Patents

Literature

168results about How to "High iron removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

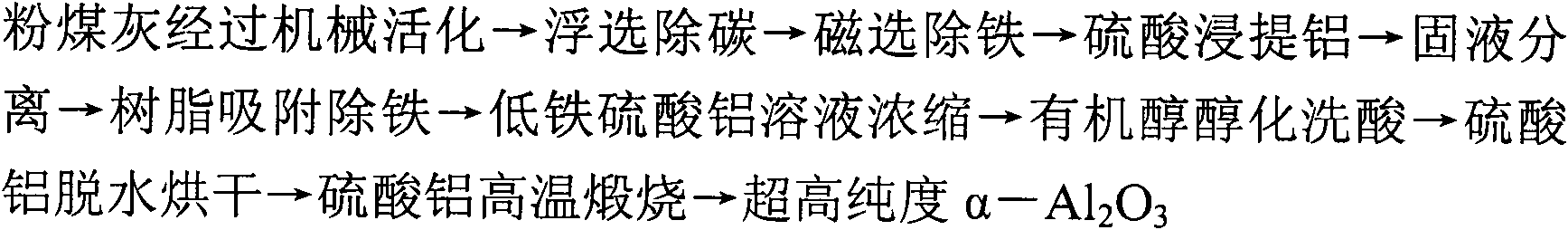

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

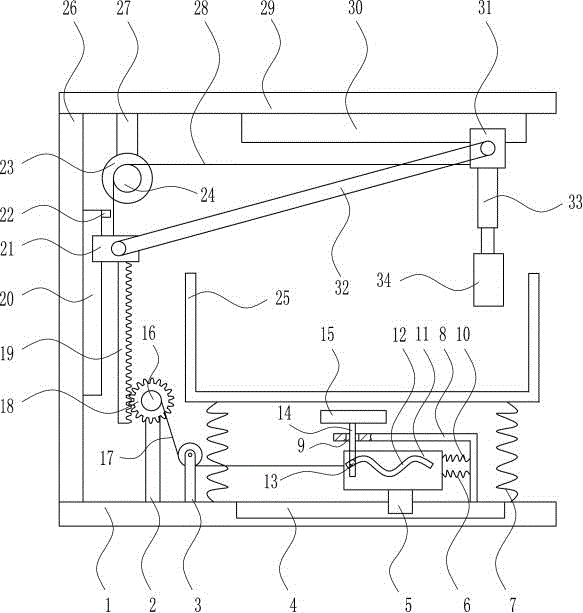

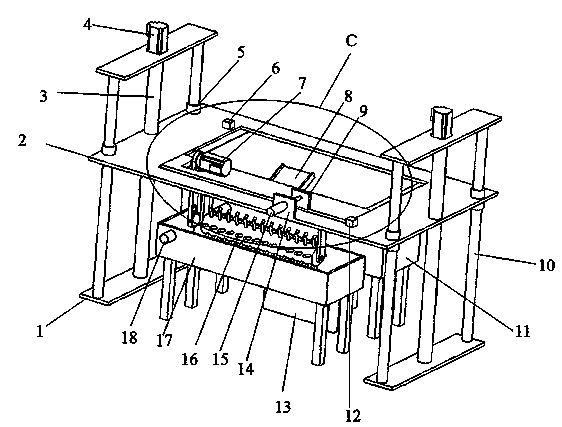

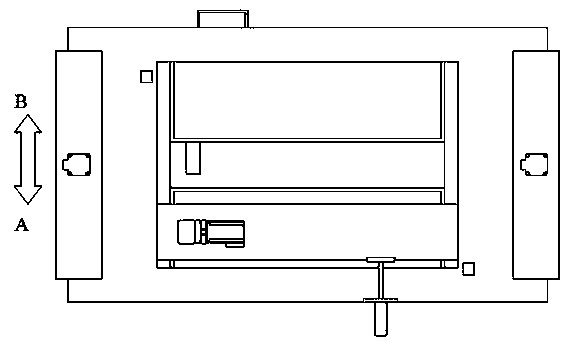

Magnetic separation iron removing equipment for aluminum scrap recycling

ActiveCN106140459AThorough iron removalUniform iron removalMagnetic separationMaterials scienceFerric

This invention relates to iron removing equipment for aluminum scrap recycling, in particular to magnetic separation iron removing equipment for aluminum scrap recycling. According to technical purposes, the magnetic separation iron removing equipment is capable of removing iron thoroughly, evenly and efficiently. To achieve the technical purposes, the magnetic separation iron removing equipment for aluminum scrap recycling comprises a baseplate, a first support rod, a fixed pulley, a first sliding rail, a first sliding block, a first spring, a second spring, an L-shaped guide plate, a third spring, a moving block, a sliding shaft, a lifting rod, a collision block, a first reel, a first bracing wire, a gear, a rack, a second sliding rail, a second sliding block, a first travel switch, a motor, a second reel, a processing frame, a left frame, a second support rod, a second bracing wire, a top plate, a third sliding rail, a third sliding block, a connecting rod, an electric pushing rod and a magnet. According to the magnetic separation iron removing equipment for aluminum scrap recycling, the effects of thorough, even and efficient iron removing are achieved.

Owner:江苏卡斯莱特环保科技股份有限公司

Method for eluting Fe<3+> in P204 extracting agent

InactiveCN102660679AImprove extraction efficiencyAchieve regenerationProcess efficiency improvementElutionHydrometallurgy

The invention discloses a method for eluting Fe<3+> in a P204 extracting agent, and belongs to the technical field of hydrometallurgy. The method is based on the principle that the stability of complex generated in the reaction between Fe<2+> and the P204 extracting agent is lower than that of the Fe<3+>, and achieves the aim of eluting Fe<3+> in the poisonous extracting agent by adding a reducing reagent into the extracting agent; and the elution efficiency of the Fe<3+> is more than 80%, so that the Fe<3+> in the P204 extracting agent can be effectively removed. The method can be applied to the technology for extracting vanadium in stone coal by an acid leaching method, and the P204 extracting agent combined with the Fe<3+> is treated by the method, so that the vanadium extraction efficiency can be improved by more than 60%, and the extracting agent can be regenerated and recycled. Compared with the existing method for removing Fe by concentrated sulfuric acid of industry, the method has the advantages of being higher in efficiency for removing Fe by the reducing reagent, lower in requirement for equipment, less in pollution for environment and worth of being widely popularized.

Owner:BEIJING UNIV OF CHEM TECH

Zinc smelting technology for low-zinc high-iron roasting ore by wet method

InactiveCN104233373ASolving Quantitative SeparationsOptimizing Process ParametersPhotography auxillary processesProcess efficiency improvementZinc smeltingImpurity

The invention relates to a zinc smelting technology for a low-zinc high-iron roasting ore by a wet method. The technology comprises a leaching process, a purifying process and an electrolyzing process. The technology employs a smelting method that a wet method can solve the problem of lean impurity high-iron raw material, iron removal efficiency is high, and various production consumption and production cost are not increased. The quality of 58% qualified high-purity zinc is greater than or equal to 99.995%, and quality of 42% qualified high purity zinc is greater than or equal to 99.99%.

Owner:无锡市森信精密机械厂

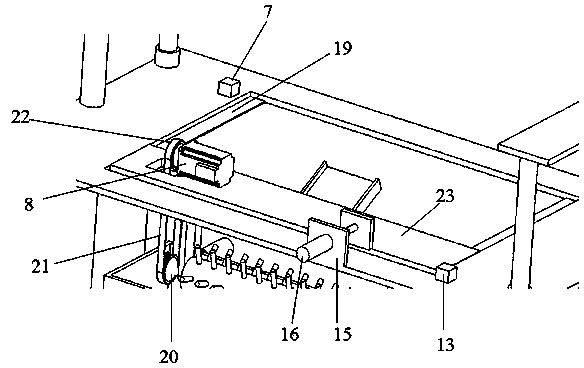

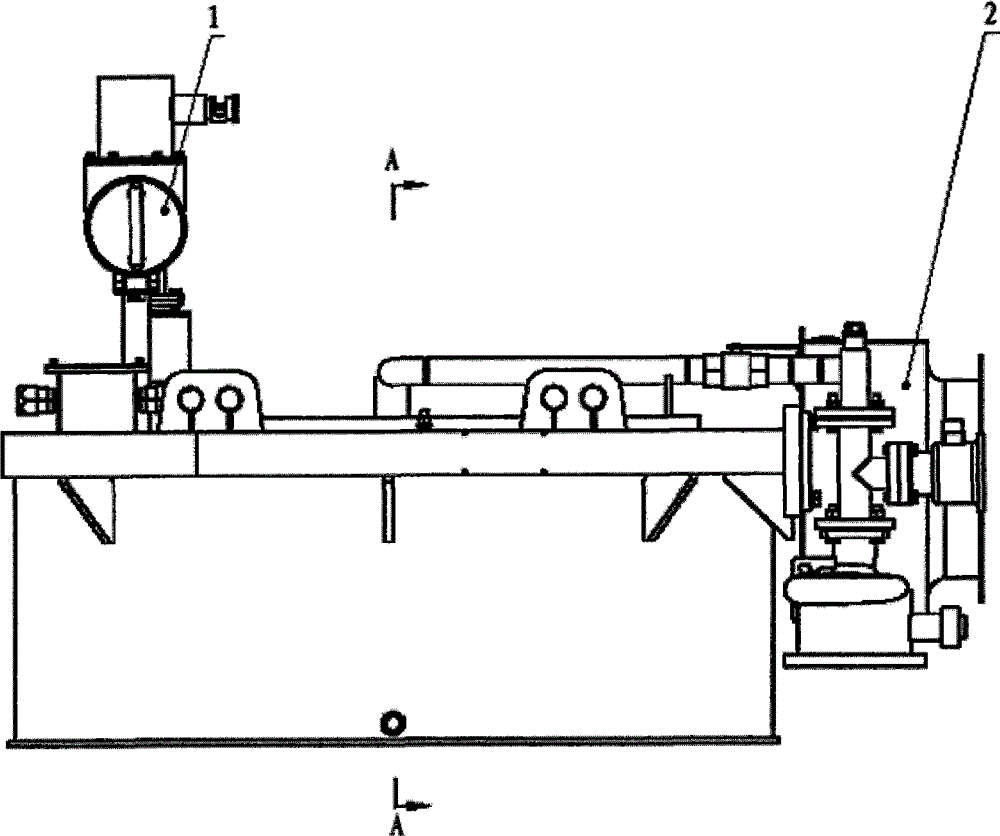

Dual-station tank type de-ironing device

InactiveCN104226471AImprove reliabilityCompact structureMagnetic separationProduction lineMotor drive

The invention discloses a dual-station tank type de-ironing device. According to the dual-station tank type de-ironing device, clean water is poured into a washing tank from a washing tank inlet, a horizontal moving plate is moved to a station A by a moving air cylinder, a magnetic column is submerged into the washing tank, a de-ironing motor drives the magnetic column to rotate at a high speed, so as to remove iron from the magnetic column, meanwhile, mud fluid to be de-ironed is poured into a de-ironing tank from a de-ironing tank inlet, the horizontal moving plate is pushed to the de-ironing tank by the moving air cylinder, a vertical moving plate moves downwards, so as to enable the magnetic column to be submerged into the mud fluid, the de-ironing motor drives the magnetic column to rotate at a high speed, so as to de-iron, the magnetic column is submerged into the washing tank again by the vertical moving plate and the moving air cylinder after de-ironing is completed, so as to wash off the adsorbed iron, and thus, a de-ironing process is completed. According to the dual-station tank type de-ironing device, the problems of the traditional equipment that de-ironing equipment is low in efficiency, the labor intensity is high and the degree of automation is low are solved, and meanwhile, the forming of an automatic production line is facilitated. The dual-station tank type de-ironing device has the advantages of simplicity in operation and high de-ironing quality.

Owner:GUANGXI BEILIU CITY ZHICHENG CERAMIC AUTOMATION TECH

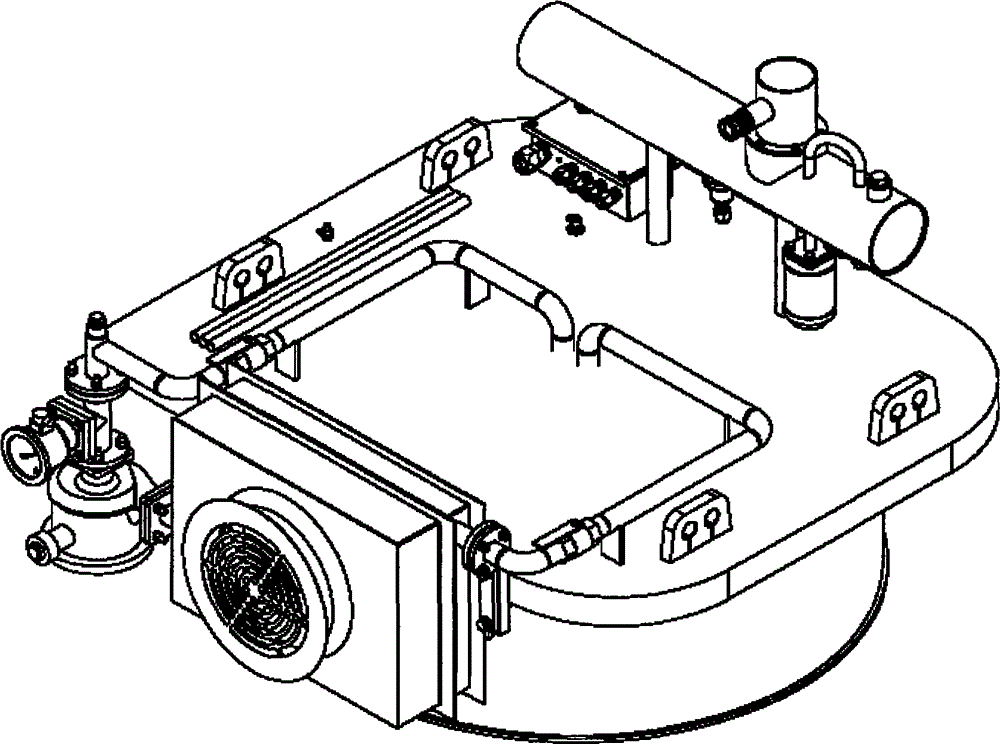

High-gradient internal circulation oil cooling iron remover

ActiveCN103056023ALow circulation resistanceEven and reasonable cycleHigh gradient magnetic separatorsIron absorptionTransformer oil

The invention relates to a high-gradient internal circulation oil cooling iron remover, which comprises a magnetic coil (4), an internal circulation oil path system (3), an external cooling system (2) and an oil conservator (1), wherein the magnetic coil (4) is used for generating an excitation magnetic field capable of realizing the iron absorption effect of the iron remover; the magnetic circuit of the magnetic coil (4) is an opened magnetic circuit structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating oil of a transformer; the external cooling system (2) is used for dissipating heat of the oil of the transformer so as to realize internal heat dissipation balance of the high-gradient internal circulation oil cooling iron remover; and the oil conservator (1) is used as a complementary container when oil in the transformer is inflated in the event of operating equipment. By adopting the internal circulation structure, the high-gradient internal circulation oil cooling iron remover disclosed by the invention is capable of simplifying external circulation pipelines, reducing oil path circulation resistance, avoiding the problems of being complex and interferential in oil path arrangement, low in circulation efficiency, leaked in welding spot and the like, ensuring the iron remover to work normally, and increasing the iron removing efficiency.

Owner:LONGI MAGNET CO LTD

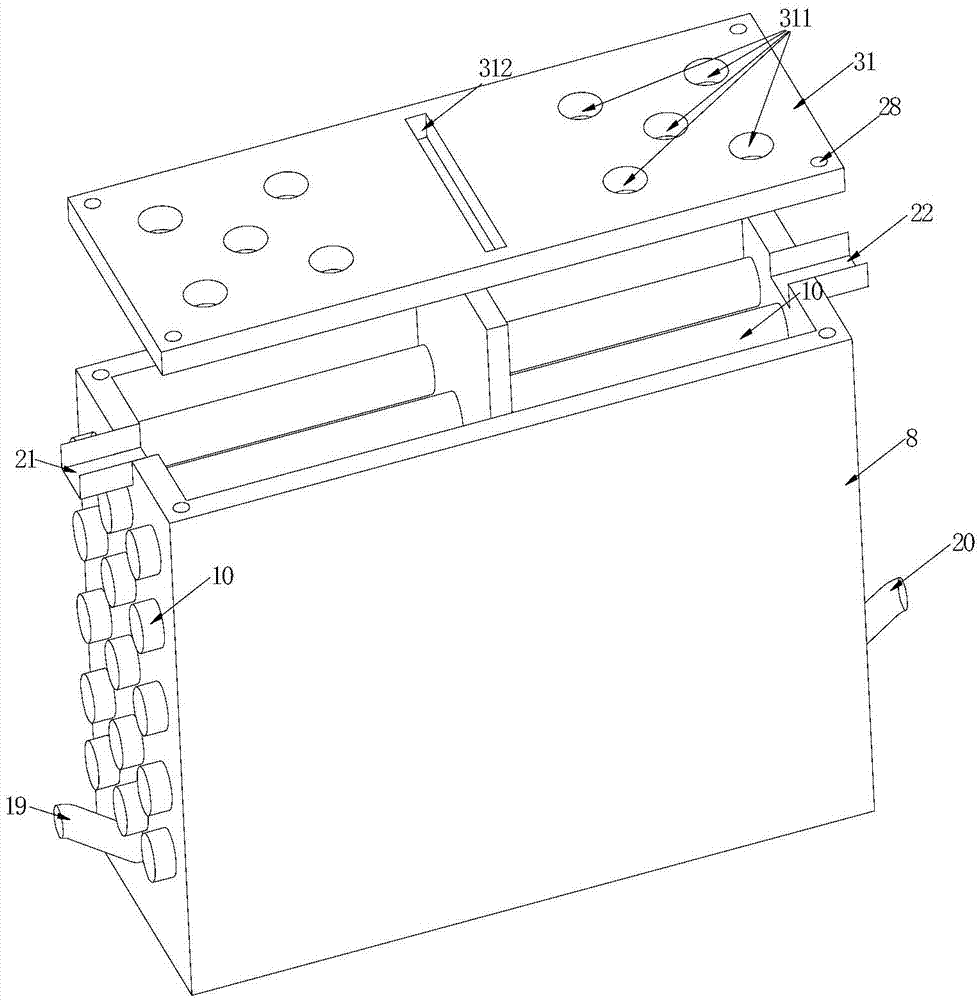

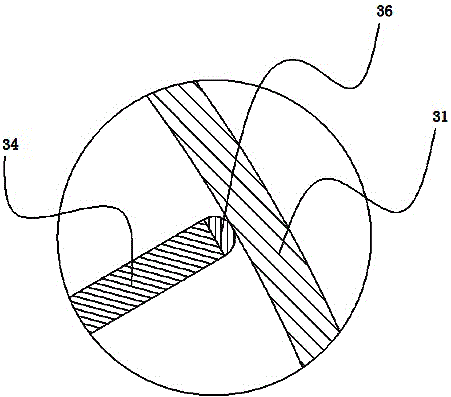

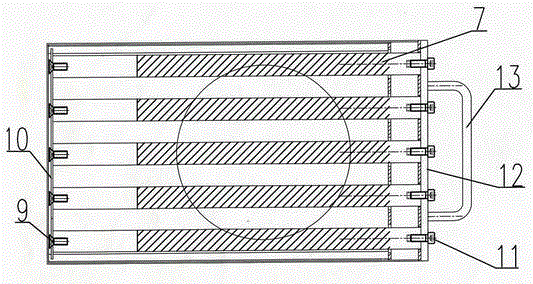

Magnetic rod with movable magnets and iron removal device applying magnetic rod

InactiveCN103657846ASimple structureStrong magnetismHigh gradient magnetic separatorsInlet channelIron removal

The invention discloses a magnetic rod with movable magnets. The magnetic rod is characterized by comprising a shell part and a piston part, wherein a magnetic rod piston cavity is formed in the shell part and is a columnar space, one end of the magnetic rod piston cavity is communicated with a first air inlet channel, and the other end of the magnetic rod piston cavity is communicated with a second air inlet channel; the piston part comprises a plurality of permanent magnets, a plurality of concentrating flux plates and connecting pieces used for connecting the permanent magnets with the concentrating flux plates; the two adjacent permanent magnets are distributed in a manner that like poles repel, and each concentrating flux plate is arranged between the two adjacent permanent magnets; the piston part is arranged in the magnetic rod piston cavity, is in leak-proof fit with the magnetic rod piston cavity and does a straight reciprocating motion in the magnetic rod piston cavity. The magnetic rod with movable magnetic regions disclosed by the invention is simple in structure. The iron removal device applying the magnetic rod achieves continuous iron removal of slurry and powder, and is simpler in structure, longer in service life and high in iron removal efficiency.

Owner:廖明勇

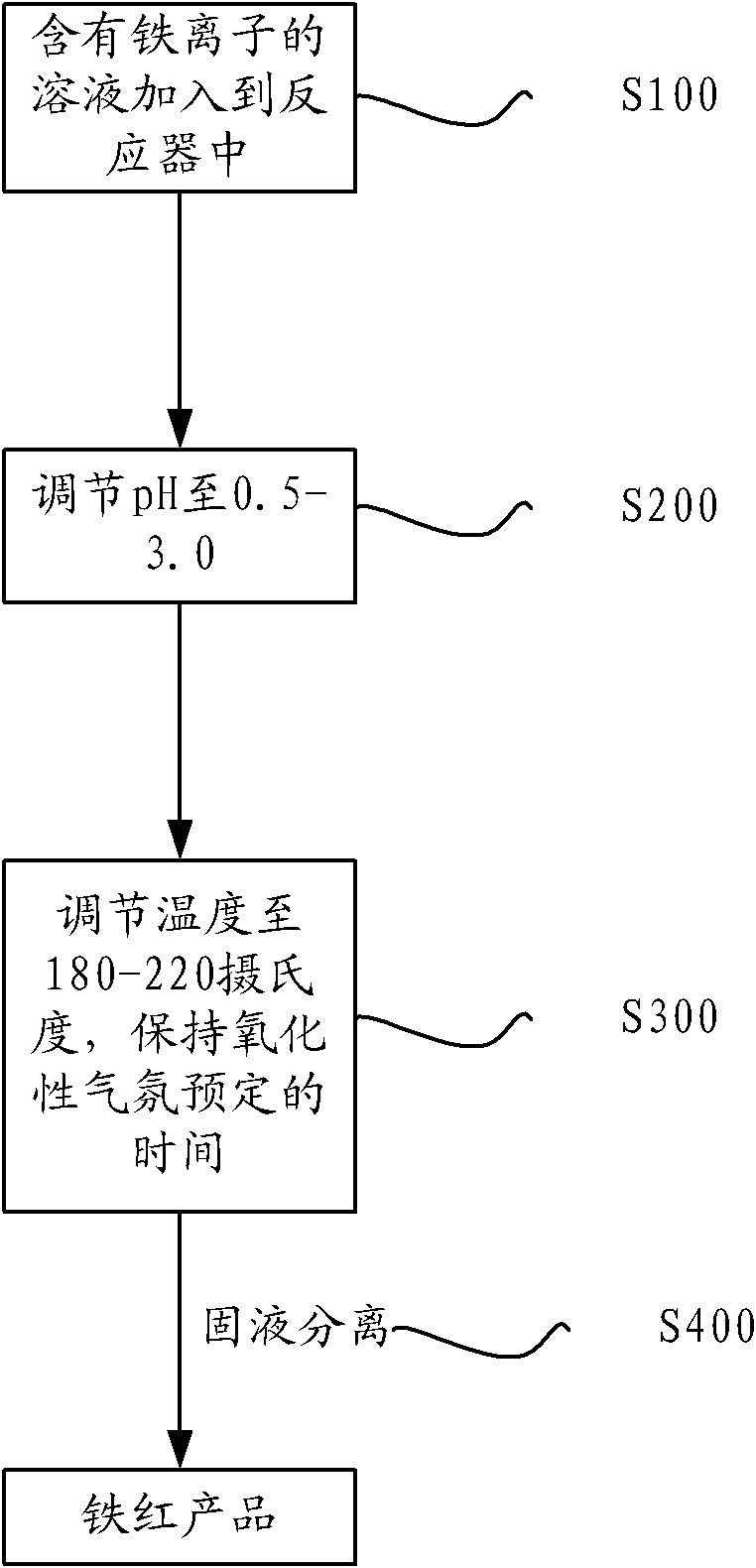

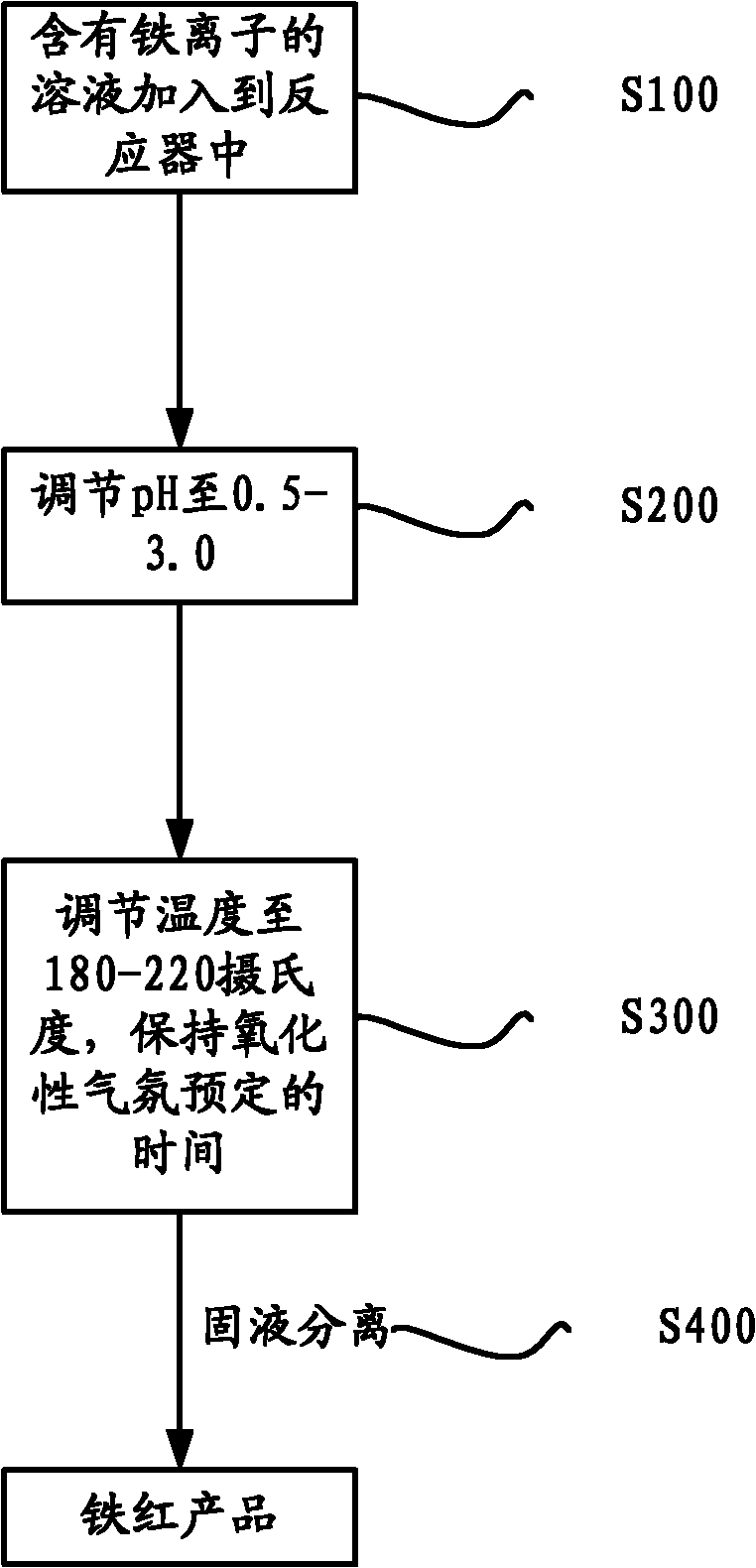

Method for preparing iron oxide red

ActiveCN102153148AEfficient preparationSolve storage problemsFerric oxidesFerric ionIron oxide cycle

The invention provides a method for preparing iron oxide red by utilizing a solution containing iron ions, wherein the iron ions are at least one kind of ferrous ions and ferric ions. The method comprises the following steps of: (1) adding the solution containing iron ions into a reactor; (2) adjusting the pH value of the solution to be 0.5-3.0; (3) adjusting the temperature in the reactor to be 180-220 DEG C, maintaining the temperature for a predetermined time at oxidizing atmosphere to obtain a solid-liquid mixture containing ferric oxides; and (4) carrying out solid liquid separation on the solid-liquid mixture to obtain an iron oxide red product. By utilizing the method, iron in the solution can be effectively recycled and the iron oxide red can be prepared.

Owner:CHINA ENFI ENGINEERING CORPORATION

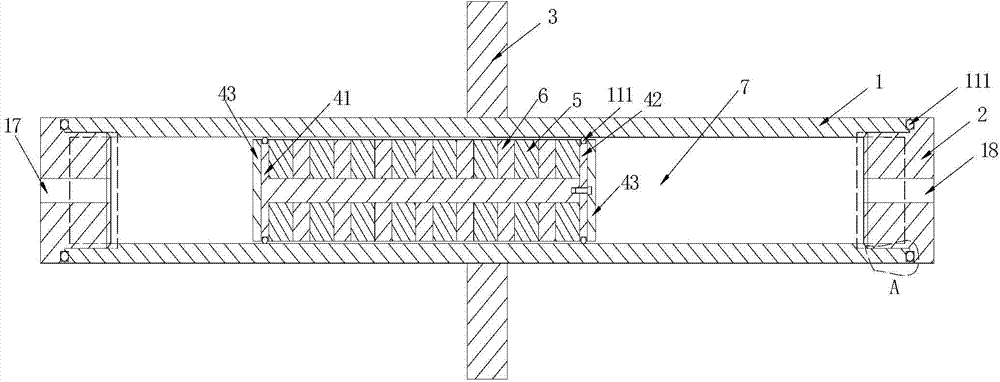

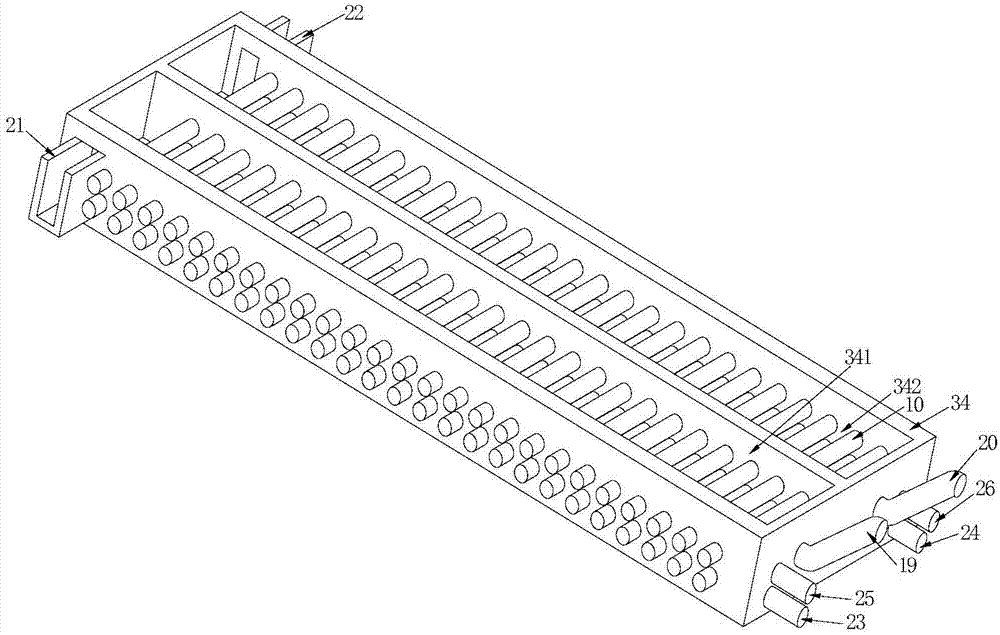

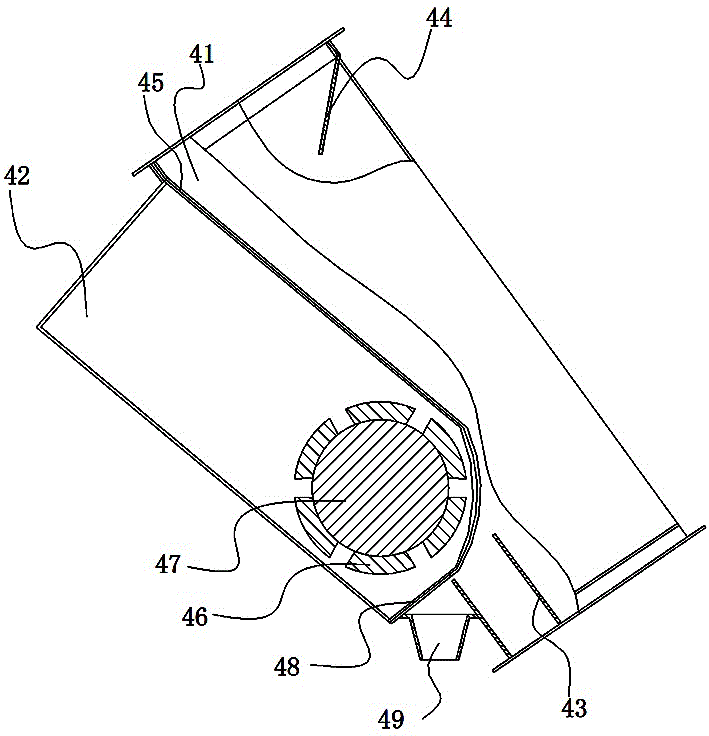

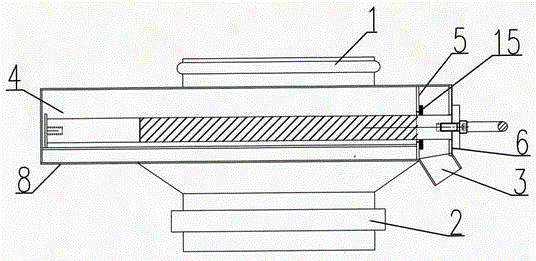

Method and device for deironing continuously in slurry in bi-twisting mode

InactiveCN103977888AGood iron absorption effectImprove slurry qualityMagnetic separationScrapEngineering

The invention discloses a method and device for deironing continuously in slurry in a bi-twisting mode, and belongs to the field of magnetically separating solids in slurry. Magnetic bars in magnetic bar groups are placed in a slurry barrel for adsorbing scrap iron in slurry, and then the scrap iron adsorbed on the magnetic bars is removed. The method and device for deironing continuously in slurry in a bi-twisting mode are characterized in that the magnetic bars in the magnetic bar groups are arranged horizontally; one part of the magnetic bars in the magnetic bar groups are positioned in the slurry, and the other part of the magnetic bars are all exposed out of the liquid level of the slurry; the magnetic bar groups rotate, so that the scrap iron adsorbed on the part of magnetic bars exposed out of the liquid level of the slurry is removed. The method and device for deironing continuously in slurry in a bi-twisting mode, which are provided by the invention, have the beneficial effects that the skillful design of a sandwiched wall cavity enables the slurry in the cavity to be in contact with the magnetic parts maximally, and the magnetic force is applied to the slurry uniformly, and a preferable deironing effect is obtained; the magnetic parts rotate continuously so that deironing is carried out uninterruptedly, and the deironing efficiency is improved greatly; the stability is extremely high, and the maintenance cost is extremely low.

Owner:钟娟英

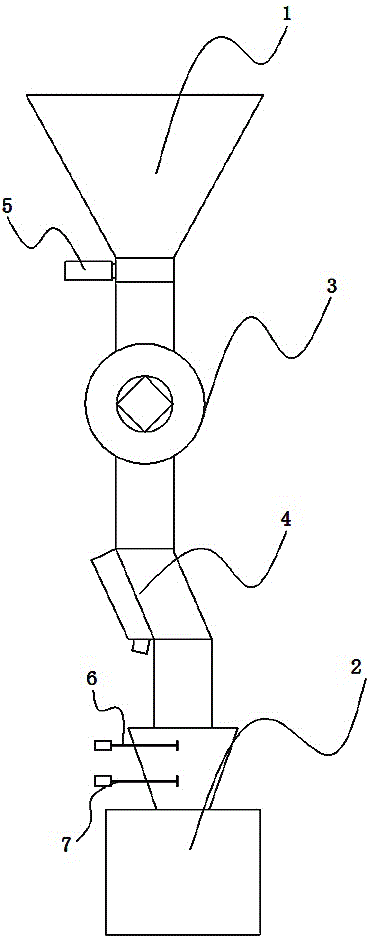

Intermittent feeding device for powder packing

ActiveCN106275599AGuaranteed production environmentGuaranteed stable packagingConveyorsLarge containersImpellerIron removal

The invention discloses an intermittent feeding device for powder packing. The intermittent feeding device for powder packing comprises a feeding bin (1), a packing machine (2), an impeller feeding device (3), a rotation stopping type level gage A (6), a rotation stopping type level gage B (7) and a pipe type iron remover (4), wherein the rotation stopping type level gage A (6) and the rotation stopping type level gage B (7) are mounted on a receiving hopper of the packing machine (2); the feeding bin (1) is connected with the packing machine (2); the impeller feeding device (3) and the pipe type iron remover (4) are successively arranged on a connecting channel for the feeding bin (1) and the packing machine (2) from top to bottom; and a plug valve (5) is further mounted on a discharging opening of the feeding bin (1) and comprises a plug board (106), a guide plate (102), a driving mechanism (103) and an elastic sealing device (105). The intermittent feeding device for powder packing has the beneficial effects of intermittent quantitative discharging, high iron removal efficiency, high packing efficiency, zero powder leakage, low powder waste rate and low production cost.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

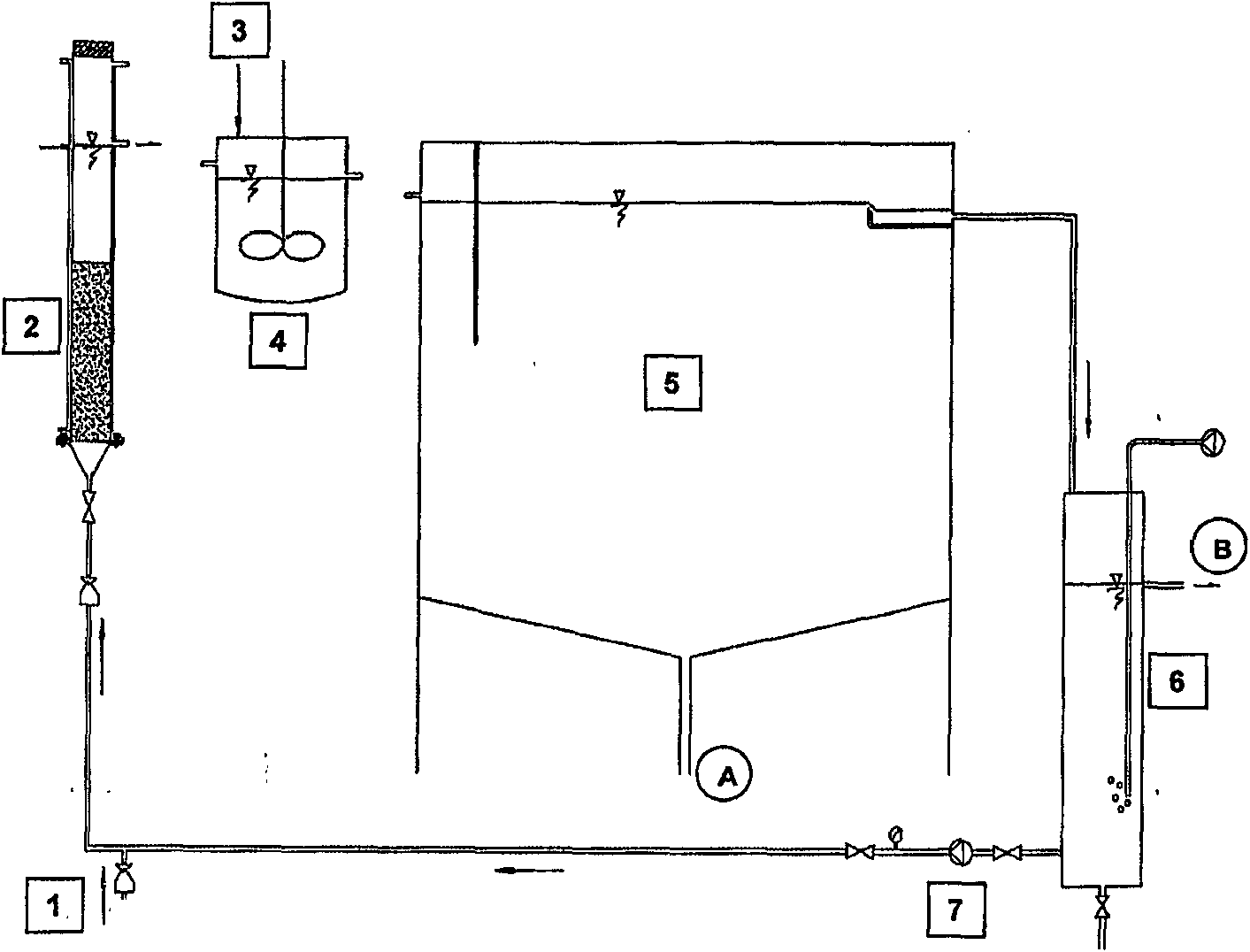

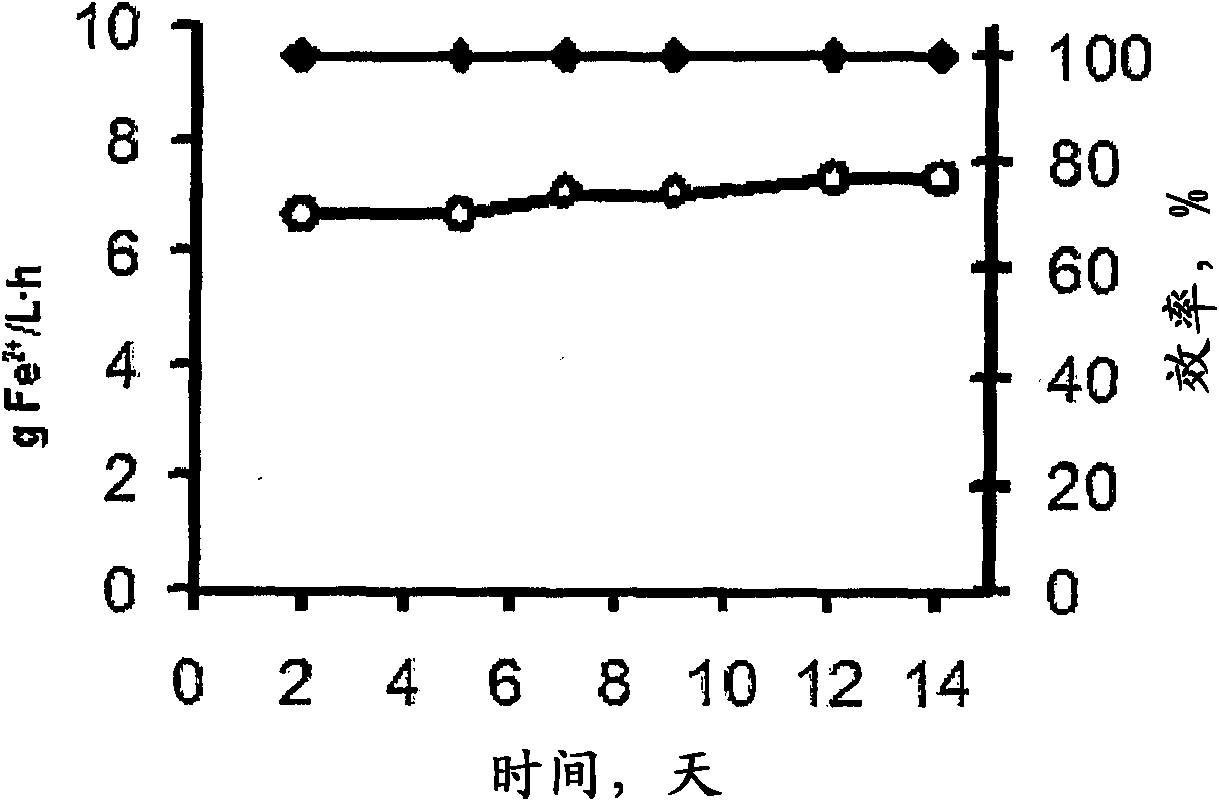

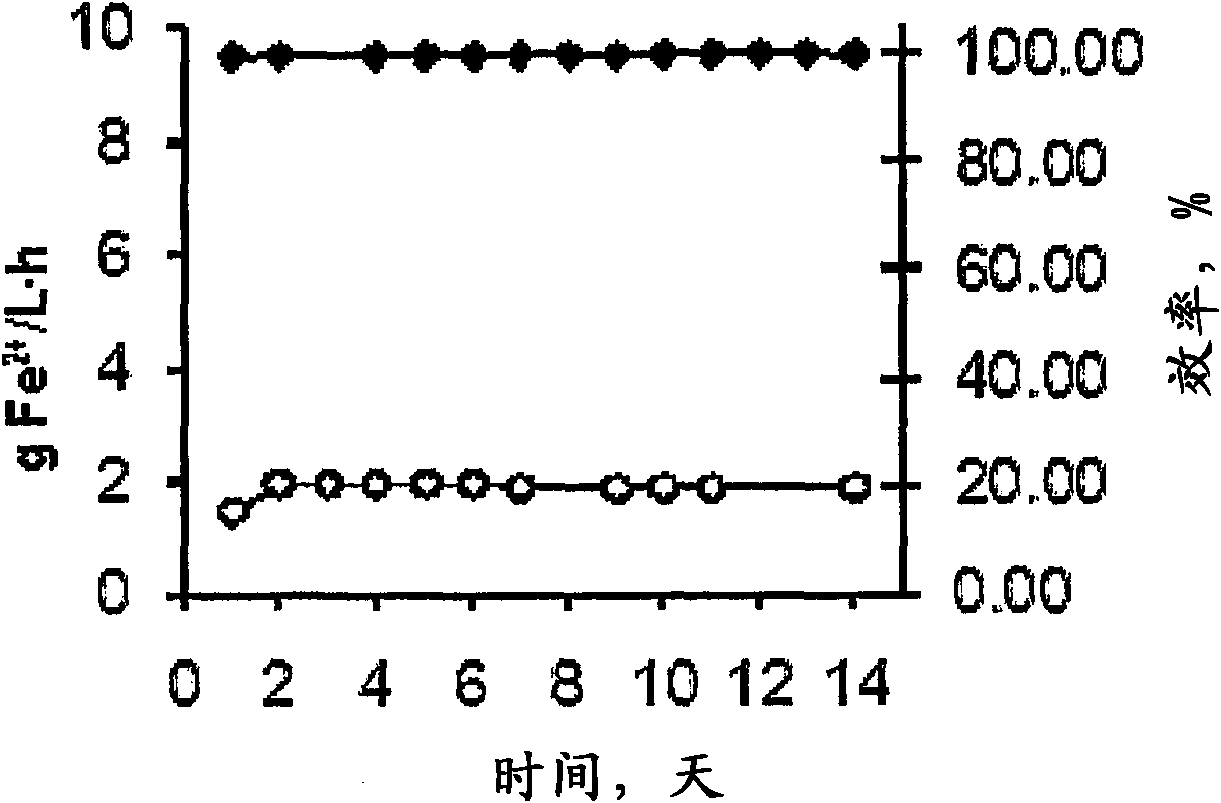

Process for extracting iron from an aqueous acid solution

InactiveCN102216227AQuick and effective removalImprove performanceWaste water treatment from quariesWaste water treatment from metallurgical processActivated carbonAqueous solution

The invention relates to an iron extraction process from an aqueous acid solution containing ferrous ions. The acidic feed solution is first passed to a fluidized bed reactor for the oxidation of the ferrous ions preferably by microbes (Leptospirillum ferriphilum) to give ferric ions, followed by introducing the solution obtained to a concentrator for the precipitation of a compound containing ferric ions from the solution to give solid matter. The final product, i.e. solid matter containing ferric ions, is collected. In the process, the solution to be treated is passed through the fluidized bed at a flow rate sufficient for effective fluidization and mixing in the fluidized bed. Further, an apparatus for performing the iron extraction process is claimed. The carrier for the microbes may be activated carbon.

Owner:TALVIVAARAN KAIVOSOSAKEYHTIO

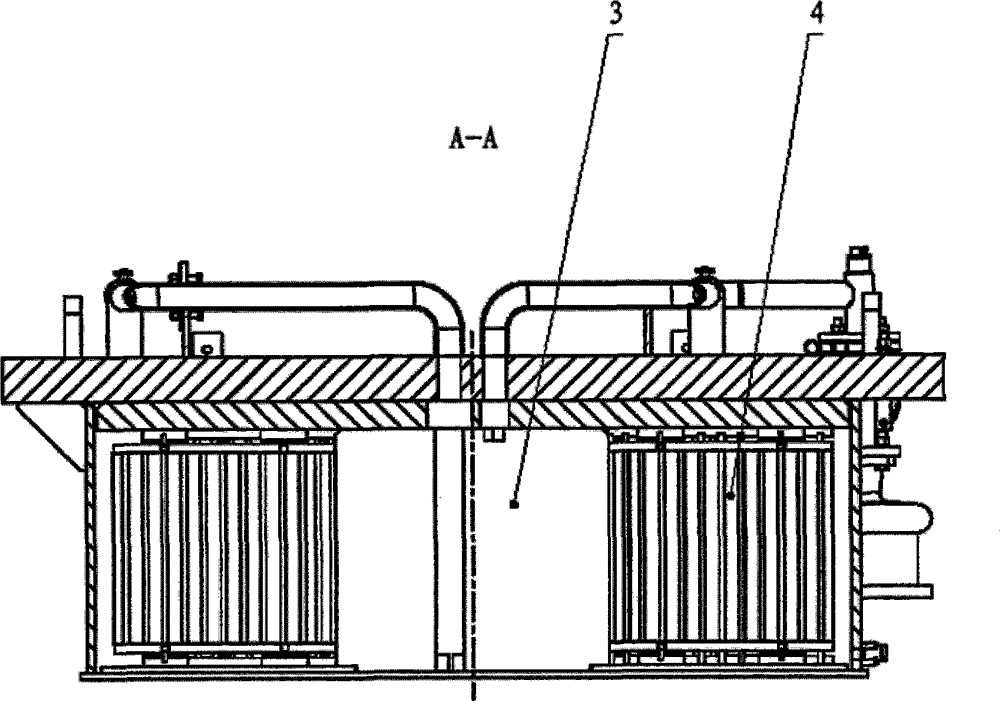

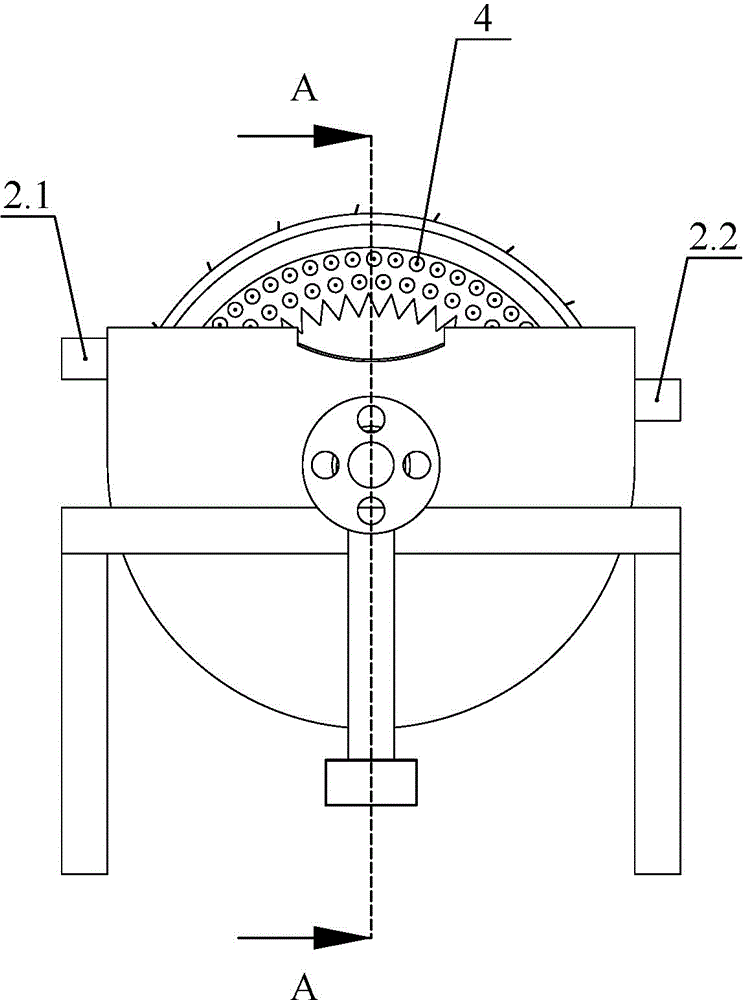

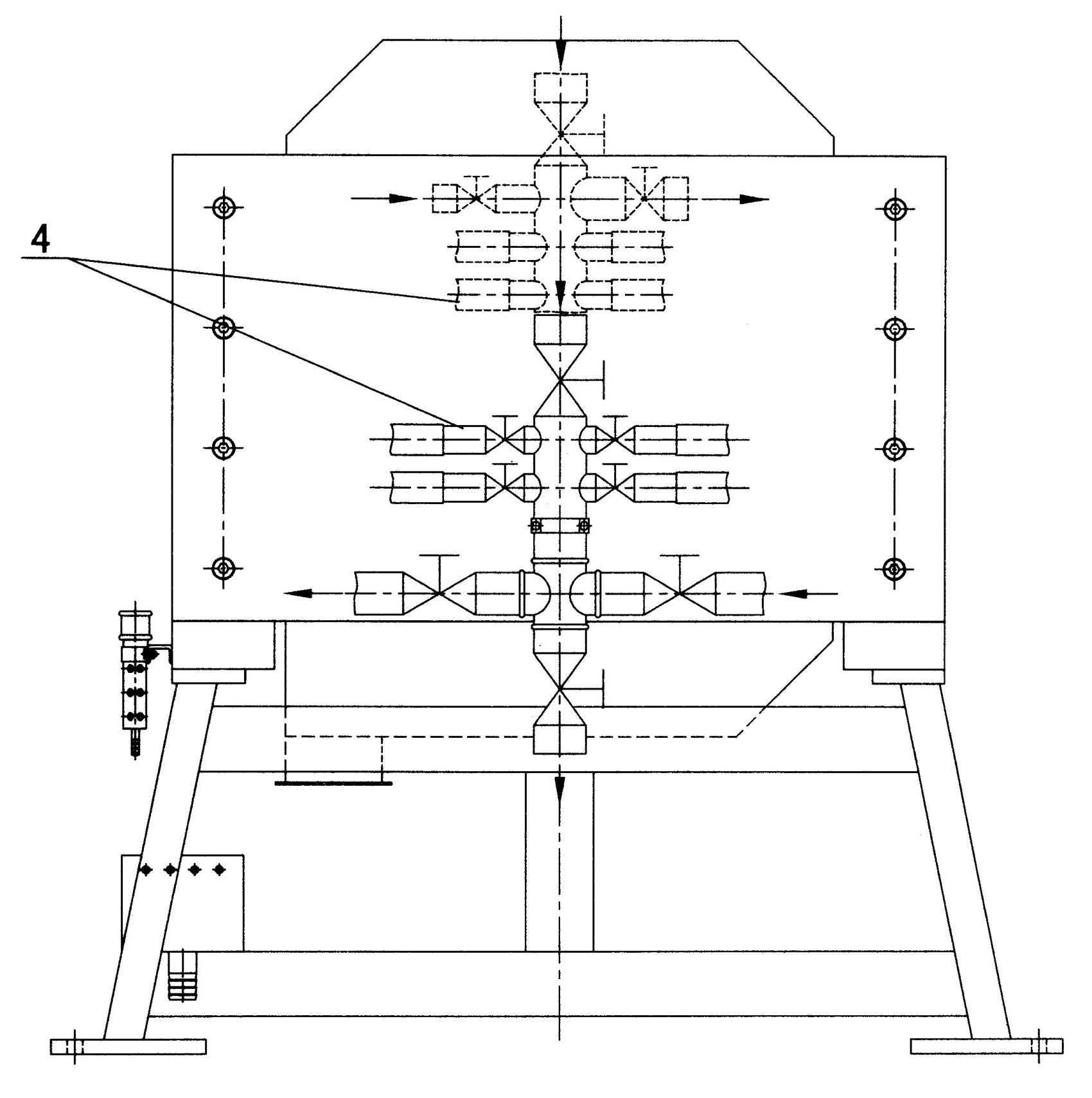

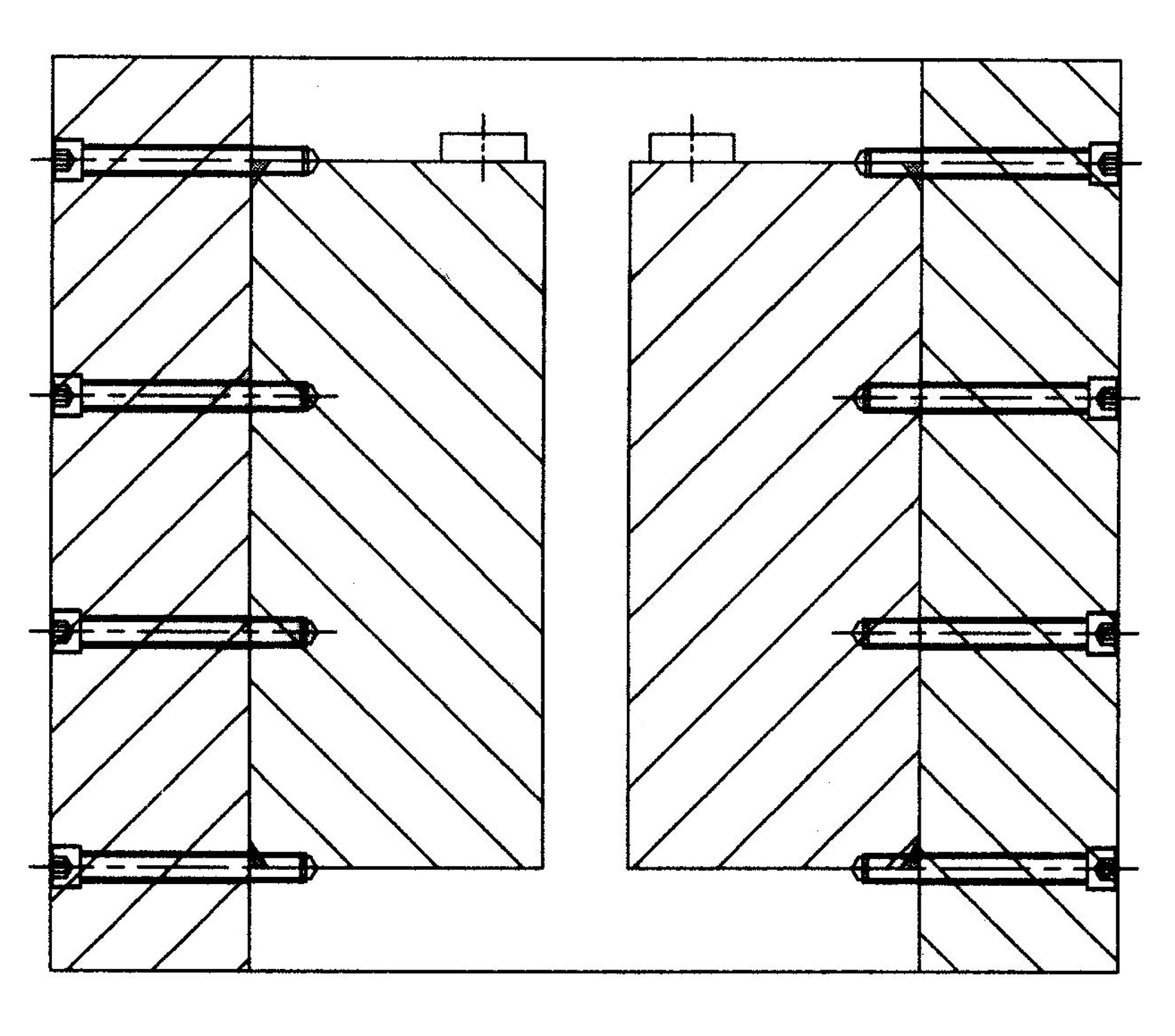

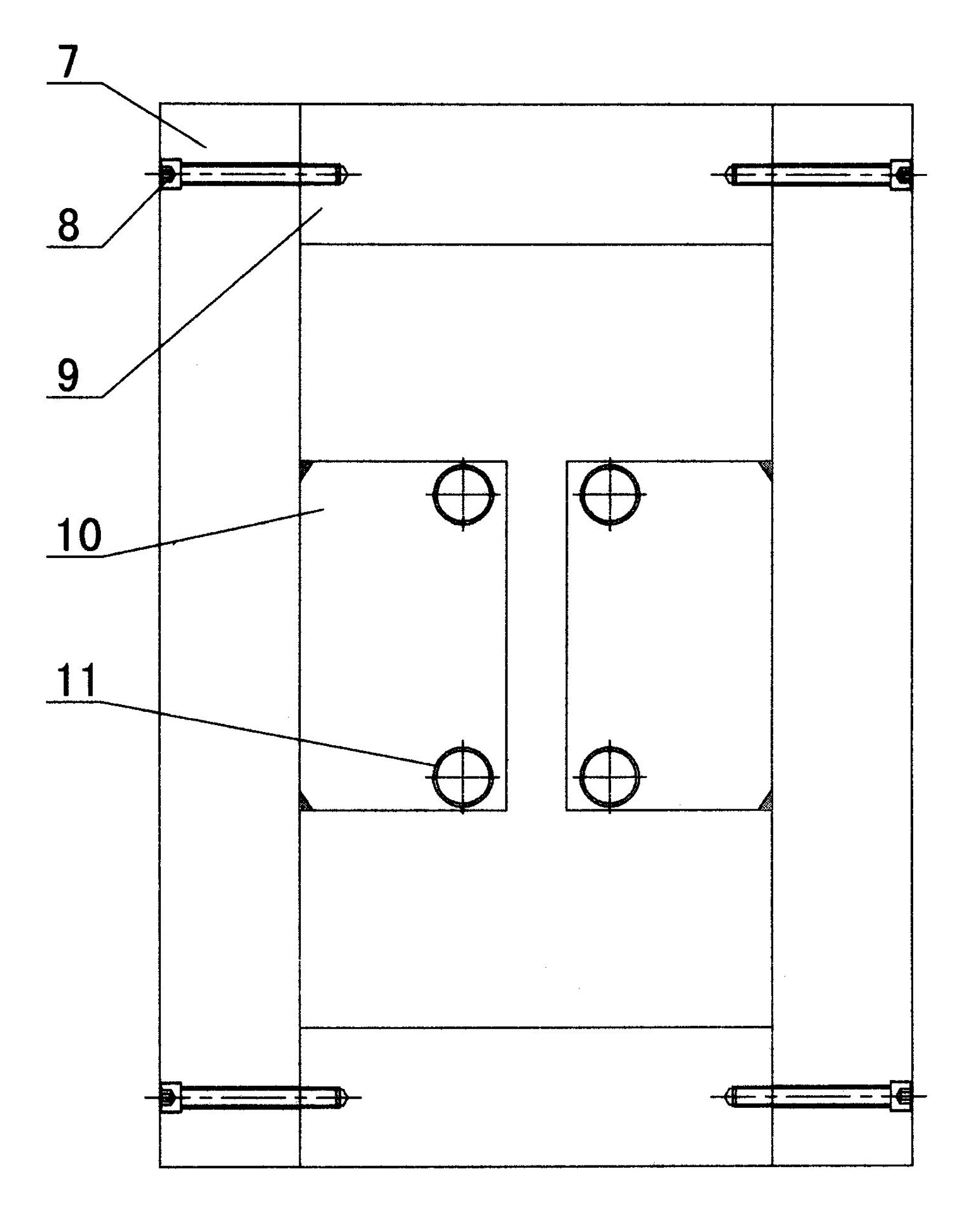

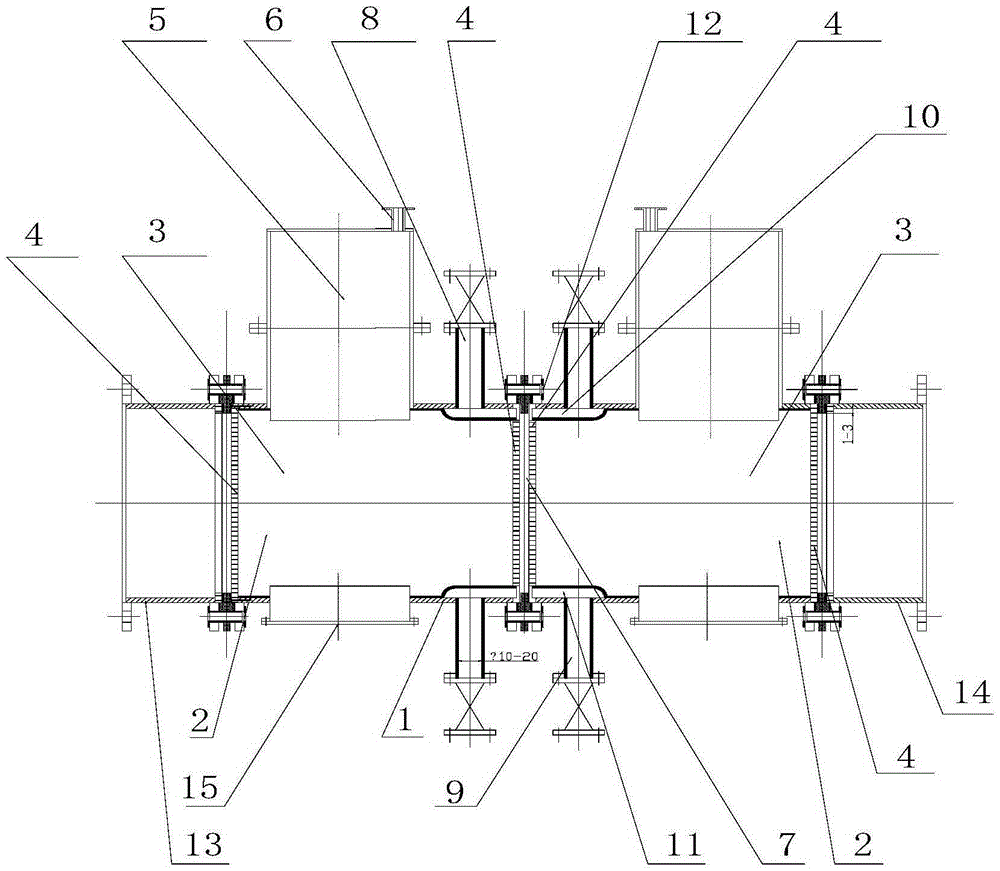

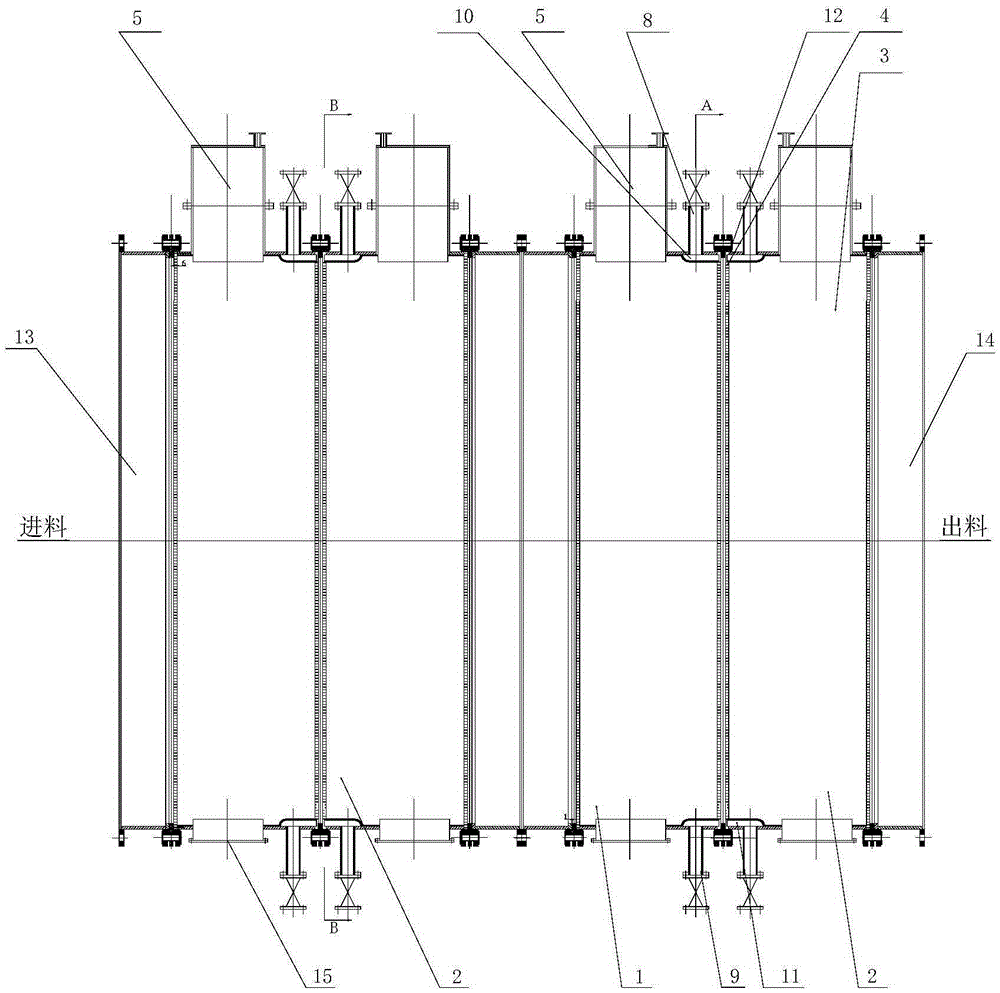

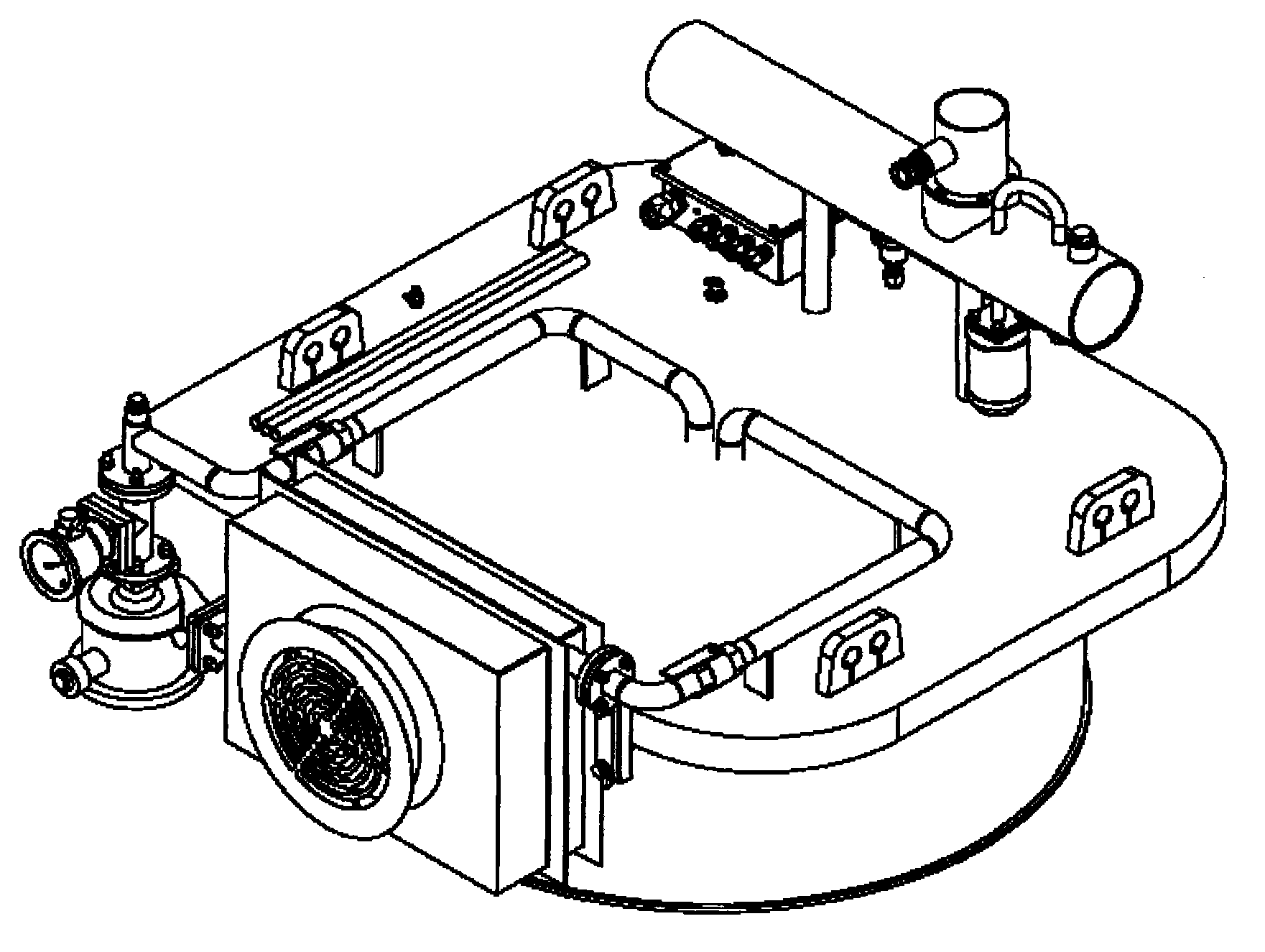

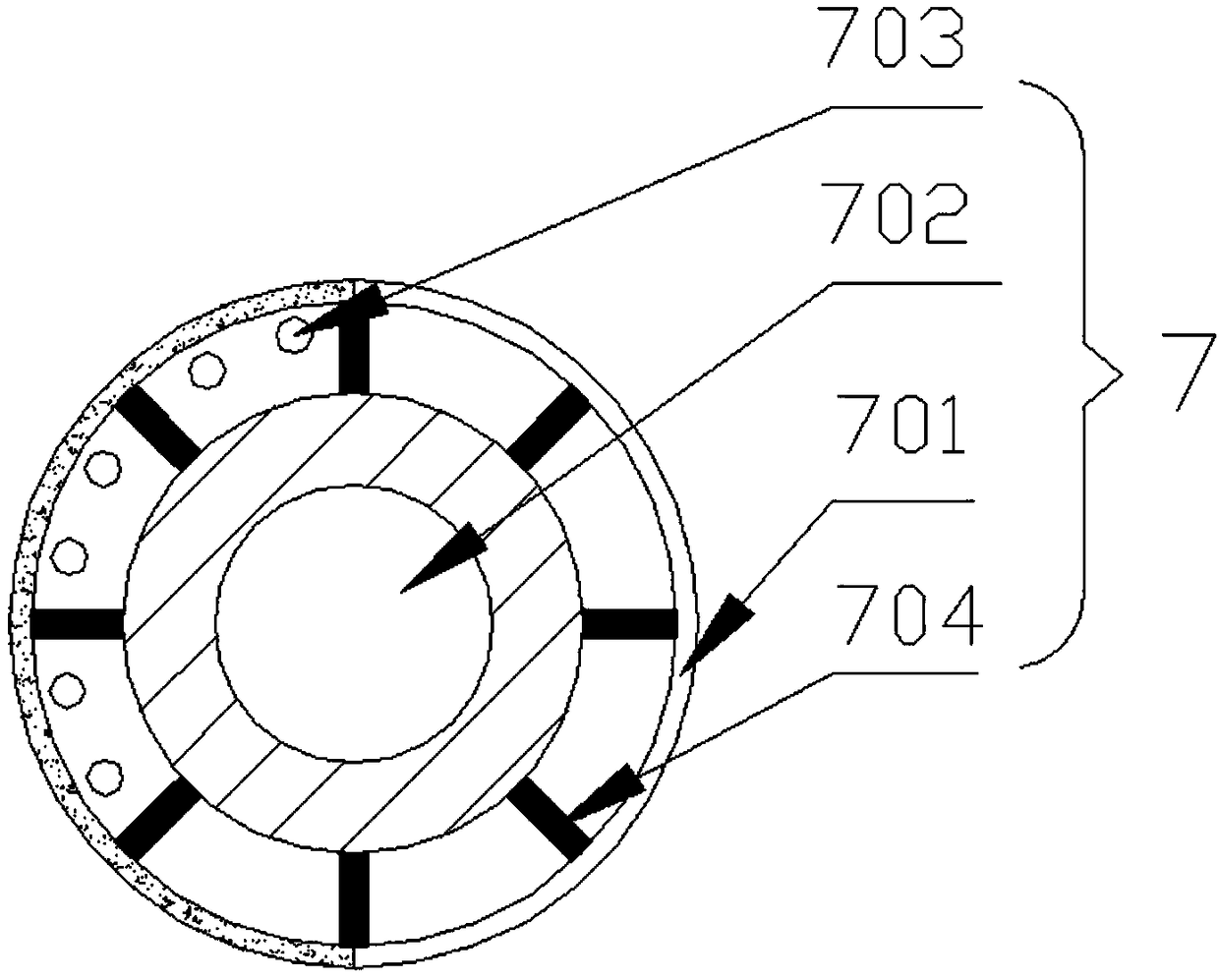

Hyperfine high-gradient magnetic separator

InactiveCN101934247ASimple and scientific structureHigh iron removal efficiencyHigh gradient magnetic separatorsWash waterMagnetic media

The invention relates to the technology of beneficiation machinery, in particular to a hyperfine high-gradient magnetic separator which is suitable for deironization and extraction of non-metal minerals and beneficiation of weak magnetic minerals. The hyperfine high-gradient magnetic separator comprises a main body equipment part and a rectifying control cabinet part, and the main body equipment part comprises a main body support, a magnet yoke, a magnet exciting coil and a magnetic medium box, wherein the magnet yoke is arranged on the upper part of the main body support; the magnet exciting coil is arranged around the magnet yoke; the magnetic medium box is arranged at a gap of the centre of the inner side of the magnet yoke, and the upper part of the magnetic medium box is connected with a vibration mechanism; pipe systems for enabling ore pulps to flow in and flow out and washing water to flow in and flow out are arranged at the two sides of the exterior of the magnet yoke; the pipe systems comprise various pneumatic valves, electromagnetic valves and ball valves; the pipe systems are connected with the magnetic medium box; and the rectifying control cabinet part comprises an excitation magnet and an breakage magnet, as well as a control system, wherein the excitation magnet and the breakage magnet are used for controlling the magnet exciting coil, and the control system is used for controlling actions and resetting of each valve in the pipe system, and controlling error alarming and resetting. The invention is the most ideal non-metal deironization equipment which has the advantages of strong mine-feeding granularity, concentration and grade fluctuation adaptability, reliable work and convenient operation and maintenance.

Owner:岳阳大力神电磁机械有限公司

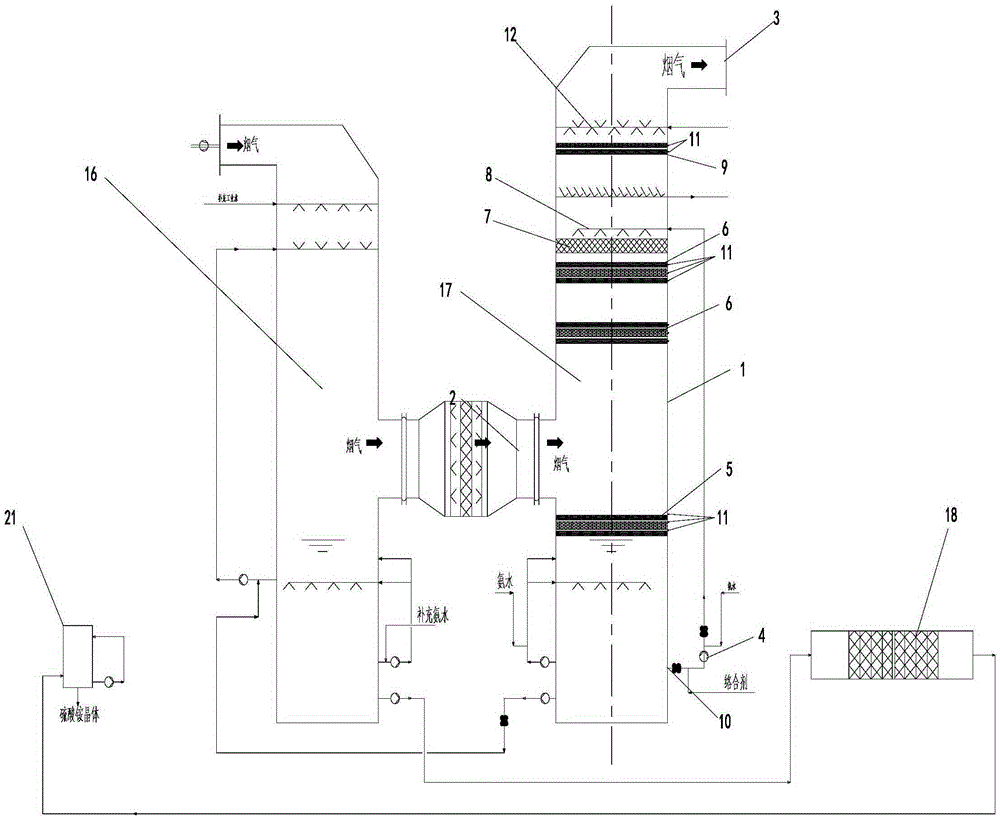

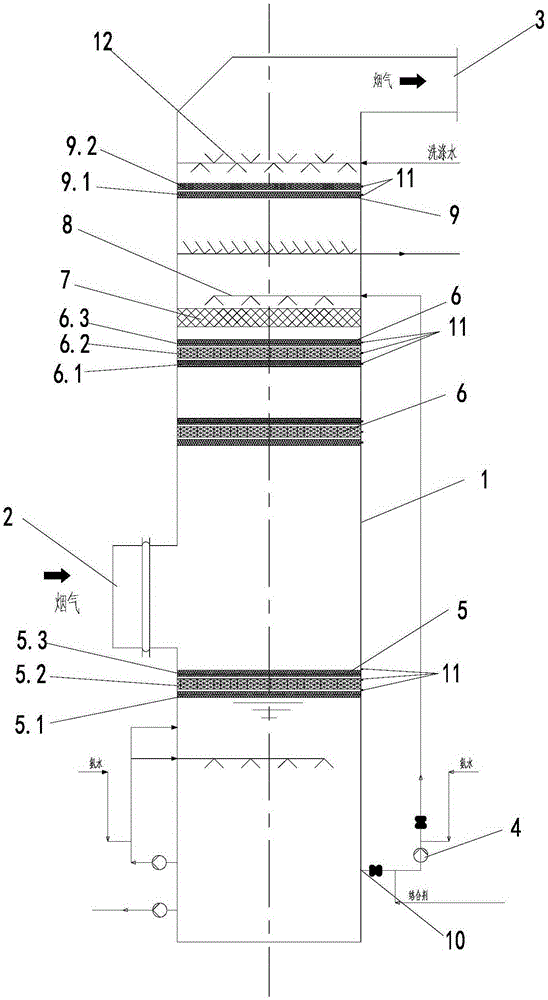

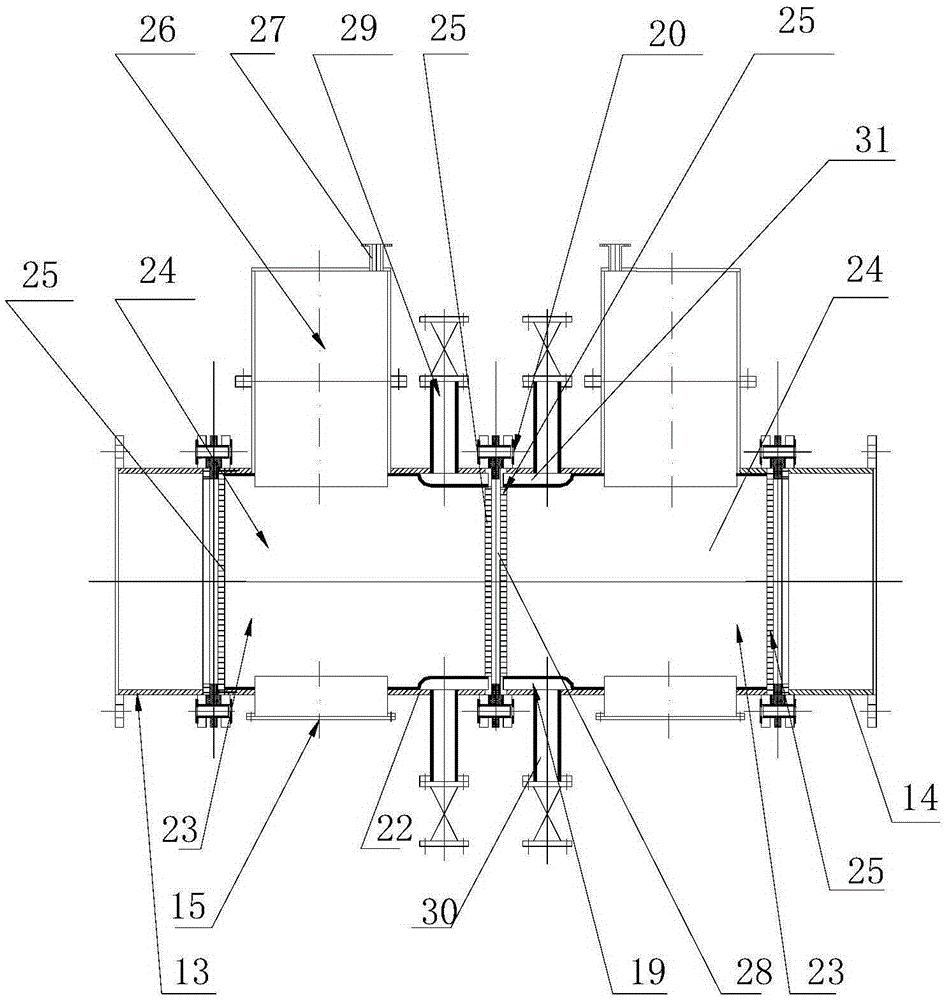

Ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration

ActiveCN105413422AEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationAmmonium sulfateFlue gas

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

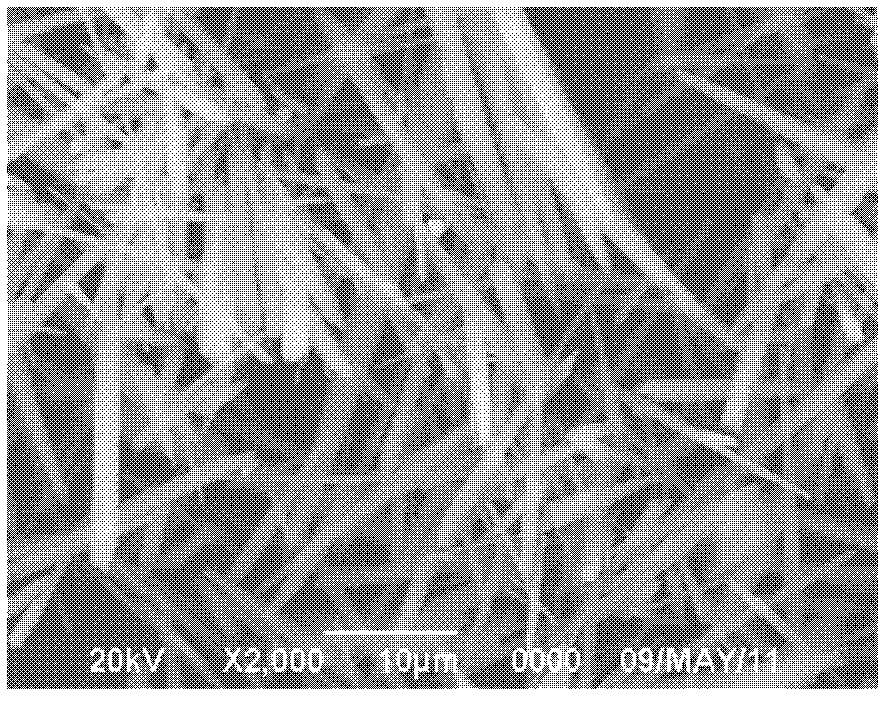

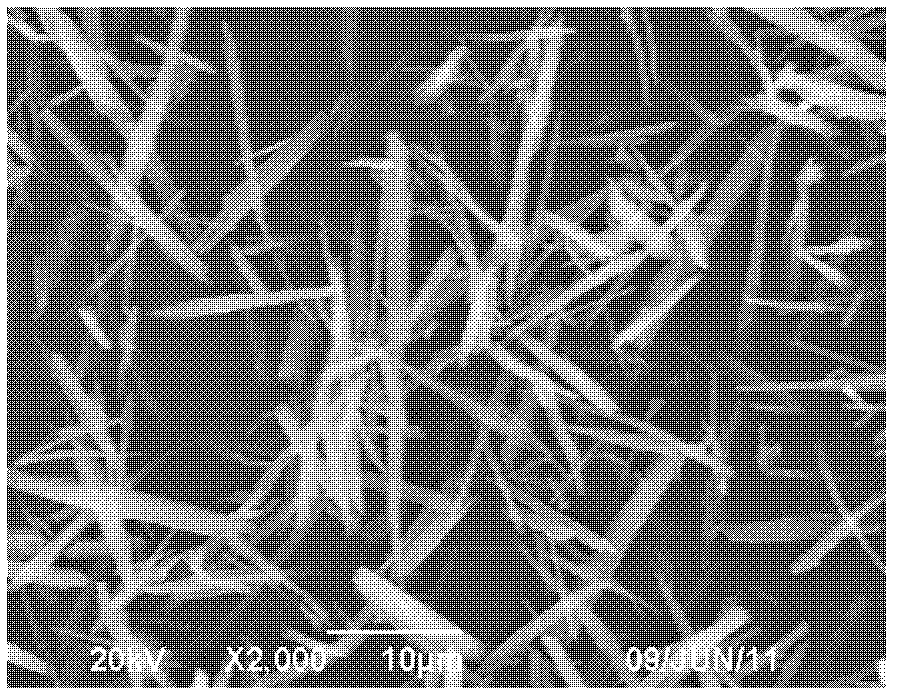

Method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite

ActiveCN102618932ANo waste dischargeReduce manufacturing costPolycrystalline material growthAlkali metal silicatesSodium BentoniteSurface-active agents

The invention discloses a method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite, which comprises the following steps of: adding sulfuric acid solution to bentonite mineral powder which is taken as an initial raw material; reacting; then performing filtering separation; collecting an acid-leached filtrate and acid-leached filter cakes; adding salpeter solution and isoamyl alcohol to the acid-leached filtrate; performing liquid separation and collecting an aqueous phase to obtain aluminum salt solution; adding urea and a surface active agent to the aluminum salt solution; reacting; then, separating, washing and drying to obtain basic ammonium aluminum carbonate hydroxide whiskers; and calcining the basic ammonium aluminum carbonate hydroxide whiskers to obtain aluminum oxide whiskers. Aluminum oxide and silicon dioxide which are required by the method disclosed by the invention respectively come from bentonite ore, and other industrial raw materials do not need to be adopted, so that the production cost can be effectively reduced. The method disclosed by the invention has the advantages that the recovery rate is high; the yield of the aluminum oxide in the bentonite can reach at least 90 percent; and the yield of the amorphous silicon dioxide can reach at least 95 percent.

Owner:HEFEI UNIV OF TECH

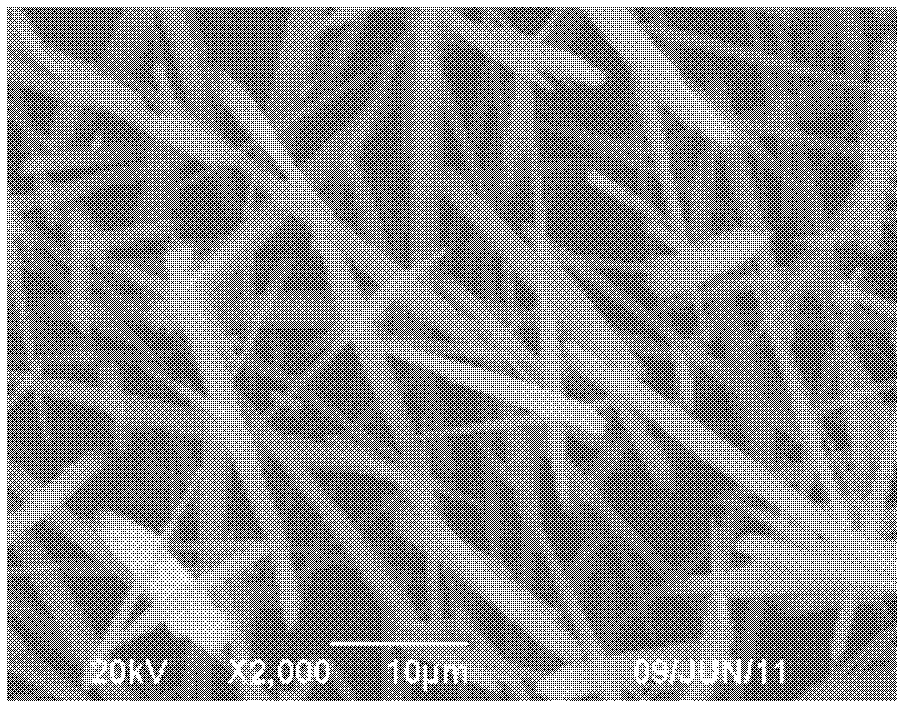

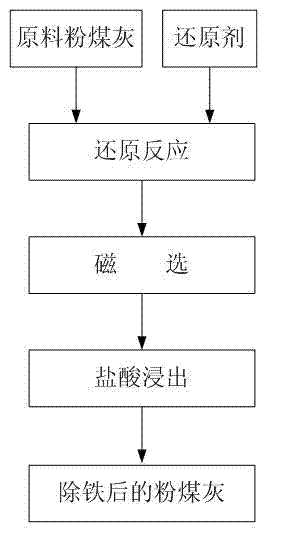

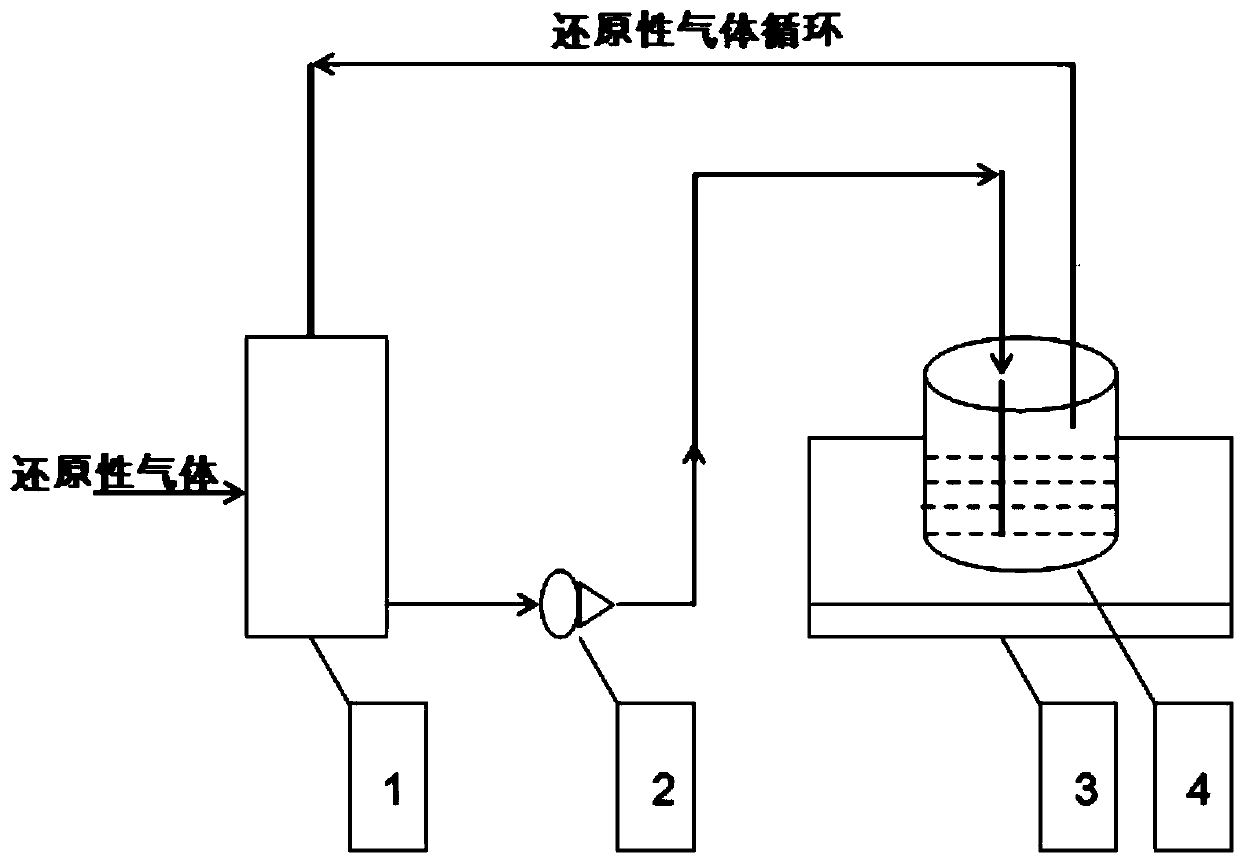

Method for efficiently deironing coal ash

The invention provides a method for efficiently deironing coal ash. Fine powder of raw coal ash is sequentially subjected to reduction, magnetic separation and hydrochloric acid leaching treatment, thereby finally obtaining the coal ash with the Fe2O3 content less than 0.02%. The method has the beneficial effects that the technology operation is simple, and the deironing efficiency is high, so that the Fe2O3 content in the coal ash is reduced to be lower than 0.02%; the calcium impurity also can be removed; moreover, a molecular sieve prepared by utilizing the coal ash after deironing by the method is high in quality, and the Fe2O3 content is less than the commercial value; not only can a duct of the molecular sieve be prevented from being blocked by a ferrum ion, but also the adsorption-desorption circulation service life can be prolonged. In addition, with the method, iron powder can be recycled in the magnetic separation process for iron smelting.

Owner:NORTHEASTERN UNIV

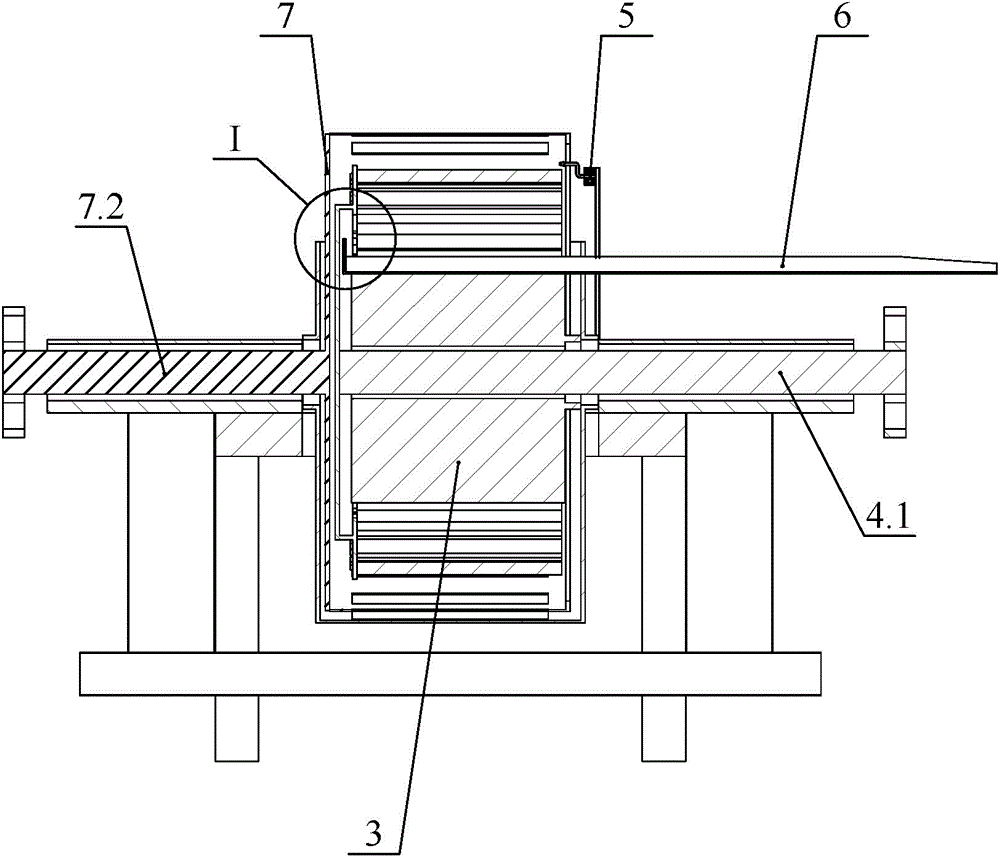

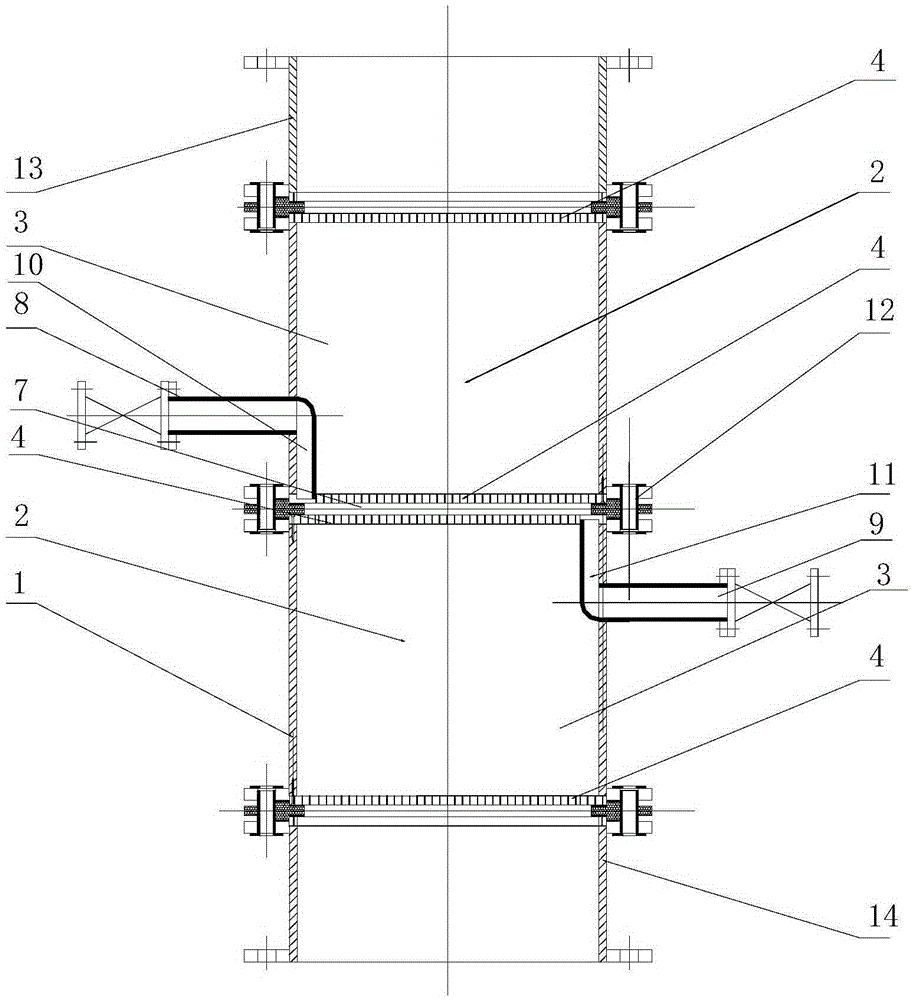

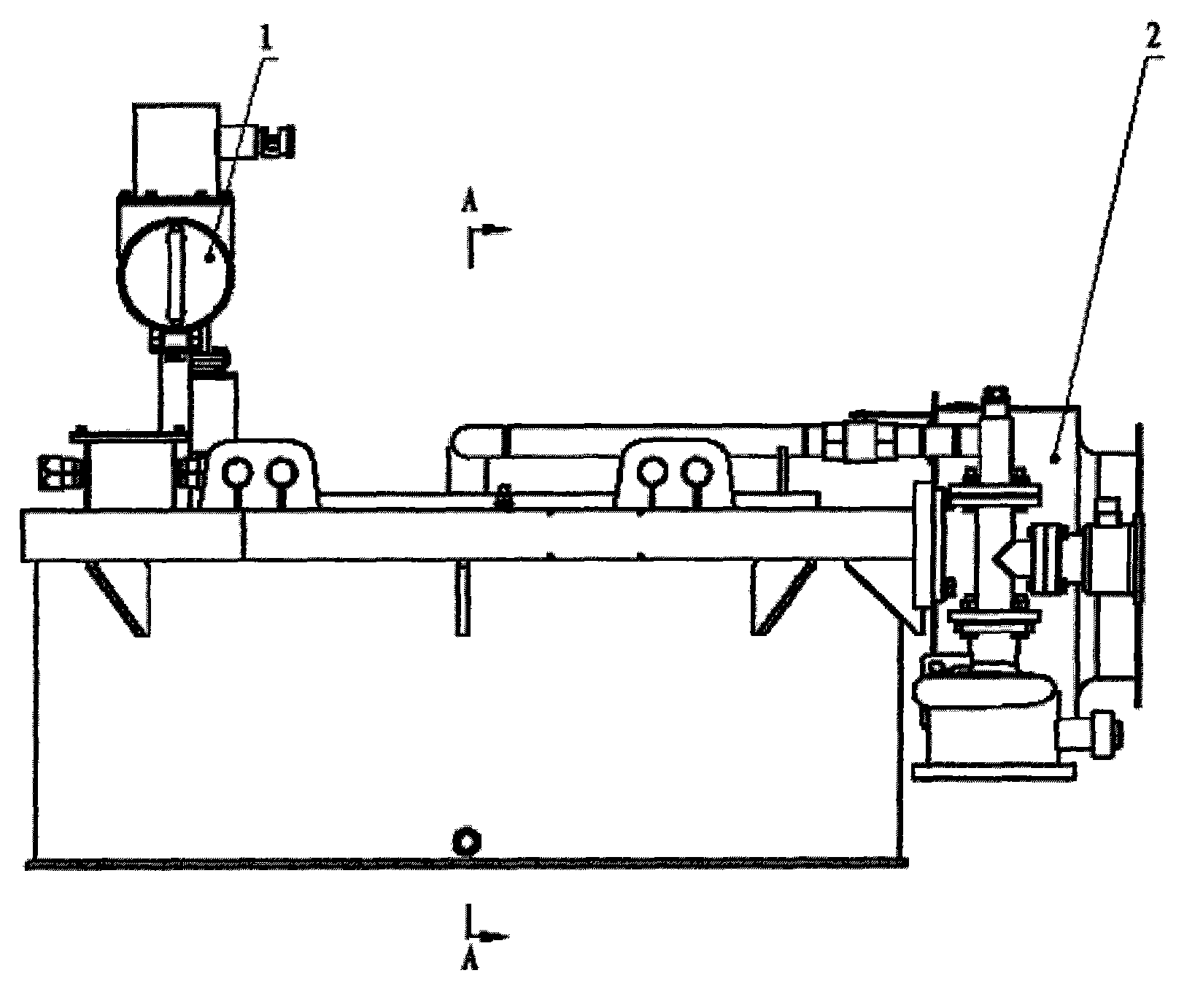

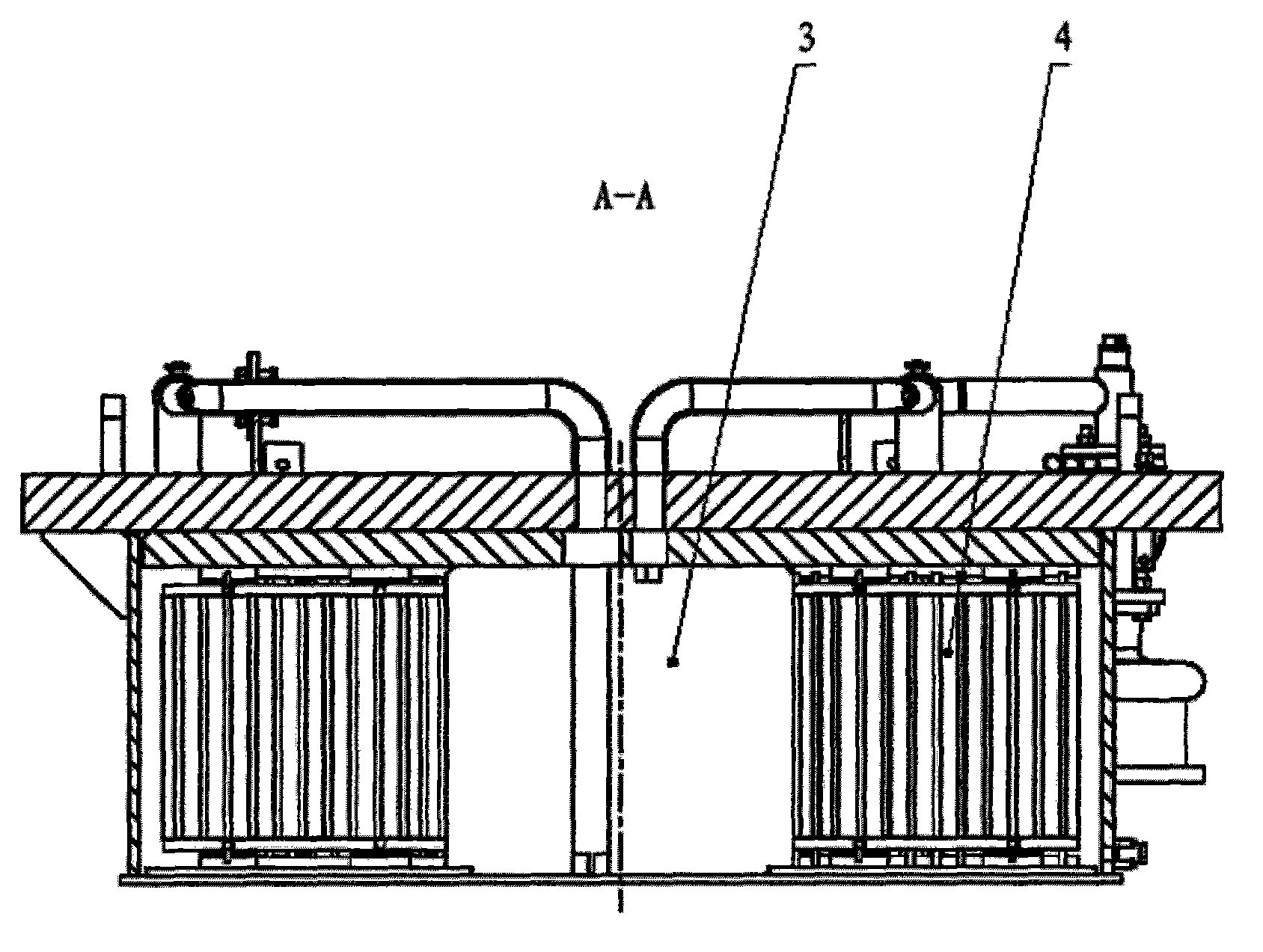

High-gradient internal circulation oil cooling iron remover

ActiveCN103008100ALow circulation resistanceEven and reasonable cycleHigh gradient magnetic separationTransformers/inductances coolingExpansion tankTransformer oil

The invention discloses a high-gradient internal circulation oil cooling iron remover which comprises a magnetic system coil (4), an internal circulation oil path system (3), an external cooling system (2) and an expansion tank (1), wherein the magnetic system coil (4) is used for generating an excitation magnetic field which realizes the iron sucking function of the iron remover; the magnetic path of the magnetic system coil (4) is in an opened magnetic path structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating transformer oil; the external cooling system (2) is used for radiating the heat of the transformer oil so as to realize the heat radiation balance in the high-gradient internal circulation oil cooling iron remover; and the expansion tank (1) is used as a compensation container for the transformer oil expansion when equipment operates. By adopting the internal circulation structure, the external circulation pipeline is simplified, the oil path circulation resistance is reduced, problems that an oil path is complexly arranged with interference, the circulation efficiency is low, a welding spot has leakage and the like are avoided, the normal operation of the iron remover is ensured, and the iron removing efficiency is improved.

Owner:LONGI MAGNET CO LTD

Powder de-ironing separator

InactiveCN105107621AGood removal effectImprove screening qualityMagnetic separationIron removalEngineering

The invention discloses a powder de-ironing separator. A feed opening is formed in the upper part of the de-ironing separator box body, and a discharge opening is formed in the lower part of the de-ironing separator box body; an iron discharge opening is formed in the side surface of lower part of the de-ironing separator box body; the inner chamber of the de-ironing separator is divided into an iron absorbing area and an iron unloading area using a separating plate at the longitudinal position; round holes allowing magnetic bars to penetrate through are formed in the separating plate; guide rails enabling a magnetic frame to slide are arranged on the two side walls of the inner chamber of the de-ironing separator box body in the horizontal direction; the magnetic frame is composed of a magnetic bar front fixing plate, a magnetic bar rear fixing plate, and the magnetic bars; a non-magnetic zone is arranged at the tail ends of the magnetic bars; one end of each magnetic bar is fixed to the magnetic bar front fixing plate through screws, and the other end of each magnetic bar penetrates through the round hole formed in the separating plate and is fixed to the magnetic bar rear fixing plate through a fastener; the end, positioned at the iron unloading area, of each magnetic bar penetrates through a rubber plate with a round hole; a magnetic frame handle is mounted on the magnetic bar front fixing plate. The technical scheme provided by the invention can be used to conveniently remove the powdered iron and iron scraps on the surface of the permanent magnetic de-ironing separator, improve the screening quality of the dry powder, reduce labor work, and meanwhile improve the iron removal efficiency.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

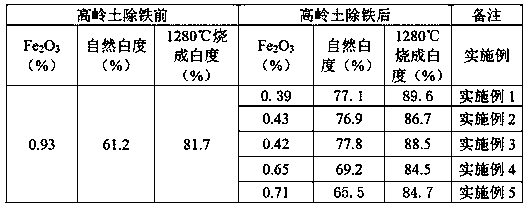

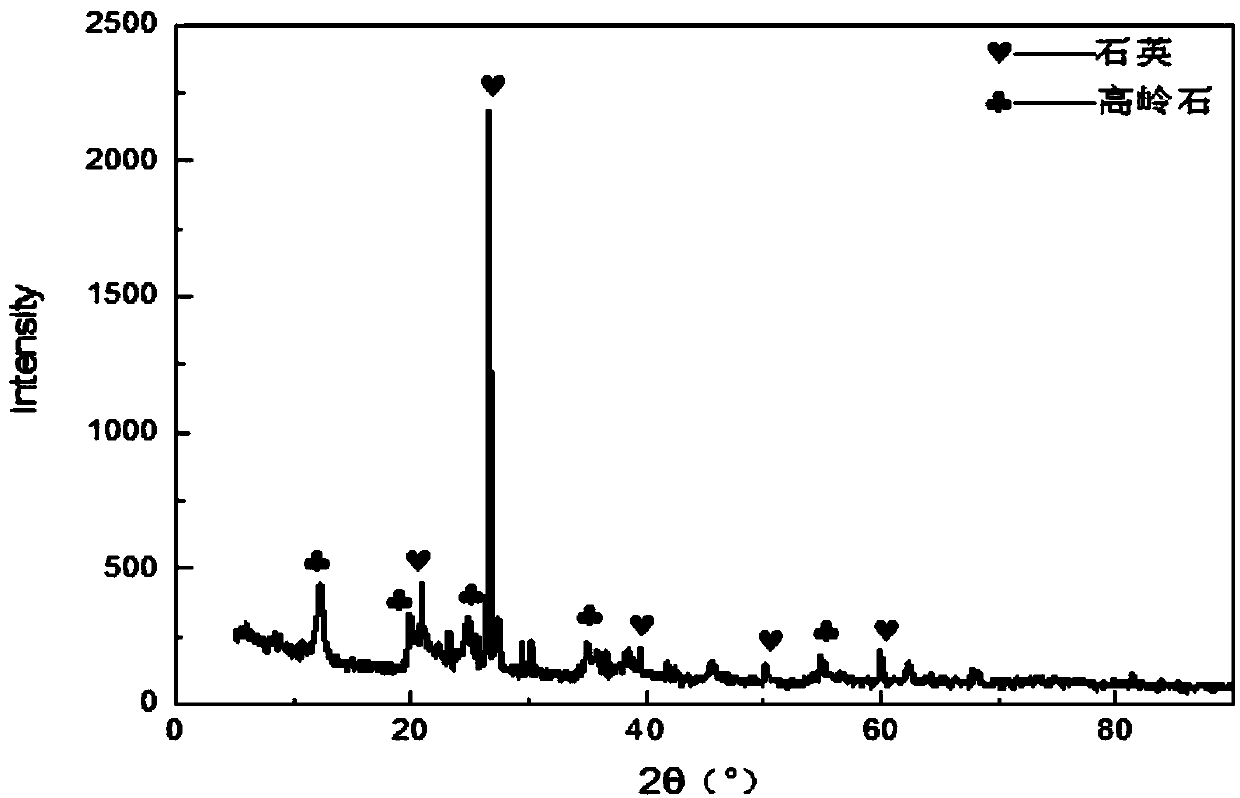

Mixed flora and application thereof in iron removal and whitening for kaolin

InactiveCN107603913AGood removal effectExtended service lifeBacteriaFerrous oxidesMicroorganismIron removal

The invention discloses mixed flora and application thereof in iron removal and whitening for kaolin. The mixed flora is prepared from the following components: iron-reducing bacteria RBFL, iron-reducing bacteria FeRB-FL1404, iron-reducing bacteria FL-HI, thermoanaerobacter ethanolicus, achromobacter, Geobacter bremensis Straub and Buchholz-Cleven; due to a synergistic effect of microbial strainsin the mixed flora, the iron-removing effect of the microbes for the kaolin can be improved. The bacterial liquid obtained by culturing the mixed flora is used for reducing Fe2O3 in the kaolin, and insoluble Fe2O3 is reduced into water-soluble Fe<2+> which can be removed by solid-liquid separation, so that the content of Fe2O3 in the kaolin can be reduced and the whiteness of the kaolin can be improved. The mixed flora has the advantages that the cost is low, the environmental-friendly effect is achieved, the kaolin ore with original low mining value and low grade can be mined, the service life of the mine can be prolonged, and the high quality of the low-grade kaolin can be realized.

Owner:FUJIAN NORMAL UNIV

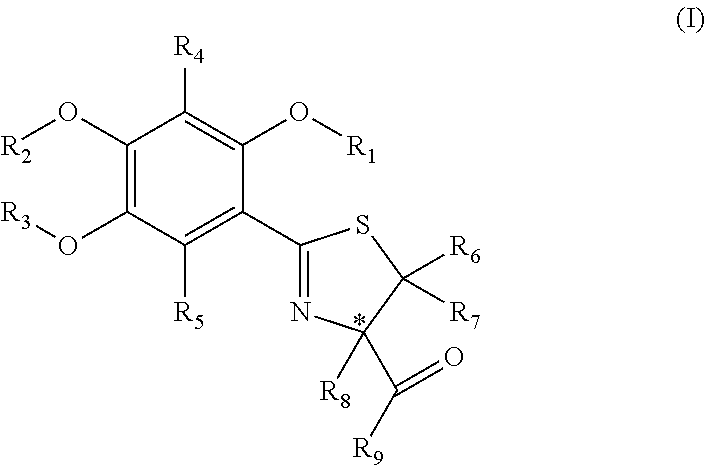

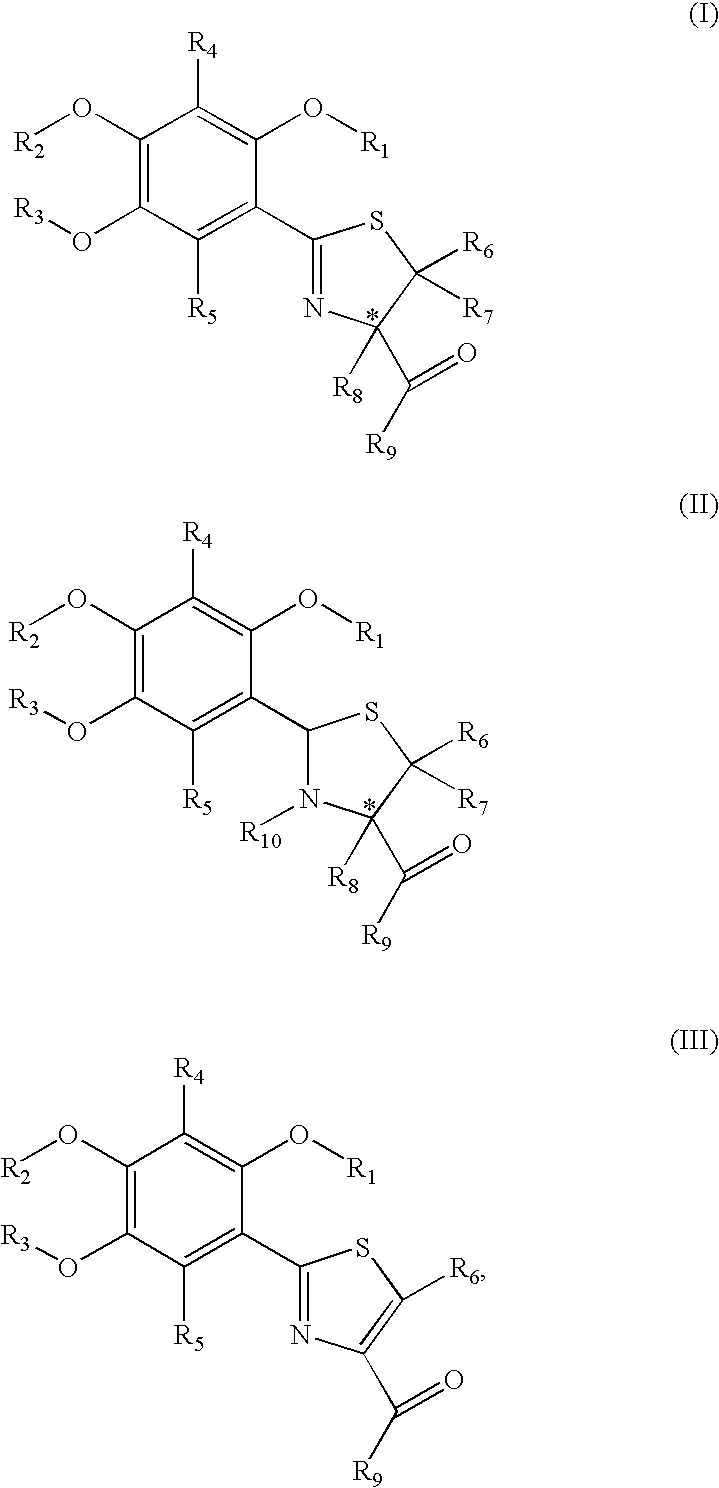

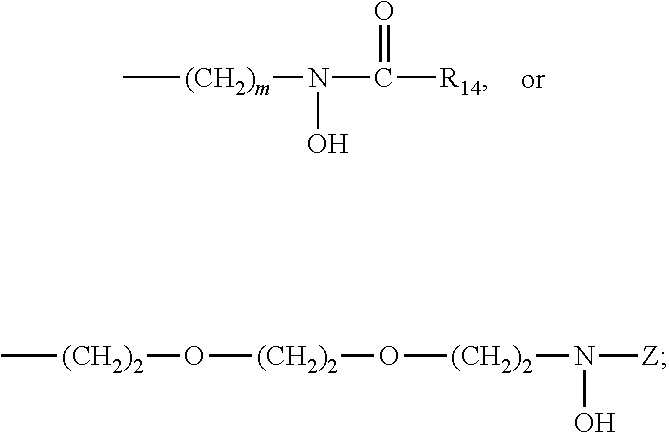

Desferrithiocin derivatives and methods of use thereof

InactiveUS8604216B2Reduce oxidative stressHigh iron removal efficiencyOrganic active ingredientsBiocideBiological bodyOxidative stress

Compounds represented by structural formulas such as Structural Formula (I):are highly efficient in clearing excess iron from an organism. The invention also discloses methods of treating conditions such as metal overload, oxidative stress, and neoplastic and preneoplastic conditions.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

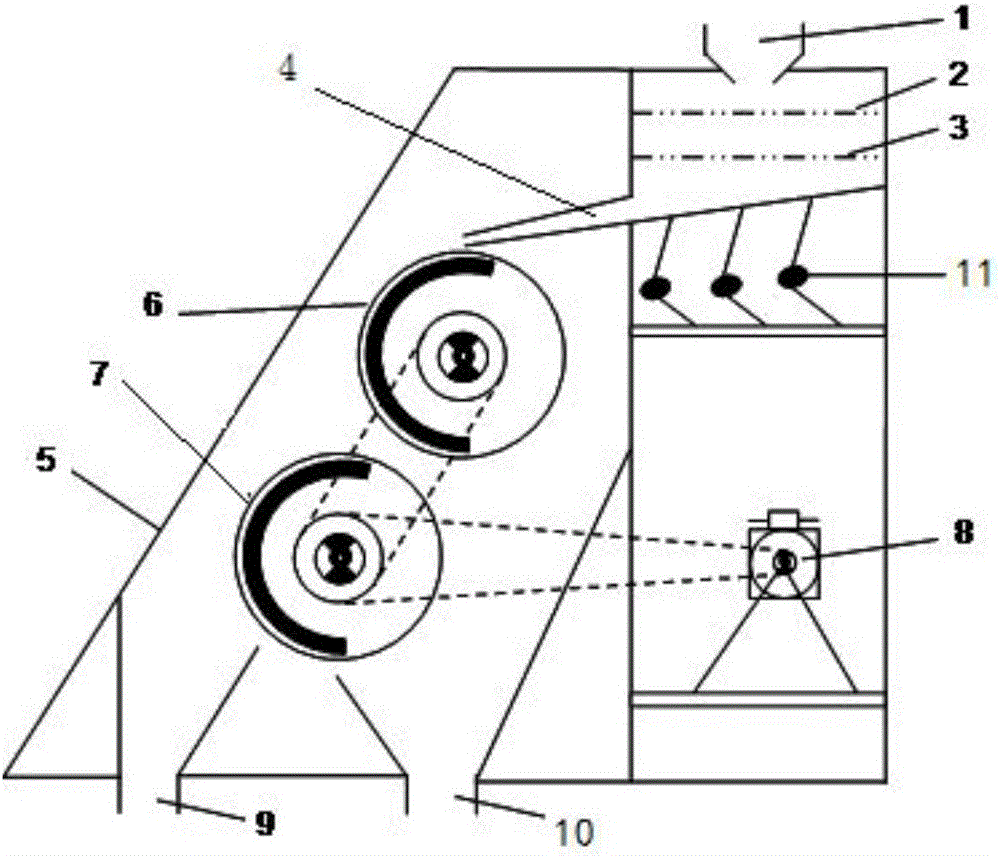

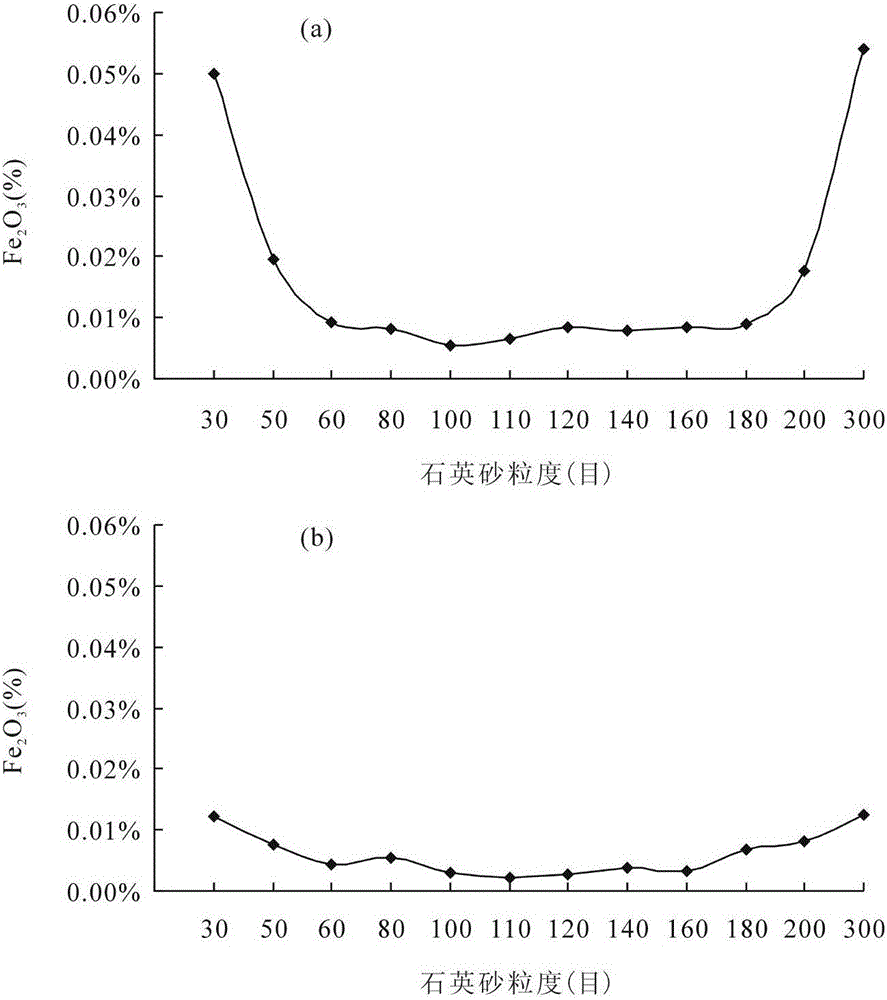

Method for carrying out classification magnetic separation according to particle sizes of quartz sand, and magnetic separator thereof

ActiveCN106733162AHigh iron removal efficiencyIncrease the magnetic field strengthMagnetic separationMagnetic separatorSieve

The invention discloses a method for carrying out classification magnetic separation according to the particle sizes of quartz sand, and a magnetic separator thereof, and relates to the technical field of quartz sand treatment. The method is characterized by comprising the following steps: crushing quartz stone at first; then carrying out grading screening by virtue of sieve screens, wherein the size of the first-stage sieve screen is 50-70 meshes, and the size of the second-stage sieve screen is 170-190 meshes; and then inputting the quartz sand subjected to the grading screening into the magnetic separator separately and carrying out magnetic separation. The magnetic separator comprises a screening device and a magnetic separator body, wherein the screening device is arranged at the upper side of the magnetic separator; a charge port is formed in the upper part of the screening device; the screening device comprises the first-stage sieve screen and the second-stage sieve screen; the second-stage sieve screen is arranged at the lower side of the first-stage sieve screen; charge channels connected to the magnetic separator body are formed in the screening layers of the first-stage sieve screen and the second-stage sieve screen; and the magnetic separator body comprises a rack, a first magnetic drum, a second magnetic drum and a transmission motor. The iron removal efficiency of the magnetic separation method and the magnetic separator is greatly increased.

Owner:ANHUI SCI & TECH UNIV

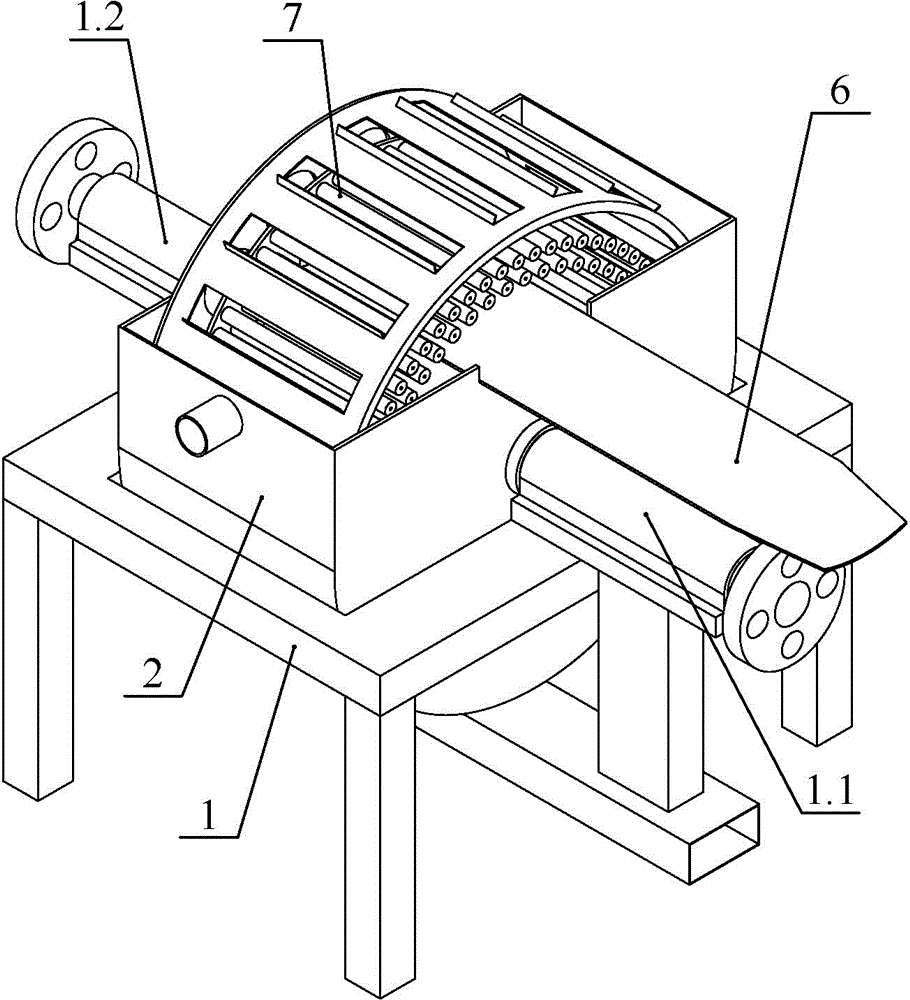

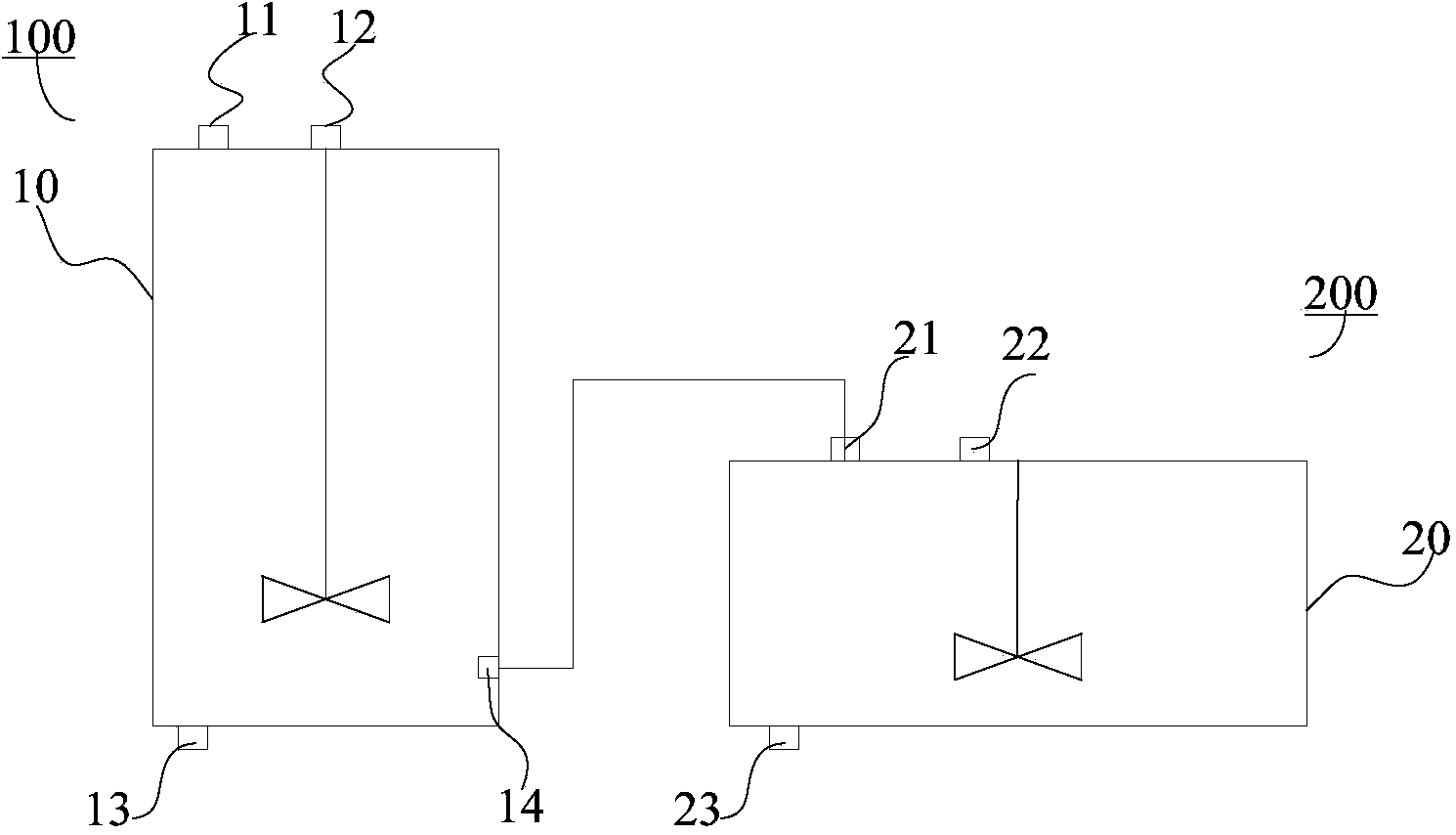

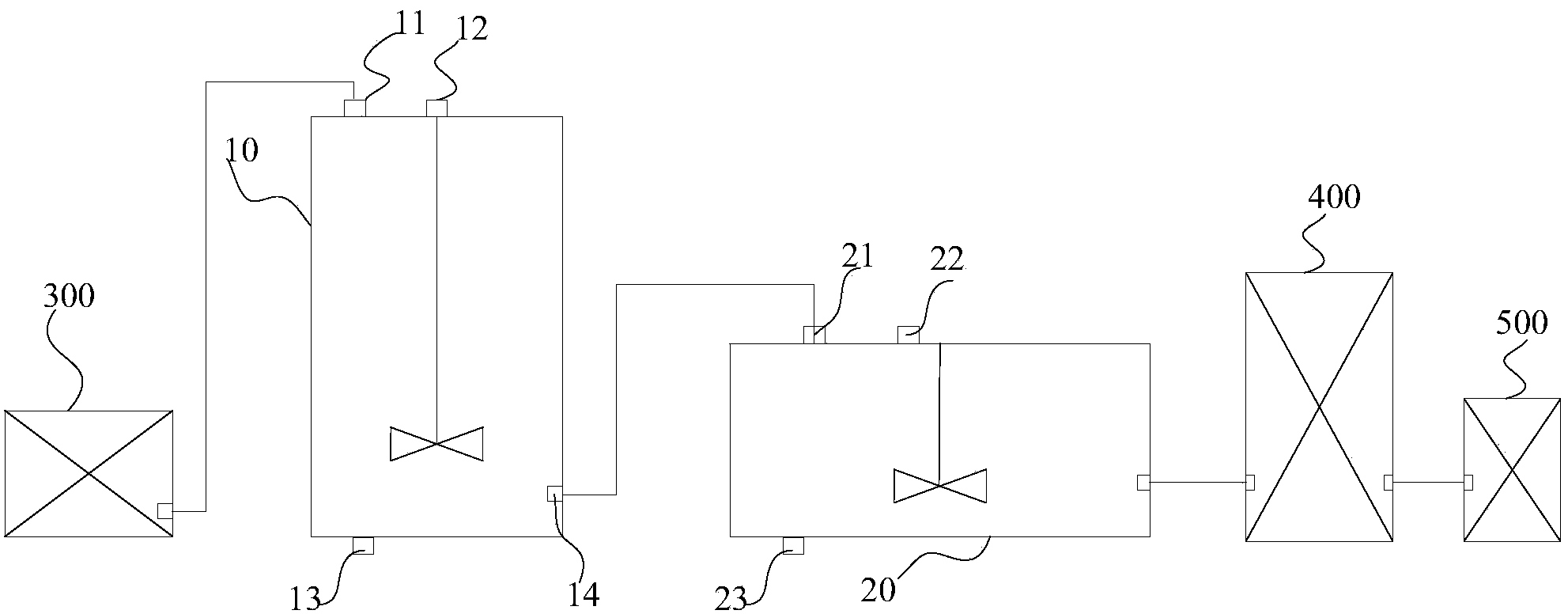

System for removing iron in iron-containing zinc sulfate solution

ActiveCN104004915AImprove iron removal efficiency and equipment utilizationSolve land occupation and environmental pollution problemsProcess efficiency improvementFerricSlurry

The invention discloses a system for removing iron in an iron-containing zinc sulfate solution. The system comprises a vertical reaction kettle and a horizontal reaction kettle, wherein the vertical reaction kettle comprises a vertical reaction kettle body, an iron-containing zinc sulfate solution feed port, a first steam inlet, a first oxygen inlet and a first iron-removed slurry outlet, and the horizontal reaction kettle comprises a horizontal reaction kettle body, a first iron-removed slurry feed port, a second steam inlet and a second oxygen inlet. According to the system for removing iron in the iron-containing zinc sulfate solution, due to the combination of the vertical reaction kettle and the horizontal reaction kettle, the problem of production halts caused by scaling in the kettle in deironing can be effectively solved, continuous and stable production can be guaranteed, so that the deironing efficiency and use ratio of the equipment are remarkably improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

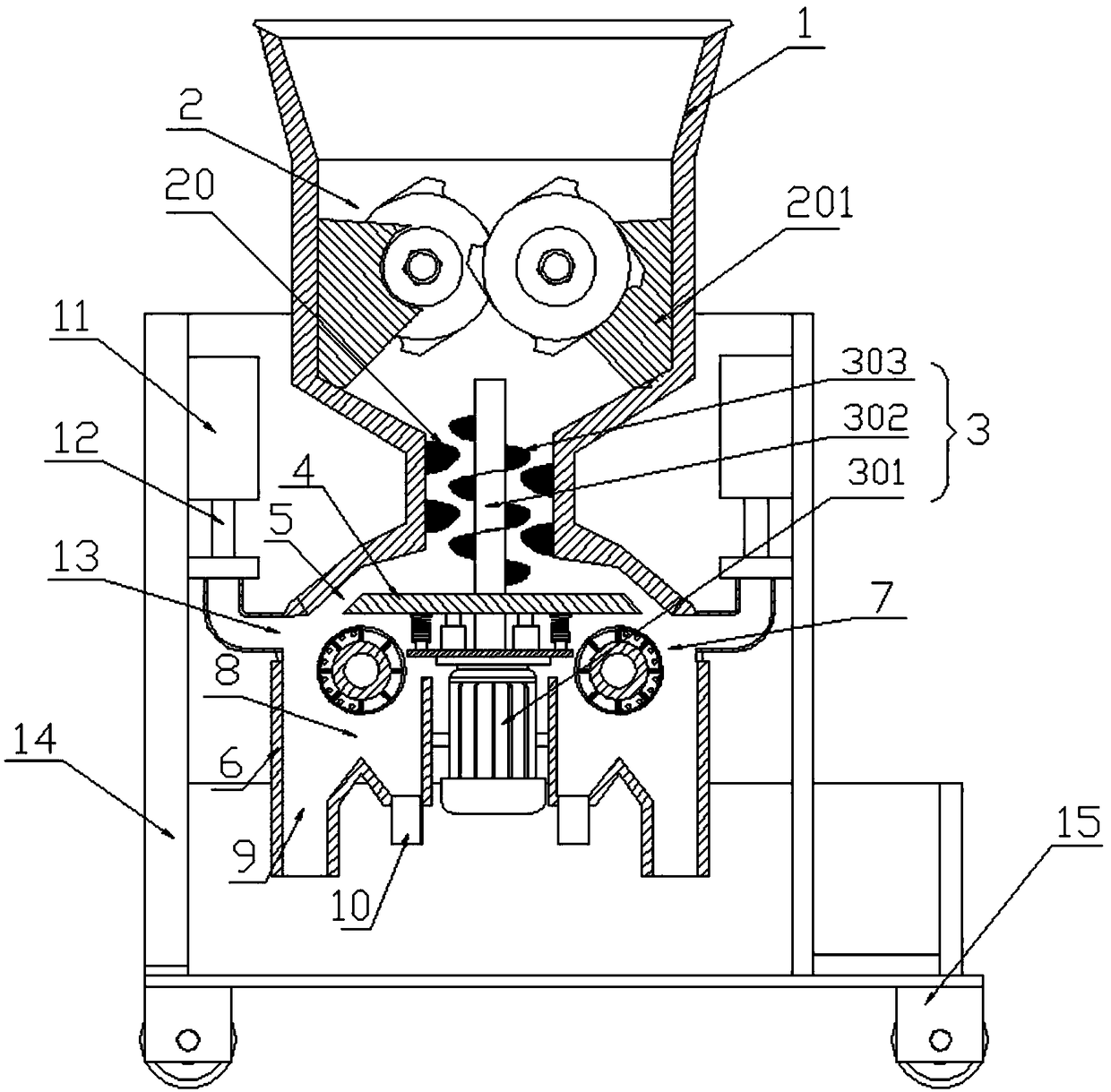

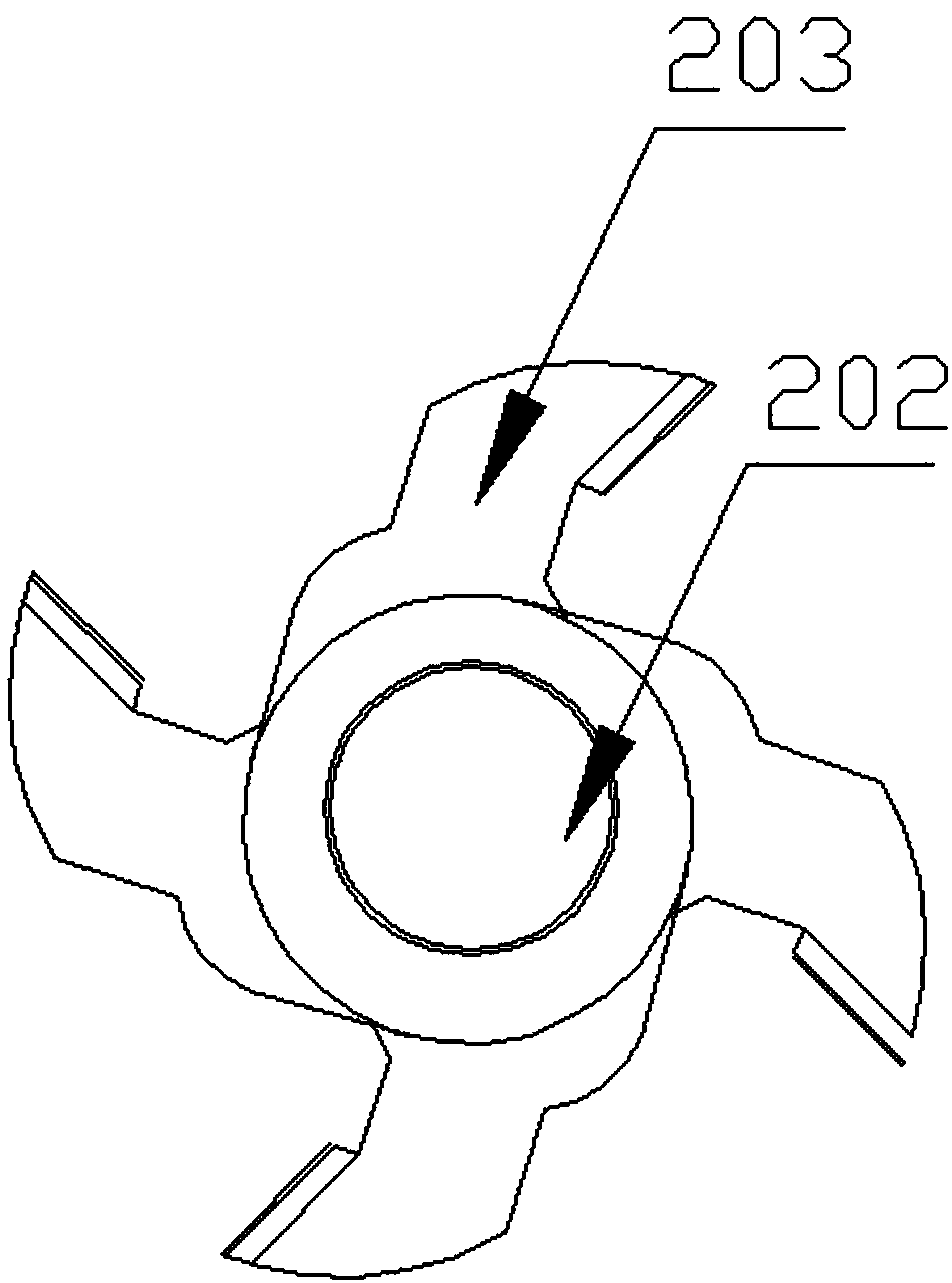

Material breaking equipment for brick making

The invention discloses material breaking equipment for brick making. The material breaking equipment comprises an equipment shell. A feeding bin is arranged on the upper portion of the equipment shell, a crushing mechanism is arranged in the middle of the equipment shell, and an outlet in the lower portion of the equipment shell is of a toe-out structure. The outlet in the lower end of the equipment shell is provided with a stirring assembly which is composed of a motor, a stirring shaft and a stirring roll. A crushing roll nail is fixed into the equipment shell, and the crushing roll nail iscrossed with the stirring roll. The motor is arranged on a fixing plate which is connected with a vehicle frame, and the upper end of the fixing plate is connected with a mounting plate by arranginga vibration motor and a vibration elastic piece. The mounting plate and the equipment shell form discharging openings which are downwards oblique, and iron removing stock bins are arranged in the discharging direction of the discharging openings. Iron removing assemblies are arranged in the iron removing stock bins, and an air draft device is arranged on the vehicle frame. A branch pipe is arranged at the lower end of the air draft device. According to the material breaking equipment for brick making, the disadvantages that existing red brick materials are prone to causing blocking after beingcrushed, dust pollution occurs to a workshop, and the brick making quality is poor are overcome to improve the competitiveness of enterprises.

Owner:邵东市中兴建材有限公司

Method for separating zinc and iron in zinc hydrometallurgy leaching slag

InactiveCN106222429AReduce consumptionLess investmentProcess efficiency improvementElectrolysisIndium

The invention relates to a method for separating zinc and iron in zinc hydrometallurgy leaching slag. Specifically, the leaching slag in zinc hydrometallurgy and preheated electrolysis waste liquor are added into a surge tank to be subjected to size mixing, sulfur disperser wood sodium sulfonate is added, and slurry is obtained; the above slurry is beaten into an autoclave through a booster pump, compressed air is led into the autoclave to conduct high-pressure leaching, the slurry obtained after the reaction is conveyed into a flash drum to be subjected to temperature and pressure reduction, and then the slurry obtained after temperature and pressure reduction is conveyed into a filter press to be subjected to pressing filtering, and filter liquor and filter residues are obtained; and the iron is deposited in the filter residues in the form of hematite, and after copper and indium are recycled from the filter liquor, neutral leaching is executed again. The above method for separating the zinc and the iron in the zinc hydrometallurgy leaching slag has the beneficial effects that the procedure is simple, fuel is saved, the investment cost is reduced, the iron removing efficiency is high, and valuable metal in the leaching slag can be recycled at the same time.

Owner:HENAN YUGUANG ZINC IND

Flue gas pollutant cooperation removal technology based on electrolysis

InactiveCN105344215AImprove conversion rateSimple structureCombination devicesGas treatmentAmmonium sulfateElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

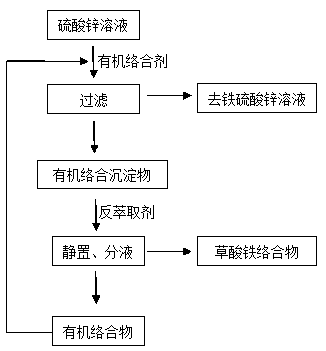

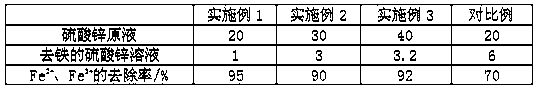

Method for removing iron in zinc sulfate solution

The invention discloses a method for removing iron in a zinc sulphate solution. The method comprises the steps: adding an organic complexing agent to the zinc sulphate solution and carrying out iron removal, stirring and filtering to obtain an iron-free zinc sulphate solution and an organic complex precipitate; adding a back-extractant to the organic complex precipitate and back extracting the organic complex precipitate to separate the organic complexing agent from the iron; and recycling the back-extracted organic complexing agent for iron removal. The method disclosed by the invention has the advantages that the iron in the zinc sulfate solution can be effectively removed; the iron removing efficiency is high and the process is simple; the iron removing rate is up to 90%; and the iron removing cost is reduced.

Owner:衡阳市大宇锌业有限公司

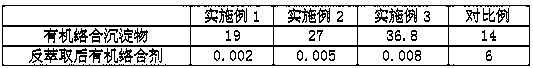

Rapid efficient iron-removing whitening method for low-grade raw material

InactiveCN109553382AAchieve iron removalTo achieve the purpose of whiteningClaywaresOrganic acidIron removal

The invention discloses a rapid efficient iron-removing whitening method for a low-grade raw material, comprising the following steps: pulverizing the low-grade raw material into mineral slurry, adding an organic acid, introducing a reducing gas, conducting a reaction at 25-95 DEG C, and after completion of the reaction, conducting solid-liquid separation, washing and drying to obtain a raw material having a reduced iron content. According to the invention, the reducing gas is directly introduced to perform iron removal and whitening when acid soaking is conducted, no new impurity is introduced, the operation is fast and efficient, and the introduced reducing gas can be recycled, so the method saves energy and is friendly to environment and low in processing cost. The raw material processed by the method is directly used for ceramic production, and the product whiteness and performance indicators fully meet the requirements of industry.

Owner:清远市简一陶瓷有限公司 +1

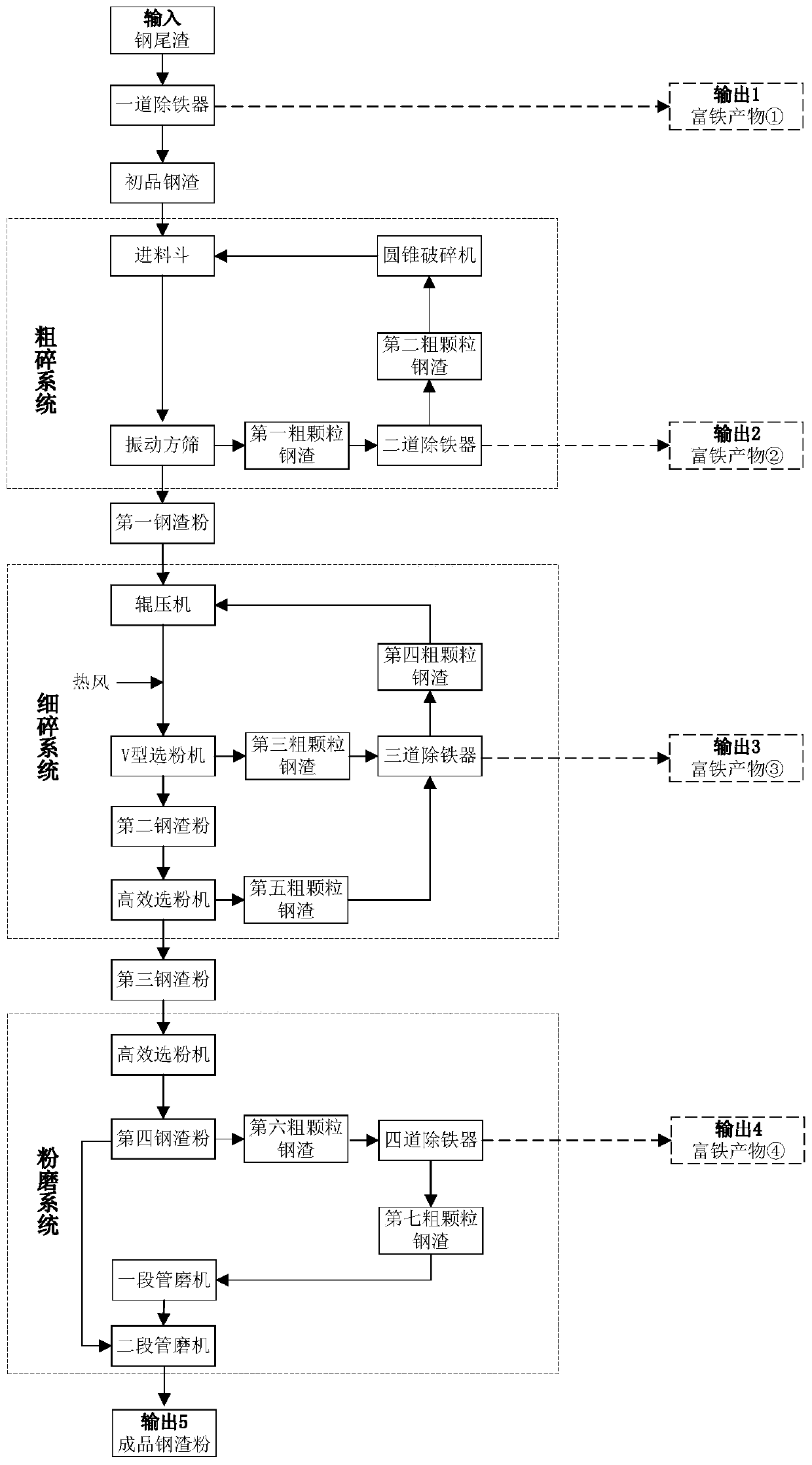

Steel slag real-time circular iron removal and grinding method

ActiveCN110788114AReduce lossImprove grinding efficiencySievingTransportation and packagingIron powderSlag

The invention discloses a steel slag real-time circular iron removal and grinding method, which belongs to the technical field of steel slag comprehensive utilization, and includes the following steps: feeding and iron removal, coarse crushing and iron removal, fine crushing and iron removal, and grinding and iron removal, and finally the ground steel slag with the specific surface area of 400 m2 / kg-500m2 / kg, and the metallic iron content smaller than or equal to 0.3%. Through utilizing the steel slag real-time circular iron removal and grinding method provided by the invention, the steel slagreal-time circular iron removal is combined with the 'more crushing and less grinding' and the 'segmented grinding' technologies for steel slags, so that not only the metallic iron in the steel slagsis fully recovered, but also the grinding efficiency in the steel slags is further improved, the energy consumption is reduced, and steel slag micro powder is obtained.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

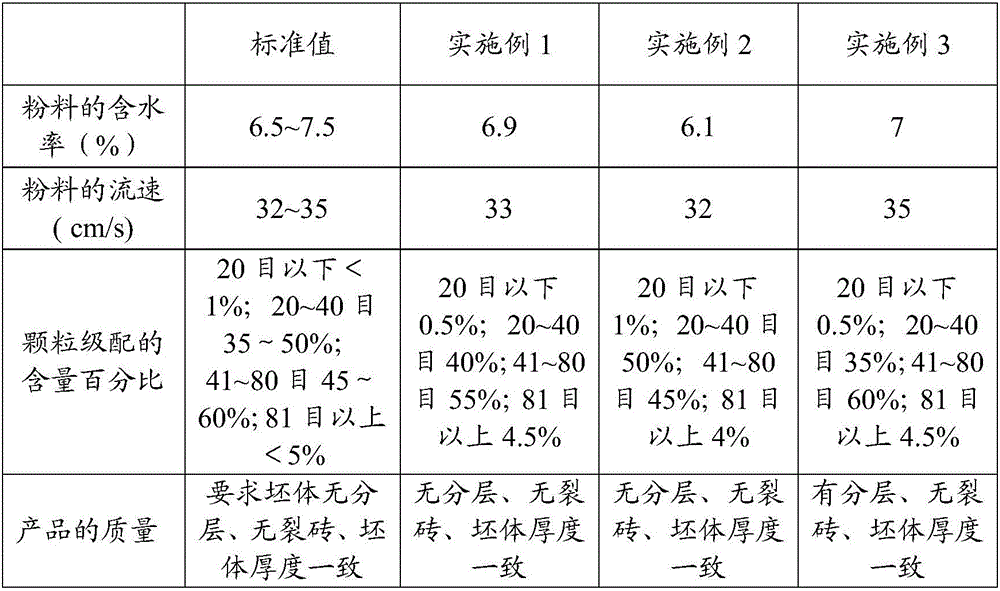

Preparation method of ceramic powder

The invention discloses a preparation method of ceramic powder. The preparation method comprises the following steps: delivering raw materials to obtain pre-mixture; smashing and slurrying the pre-mixture to obtain slurry; carrying out sieving and deironing on the slurry; carrying out spray granulation on the slurry subjected to the sieving and deironing. The step of smashing and slurrying the pre-mixture to obtain slurry is characterized in that the pre-mixture is smashed by a ball mill, the percent contents of ballstones of different diameters in the ball mill are 30mm to 40mm to 50mm to 60mm=(5 to 20) to (25 to 35) to (30 to 50) to (5 to 20), the revolving speed of the ball mill is 10-15 rpm, and the ballstones used by ball milling are high-aluminum ballstones. The preparation method is characterized in that the ballstones of different diameters are mutually cooperated to smash the pre-mixture, meanwhile, the slurry is subjected to deironing by a deironing slot and an electromagnetic de-ironing separator, the preparation efficiency of the ceramic powder is improved, energy consumption is small, and efficiency is high.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +3

Multifunctional composite fluxing agent

The invention discloses a multifunctional composite fluxing agent. The multifunctional composite fluxing agent comprises the components of, by mass, 1-4% of rare earth compound, 40-45% of sodium chloride, 40-45% of potassium chloride, 2-18% of sodium fluoroaluminate and 1-4% of boride, wherein the sum of the mass of the rare earth compound and the mass of the boride accounts for 3-8% of the total mass of a rare earth fluxing agent. The multifunctional composite fluxing agent is obvious in dehydrogenation, deoxygenization and deironing effect, enables the hydrogen content in molten aluminum to be reduced to 0.10-0.15ml / 100gAl, removes non-metallic inclusions above 10 micrometers in size almost, enables inclusions below 10 micrometers in size to be reduced by 60-80%, enables the iron element content to be reduced from above 0.9% to below 0.5%, is high in deironing efficiency, simple in technology and convenient to operate and can improve the comprehensive performance of aluminum alloy.

Owner:南通曼特威金属材料有限公司

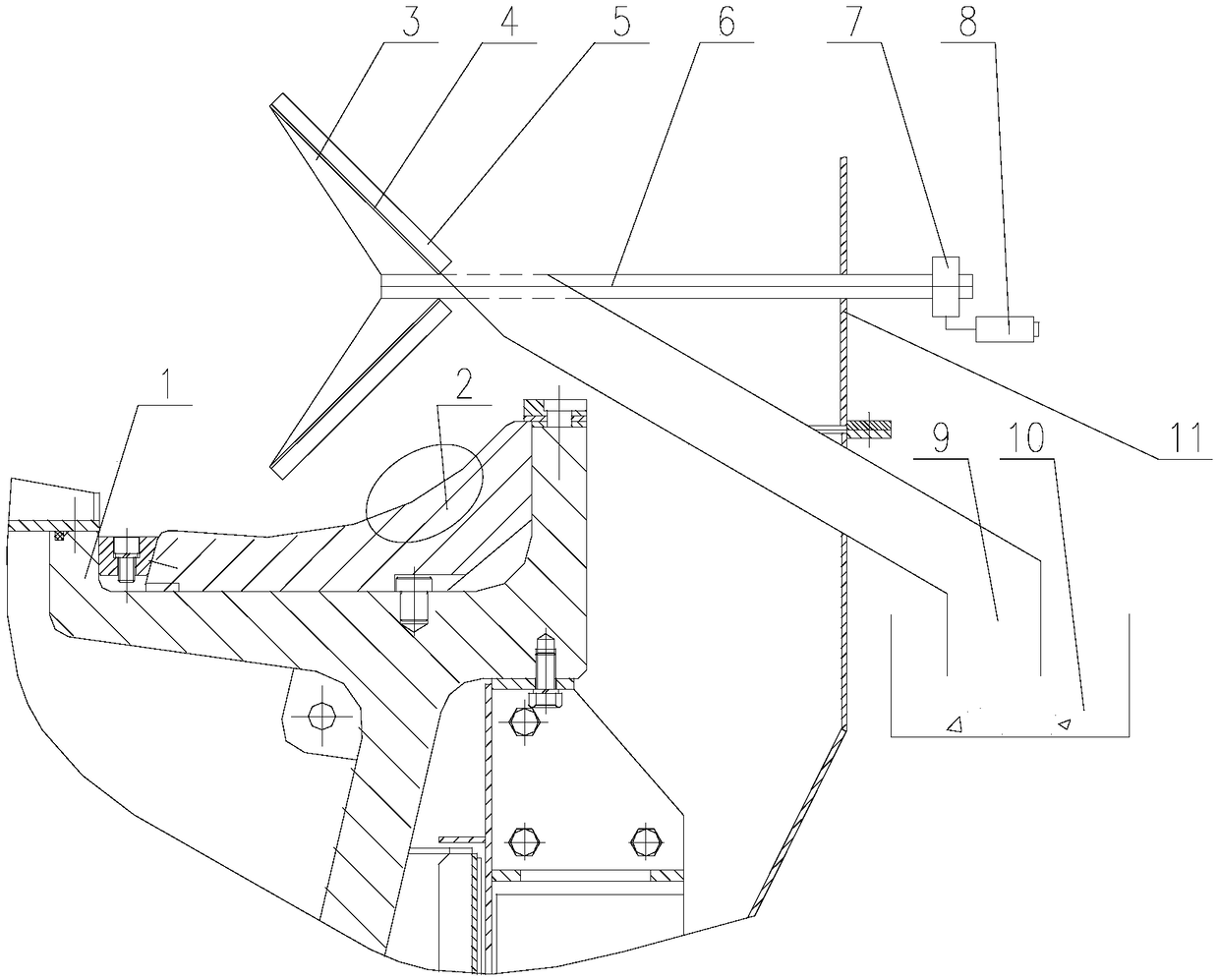

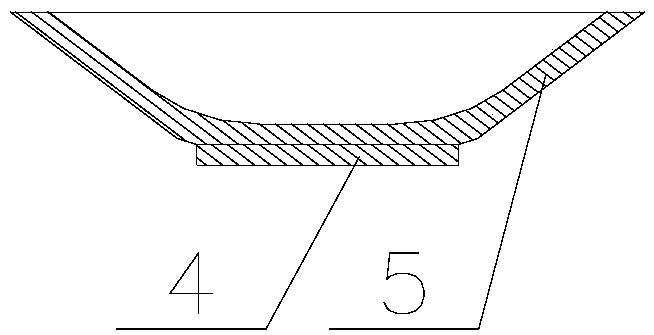

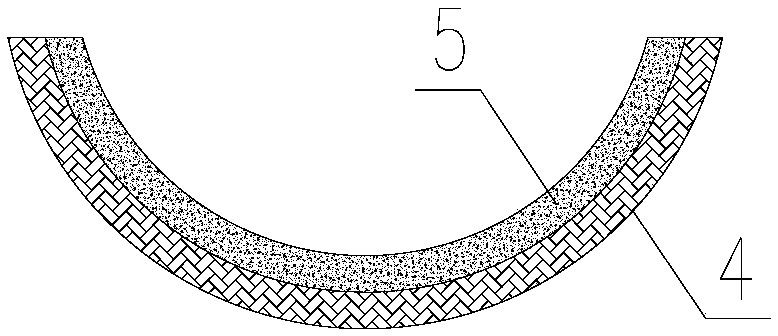

Iron removing device inside vertical mill

PendingCN108940466APrevent circular millingReduce chance of vibrationMagnetic separationGrain treatmentsEngineeringElectromagnet

The invention provides an iron removing device inside a vertical mill. The iron removing device inside the vertical mill comprises a vertical mill shell, and further comprises a rotary shaft, an electromagnetic device and an unloading device; the left end of the rotary shaft extends into the vertical mill shell, and the right end of the rotary shaft is connected with a drive mechanism; the electromagnetic device is obliquely arranged above a vertical mill abrasive disk and comprises an electromagnet and an abrasion-resisting board arranged on the outer side face of the electromagnet; the innerside face of the electromagnet is fixedly connected with the rotary shaft through a support ribbed plate; the adsorption face of the abrasion-resisting board is an inward concaved curved face; the unloading device is a discharging scraper-trough conveyer; the feeding end of the discharging scraper-trough conveyer is located inside the vertical mill shell and corresponds to the unloading end of the abrasion-resisting board; and the discharging end of the discharging scraper-trough conveyer is located outside the vertical mill shell. The iron removing device inside the vertical mill can separate and remove iron materials released by polishing large materials in time, so that damage to a vertical mill material bed and abrasion-resisting materials is greatly reduced.

Owner:NANJING KISEN INT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com