Method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite

A technology of aluminum oxide whiskers and ammonium aluminum carbonate, which is applied in the directions of alkali metal silicates, chemical instruments and methods, silicates, etc. Alumina whisker method, high production cost, high recovery rate, high iron removal efficiency and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

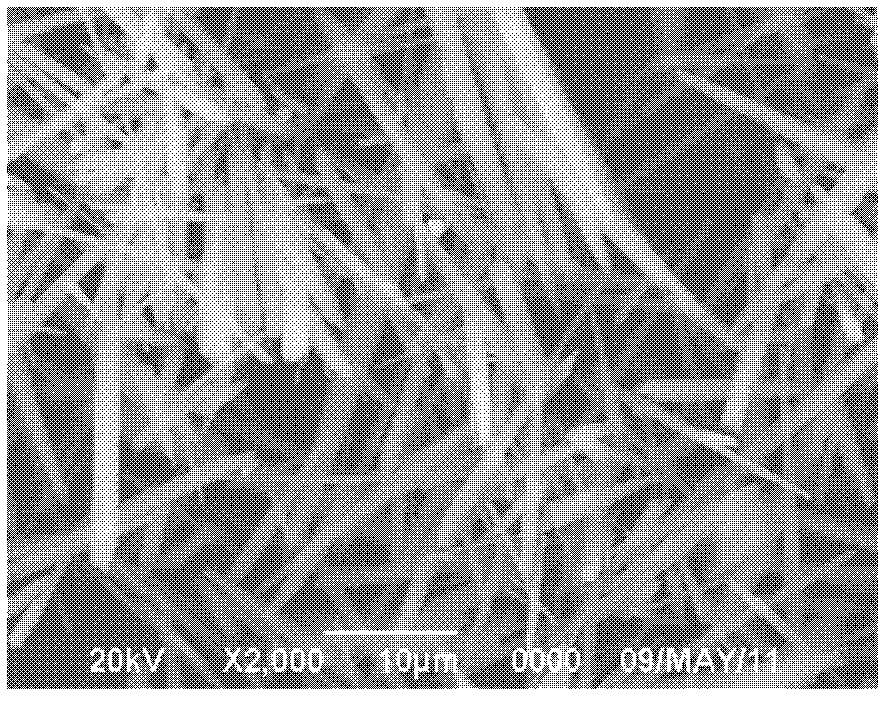

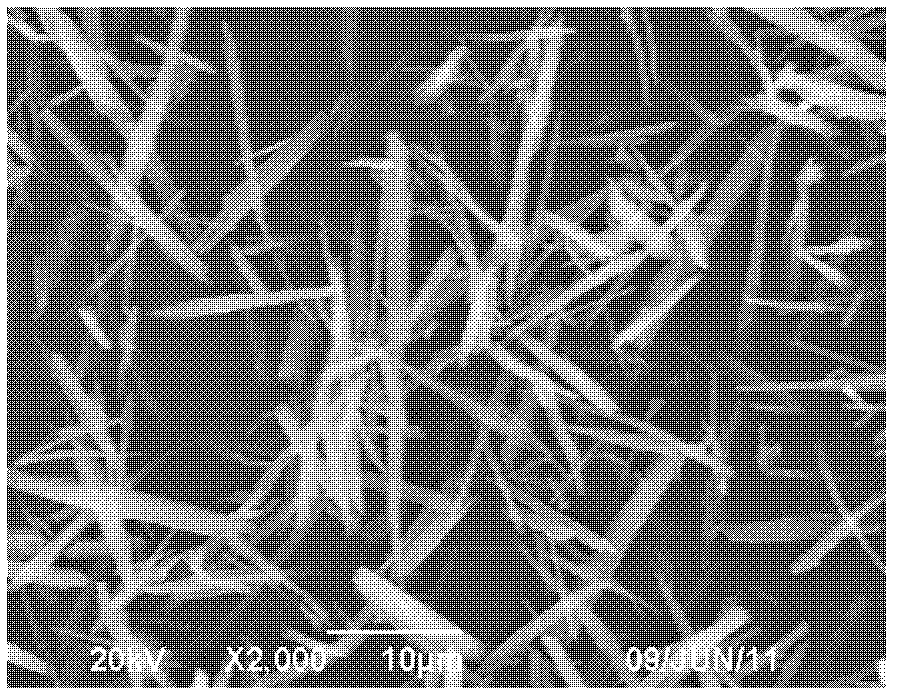

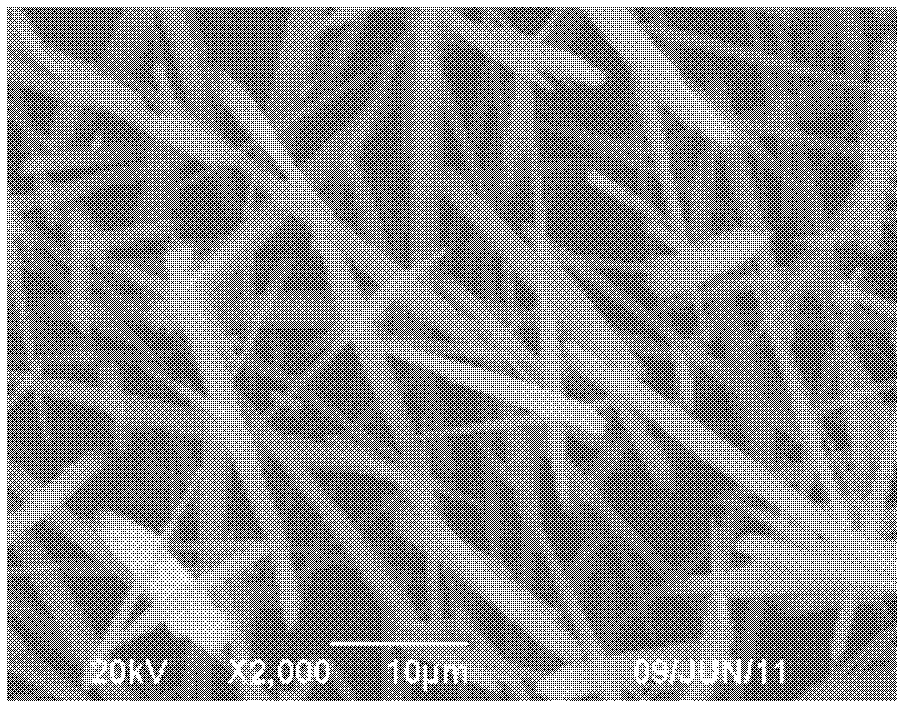

Image

Examples

Embodiment 1

[0047] 1, add the sulfuric acid solution that concentration is 20wt% to the bentonite mineral powder of particle diameter≤75 μ m, the mass ratio of bentonite mineral powder and sulfuric acid solution is 1: 5, react at 100 ℃ of temperature after 3h and filter to obtain acid leaching filter cake and Acid leaching filtrate, washing the acid leaching filter cake with clear water to neutrality, collecting acid leaching filter cake, acid leaching filtrate and lotion respectively;

[0048] 2. Mix the acid leaching filtrate obtained in step 1 and the lotion evenly to obtain a mixed solution, add 0.5% of the volume of the mixed solution to the mixed solution and have a mass concentration of 66% nitric acid solution, stir for 10 minutes, and then add the same volume of the mixed solution Isoamyl alcohol, shaken for 15min, let stand to separate layers, and collect the water phase to be the aluminum sulfate solution;

[0049] 3. Add 45mL of the aluminum sulfate solution obtained in step 2...

Embodiment 2

[0056] 1. Adding a sulfuric acid solution with a concentration of 40wt% to bentonite slag with a particle size of ≤100 μm, the mass ratio of bentonite slag and sulfuric acid solution is 1:4, react at a temperature of 95° C. for 4 hours and then filter to obtain acid leaching filter cake and For the acid leaching filtrate, the acid leaching filter cake is washed with clear water until neutral, and the acid leaching filter cake, acid leaching filtrate and washing liquid are collected respectively.

[0057] 2. Mix the acid leaching filtrate and lotion obtained in step 1 evenly to obtain a mixed solution, add a nitric acid solution with a mass concentration of 0.8% of the mixed solution volume to the mixed solution, stir and react for 8 minutes, and then add 0.5 times the mixed solution volume Isoamyl alcohol, shaken for 20min, let stand to separate layers, and collect the water phase, which is the aluminum sulfate solution.

[0058] 3. Add 45mL of the aluminum sulfate solution ob...

Embodiment 3

[0065] 1. Adding a sulfuric acid solution with a concentration of 50wt% to the bentonite slag with a particle size of ≤125 μm, the mass ratio of the bentonite slag and the sulfuric acid solution is 1:3, reacting at a temperature of 85° C. for 5 hours and then filtering to obtain acid leaching filter cake and For the acid leaching filtrate, the acid leaching filter cake is washed with clear water until neutral, and the acid leaching filter cake, acid leaching filtrate and washing liquid are collected respectively.

[0066] 2. Mix the acid leaching filtrate and washing liquid obtained in step 1 to obtain a mixed solution, add a nitric acid solution with a mass concentration of 1% of the volume of the mixed solution to the mixed solution, and stir for 5 minutes, then add 2 times the volume of the mixed solution Isoamyl alcohol, shaken for 10 minutes, let stand to separate layers, and collect the water phase, which is the aluminum sulfate solution.

[0067] 3. Add 45mL of the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com