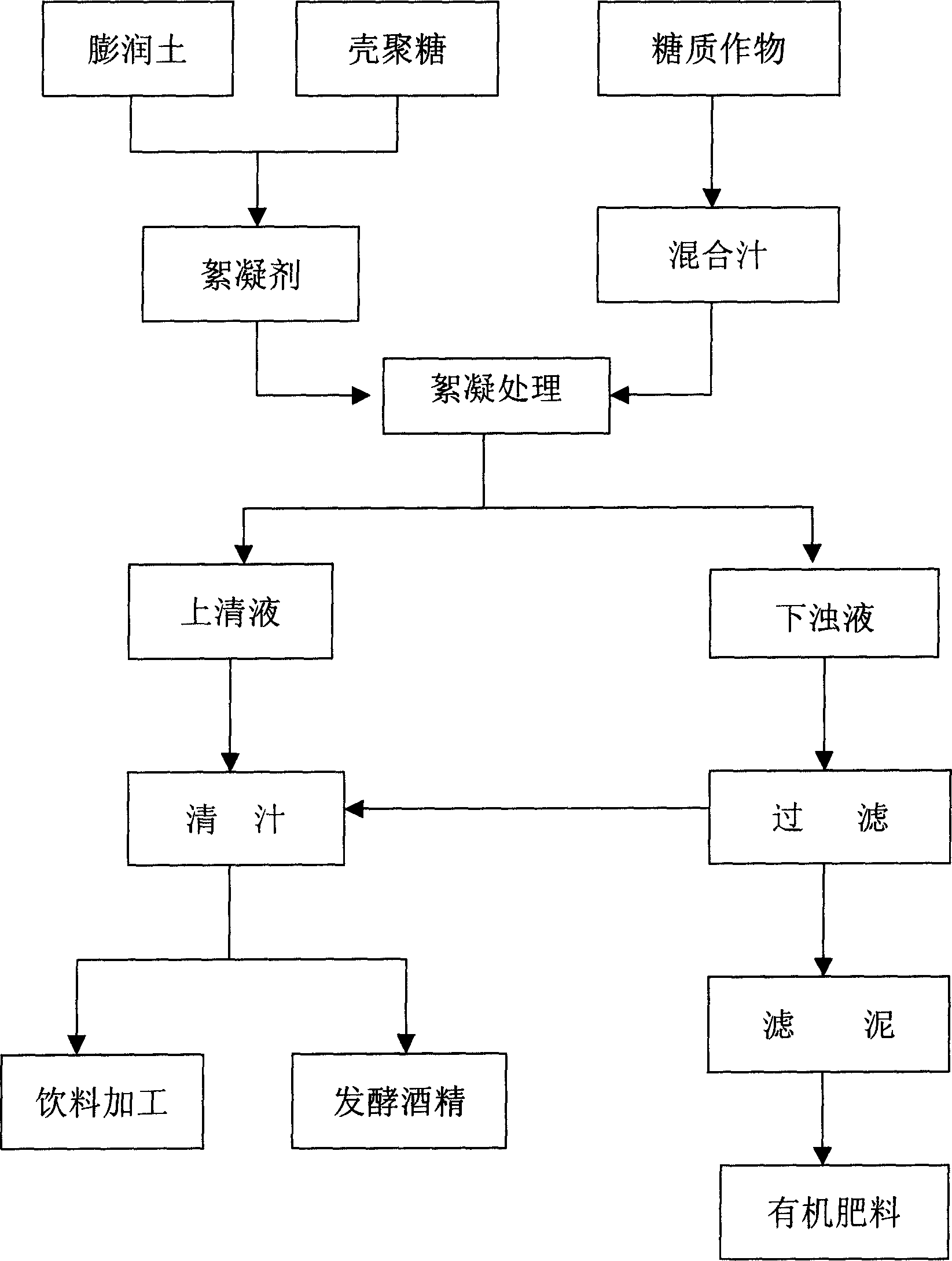

Method of clarifying saccharic crop pressed juice mixture by using bentonite-chitin composite flocculant

A composite flocculant and bentonite technology, which is applied in the purification of sugar juice, production and application of sugar, etc., can solve problems such as restricting economic benefits, deteriorating flavor of sugar cane juice, and turbidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] According to the ratio of 50mL: 40g, 50mL of 1.0% chitosan (90% degree of deacetylation) solution was mixed with 40g of modified bentonite to form bentonite-chitosan paste. The bentonite-chitosan paste was placed in a blast oven at 60°C, and after drying, it was ground into a powdery composite flocculant for future use.

[0014] Take 45kg of the sugarcane stems of Funong 91-4710 variety, wash and cut them into multiple sections, put them in a sugarcane press to squeeze the sugarcane juice, and then squeeze the slag for a second squeeze. The light rate is 6%). In order to prevent the sugarcane mixed juice from becoming turbid and sour due to microbial contamination, the sugarcane mixed juice was heated to 68°C and kept for 5 minutes. Take 1000 mL of heated sugarcane mixed juice and add 12 g of bentonite-chitosan composite flocculant, and stir with a magnetic stirrer (150 r / min) for 5 min. Use a fast settler for 20 minutes. After decanting the supernatant, the turbid l...

Embodiment 2

[0016] According to the ratio of 50mL: 40g, 25mL of 1.0% chitosan (90% degree of deacetylation) solution was mixed with 20g of modified bentonite to form bentonite-chitosan paste. The bentonite-chitosan paste was placed in a blast oven at 60°C, and after drying, it was ground into a powdery composite flocculant for future use.

[0017] Take 45kg of sweet sorghum variety "Leo" stalks, wash and remove the leaf sheaths, cut into multiple sections, put them in a press to squeeze sweet sorghum juice, squeeze the dregs for a second squeeze, and combine the sweet sorghum juice from the two squeezes into a turbid state Mixed juice (light transmission 4%). In order to prevent the mixed juice from becoming turbid and sour due to microbial contamination, heat the mixed juice to 68°C and keep it for 5 minutes. Take 500 mL of mixed juice and add 6 g of bentonite-chitosan composite flocculant, and stir with a magnetic stirrer (150 r / min) for 5 min. Use a fast settler for 20 minutes. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com