Method for coproducing white carbon black and sodium sulfate from waste sulfuric acid and bentonite alkaline extraction waste liquid rich in christobalite

A technology of white carbon black and bentonite, applied in the direction of alkali metal sulfite/sulfite, chemical instruments and methods, alkali metal compounds, etc., can solve the problem of low utilization rate of sulfuric acid, to avoid the precipitation of sodium sulfate crystals, Avoid the formation of gel, the effect of high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

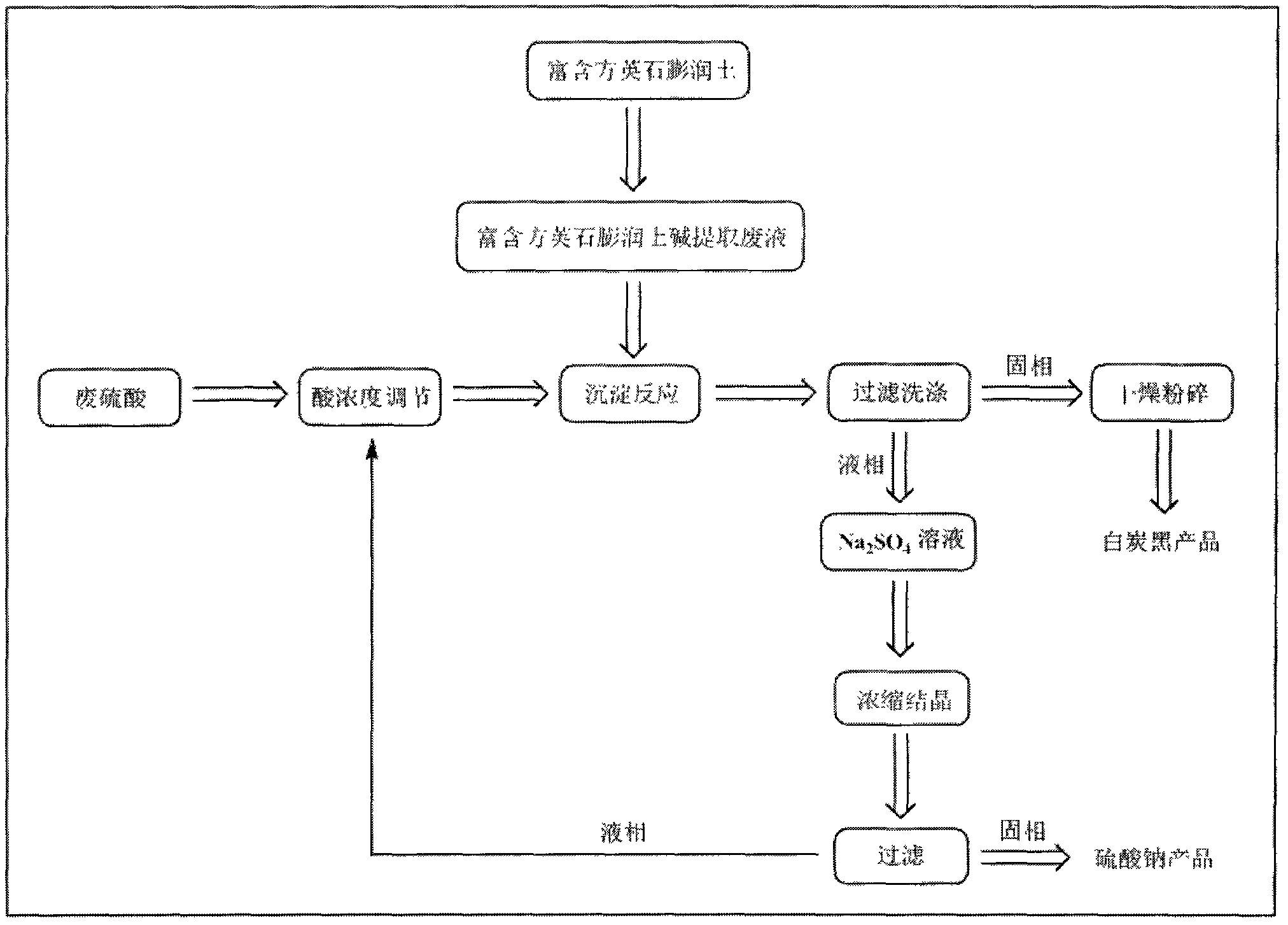

Method used

Image

Examples

Embodiment 1

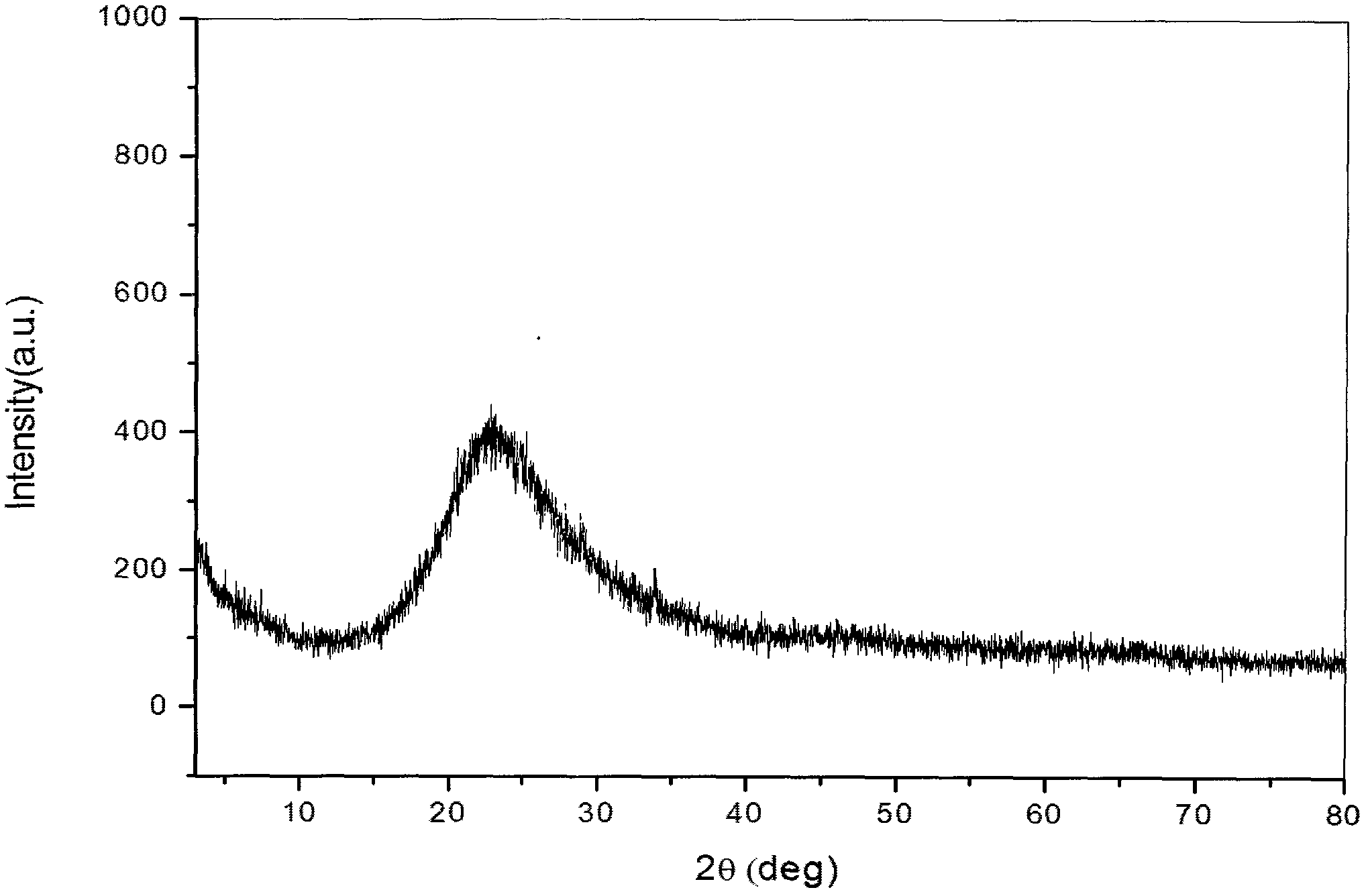

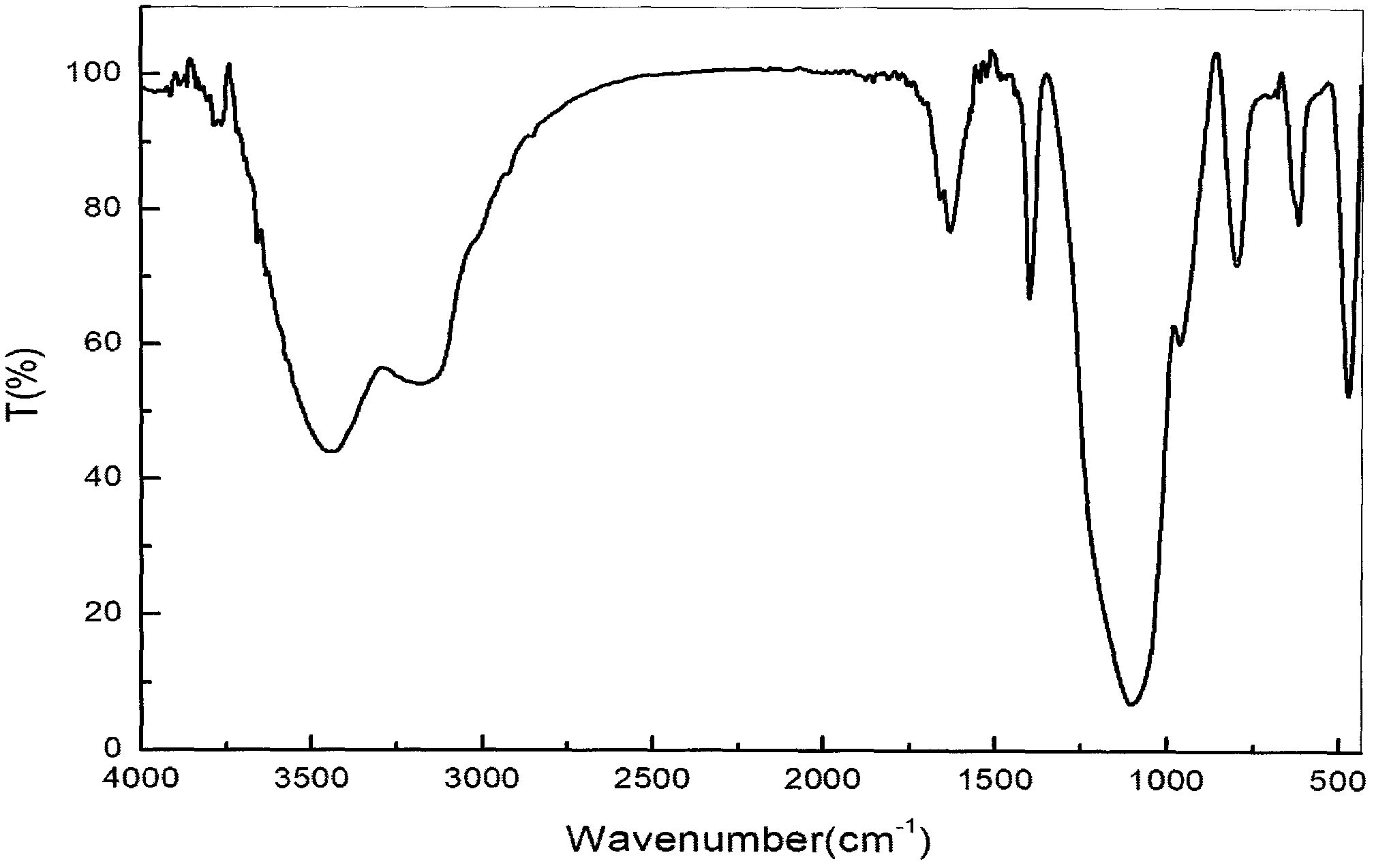

[0030]Collect the waste liquid obtained after alkali extraction and separation of cristobalite-rich bentonite by collecting dilute alkali solution. After measuring the waste liquid Baume degree=6°Bé, modulus SiO 2 / Na 2 O=1.1. Add precipitant waste sulfuric acid in above-mentioned waste liquid and react, waste sulfuric acid concentration is 20% (mass fraction), sulfuric acid solution add-on is 100ml / L, reaction temperature is controlled at 70 ℃, reaction time 1 hour, obtains amorphous white carbon Black precipitates, obtains white carbon black product after filtering, washing, drying, and the white carbon black product purity of making > 99% (see X-ray diffractogram figure 2 , see the infrared spectrum image 3 ), the DBP oil absorption value is 2.6ml / g, and the specific surface area is 240m 2 / g, the average particle size of the particles is 450nm. The determination of DBP oil absorption value is based on "Determination of Absorption Value of Dibutyl Phthalate Precipitat...

Embodiment 2

[0032] The reaction raw materials, conditions and other corresponding test methods are the same as in Example 1.

[0033] Collect the filtrate that obtains after the white carbon black precipitation filtration in embodiment 1, filtrate obtains sodium sulfate product after evaporation concentration, crystallization, filtration, oven dry, and the sodium sulfate purity of making > 99.5% (X-ray diffraction spectrum and sodium sulfate For a comparison of X-ray diffraction standard patterns, see Figure 4 ).

Embodiment 3

[0035] As a comparison, the present embodiment selects a commercially available sodium silicate solution (measured sodium silicate solution Baume degree=34 ° B é, modulus SiO 2 / Na 2 (0=3.5) and waste sulfuric acid solution (mass fraction is 20%) prepare precipitated white carbon black, reaction conditions and other corresponding test methods are identical with embodiment 1, and the white carbon black product purity of making Figure 5 ), a small amount of sodium sulfate crystals are obviously mixed in the white carbon black product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com