Preparation method of ceramic powder

A ceramic powder and slurry technology, which is applied in the field of ceramic powder preparation, can solve the problems of uneven quality of intermediate products, complex powder processing process, and low powder efficiency, and achieves stable flow rate and moisture content, which is beneficial to Spray granulation and high iron removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

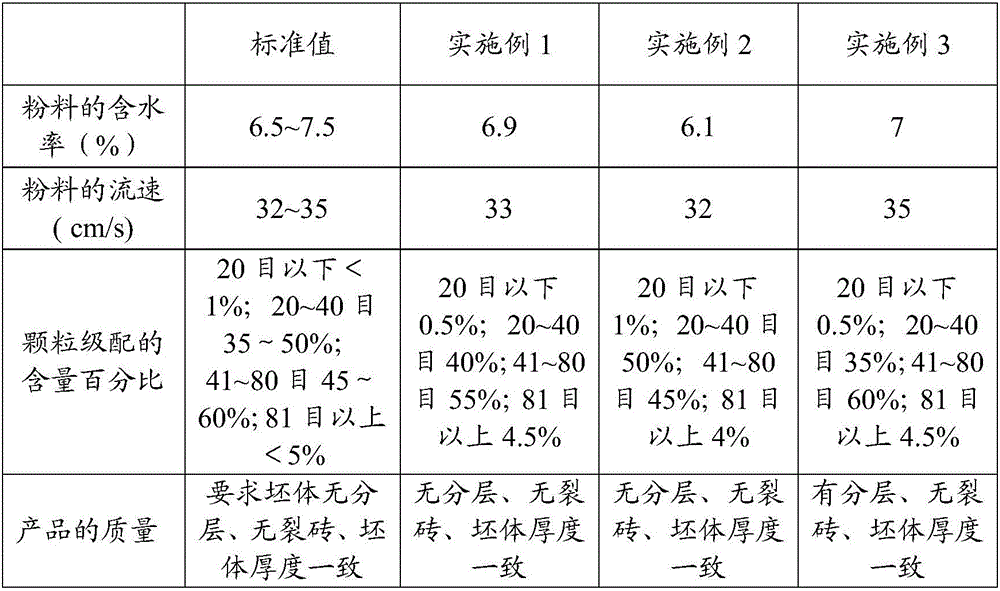

Examples

preparation example Construction

[0034] A preparation method of ceramic powder, comprising:

[0035] 1) The step of distributing raw materials to obtain pre-mixed ingredients;

[0036] Layered and superimposed on the conveying device according to the properties of the raw materials; among them, the raw materials are superimposed from bottom to top in the order of sandy materials, light materials, clay and chemical materials; pre-batching is obtained;

[0037] 2) The step of pulverizing the pre-batch to obtain the slurry and detecting it;

[0038] The pre-batch is pulverized by a ball mill; the ball stones with different diameters in the ball mill account for the weight parts of the ball stone total amount:

[0039] Ball stones with a diameter of 30mm: 5 to 20 parts;

[0040] Ball stones with a diameter of 40mm: 25 to 35 parts;

[0041] Ball stones with a diameter of 50mm: 30 to 50 parts;

[0042] Ball stones with a diameter of 60mm: 5 to 20 parts;

[0043] The ball stone adopts high alumina ball stone, w...

Embodiment 1

[0054] A preparation method of ceramic powder, comprising:

[0055] 1) The step of distributing raw materials to obtain pre-mixed ingredients;

[0056] Layered and superimposed on the conveying device according to the properties of the raw materials; among them, the raw materials are superimposed from bottom to top in the order of sandy materials, light materials, clay and chemical materials; pre-batching is obtained;

[0057] 2) The step of pulverizing the pre-batch to obtain the slurry and detecting it;

[0058] The pre-batch is pulverized by a ball mill; the ball stones with different diameters in the ball mill account for the weight parts of the ball stone total amount:

[0059] Ball stones with a diameter of 30mm: 20 parts;

[0060] Ball stones with a diameter of 40mm: 35 parts;

[0061] Ball stones with a diameter of 50mm: 35 parts;

[0062] Ball stones with a diameter of 60mm: 10 parts;

[0063] Ball stone adopts high alumina ball stone; the rotating speed of descr...

Embodiment 2

[0070] A preparation method of ceramic powder, comprising:

[0071] 1) The step of distributing raw materials to obtain pre-mixed ingredients;

[0072] Layered and superimposed on the conveying device according to the properties of the raw materials; among them, the raw materials are superimposed from bottom to top in the order of sandy materials, light materials, clay and chemical materials; pre-batching is obtained;

[0073] 2) The step of pulverizing the pre-batch to obtain the slurry and detecting it;

[0074] The pre-batch is pulverized by a ball mill; the ball stones with different diameters in the ball mill account for the weight parts of the ball stone total amount:

[0075] Ball stones with a diameter of 30mm: 15 parts;

[0076] Ball stones with a diameter of 40mm: 35 parts;

[0077] Ball stones with a diameter of 50mm: 35 parts;

[0078] Ball stones with a diameter of 60mm: 15 parts;

[0079] Ball stone adopts high-alumina ball stone; the rotating speed of describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com