Intermittent feeding device for powder packing

A technology for feeding devices and packaging, applied in packaging, transportation and packaging, loading/unloading, etc., can solve the problems of low guarantee efficiency, low iron removal efficiency, and increased production costs, so as to protect the surrounding environment and increase Effect of iron removal efficiency and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

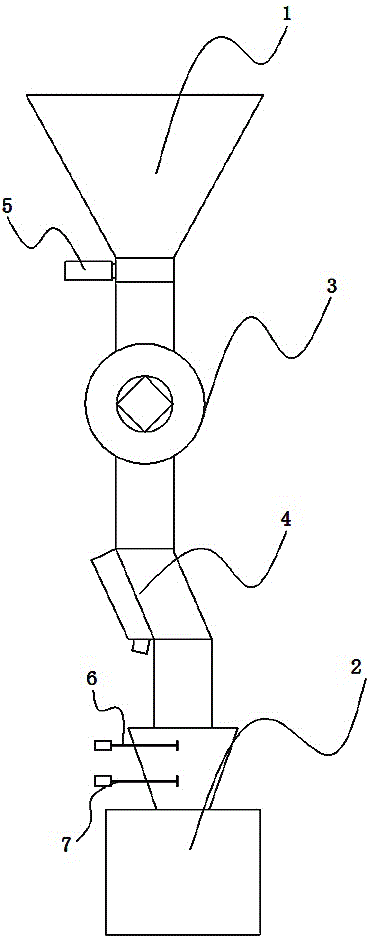

[0028] Such as figure 1 As shown, an intermittent feeding device for powder packaging, which includes a feeding bin 1, a packaging machine 2, an impeller feeding device 3, an anti-rotation level gauge A6, an anti-rotation type level gauge B7 and a pipeline type Ironware 4, the anti-rotation type material level gauge A6 and the anti-rotation type material level gauge B7 are all installed on the receiving hopper of the packaging machine 2, and the horizontal height of the anti-rotation type material level gauge A6 is higher than the anti-rotation type material level Measure the horizontal height of B7, and the impeller feeding device 3 and the pipeline type iron remover 4 are sequentially arranged on the connecting channel from top to bottom, and a plug valve 5 is installed at the discharge port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com