A method and system for recycling waste glue in viscose production

A glue and viscose technology, which is applied in the fields of rayon recycling, chemical instruments and methods, neutralization water/sewage treatment, etc., can solve the problems of increasing the pressure of environmental protection treatment and waste of viscose, so as to reduce the pressure of environmental protection treatment and reduce production Effects of cost and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

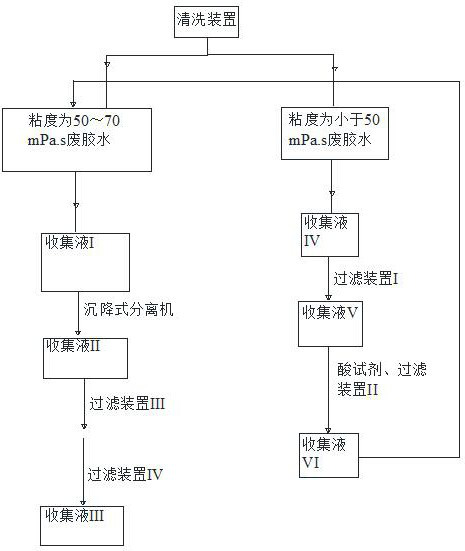

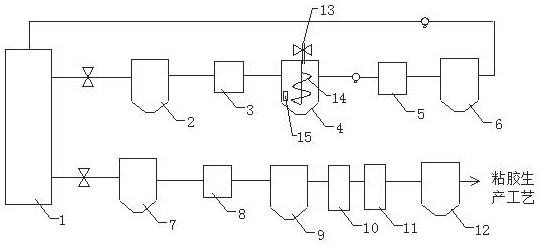

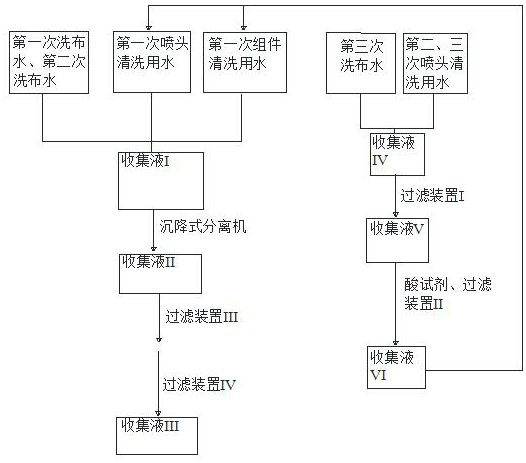

[0033] Refer to attached figure 1 , 2 , a method for recycling waste glue in viscose production, belonging to the field of viscose production, including a method for recycling waste glue with a viscosity of 50 to 70 mPa.s and a method for recycling waste glue with a viscosity less than 50 mPa.s;

[0034] Said viscosity is 50~70mPa.s waste glue recycling method,

[0035] Collect waste glue with a viscosity of 50-70mPa.s. The waste glue comes from the cleaning water of filter cloths, nozzles and components. The temperature of the process environment is controlled at 18-22°C, and then placed in the collection tank I7 to obtain the collected liquid. 1; the collection liquid I in the collection tank 17 is input into the sedimentation type separator 8 again, and the sedimentation type separation machine 8 is 5000r / min operation with the rotating speed, the collection liquid I is separated, and the solid impurities and the collection liquid II are obtained. The solid impurities are...

Embodiment 2

[0042] Compared with Embodiment 1, the difference between this embodiment is that the sedimentation separator 8 separates the collected liquid I at a speed of 6500 r / min.

Embodiment 3

[0044] Compared with Example 1, this embodiment differs in that the filter device III 10 is a filter device III 10 with a filtration precision of 50 μm, and the filter device IV 11 is a filter device IV11 with a filtration precision of 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com