Particles containing sodium fatty acid methyl ester sulfonate and preparation method thereof

A technology of sodium fatty acid methyl ester sulfonate and particles, which is applied in the field of daily chemicals and can solve problems such as easy agglomeration, affecting the use of MES, and health hazards to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 40kg diatomite, 15kg precipitated silica, 3kg4A zeolite (Gantz whiteness 96%, apparent density 0.3g / cm 3 ), 25kg of cross-linked starch are added to the high-speed mixer with a stirring speed of 150rpm and stirred for 8min. The percentage content is 30%) was added therein for wet granulation, and then 12.5 kg of 4A zeolite was added and mixed for 3 minutes for wet granulation. The final granules obtained by two-step wet granulation are dried in a fluidized bed at 120° C. for 15 minutes, and finally sieved through a 18-80 mesh sieve to obtain granules containing sodium fatty acid methyl ester sulfonate.

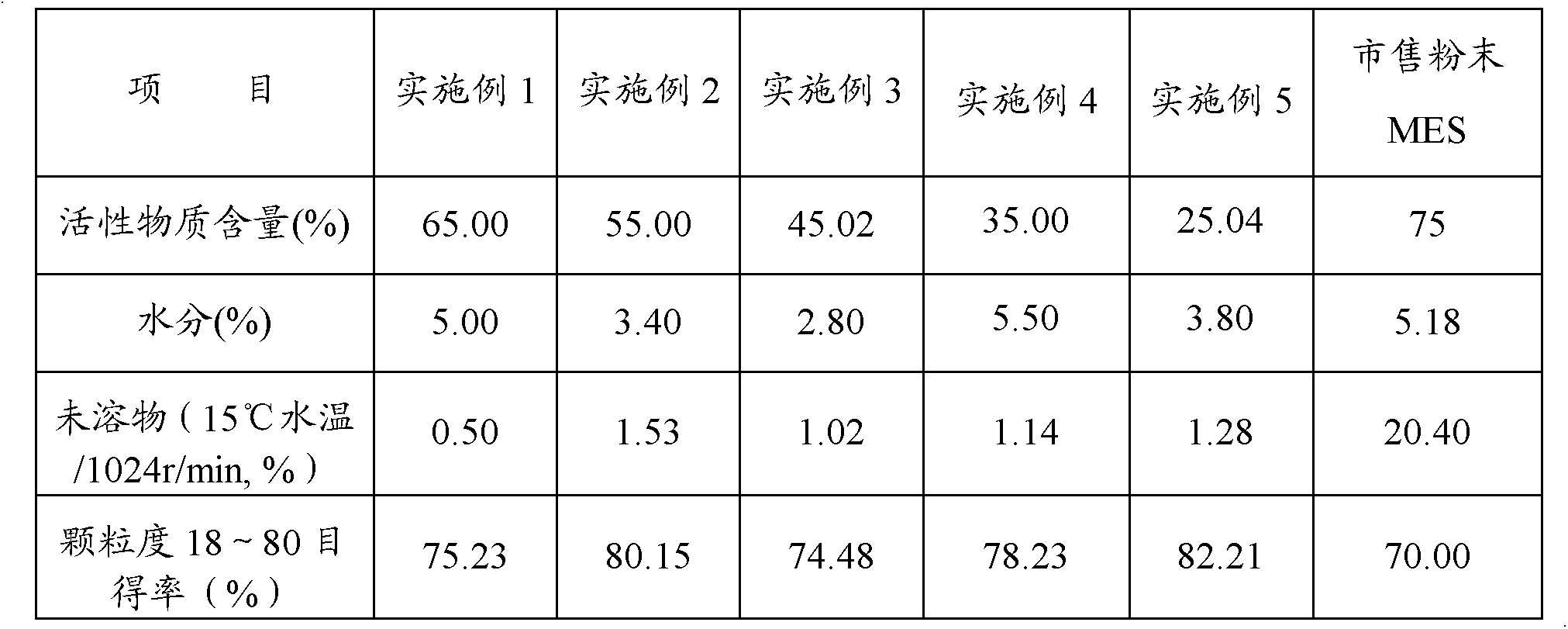

[0027]The sodium fatty acid methyl ester sulfonate particle obtained above is checked, and the results are as shown in table 1 and table 2, and its active substance sodium fatty acid methyl ester sulfonate content is 65.00%, moisture content 5.00%, undissolved matter is lower, The particle size distribution is uniform. Therefore, the high activity sodium fatty acid me...

Embodiment 2

[0029] 40kg fumed silicon dioxide, 74kg natural zeolite, 20kg carboxymethyl starch, 15kg bentonite are added to a high-speed mixer with a stirring speed of 100rpm and stirred for 7min. The mass percent content of sodium ester sulfonate is 70%, and the mass percent content of water is 30%) is added thereinto for wet granulation. Then add 26kg of 4A zeolite and continue mixing for 3 minutes for wet granulation. The final granules obtained by two-step wet granulation are dried for 30 minutes in a fluidized bed at 90° C., and finally sieved through a 18-80 mesh sieve to obtain granules containing sodium fatty acid methyl ester sulfonate.

[0030] The particles obtained above were inspected, and the results are shown in Table 1 and Table 2. The active substance content was 55.00%, the moisture content was 3.40%, the undissolved matter was relatively low, and the particle size distribution was uniform. Therefore, the active substance content in the high active particles obtained by...

Embodiment 3

[0032] With 25kg white carbon black, 55kg4A zeolite (Gantz whiteness 96%, apparent density 0.3g / cm 3 ), 10kg oxidized starch, 90kg bentonite are added to the high-speed mixer that stirring speed is 100rpm and stir 7min, after mixing uniformly, 275kg paste sodium fatty acid methyl ester sulfonate (mass percentage content 70% of fatty acid methyl ester sodium sulfonate, The mass percent content of water is 30%) was added therein for wet granulation, and then 45kg of 4A zeolite was added and mixed for 3 minutes for wet granulation. The final granules obtained by two-step wet granulation in a fluidized bed at 100°C are dried for 30 minutes, and finally sieved through a 18-80 mesh sieve to obtain granules containing sodium fatty acid methyl ester sulfonate.

[0033] The particles obtained above were inspected, and the results are shown in Table 1 and Table 2. The active substance content was 45.02%, the moisture content was 2.80%, the undissolved matter was relatively low, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com