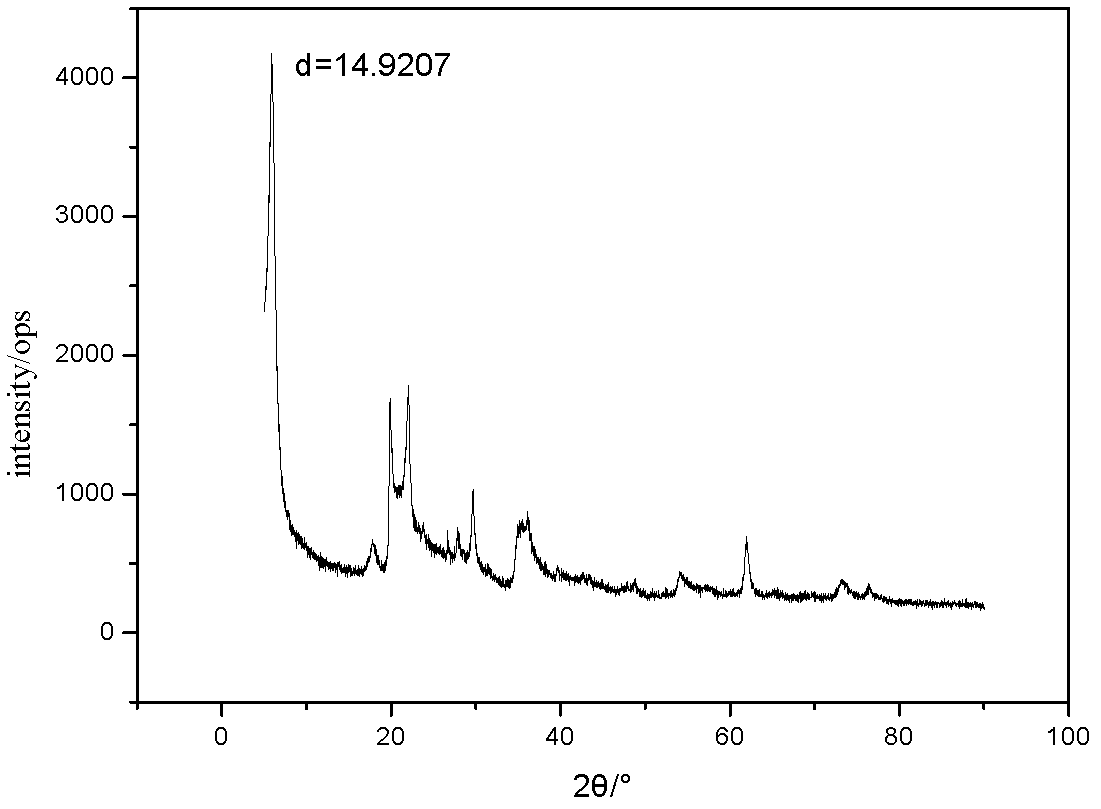

Method used

Image

Examples

Embodiment 1

[0033] The first step, the preparation of purified calcium-based bentonite

[0034] Calcium-based bentonite slag powder and tap water are added according to the mass ratio of calcium-based bentonite slag powder: tap water=1: 6, stirred for 30 minutes, allowed to stand for 24 hours, then stirred for 15 minutes, and then tap water is added to prepare a mass ratio of calcium-based bentonite slag powder : the feed liquid of water=1: 10, continue to stir 15min, then let stand and settle for 4h, take out the supernatant and be used for preparing feed liquid again next time, take out the fine soil of the upper layer from the sediment, discard the sand grains of the lower layer, the The refined soil is dried in an oven at a temperature of 100°C until the quality of the refined soil remains unchanged, then crushed, and passed through a 200-mesh sieve to obtain purified calcium-based bentonite;

[0035] The second step, solution polymerization

[0036]First, weigh 8.5 g of the purified...

Embodiment 2

[0043] The first step, the preparation of purified calcium-based bentonite

[0044] Will leave standstill 24h, the tap water that adds again after stirring 15min is changed into the supernatant that this step takes out in embodiment 1, and other steps are with the first step of embodiment 1;

[0045] The second step, solution polymerization

[0046] First, weigh 8.5g of purified calcium-based bentonite and 0.425g of sodium carbonate sodium carbonate and dissolve them in 55mL of deionized water. After mixing evenly, stir in a water bath at 70°C for 15 minutes for sodiumization. After the sodiumization is complete, let it stand at room temperature. Then, add 1.125 g of acrylamide and 0.375 g of acrylic acid and stir at room temperature for 60 minutes, mix well and then heat up to 70°C, then add 0.01 g of initiator potassium persulfate-sodium sulfite and 0.2 g of crosslinking agent N, N-methylenebisacrylamide g, continue to stir and carry out polymerization reaction for 80 minut...

Embodiment 3

[0051] The first step, the preparation of purified calcium-based bentonite

[0052] With the first step of embodiment 1;

[0053] The second step, solution polymerization

[0054] First, weigh 8.5 g of purified calcium-based bentonite and 0.425 g of sodium carbonate sodium carbonate and dissolve them in 40 mL of deionized water. After mixing evenly, stir in a water bath at 70°C for 15 minutes for sodiumization. After the sodiumization is complete, let it stand at room temperature. Then, add 1.0 g of acrylamide and 0.5 g of acrylic acid and stir at room temperature for 60 minutes, mix well and heat up to 70°C, then add 0.01 g of initiator potassium persulfate-sodium sulfite and 0.2 g of crosslinking agent N, N-methylenebisacrylamide g, continue to stir and carry out polymerization reaction for 80 minutes to obtain a wet solid phase product.

[0055] The third step is to dry the obtained composite bentonite product

[0056] The wet solid phase product obtained in the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com