Patents

Literature

91results about How to "Will not cause blockage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorption product with core of double-layer structure and manufacturing method of absorption product

The invention belongs to the field of personal hygienic products, and discloses an absorption product with a core of a double-layer structure and a manufacturing method of the absorption product. The absorption product comprises a fluid permeability surface layer, a non-fluid-permeability bottom layer and the absorption core between the fluid permeability surface layer and the non-fluid-permeability bottom layer, wherein the absorption core comprises an upper layer and a lower layer; the upper layer is a double-combed and double-formed fluffy sheet; the fluffy sheet of the upper layer is divided into a dense surface and a fluffy surface; the lower layer of the absorption core is a dense sheet; the fluffy surface of the fluffy sheet and the dense sheet of the lower layer are bonded together; macromolecule water-absorbing particles or fibers of the absorption core are evenly distributed between the fluffy surface and the dense sheet of the lower layer. The absorption product has the advantages of being capable of rapidly absorbing liquid and diffusing liquid, good in air permeability and good in closed-fit performance.

Owner:湖南倍健卫生用品有限公司

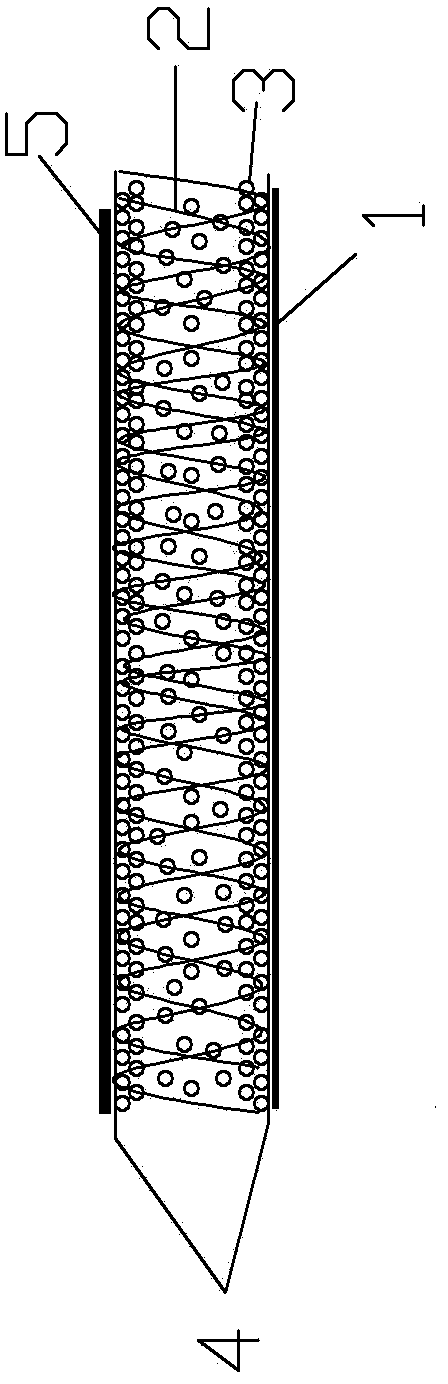

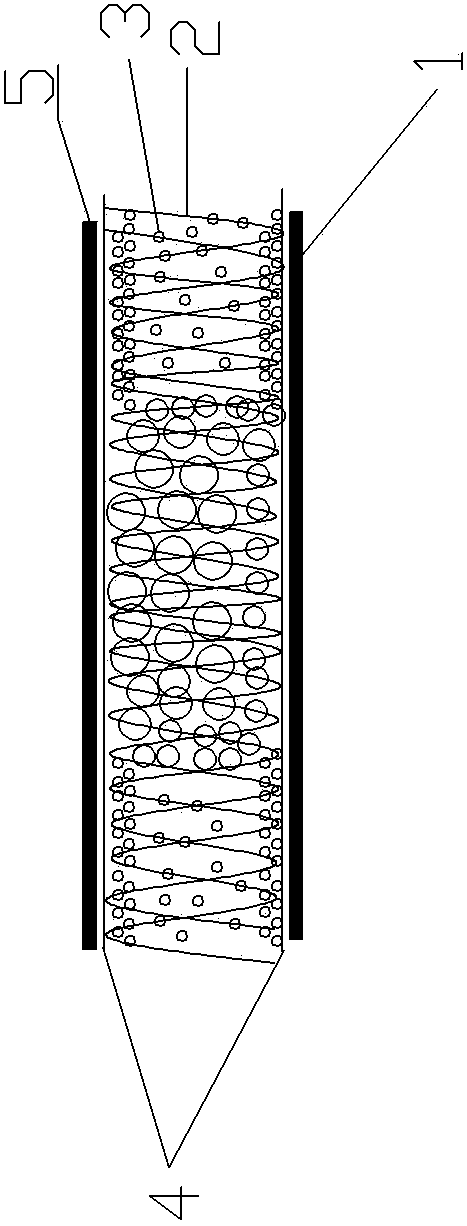

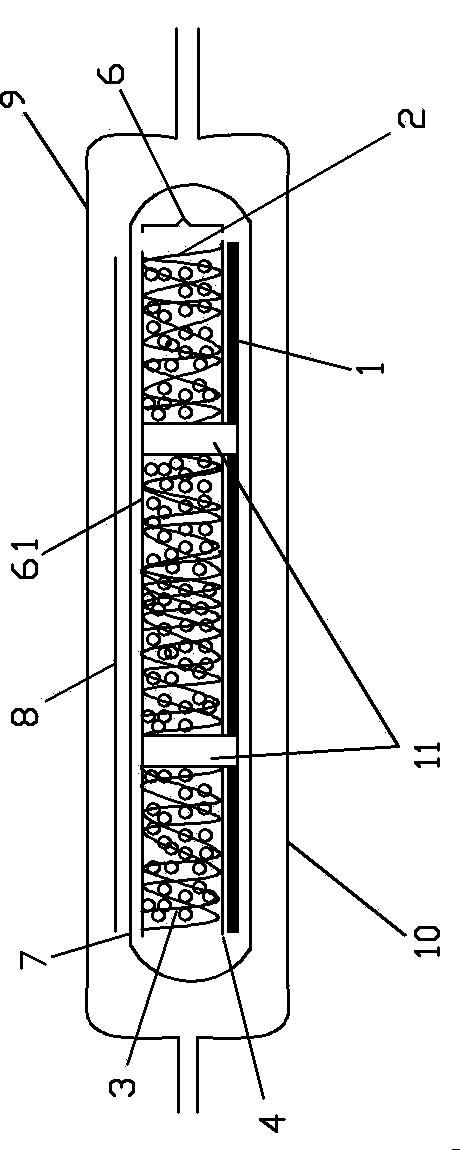

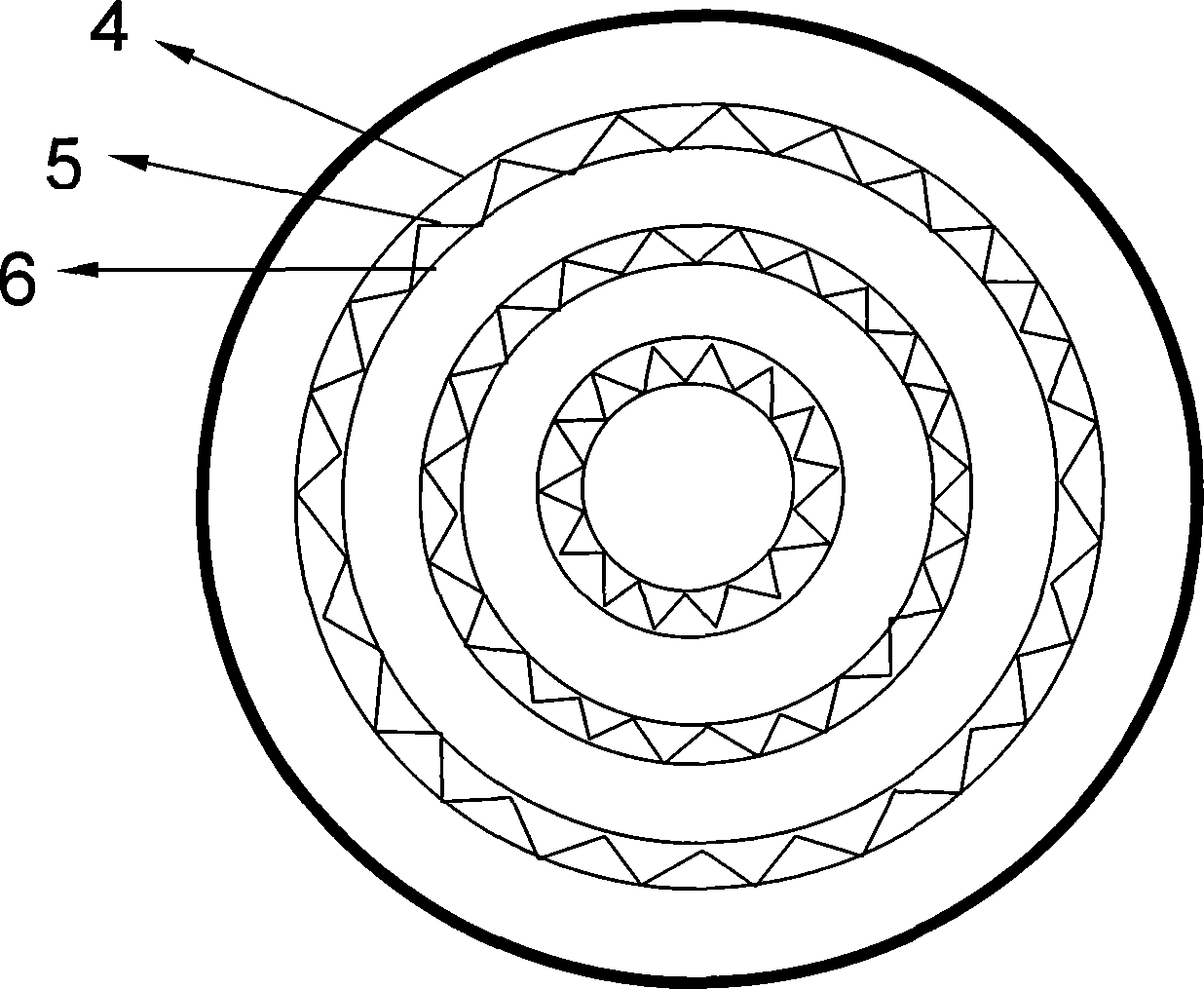

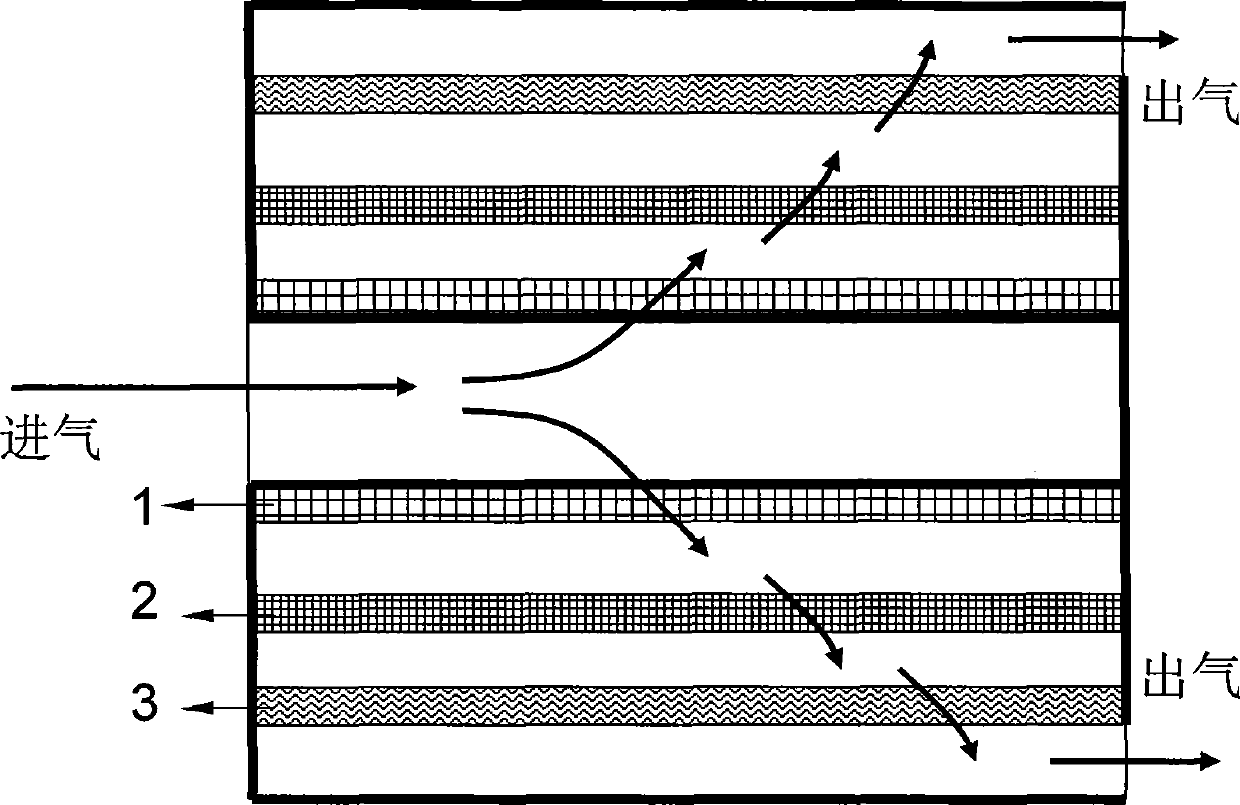

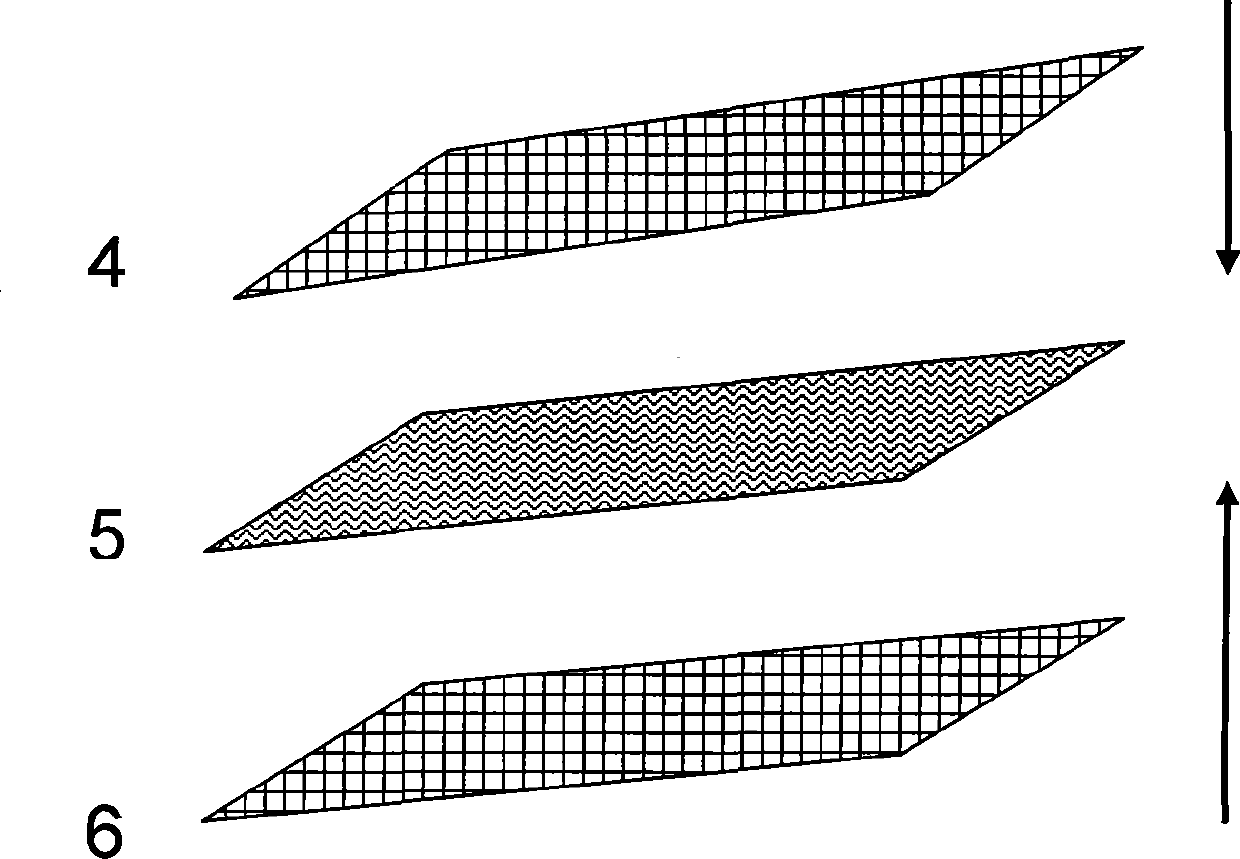

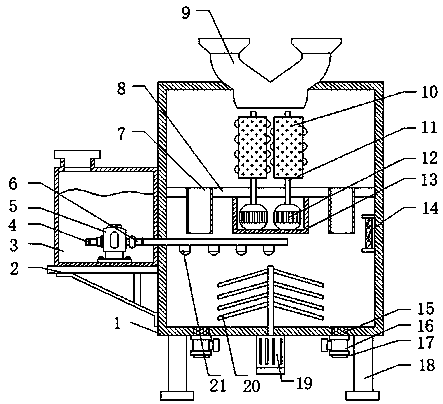

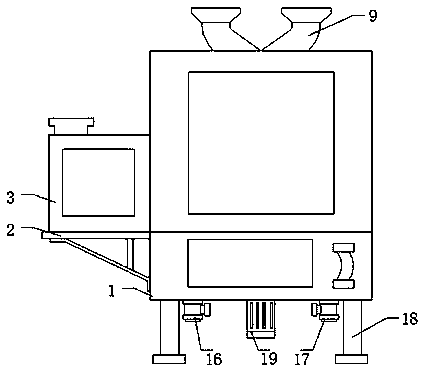

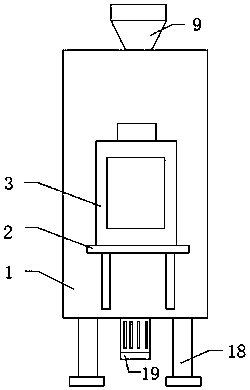

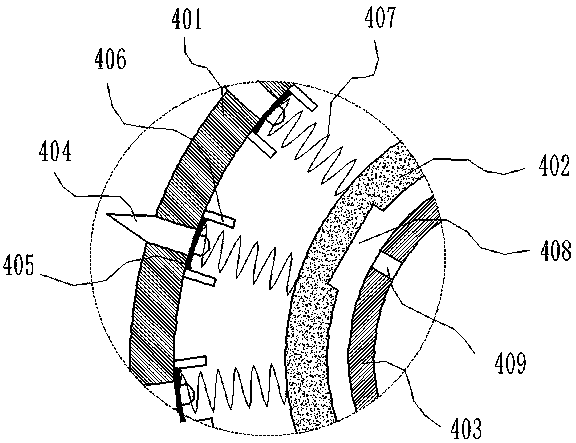

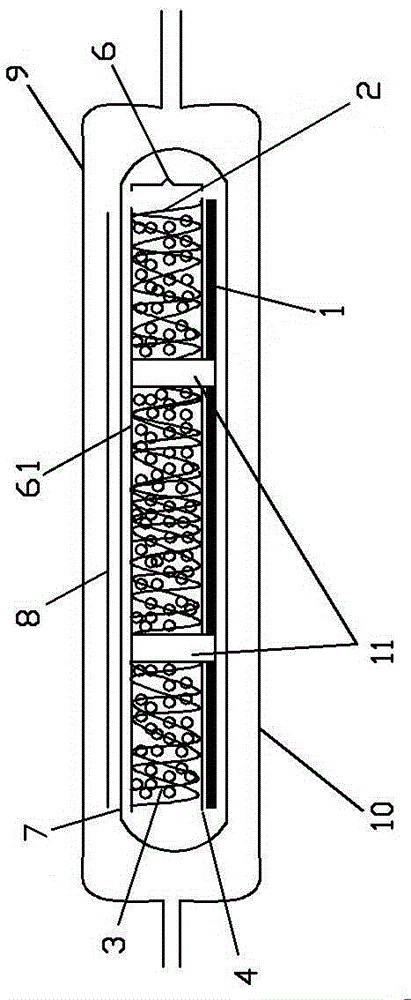

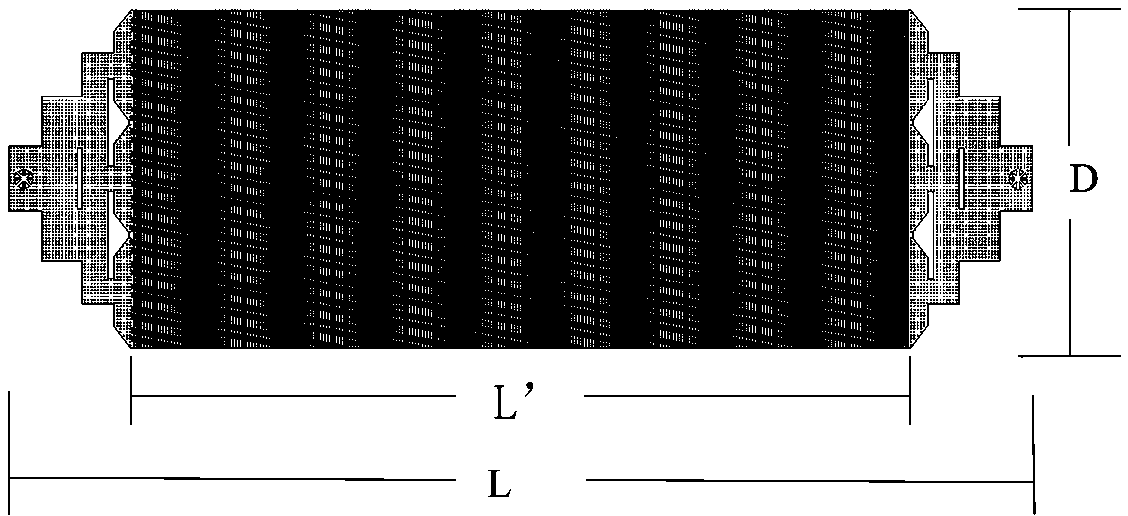

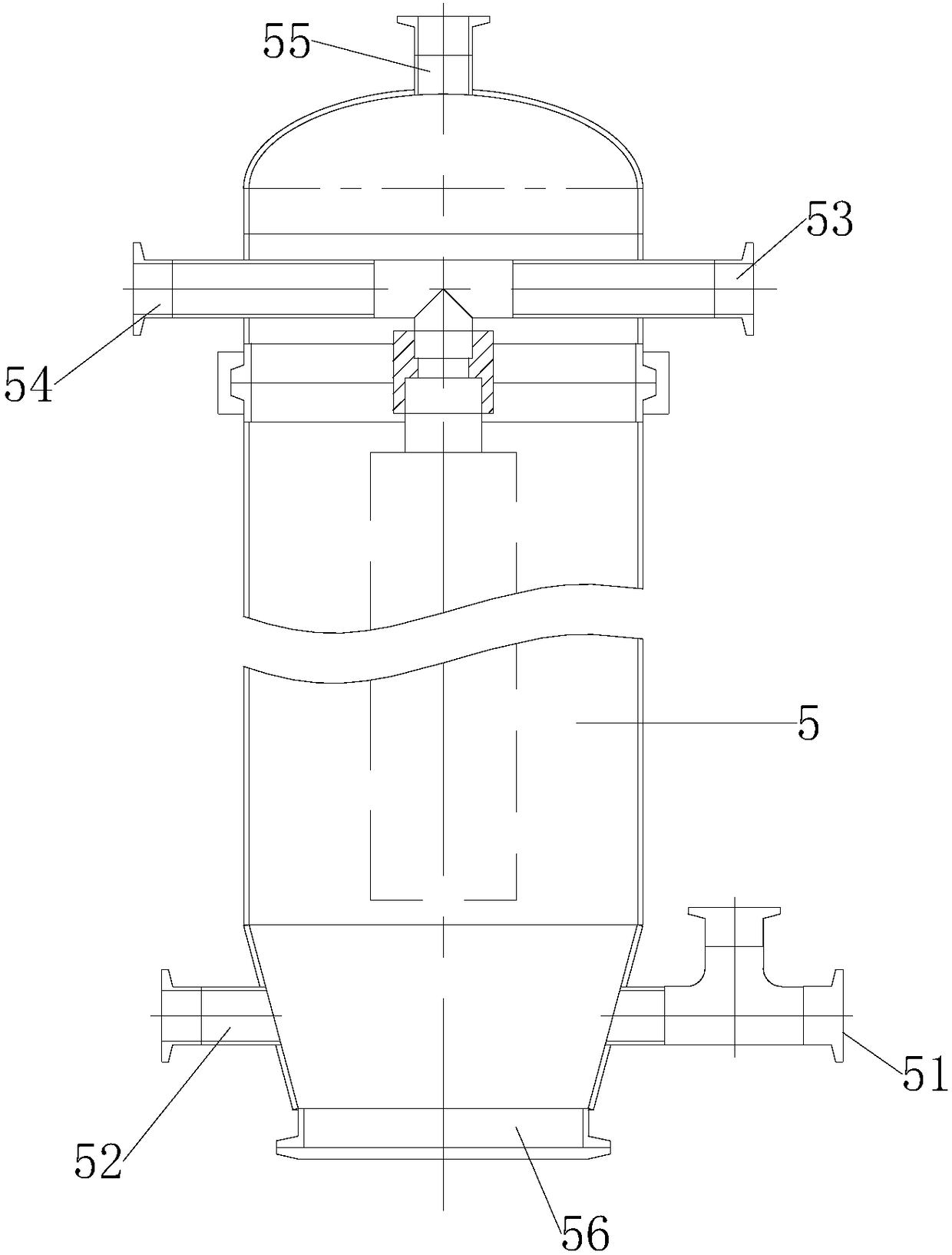

Post-treatment purifier for internal combustion engine particle emission

InactiveCN103861396AReduce filtration efficiencyImprove filtration efficiencyDispersed particle filtrationExhaust apparatusParticulatesFiltration

The invention provides a post-treatment purifier for internal combustion engine particle emission, and belongs to the technical field of environmental protection. The purifier is characterized by employing coercive means of circulation to change the exhaust path, so that all the exhaust passes through the filter; at the same time, the purifier employs filter combination with different trapping efficiencies (material, shape, density), so that smoke or / and particles with different particle sizes are respectively trapped to improve the trapping efficiency; and the purifier solves the problem of the surge of exhaust backpressure caused by rapid accumulation of smoke or / and particle in a trap device for internal combustion engine particle discharge of the prior art. Regeneration of particles can be carried out in any continuous or / and intermittent regeneration mode, such as filter catalyst coating, or be combined with other regeneration mode. The purifier reaches an overall filtration efficiency range as wide as 30-90%, and can be used as post-treatment purifier for a variety of internal combustion engine particle emission. After loading on a diesel engine, the particle emission can reach higher than grade four in national standard.

Owner:北京英泰世纪环境科技有限公司

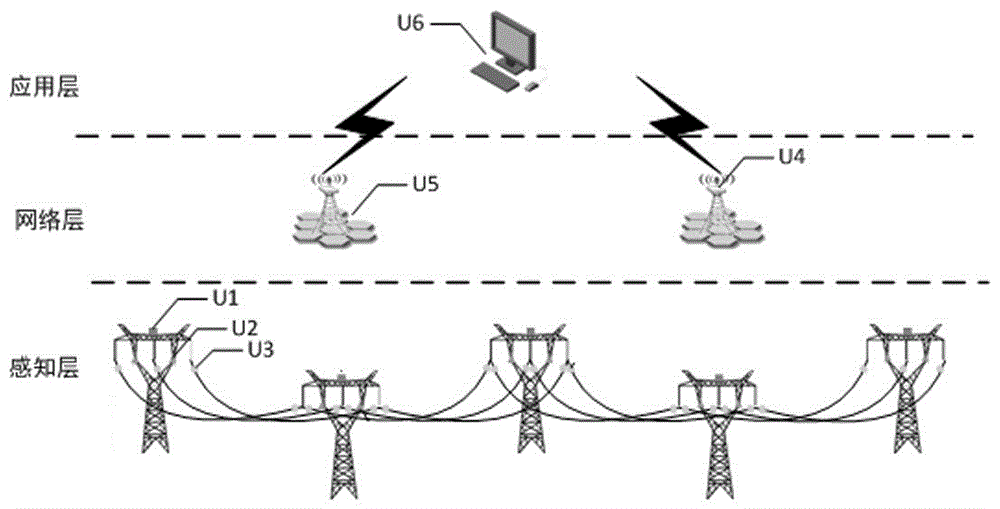

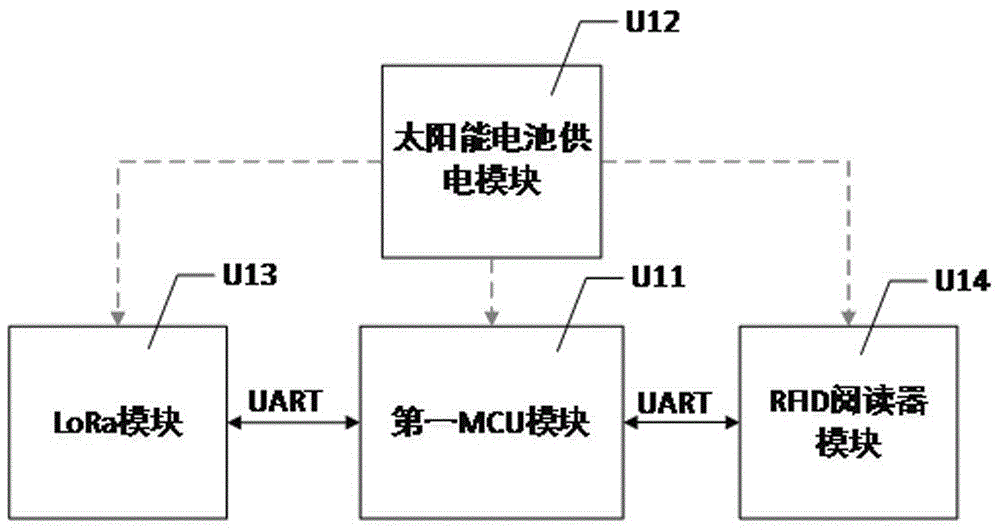

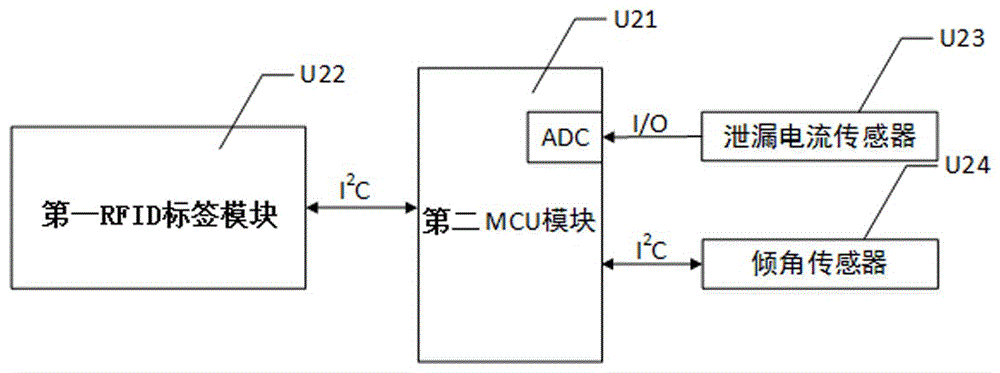

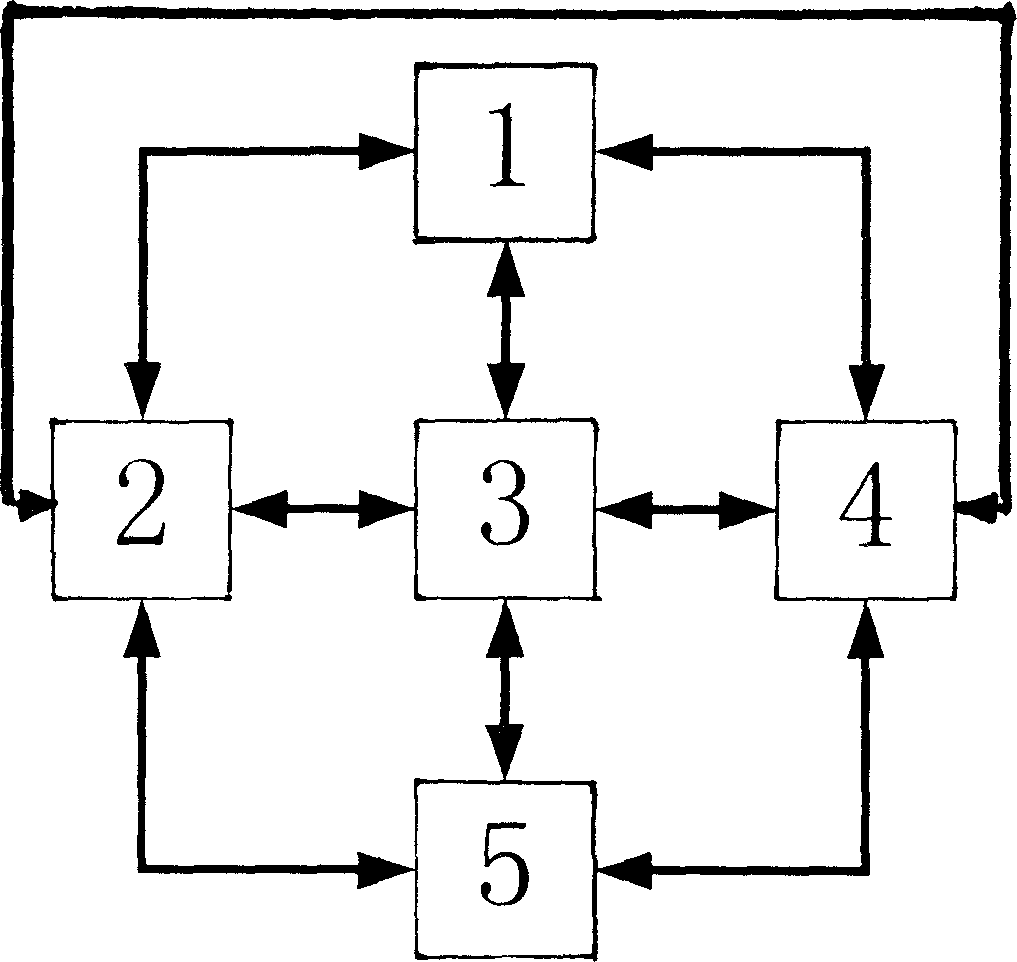

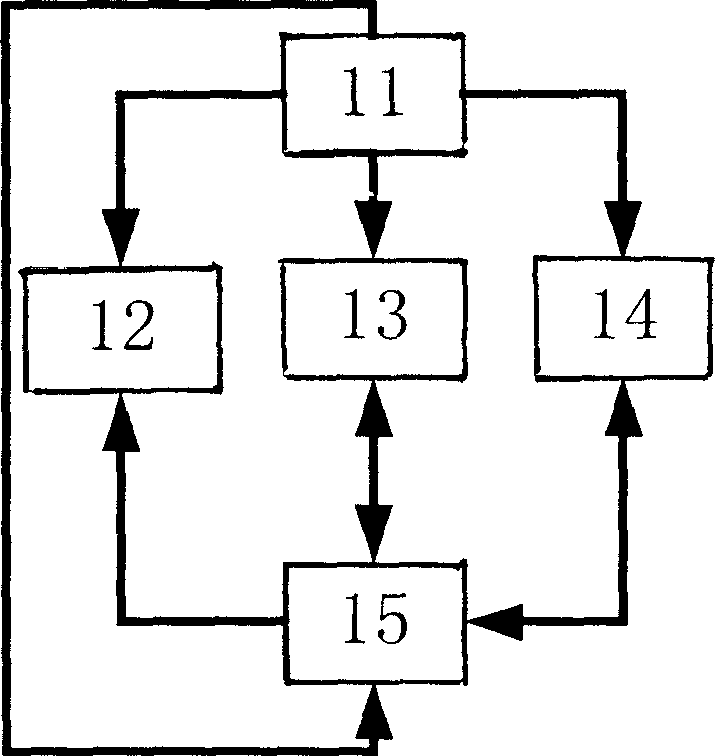

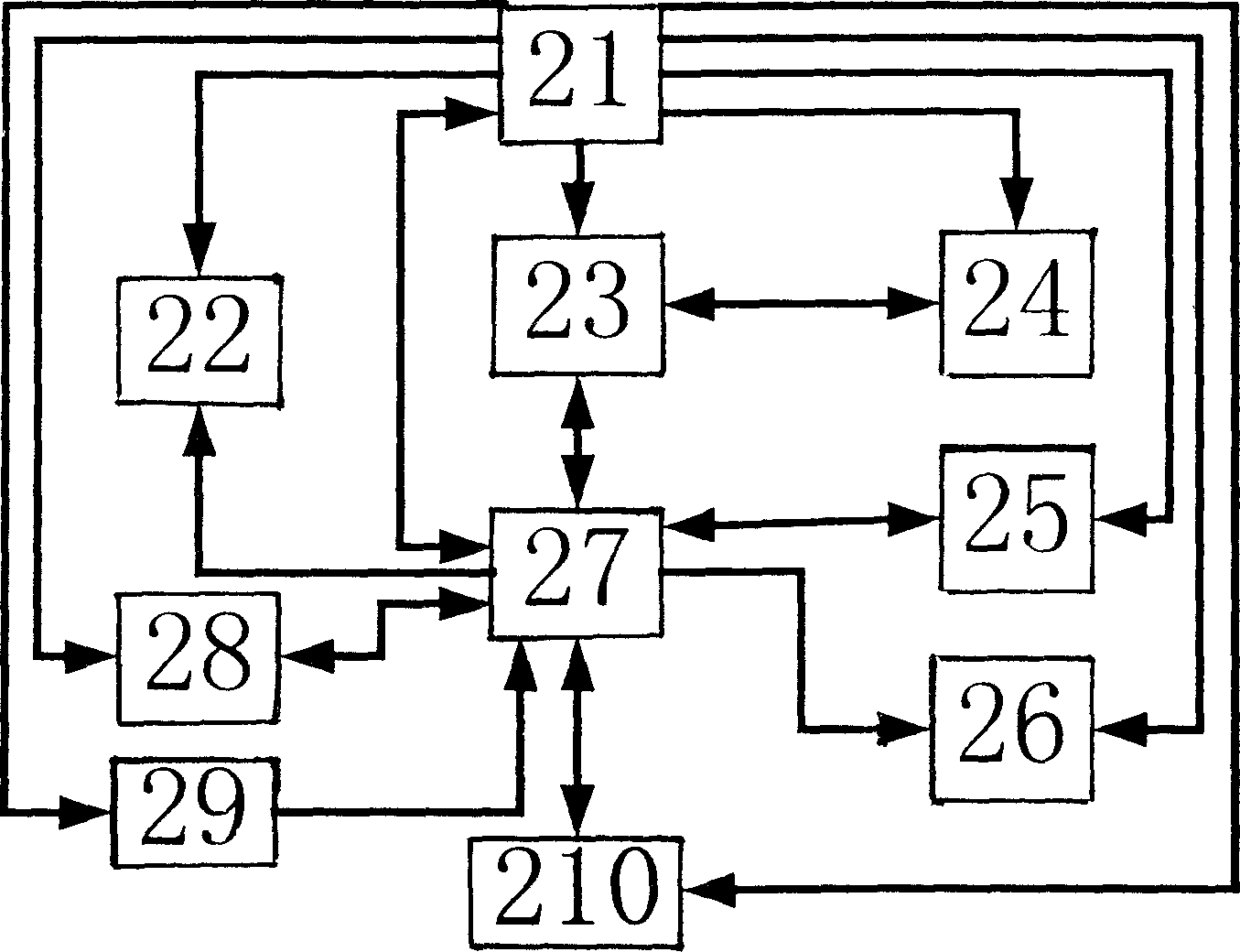

Power transmission line equipment online monitoring network system based on RFID and LoRa

InactiveCN106790643AWill not cause blockageLow costMeasurement devicesTransmission systemsTransfer procedureNetwork packet

Provided is a power transmission line equipment online monitoring network system based on RFID and LoRa. The system comprises a data forwarding module, a rod and tower state monitoring module, an electric transmission line state monitoring module, a LoRa gateway, a mobile communication tower and a monitoring center. The data forwarding module is used for receiving a rod and tower state data package and an electric transmission line state data package, packaging the rod and tower state data package and the electric transmission line state data package to be a first data package of the power transmission line equipment, and transmitting the first data package to the LoRa gateway; the rod and tower state monitoring module is used for packaging the monitored rod and tower state information to be the rod and tower state data package; the electric transmission line state monitoring module is used for packaging the monitored electric transmission line state information to be the electric transmission line state data package. The mobile communication tower is used for packaging the first data package of the power transmission line equipment to be a second data package of the power transmission line equipment and transmitting the second data package into the monitoring center. According to the power transmission line equipment online monitoring network system based on the RFID and the LoRa, technologies of the RFID and the LoRa are adopted, the cost is low, direct communication with the LoRa gateway can be conducted without an ad-Hoc network, and the information blocking or time delay generated in the transmission process does not caused.

Owner:HEFEI UNIV OF TECH

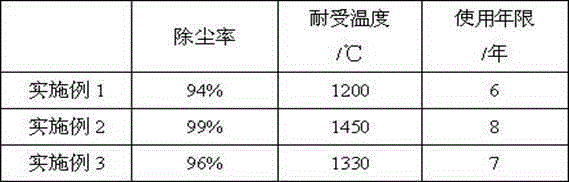

Electrostatic dust collection adsorption film and production method thereof

InactiveCN105017677AExtended service lifeSave the trouble of frequent replacementPolymer sciencePolyethylene terephthalate glycol

The invention discloses an electrostatic dust collection adsorption film and a production method thereof. The film is mainly produced from, by weight, 8-25 parts of negative oxygen ion powder, 23-40 parts of polyvinyl chloride, 14-35 parts of polyethylene glycol terephthalate, 12-34 parts of active carbon nanoparticles, 14-33 parts of polycarbonate, 6-27 parts of dimethyl ammonium formate, 5-36 parts of methyl acrylate, 12-22 parts of polyacrylamide and 25-40 parts of polyethylene glycol. Compared with films in the prior art, the electrostatic dust collection adsorption film produced in the invention has the advantages of long service life, omission of the frequent replacement trouble, no obstruction to devices, and no consumption of excess energy in the dust collection process.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

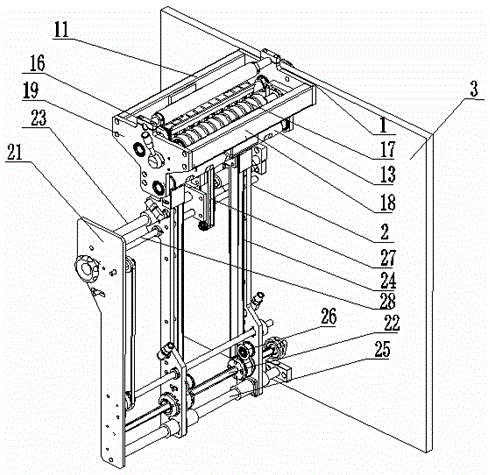

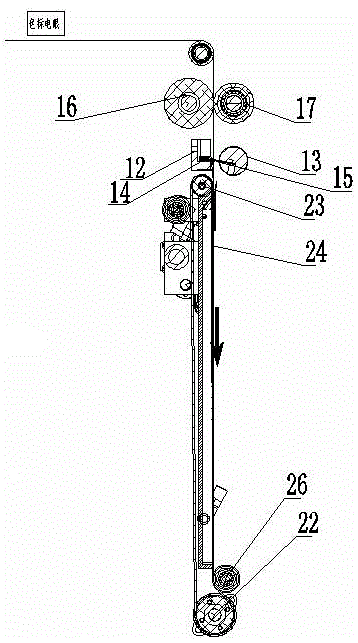

Film cutting and pulling method suitable for material packaging

ActiveCN105059606AReduce downtimeReduce laborWrapping material feeding apparatusEngineeringMechanical engineering

The present invention discloses a film cutting and pulling method suitable for material packaging, and relates to the technical field of material packing techniques. The film cutting and pulling method comprises cutting a packaging film in a transportation process of the packaging film. In comparison with the conventional packaging methods, film cutting time is saved, and the packaging speed is thus raised. When the method is used for packaging materials of different specifications, the position of a film cutting mechanism does not need to be adjusted, the length of the packaging film only needs to be set in the system, and thus precision cutting of the packaging film can be carried out; and during packaging of materials of different specifications, time for adjusting machinery equipment is saved, and thus the efficiency of the whole packaging process is raised.

Owner:上海松川峰冠包装自动化有限公司

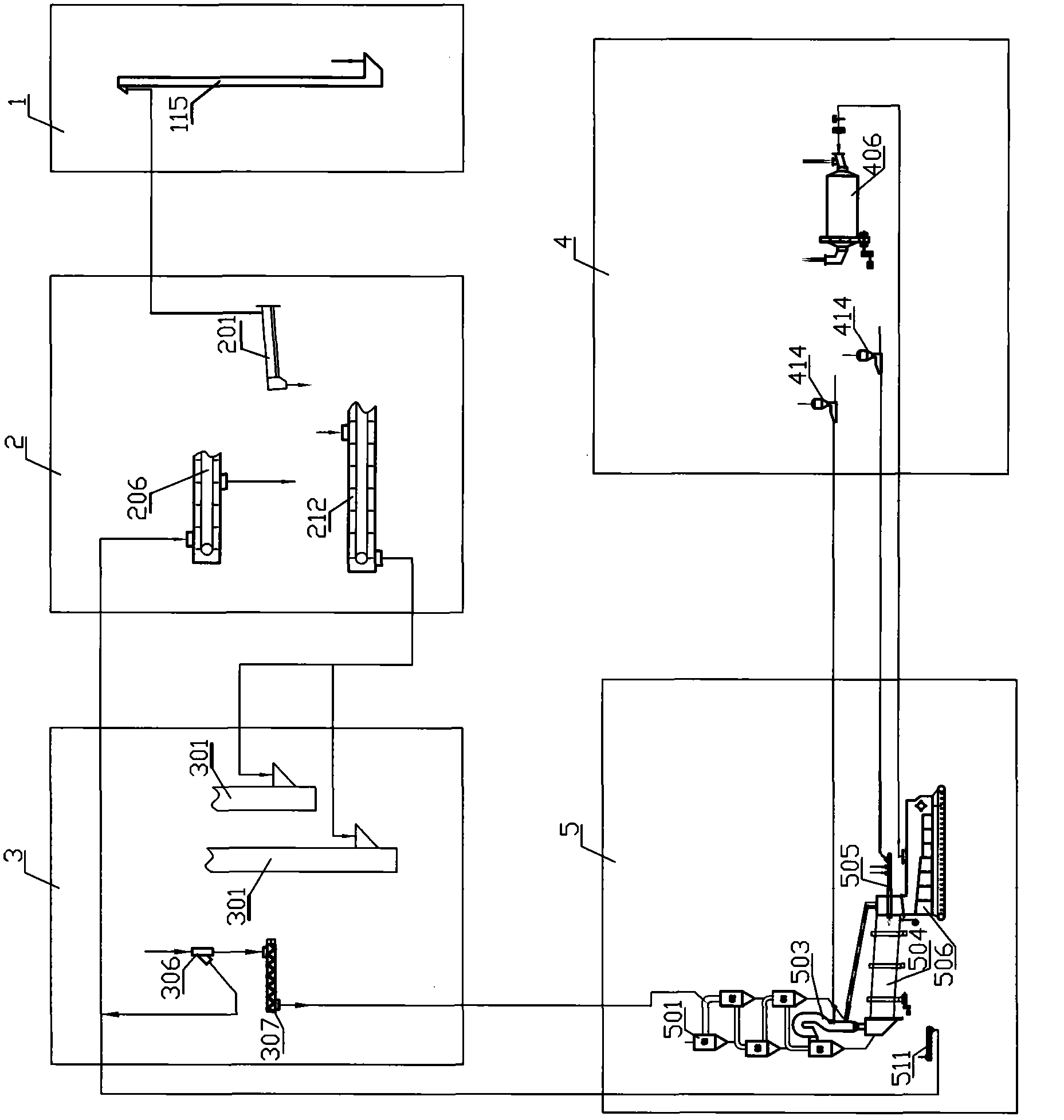

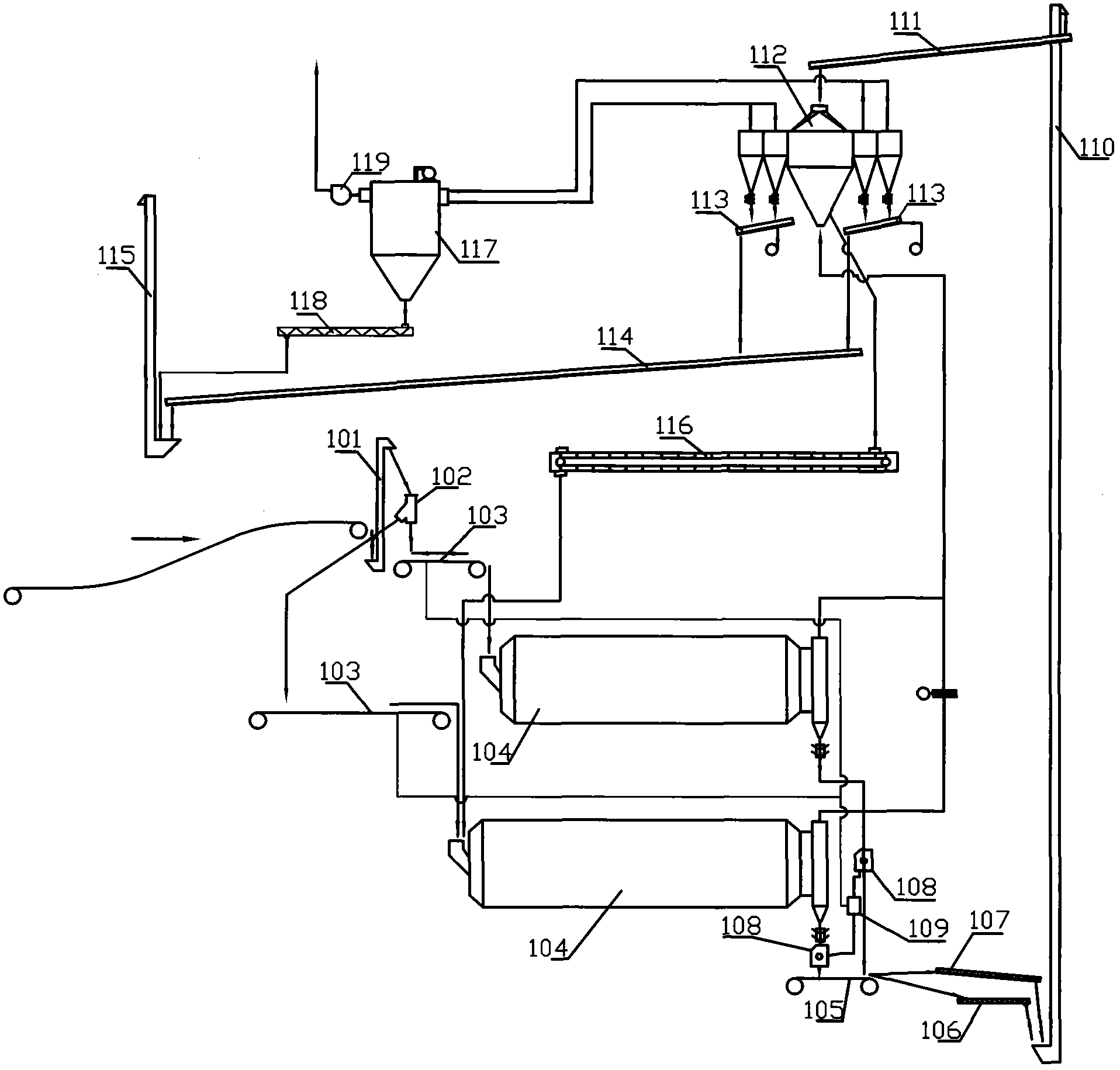

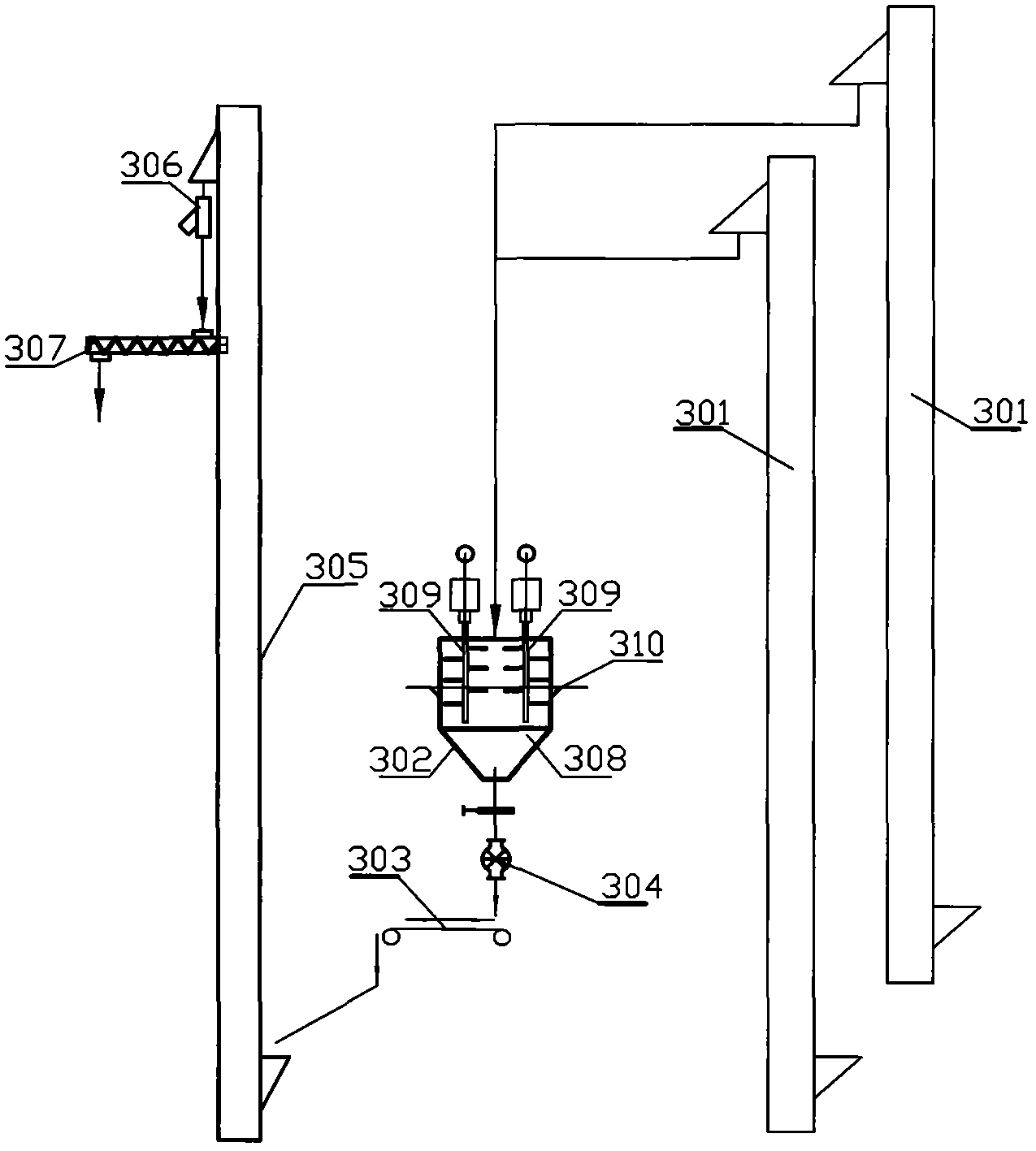

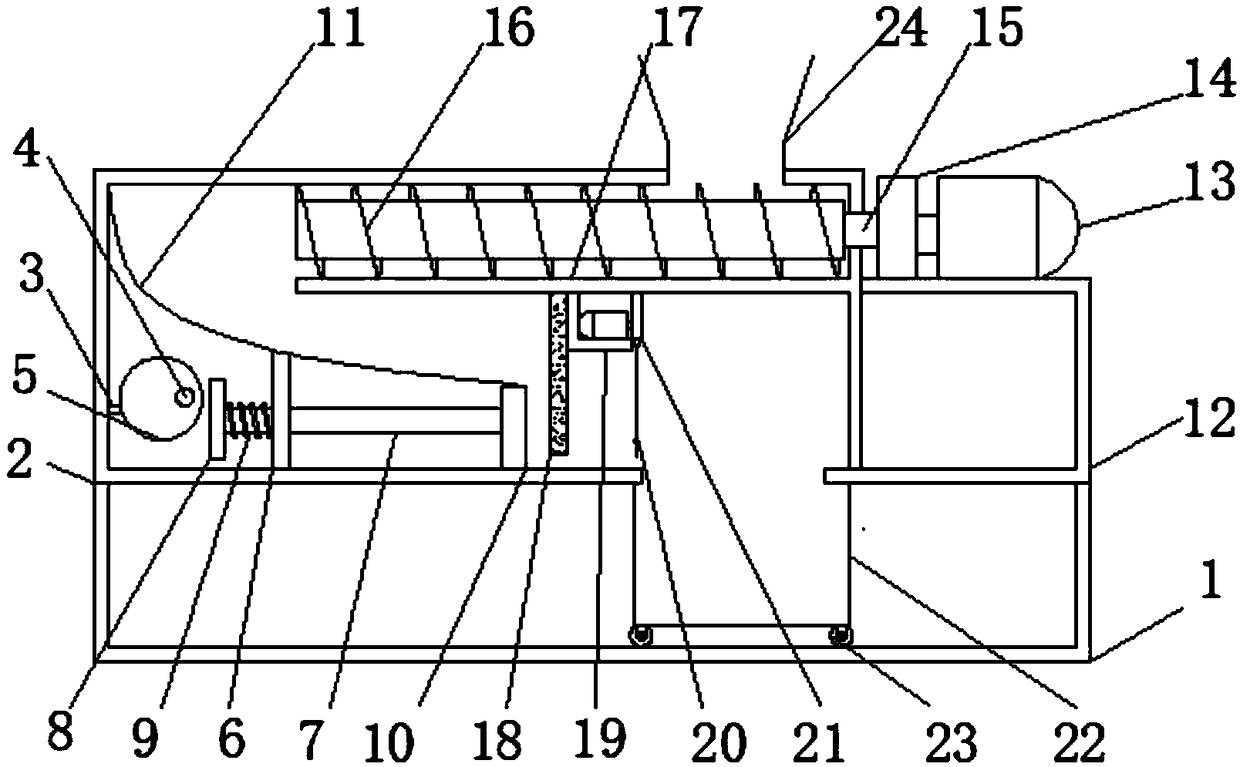

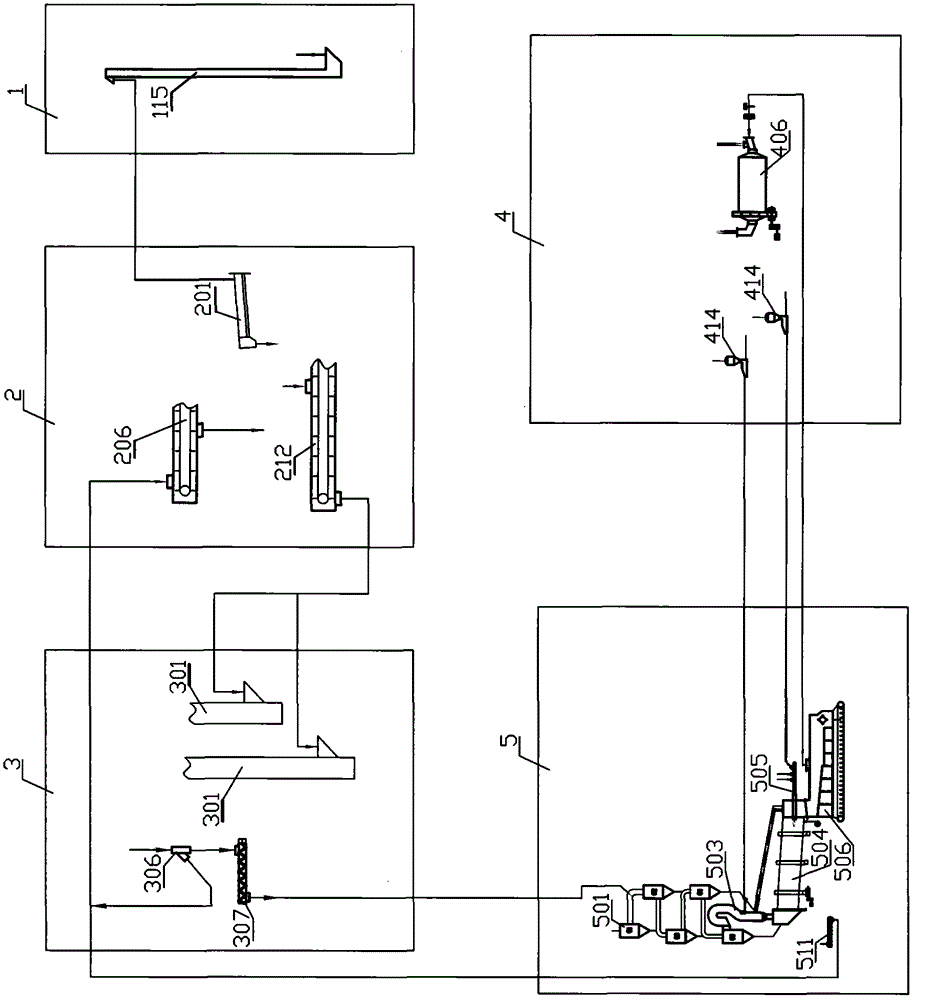

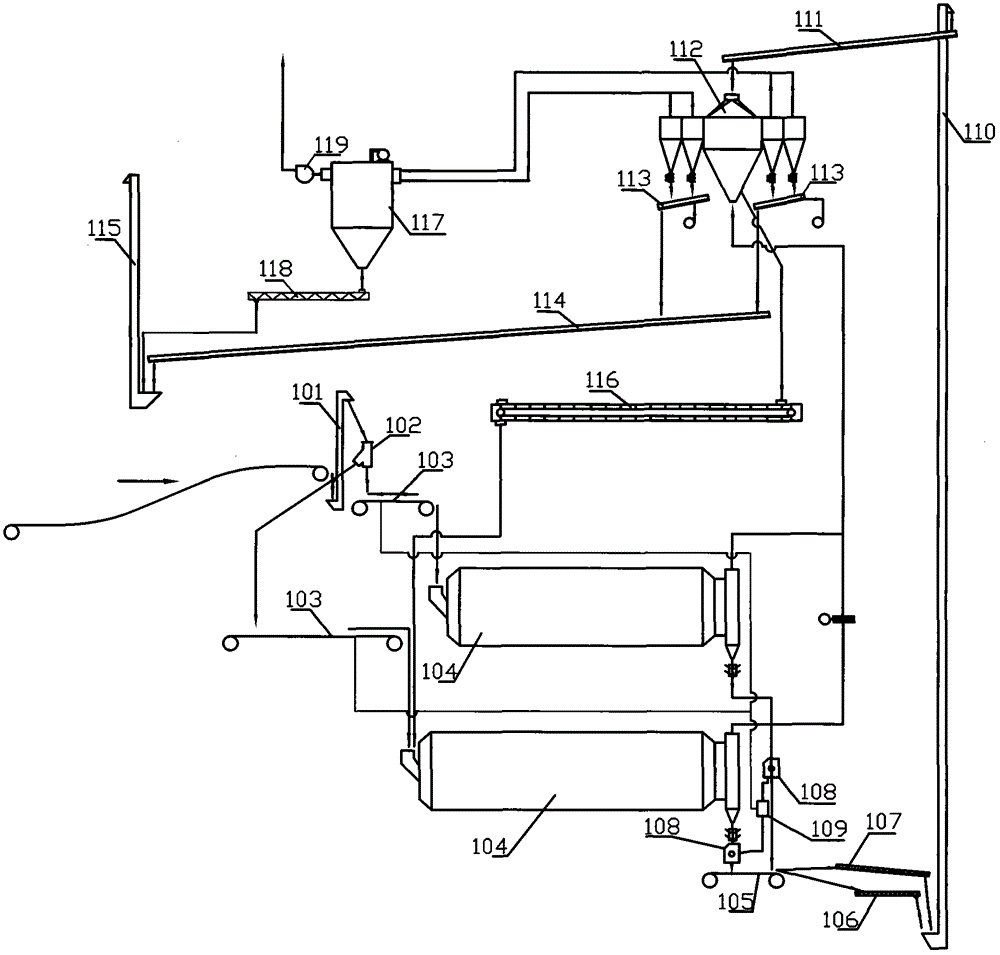

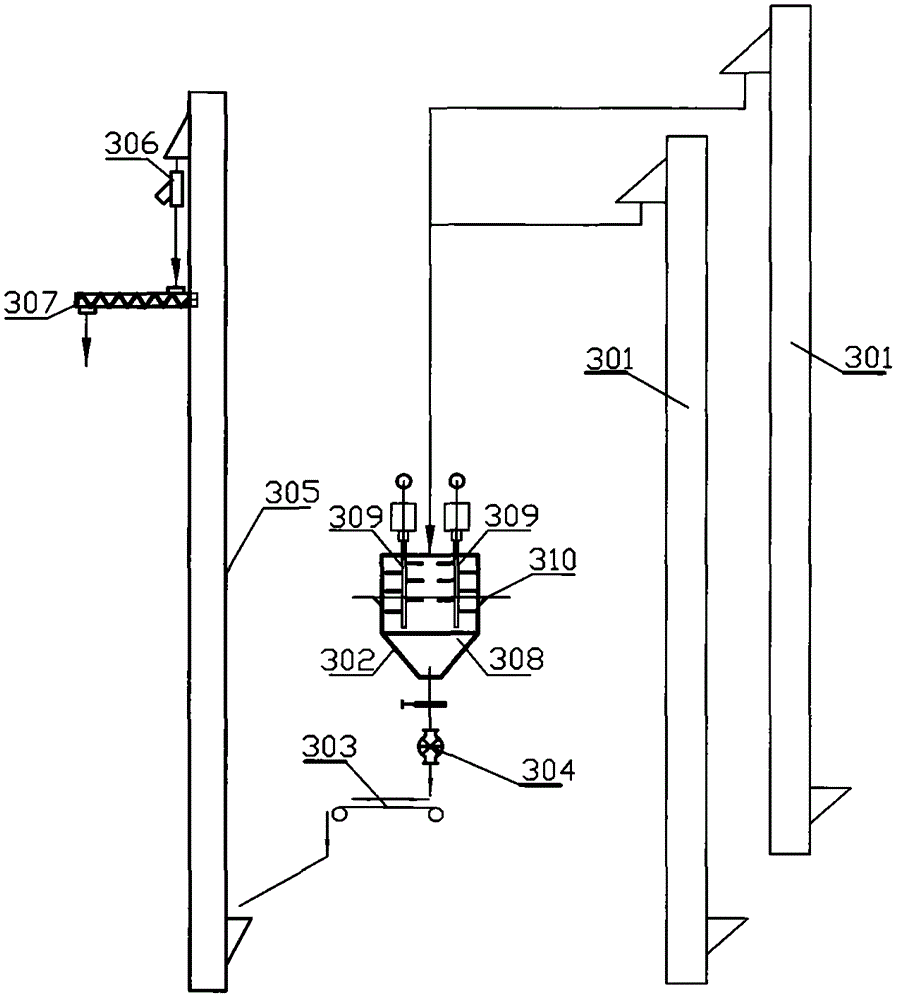

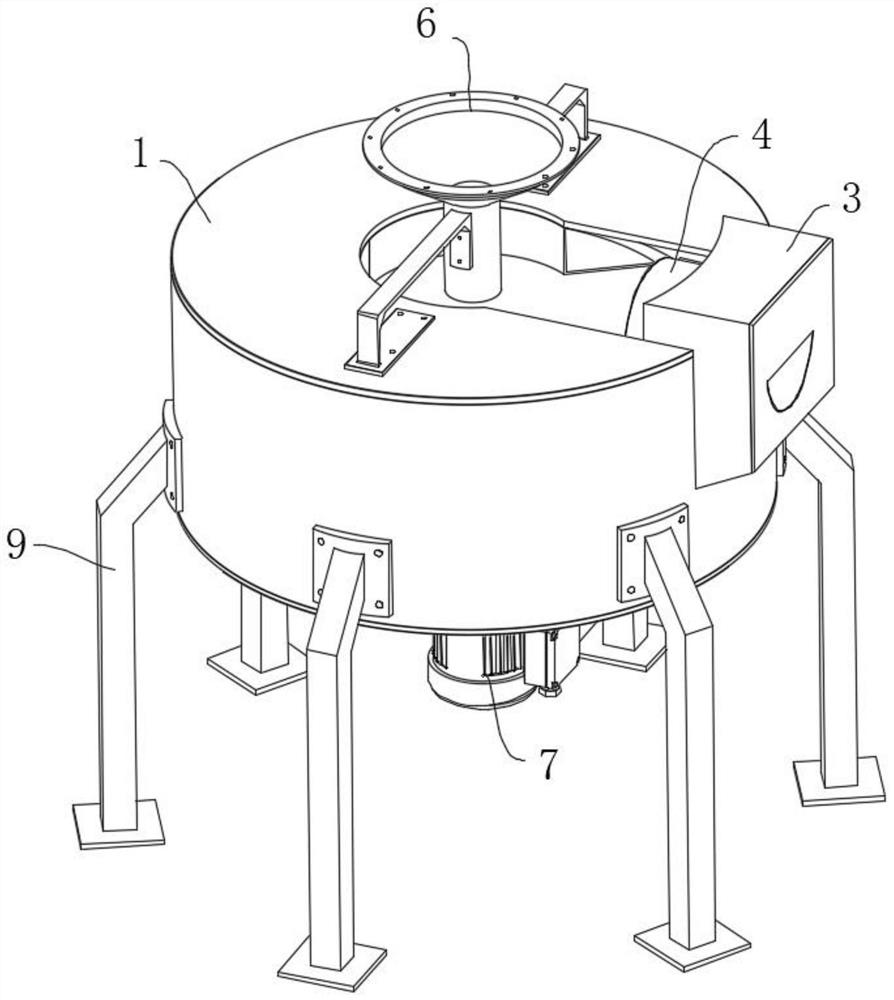

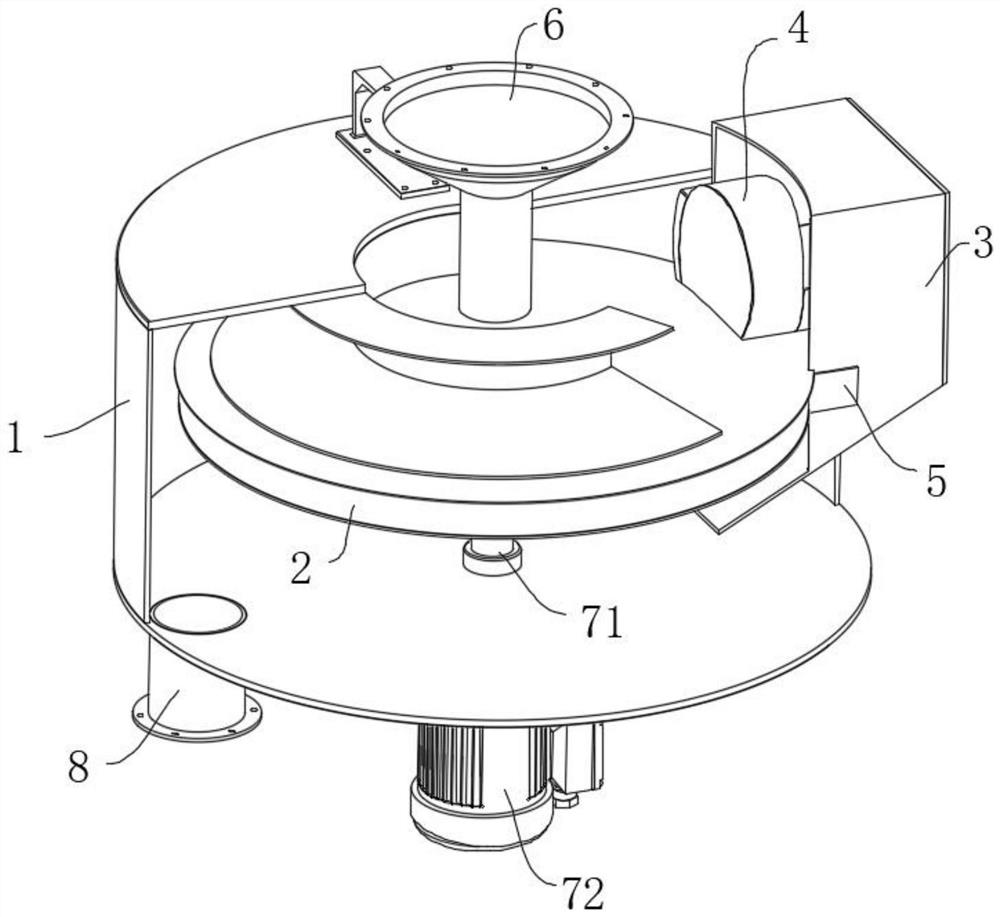

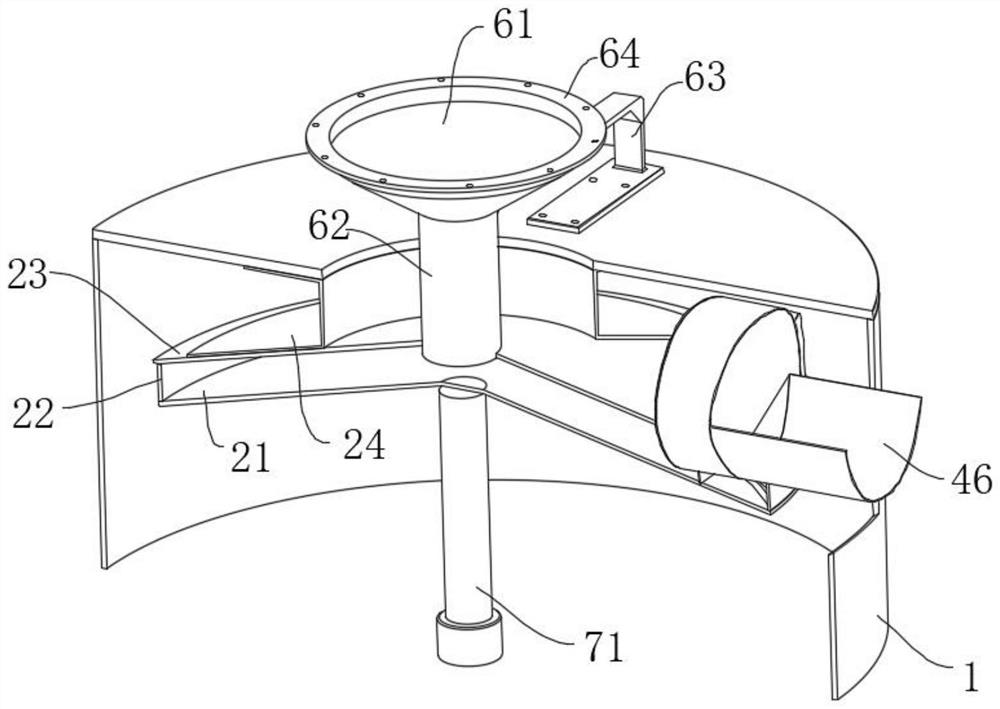

Energy-saving and environment-friendly cement clinker preparation system

ActiveCN103351106AUniform and stable qualityQuality improvementClinker productionDecompositionScrew conveyor

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

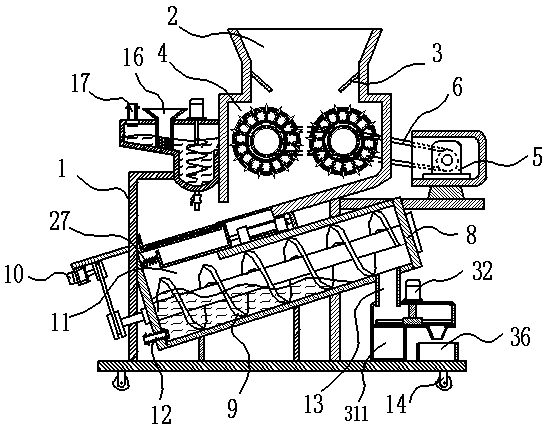

Textile broken material recovery device for textiles

PendingCN109234854ALess time to enterEasy to collectTextile disintegration and recoveryFibre disintegrationDrive shaftEngineering

The invention discloses a broken textile material recovery device for textiles. The device comprises a box body, a feeding pipe is welded to the outer wall of the top of the box body, a partition plate is welded to the inner wall of one side of the box body, a motor box is welded to the middle of the outer wall of the bottom of the partition plate, the inner wall of the bottom of the motor box isfixedly provided with first motors equidistantly distributed through bolts, a first transmission shaft is welded to the top of an output shaft of each first motor, first through holes are equidistantly distributed in the portion, close to the first motors, of the outer wall of the bottom of the partition plate, and the first transmission shafts are communicated with the upper portion of the box body through the first through holes. According to the broken textile material recovery device for the textiles, broken materials, leftover materials and the like are crushed into small uniform pieces again, subsequent treatment and placement are facilitated, the occupied area is reduced, more broken textile materials are conveniently stored, the practicability of the device is improved, the brokentextile materials are separated from sundries, debris and the like, cloth is cleaned and dried, storage is facilitated, and the environment is prevented from being contaminated.

Owner:江苏四方纺线有限责任公司

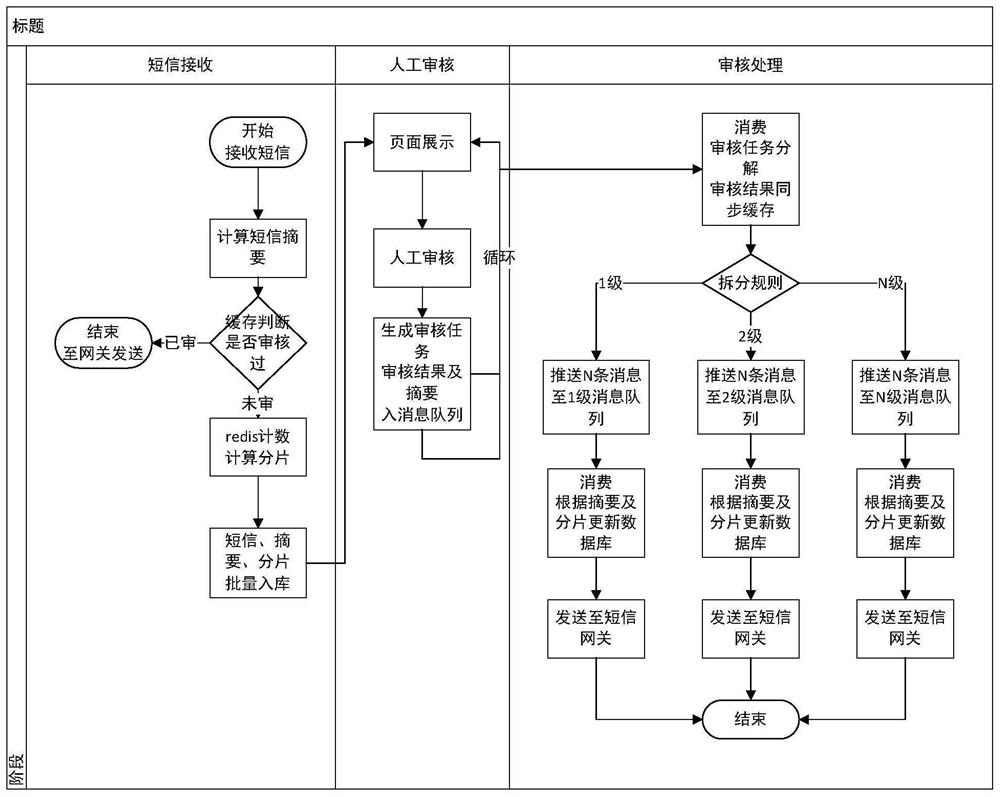

Method and device for auditing short message text based on distributed high concurrency condition

ActiveCN111628859AImprove processing powerWill not cause blockageDatabase updatingEncryption apparatus with shift registers/memoriesText messagingEngineering

The invention relates to the technical field of short message text auditing, in particular to a method and device for auditing a short message text based on a distributed high concurrency condition. The method comprises: asynchronously updating a database short message record during manual auditing, and directly returning a page to audit a next short message without waiting; carrying out task grading processing: dividing a large task into a plurality of sub-tasks, quantitatively updating database information by the sub-tasks in batches so that database blocking cannot be caused; customizing decomposition rules and message queue levels so that different types of short messages enter the message queues of different levels, and the short messages cannot be blocked in the message queues; and receiving the auditing short message and carrying out auditing processing, carrying out transverse capacity expansion in a server adding mode when meeting a performance bottleneck so that the processing capacity is improved.

Owner:上海创蓝云智信息科技股份有限公司

Environment-friendly rubber extruder

The invention provides an environment-friendly rubber extruder, and relates to the field of rubber extruders. The environment-friendly rubber extruder comprises a base, wherein a shell is fixedly arranged at the top of the base, and the left side of the inner wall of the shell is fixedly provided with a motor table; the top of the motor table is fixedly provided with a first motor, and the outputend of the first motor is movably connected with a turntable; a bracket is fixedly arranged at the bottom of the inner wall of the shell, and a push rod is inserted into the bracket; a spring sleevesthe push rod. According to the environment-friendly rubber extruder, a second motor drives a threaded push rod to rotate, a raw material is extruded on the push rod table and the top of the inner wallof the shell, the first motor drives the turntable to rotate, a push block drives the push rod to move right, the push rod drives a pressing block to move right, and the pressing block extrudes the raw material and is recovered after completion; a cutter is fixedly arranged at the bottom of a lifting device to move up and down to complete the cutting of rubber; in the quick production process, the situation that clogging is caused by the rubber in the extruder to affect production quality and production efficiency is avoided.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

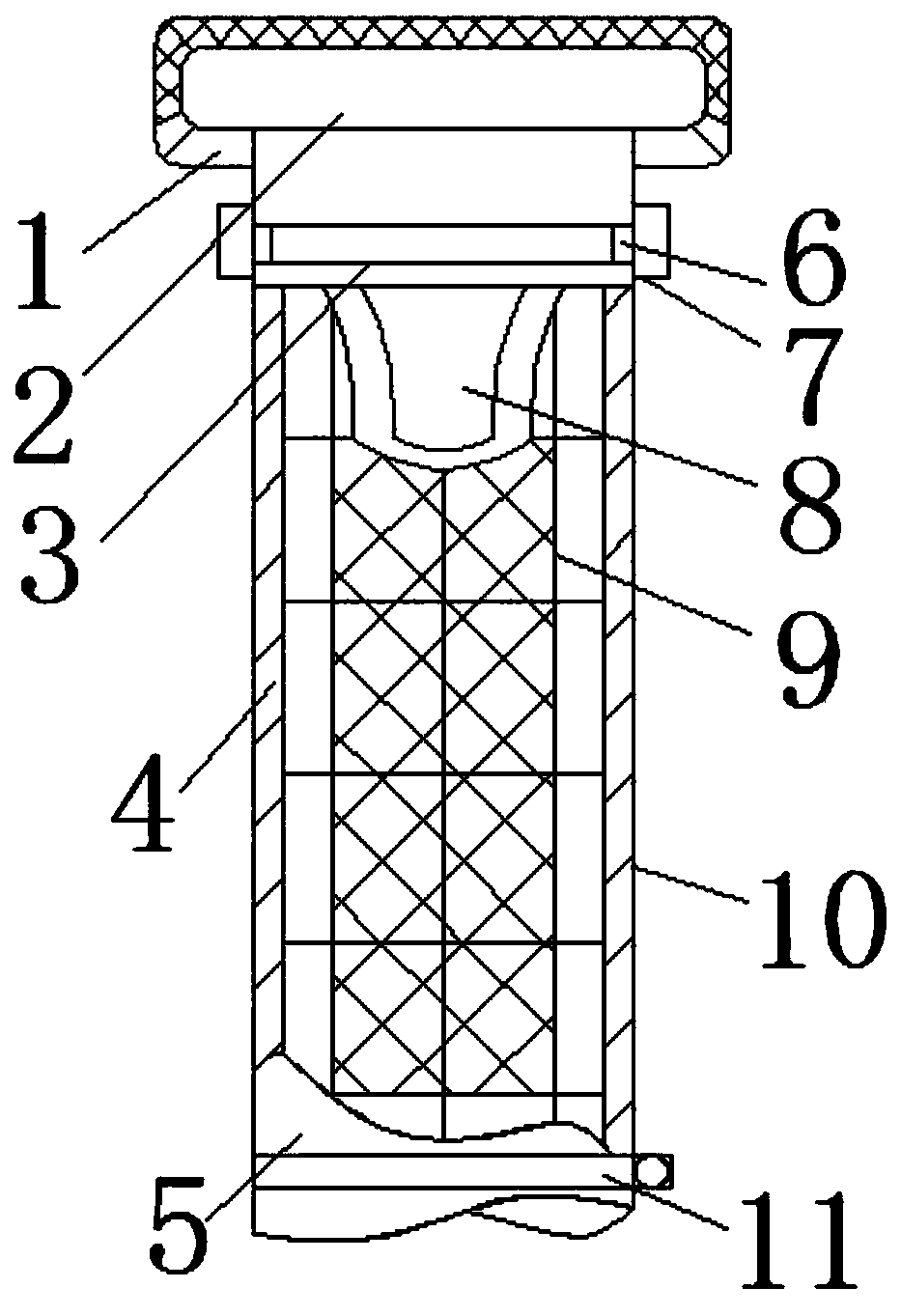

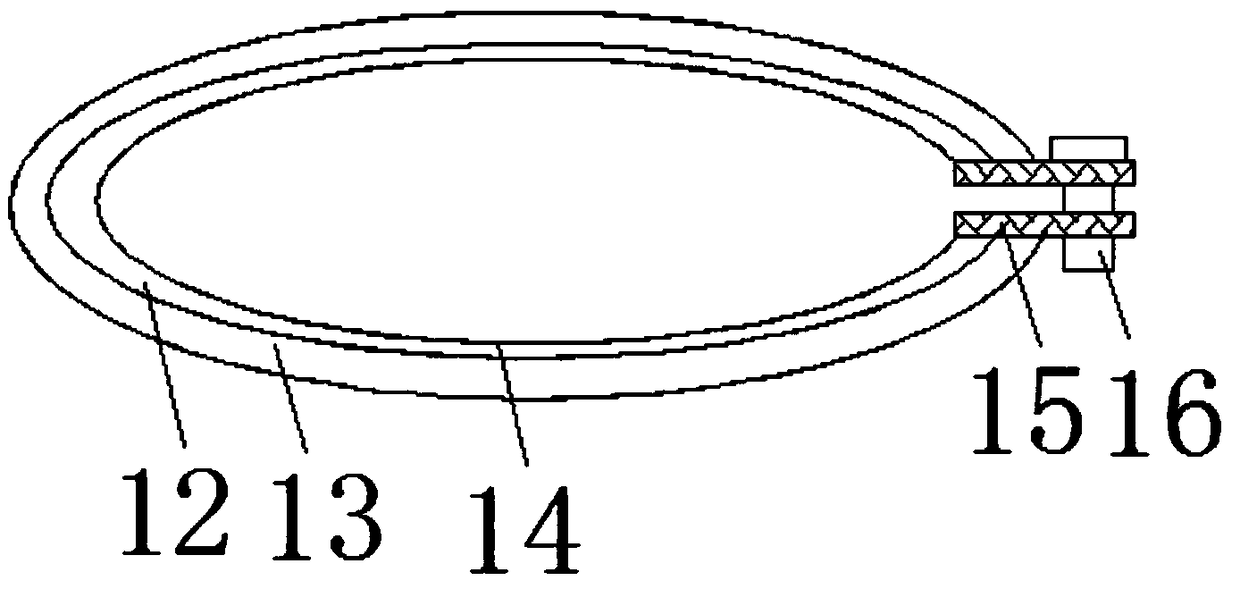

Filter bag structure of dust collector

InactiveCN108744769AWill not cause blockageGood strength and toughnessDispersed particle filtrationEngineeringDust collector

The invention discloses a filter bag structure of a dust collector. The filter bag structure of the dust collector comprises a base; one end of the base is connected with a fixing head; an air-vent port is formed in the center of the fixing head; a bag cage is fixed at the bottom of the air-vent port; the periphery of the bag cage is connected with a filter bag main body; a filter bag head is integrally formed at one end of the filter bag main body; a rubber band is embedded inside the filter bag head; the rubber band is arranged in an annular groove in a sleeving manner; the annular groove isformed in the periphery of the fixing head; the outer side of the filter bag head is clamped and connected with a hoop; the inner side of the hoop is fixed with a clamping block corresponding to theannular groove; and the inner wall of the clamping block is fitted with a rubber pad; according to the invention, through the arranged hoop and a stainless steel clamping ring, the filter bag head andthe fixing head are fixed by the cooperation of the hoop and the annular groove, and the bottom end of the filter bag main body is matched and connected with the bag cage through the stainless steelclamping ring, so that the installation verticality of the filter bag is well ensured, the shaking and wear of the filter bag are effectively reduced, and the service life of the filter bag is prolonged.

Owner:芜湖鑫霖森椽环保科技有限公司

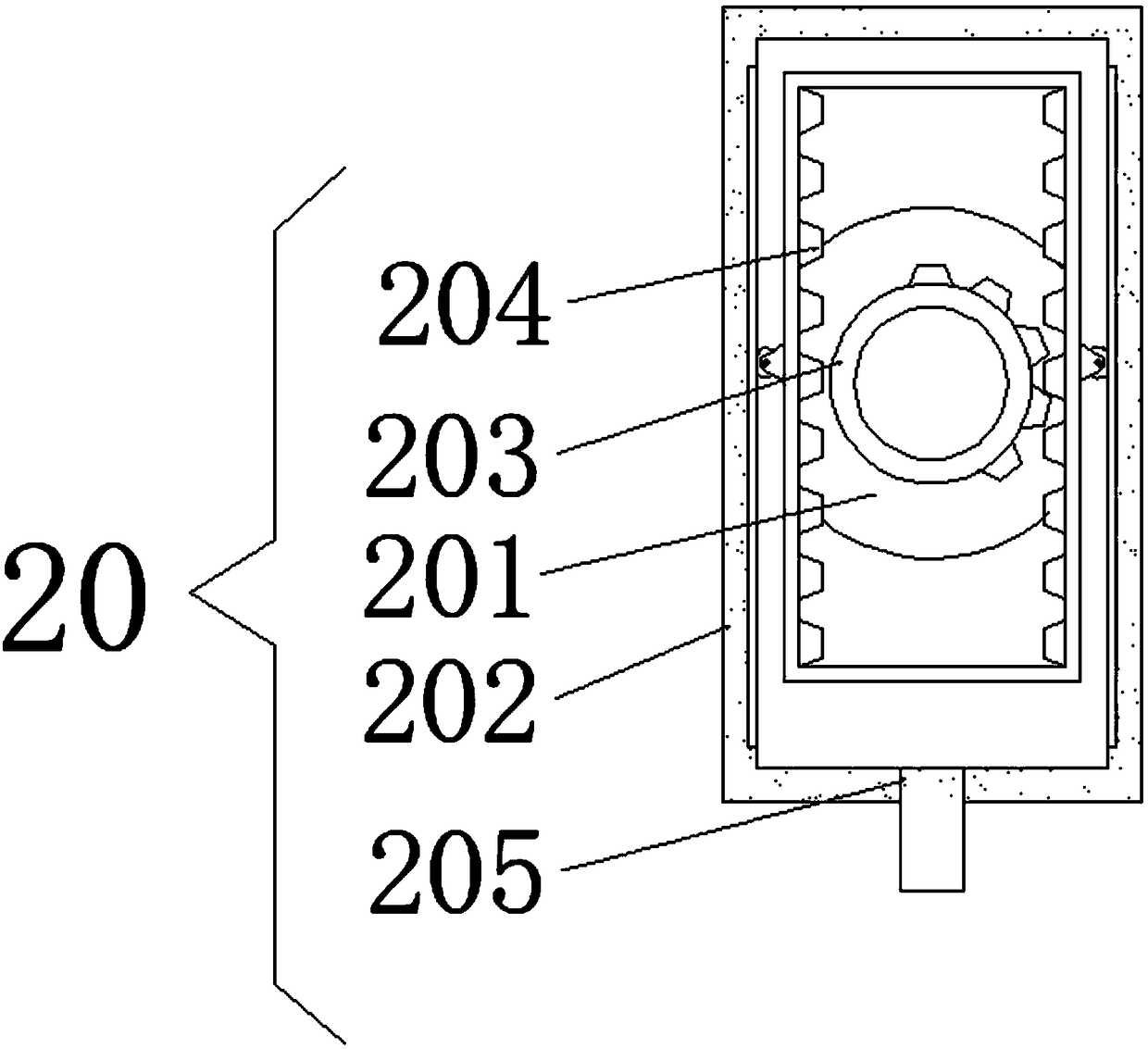

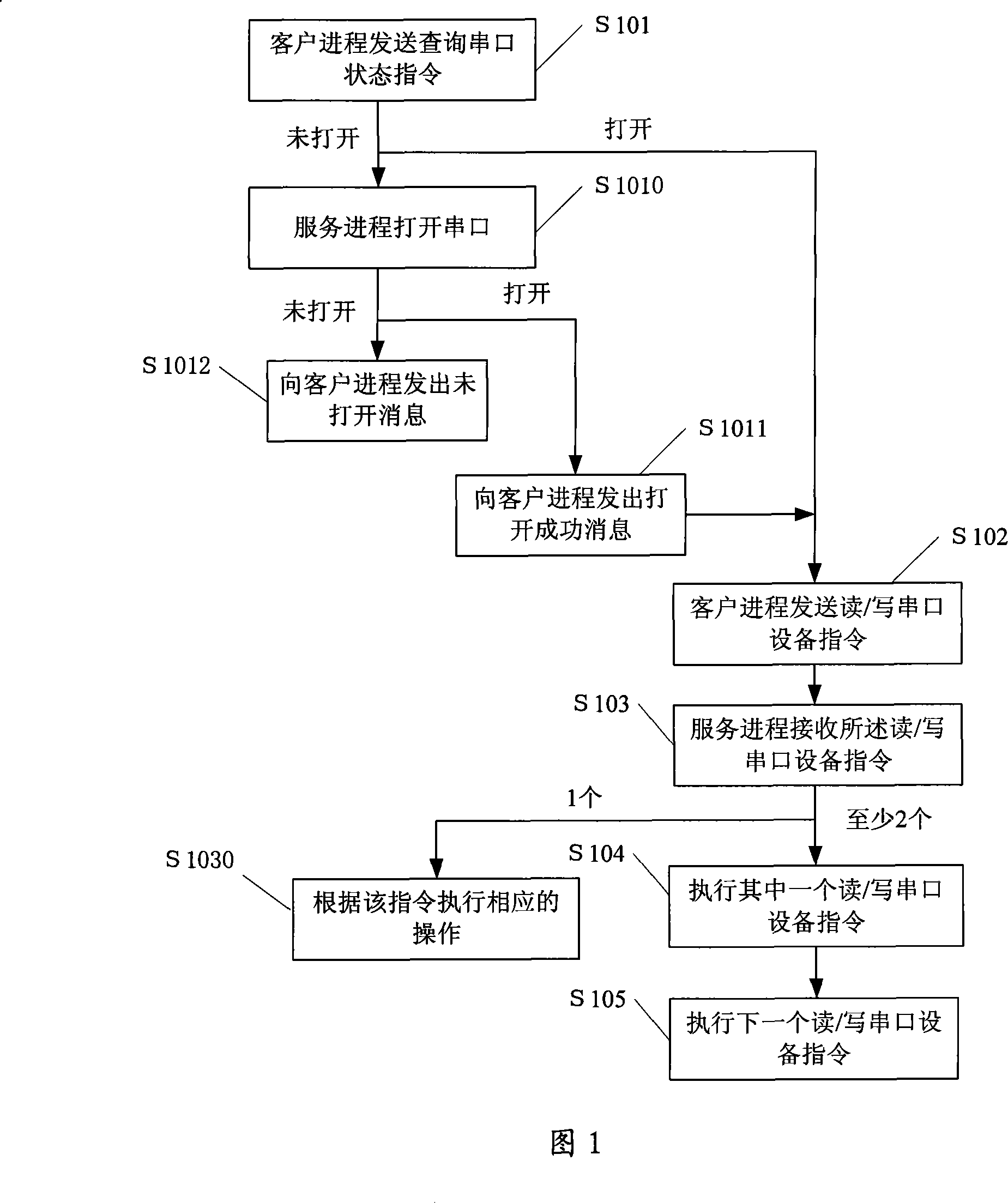

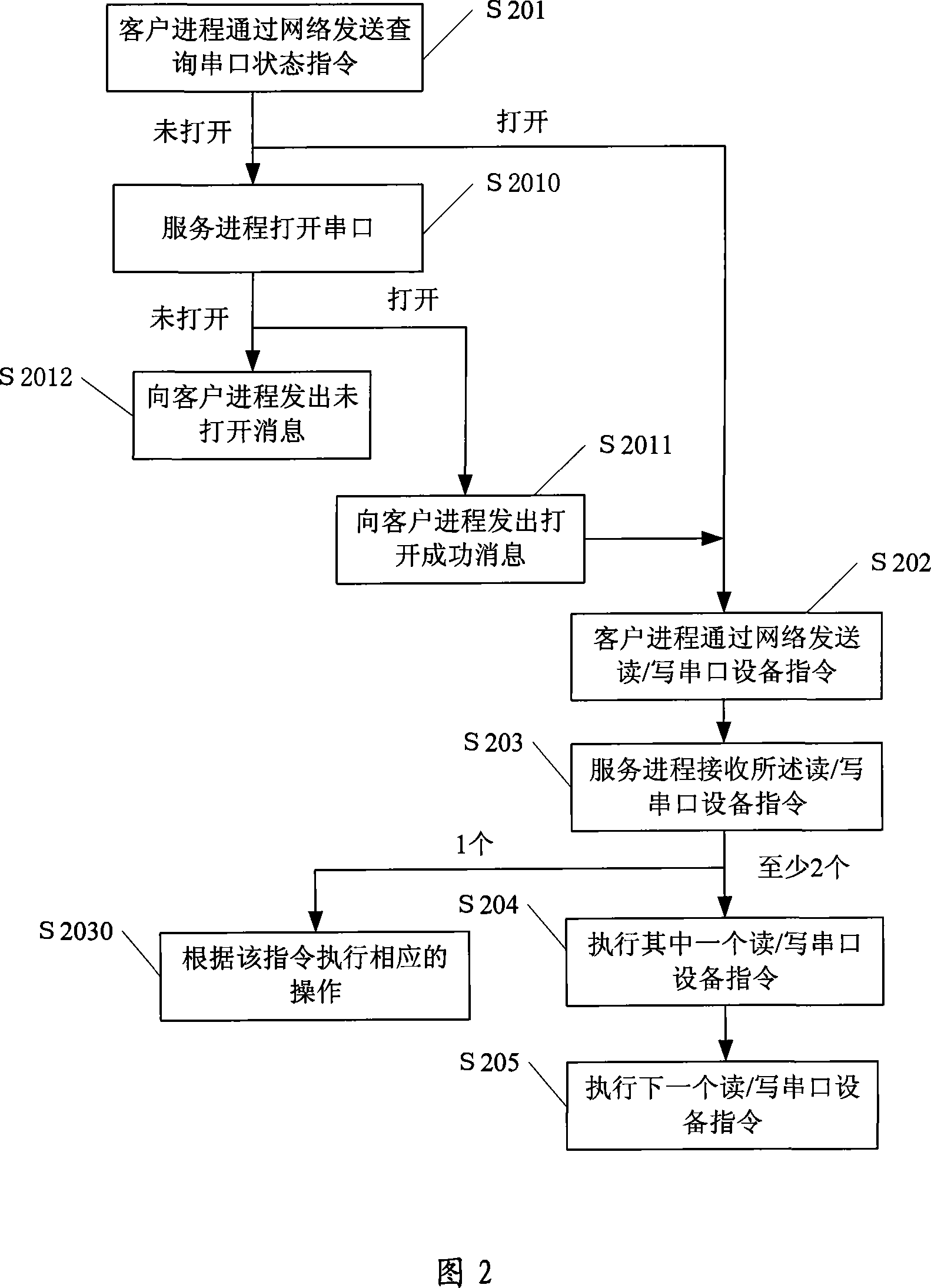

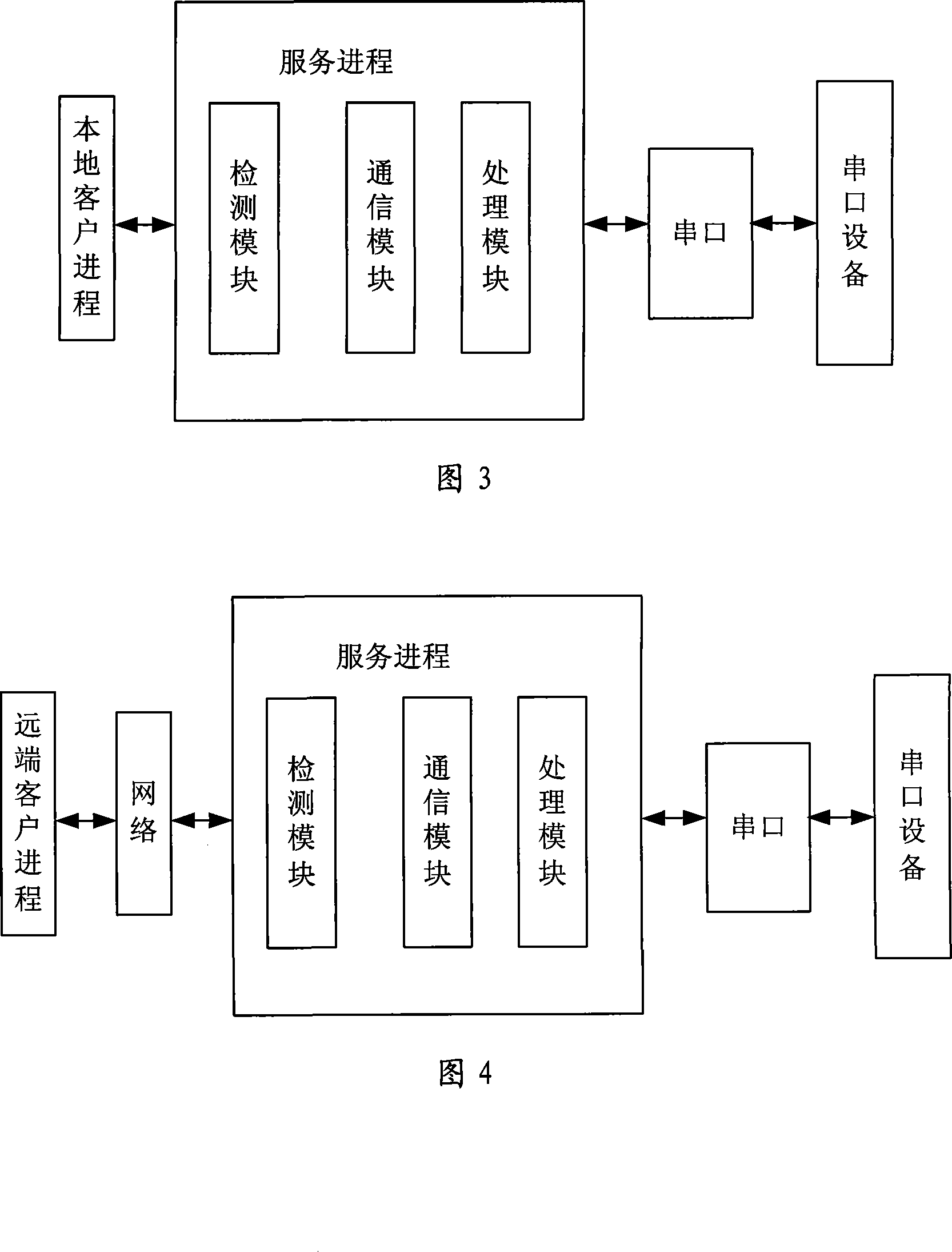

Progress and serial equipment communicating method and its device

InactiveCN101216810ATake advantage ofWill not cause idleMultiprogramming arrangementsTransmissionSerial communicationService process

The invention discloses a method for process and serial device communication, and a device thereof. The method comprises the steps as follows: a service process agent is responsible for the operation of opening a serial interface and executing an instruction of reading / writing serial device, and detects the state of the serial interface according to an inquiring instruction for detecting serial interface status messages sent by a client process; if the serial interface is opened, the instruction of reading / writing serial device is sent by the client process; the service process receives the instructions of reading / writing serial device sent by a plurality of client processes, one instruction operation of reading / writing serial device is executed first, and the next instruction of reading / writing serial device is processed after the operation is successfully completed. By adopting the method of the invention, a plurality of processes can fully utilize the serial interface and the serial device communication, and the idling of the serial device and the obstruction of the client process are avoided.

Owner:GUANGDONG VTRON TECH CO LTD

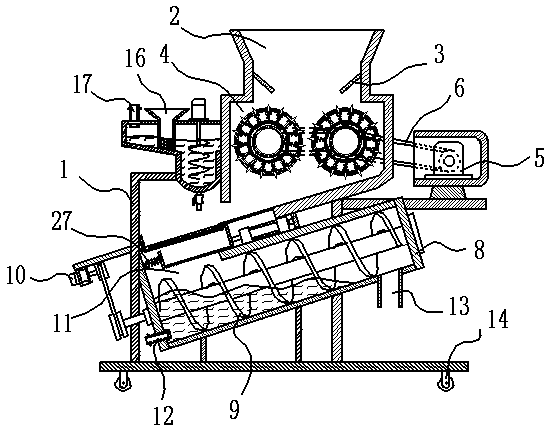

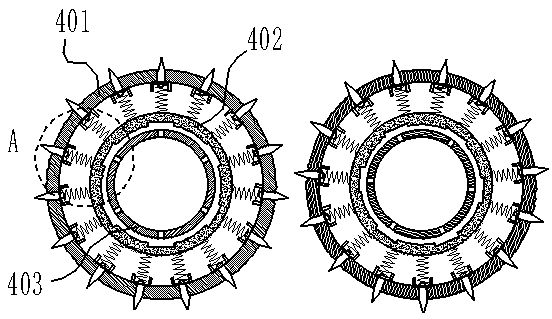

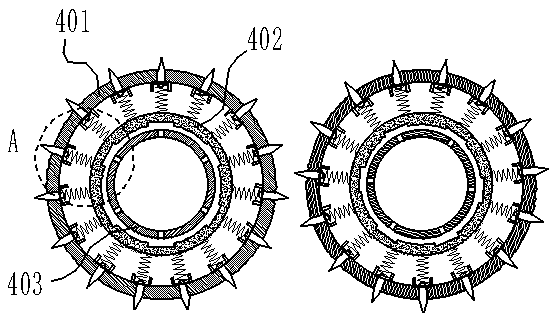

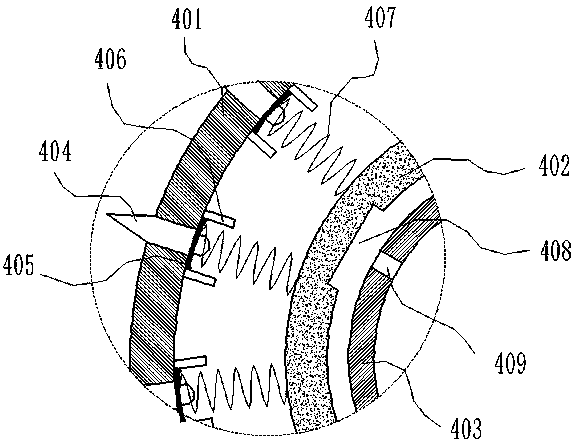

Puncturing device for food processing

The invention discloses a puncturing device for food processing. The device comprises a rack and a spiral propeller, wherein a feeding bin is arranged on the rack; an oblique bottom plate is arrangedat the lower end of the feeding bin; a puncturing assembly is arranged in the feeding bin; the puncturing assembly is connected with a puncturing motor through a belt; the puncturing assembly comprises puncturing rollers, expanding gasbags and gas expanding shafts; puncturing needles and fixed sleeves are uniformly arranged on the puncturing rollers in the shape of a circular ring; a washer is arranged between each puncturing needle and each puncturing roller, and an adjusting pressure spring is connected between each washer and each expanding gasbag; the gas expanding shafts are provided withgas outlet holes; the expanding gasbags arranged relative to the gas outlet holes are provided with notch grooves; and the end part of the outer side of each gas expanding shaft is provided with a gas nozzle. The invention aims to provide the puncturing device for food processing according to the problems; the puncturing device can not cause kernel crushing, has a good puncturing effect and can not cause the prod leakage phenomenon; and the device reduces the labor intensity of a worker and improves the efficiency of production and processing.

Owner:DONGGUAN UNIV OF TECH

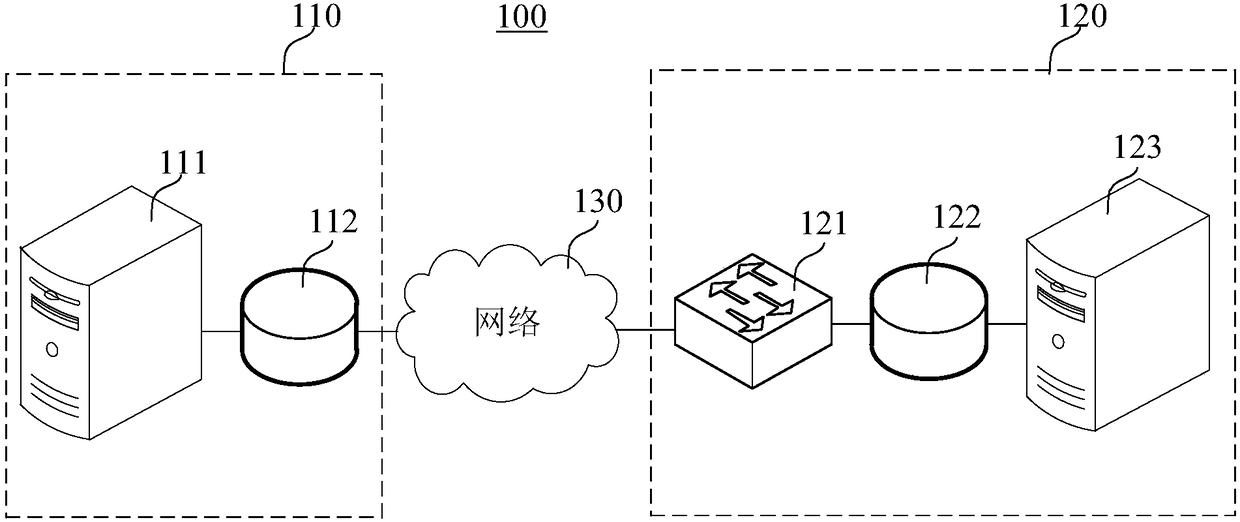

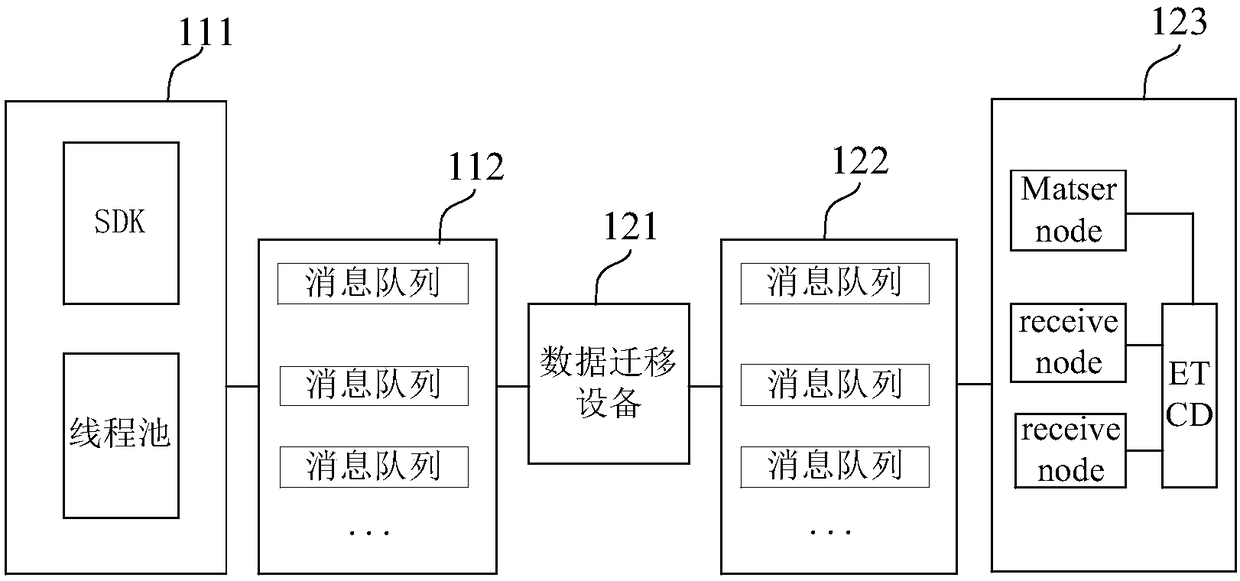

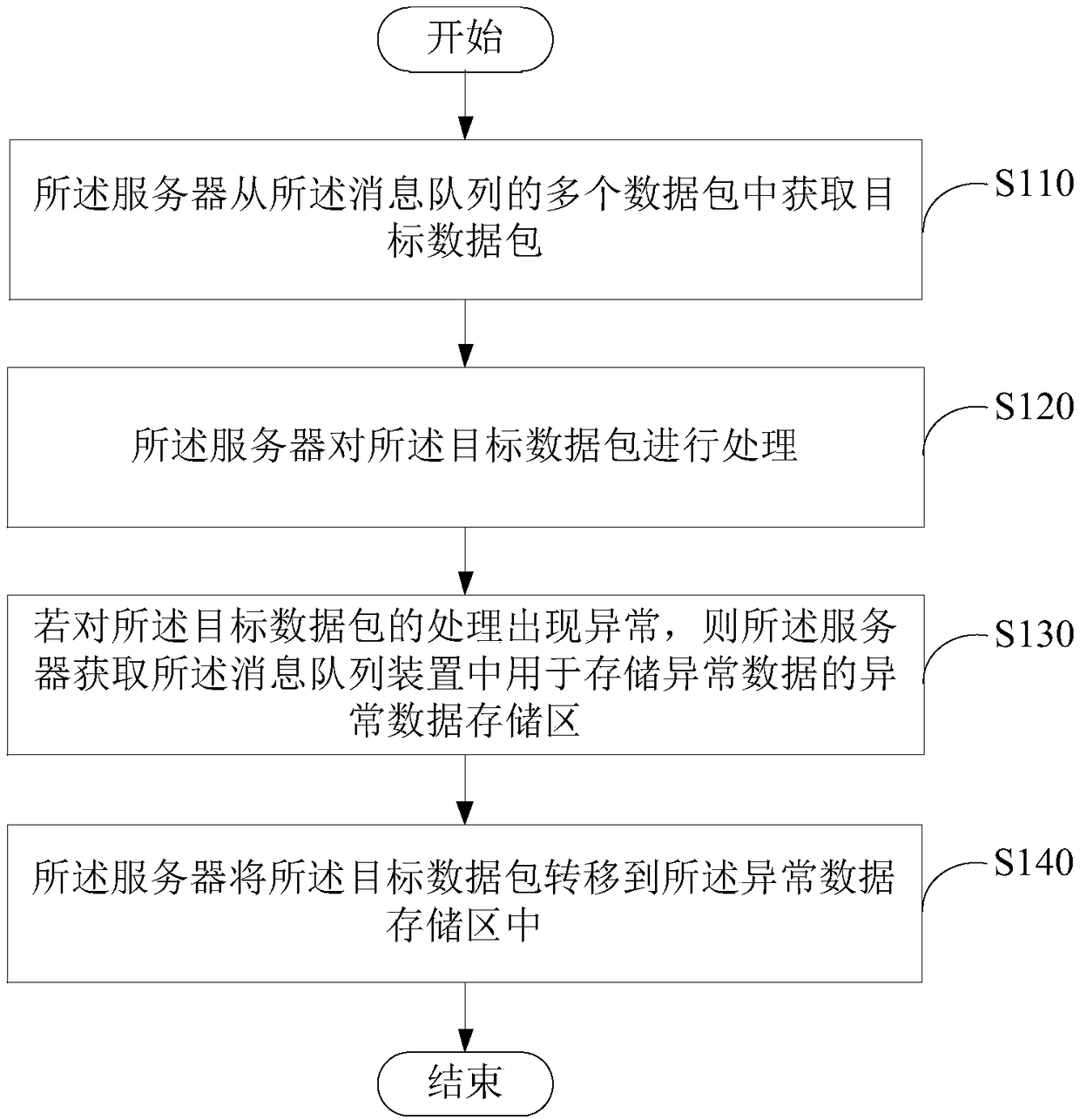

Abnormity processing method, device and server

ActiveCN108093077AWill not cause blockageImprove the problem that is not working properlyDatabase distribution/replicationTransmissionData synchronizationMessage queue

The invention discloses an abnormity processing method, device and a server. The method comprises the steps that the server obtains a target data packet from a plurality of data packets in a message queue; the server processes the target data packet, and obtains an abnormity data memory block for storing abnormal data in the message queue device when abnormity occurs during the processing; the server transfers the target data packet to the abnormality data memory block. The invention is advantageous in that when the data packet in the message queue is processed abnormally by the server, the abnormal data packet will be transferred to the abnormality data memory block, so that the abnormal data packet will not cause message queue blocking, and the problem that the whole data synchronizationcannot be normally processed due to the fact of data blocking caused by abnormality data can be resolved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

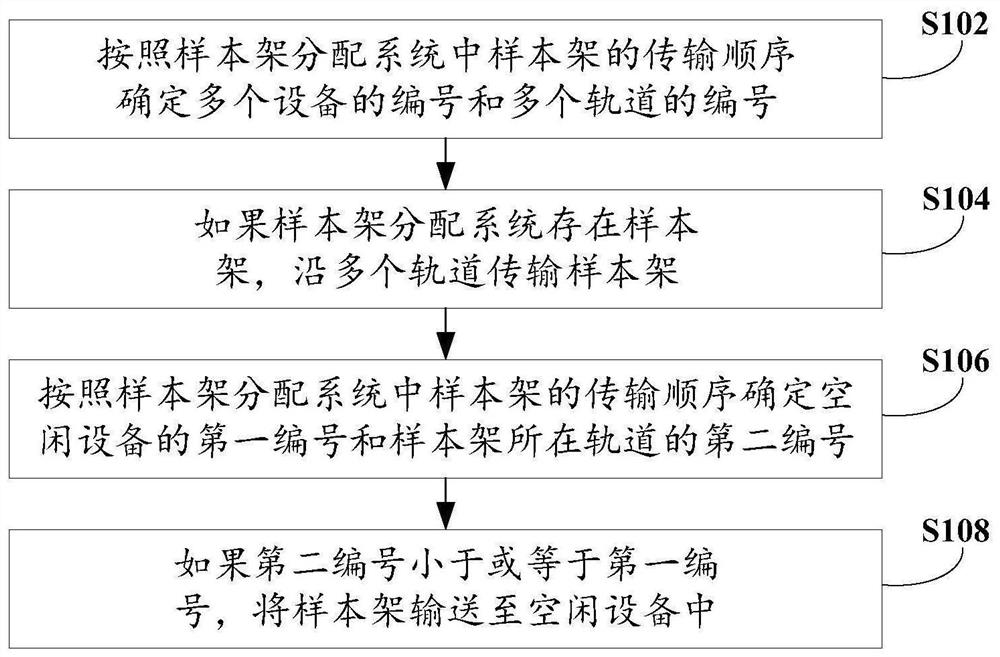

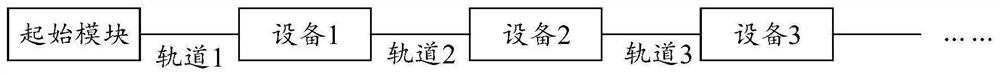

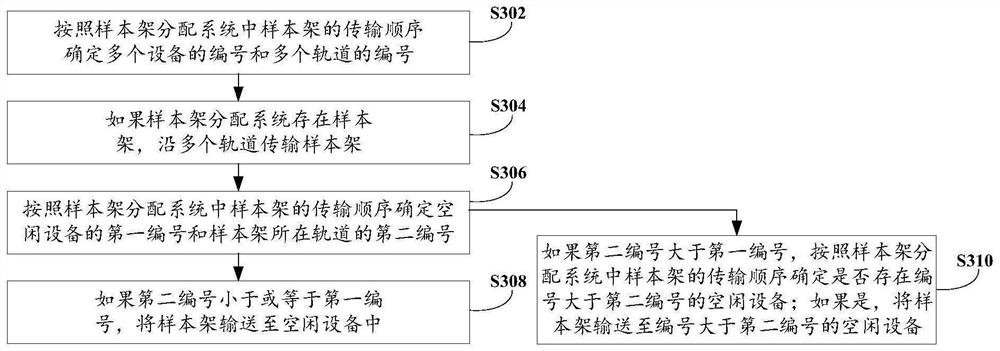

Sample rack distribution method, device and system

PendingCN113504382AImprove efficiencyImprove distribution efficiencyMaterial analysisEmbedded systemDistribution system

The invention provides a sample rack distribution method, device and system. The method comprises the following steps: determining numbers of a plurality of devices and numbers of a plurality of tracks according to a transmission sequence of sample racks in a sample rack distribution system; if the sample racks exist in the sample rack distribution system, transmitting the sample racks along a plurality of rails; determining the first number of idle equipment and the second number of a track where the sample rack is located according to the transmission sequence; and if the second number is smaller than or equal to the first number, transmitting the sample rack to idle equipment. In the mode, the sample racks can be distributed in the process that the sample racks are transmitted along a plurality of rails, so that the sample rack distribution efficiency is improved; the sample racks can be distributed as long as the sample racks exist in the sample rack distribution system, so that even if a tester directly puts the sample racks into the sample rack distribution system by mistake, the sample racks can be normally distributed, the sample rack distribution system cannot be blocked, and the conditions of wrong matching of detection results, medical negligence and the like cannot occur.

Owner:ZHUHAI LIVZON DIAGNOSTICS

Pricking equipment for melon and fruit food

The invention discloses pricking equipment for melon and fruit food. The pricking equipment comprises a machine frame and a spiral propeller, wherein a feeding chamber is arranged on the machine frame; a bottom plate is arranged at the lower end of the feeding chamber; pricking assemblies are arranged in the feeding chamber; the pricking assemblies comprise pricking rollers, expanding air bags andpneumatic shafts; pricking pins and fixed sleeves are uniformly arranged on the pricking rollers; washers are arranged between the pricking pins and the pricking rollers; adjusting pressure springs are connected between the washers and the expanding air bags; air outlet holes are formed in the pneumatic shafts; notch grooves are formed in the expanding air bags; and air taps are arranged at the end parts of the outer sides of the pneumatic shafts. The invention aims at the problems and provides the pricking equipment for melon and fruit food. The pricking equipment cannot bring about crushingof cores, can effectively avoid miss of pricking, realizes automatic conveying for sugar infusion processing, reduces the labor intensity of workers and improves the efficiency of production and processing.

Owner:DONGGUAN UNIV OF TECH

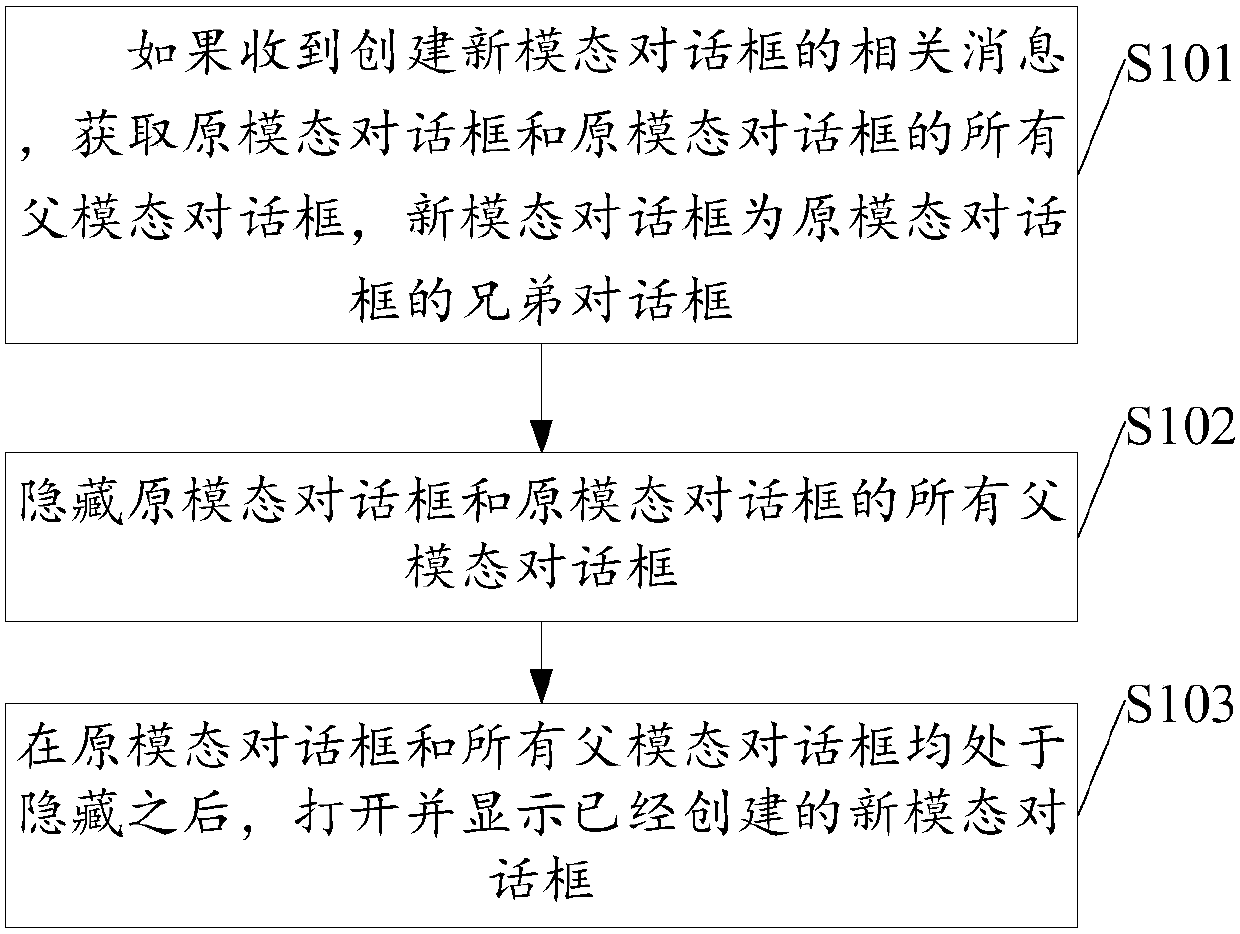

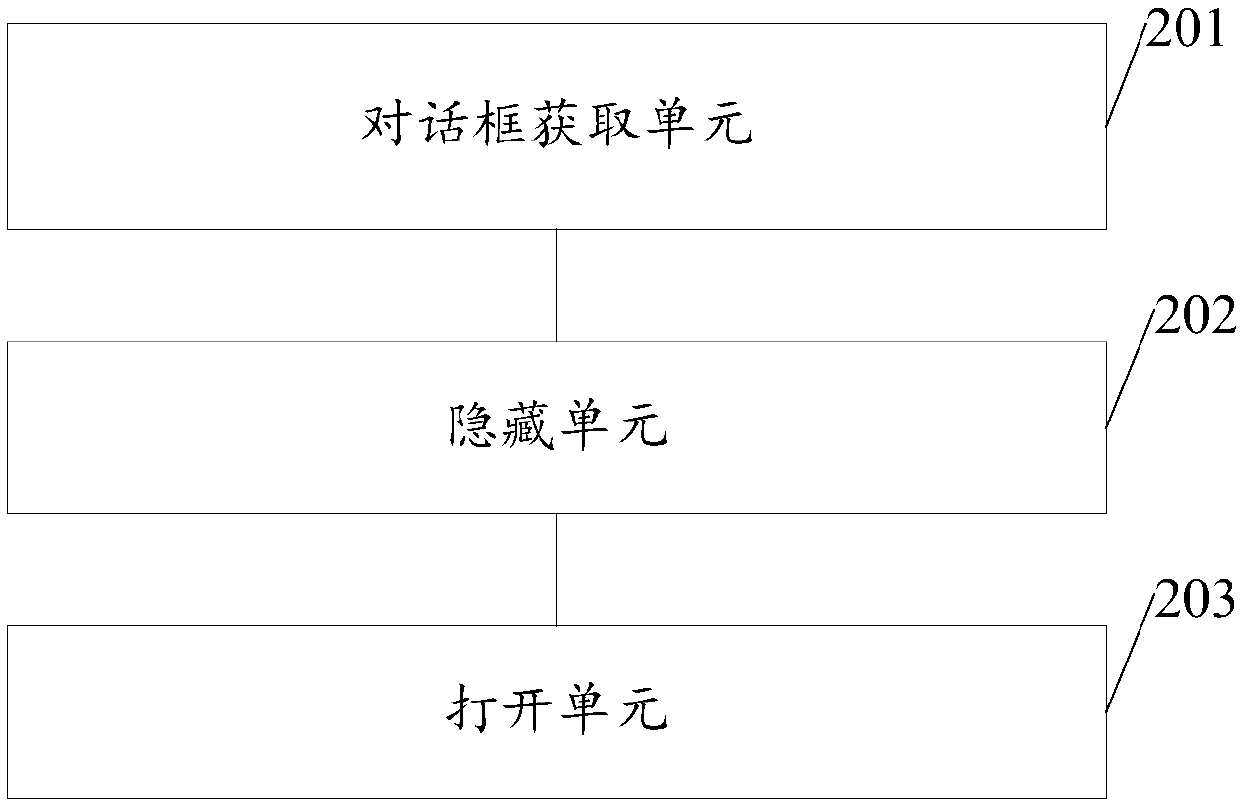

Method and device for processing model dialog boxes

ActiveCN107729107ASolve non-operational technical problemsWill not cause blockageProgram initiation/switchingExecution for user interfacesProgramming languageInformation processing

The invention discloses a method and a device for processing model dialog boxes, and is applied to the field of information processing. The method includes acquiring original model dialog boxes and all parent model dialog boxes corresponding to the original model dialog boxes if related messages for creating novel model dialog boxes are received; hiding the original model dialog boxes and all theparent model dialog boxes corresponding to the original model dialog boxes, and opening and displaying created novel model dialog boxes after the original model dialog boxes and all the parent model dialog boxes are hidden. The novel model dialog boxes are brother dialog boxes of the original model dialog boxes. The method and the device have the advantage that the technical problem of incapability of operating various existing model dialog boxes when existing brother model dialog boxes are popped up in the prior art can be solved by the aid of the method and the device.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

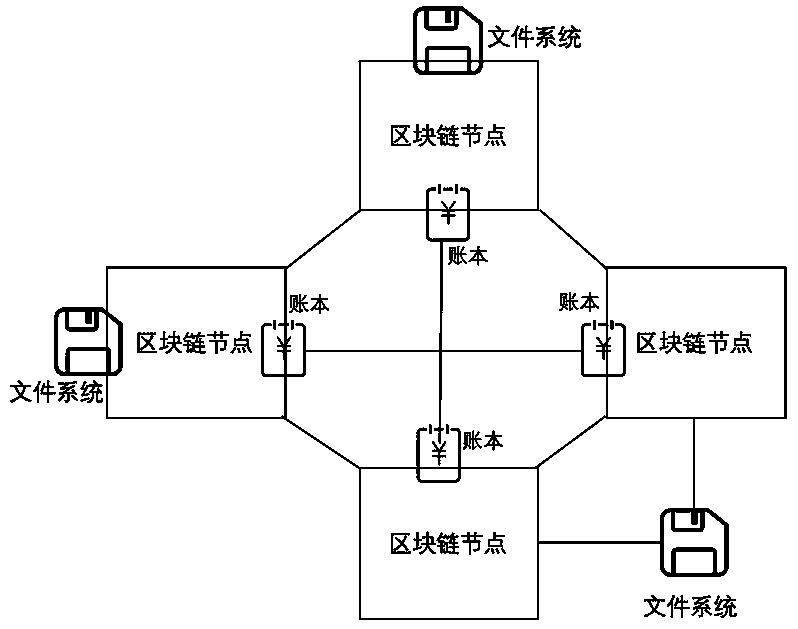

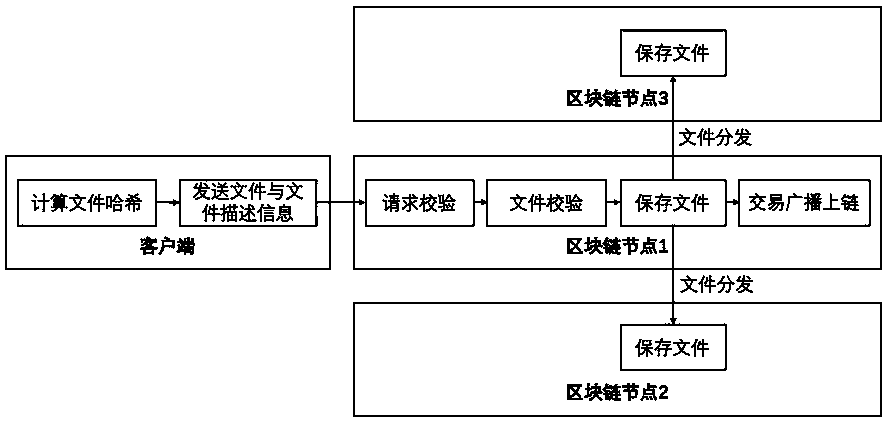

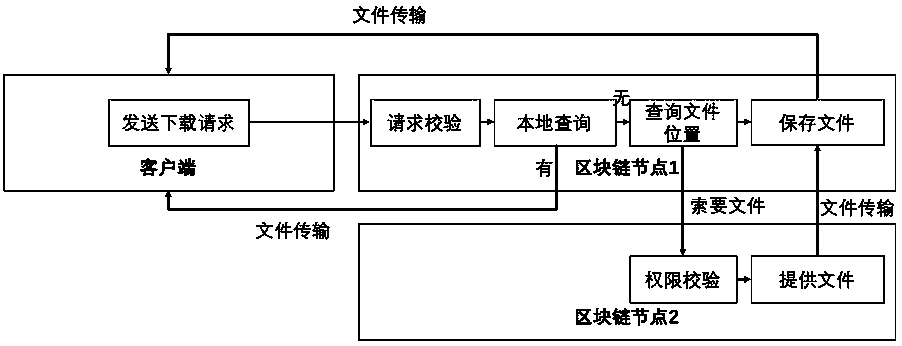

Private large file storage system based on blockchain

InactiveCN111353177AGuaranteed not to be tampered withAchieve sharingDigital data protectionFile transmissionFile system

The invention discloses a private large file storage system based on blockchain. The system is composed of blockchain nodes. A file system is integrated into the blockchain nodes, and file storage andverification are completed in the nodes; after files are uploaded to a storage system, description information of the files is recorded in a blockchain public account book, file contents are stored in the file system connected with the nodes, and the files are transmitted among the nodes through a p2p link; the descriptive data of the files is publicly stored on all nodes, and file contents are stored in a specified node, so the files are ensured not to be tampered in the blockchain system, and the privacy of the files is also ensured. According to the method, the single-point fault of a blockchain node can be avoided, a malicious node can be ensured not to steal a private file, and the storage space of the node is saved. According to the inter-blockchain file transmission scheme providedby the invention, sharing of the file between the nodes can be efficiently and stably realized, and blocking of inter-node transaction broadcast is not caused.

Owner:HANGZHOU QULIAN TECH CO LTD

Noninflammable active carbon composite material as well as preparation method and purpose thereof

InactiveCN108126659AHigh hardnessImprove thermal conductivityGas treatmentOther chemical processesActivated carbonHeat conducting

The invention relates to a noninflammable active carbon composite material as well as a preparation method and a purpose thereof. The active carbon composite material is prepared from active carbon and inorganic heat conducting particles, wherein the inorganic heat conducting particles comprise SiC particles and / or BN particles. The SiC particles and / or BN particles are added into the active carbon, so that the bulk phase temperature of the whole material is obviously homogenized; the inside heat conduction and diffusion efficiency of the material is improved, so that the flame-retardant stability of the active carbon composite material is greatly improved. Compared with the prior art, the active carbon composite material has the advantages that the pore passage blockage of active carbon cannot be caused; the active carbon adsorption performance stability is greatly improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Absorbent product with double-layer structure core and its manufacturing method

The invention belongs to the field of personal hygienic products, and discloses an absorption product with a core of a double-layer structure and a manufacturing method of the absorption product. The absorption product comprises a fluid permeability surface layer, a non-fluid-permeability bottom layer and the absorption core between the fluid permeability surface layer and the non-fluid-permeability bottom layer, wherein the absorption core comprises an upper layer and a lower layer; the upper layer is a double-combed and double-formed fluffy sheet; the fluffy sheet of the upper layer is divided into a dense surface and a fluffy surface; the lower layer of the absorption core is a dense sheet; the fluffy surface of the fluffy sheet and the dense sheet of the lower layer are bonded together; macromolecule water-absorbing particles or fibers of the absorption core are evenly distributed between the fluffy surface and the dense sheet of the lower layer. The absorption product has the advantages of being capable of rapidly absorbing liquid and diffusing liquid, good in air permeability and good in closed-fit performance.

Owner:湖南倍健卫生用品有限公司

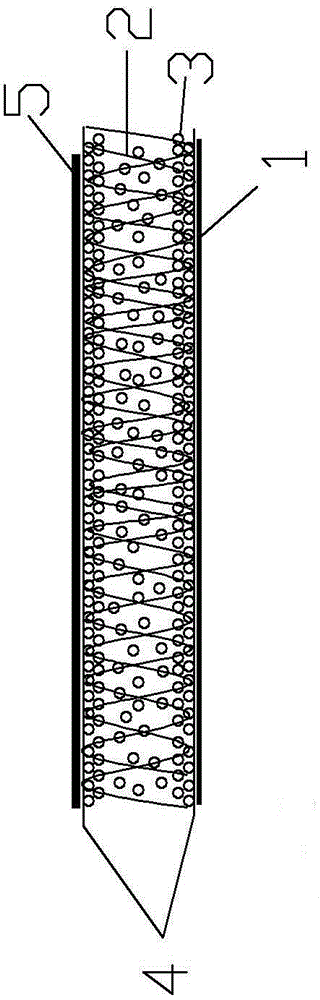

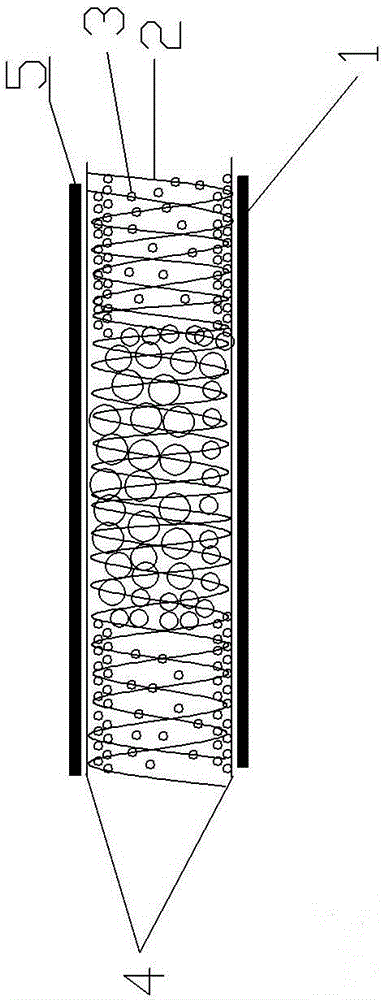

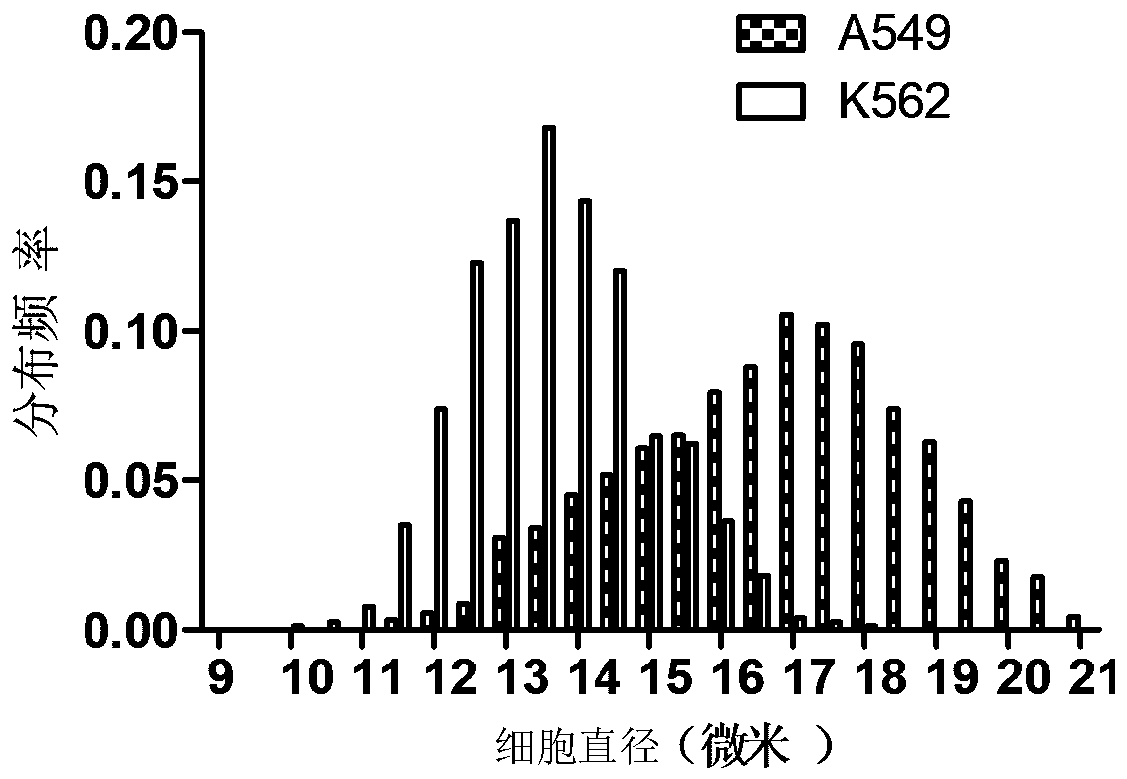

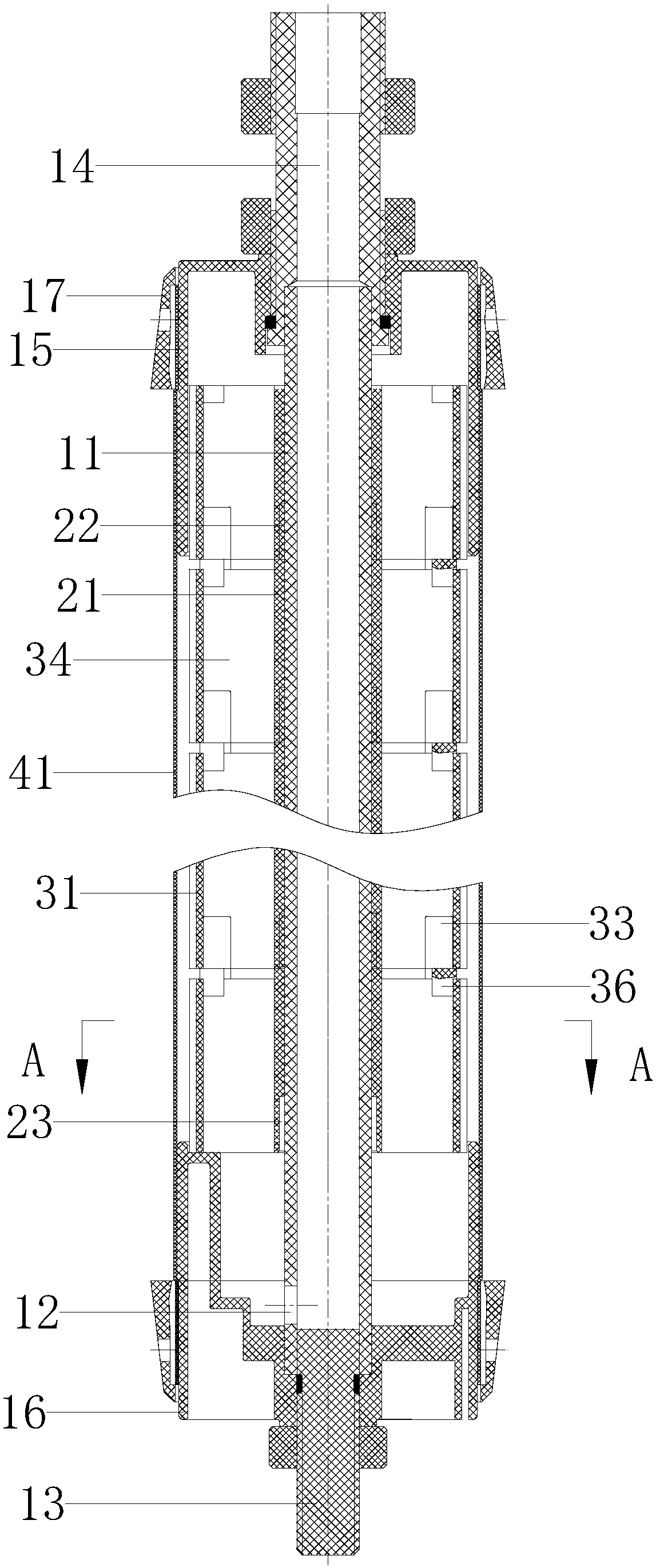

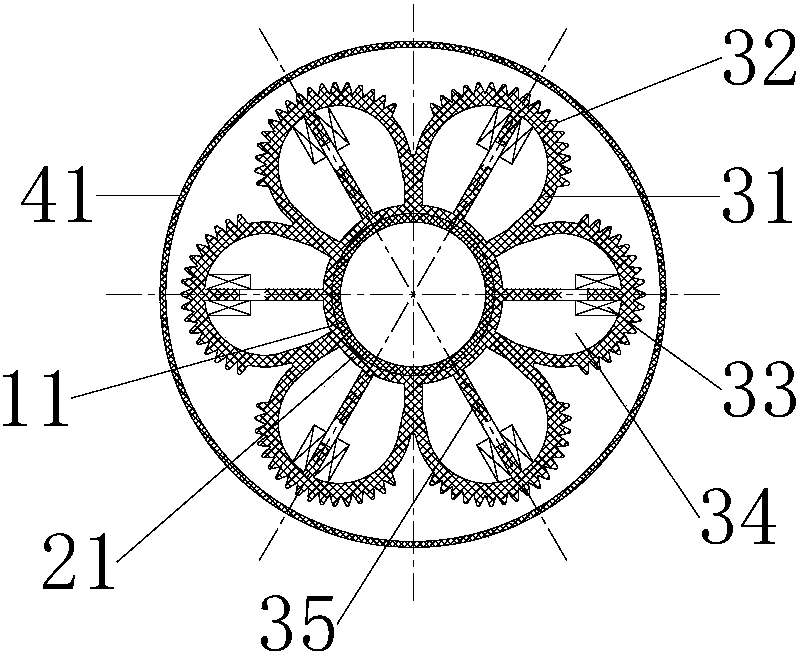

Structure, chip and use method for capturing circulating tumor cells of peripheral blood

PendingCN110564588AEfficient captureWill not cause blockageBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellPeripheral blood

The invention provides a structure, chip and use method for capturing circulating tumor cells of peripheral blood, and relates to the field of medical apparatuses. In order to increase the capturing rate of tumor cells and solve the problem that the chip is easy to block, the invention provides the following technical scheme of the structure for capturing circulating tumor cells of peripheral blood. The structure comprises a blood inlet, a waste blood outlet and a circulating tumor cell capturing region, wherein the circulating tumor cell capturing region comprises capturing units and releasechannels, and the capturing units are in misplaced arrangement in the blood flowing direction. The structure disclosed by the invention has the beneficial effects that when the peripheral blood pass through the chip / structure, large circulating tumor cells and a part of leucocyte (of which the diameter is 7-9 microns larger than a capturing interval) can be captured by the capturing units, the cells are stuck between the capturing units, other components in the blood can flow past the release channels on the two sides of the capturing units, blood blockage cannot be caused, and the purpose that the tumor cells in the blood can be captured in a higher efficiency manner is realized.

Owner:SHENZHEN CHILDRENS HOSPITAL

Application of antisludging agent containing citric acid in salt elimination closed conduit

InactiveCN106082460AStable in natureLong storage periodSpecific water treatment objectivesScale removal and water softeningTricarboxylic acidSodium sulfate

The invention relates to an antisludging agent containing citric acid. The antisludging agent is prepared from, by weight, 26-30 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, 15-19 parts of diethylenetriamine pentasodium bistriaminopenta, 7-11 parts of polyaspartic acid, 6-10 parts of citric acid, 4-8 parts of 1-bromo-3-chloro-5,5-dimethyl hydantoin, 4-8 parts of tertiary butyl hydroquinone, 3-7 parts of sodium glycocholate, 3-7 parts of lauryl sodium sulfate, 2-6 parts of tertiary butylhydroquinone, 0.5-0.9 part of a Kombuchka extracting solution, 0.4-0.8 part of a cactus extracting solution and 54-58 parts of deionized water. The antisludging agent is stable in character and long in storage life, has the good scale inhibition effect on inorganic salt sedimentations in a salt elimination closed conduit, and is free of corrosion of the salt elimination closed conduit.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Energy saving and environmental protection cement clinker preparation system

ActiveCN103351106BStable and uniform qualityReduce the load rate of the internal circulation of the millClinker productionDecompositionBucket elevator

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

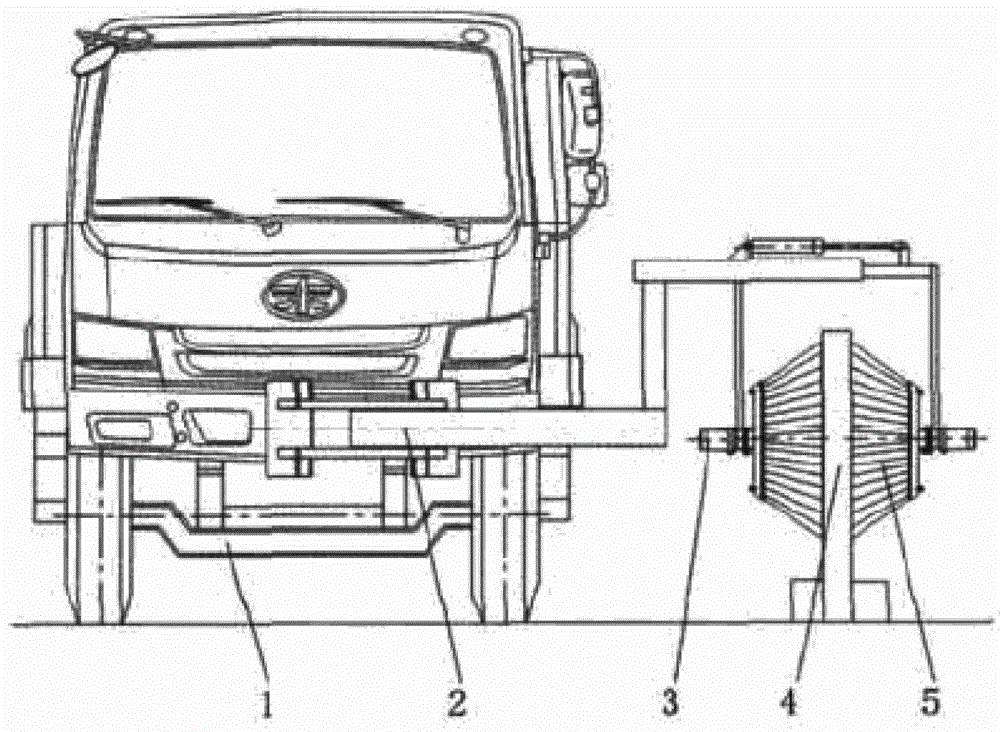

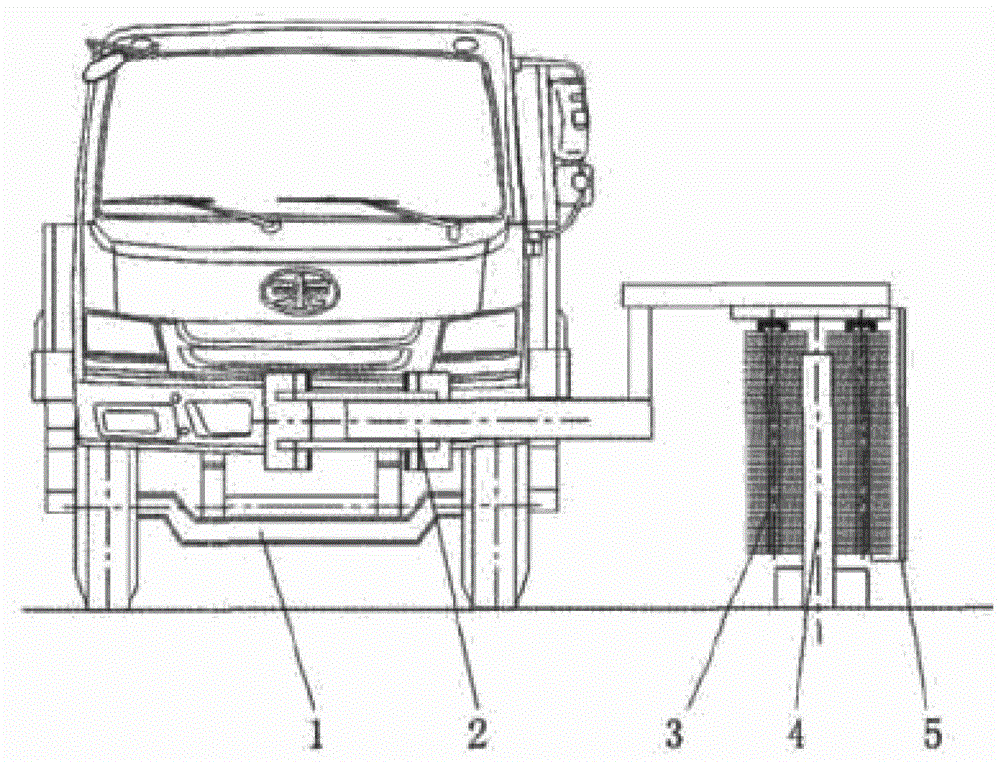

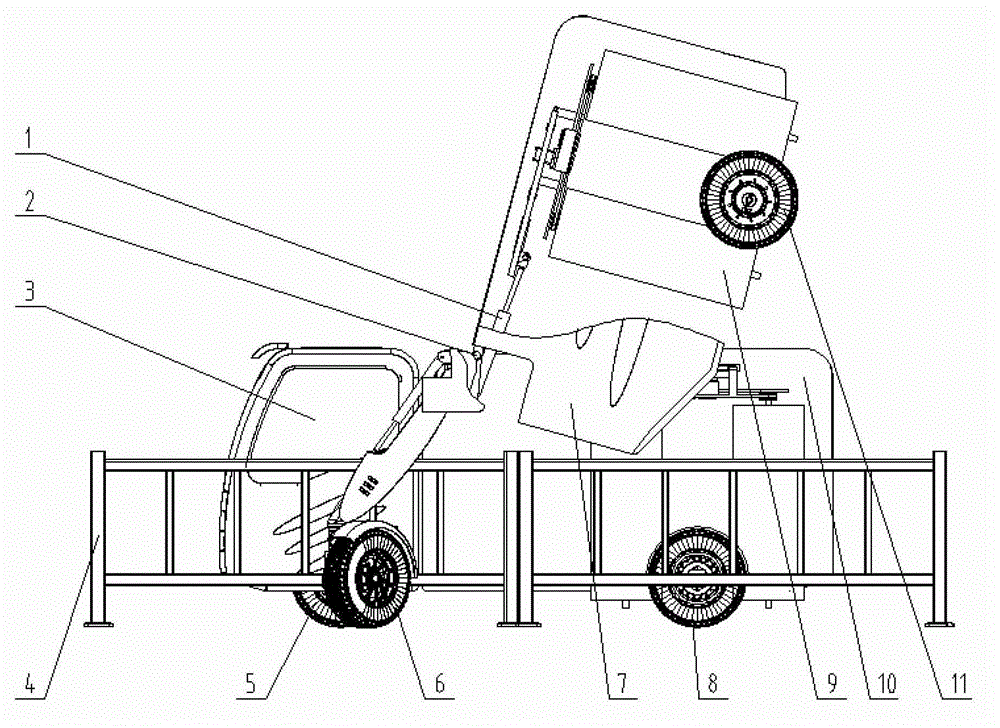

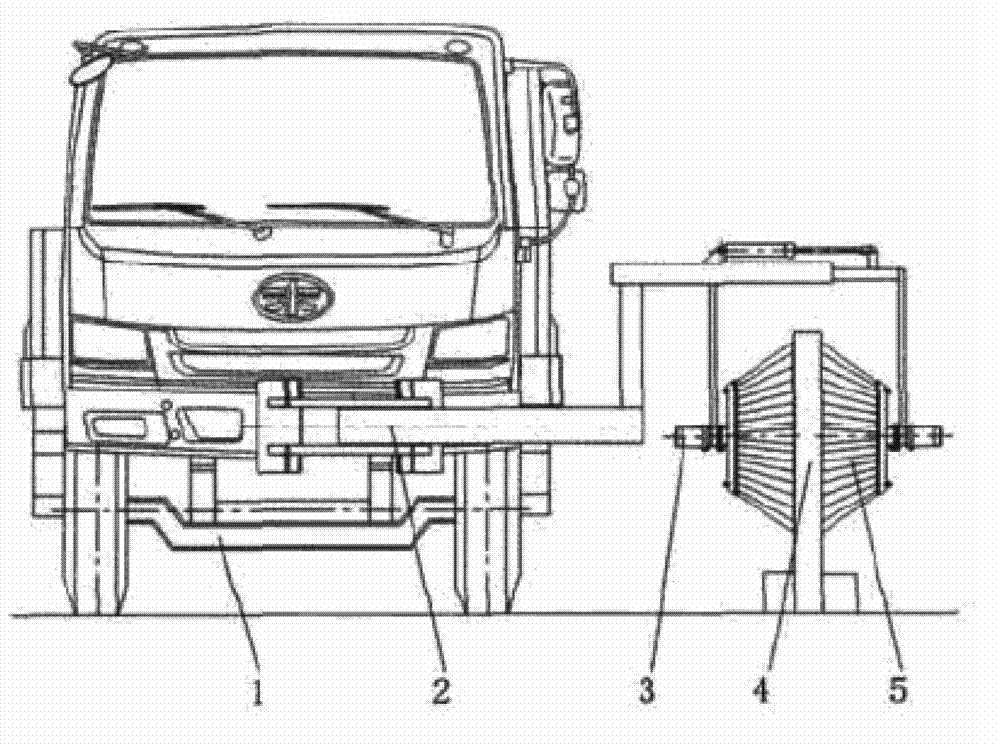

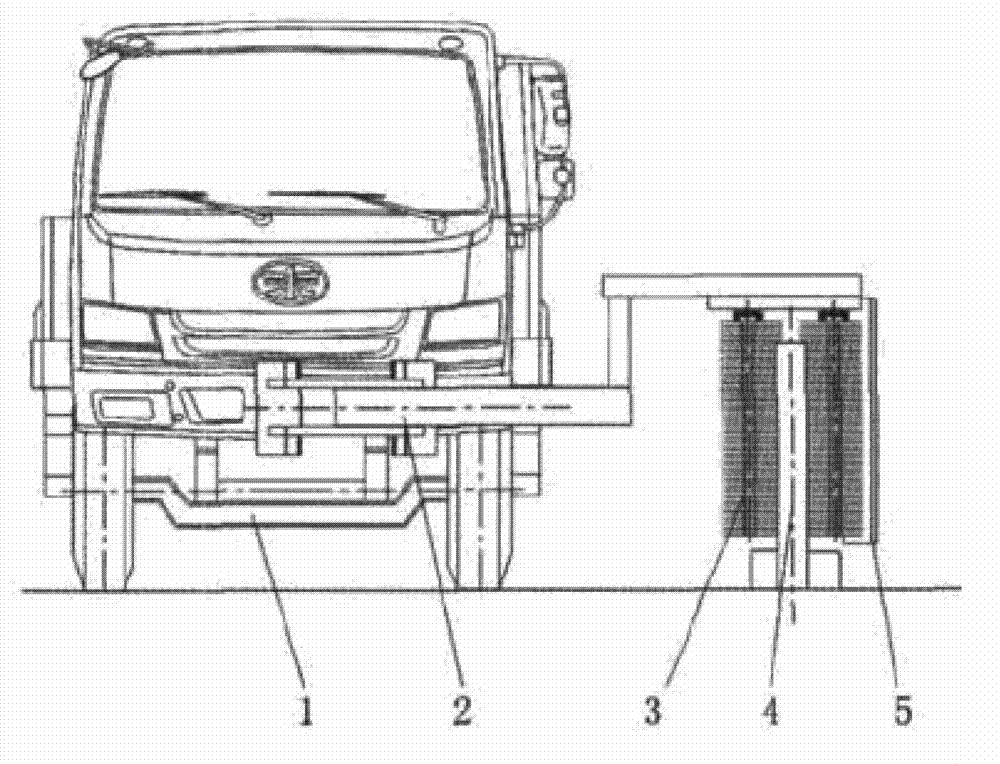

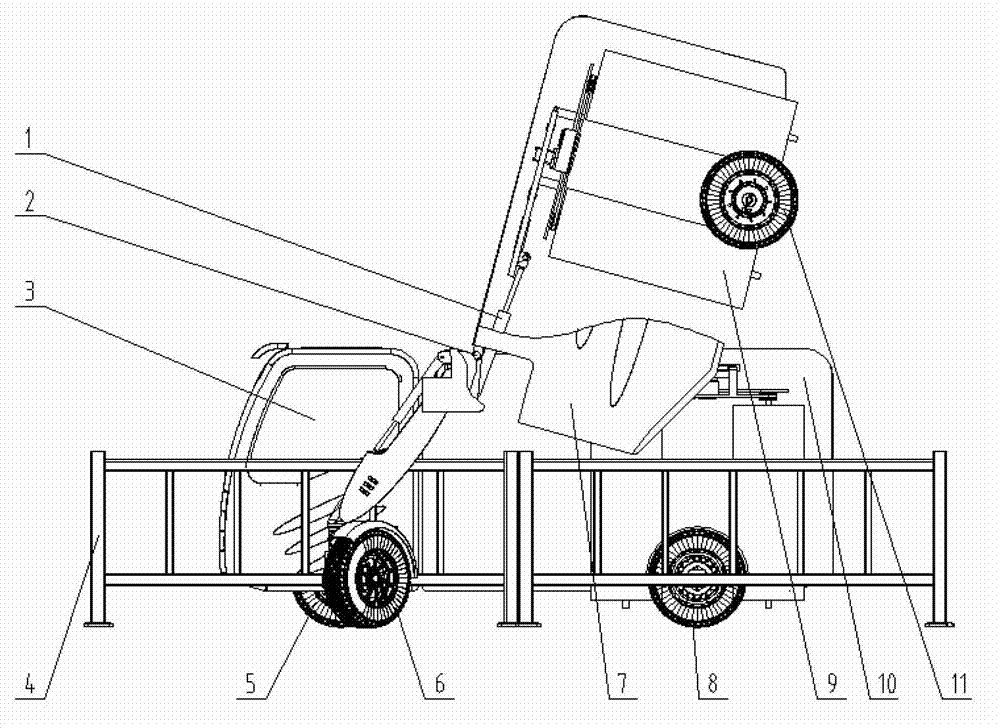

Movable vehicle body assembly and guardrail cleaning vehicle

ActiveCN102828481BOccupy lessPractical washing car efficiencyRoad cleaningCleaning methodsIndependent suspension

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

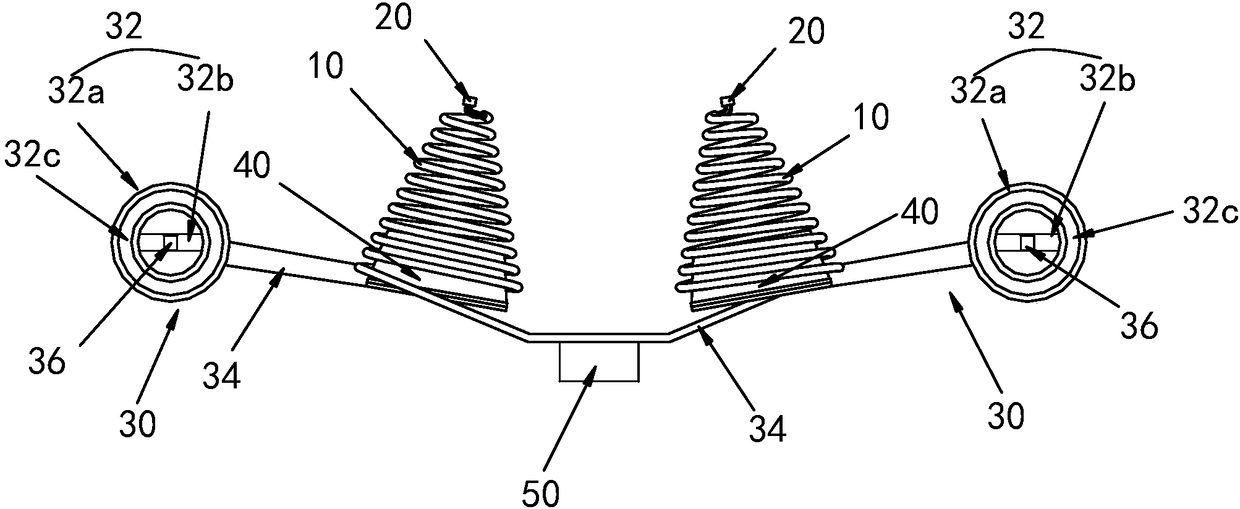

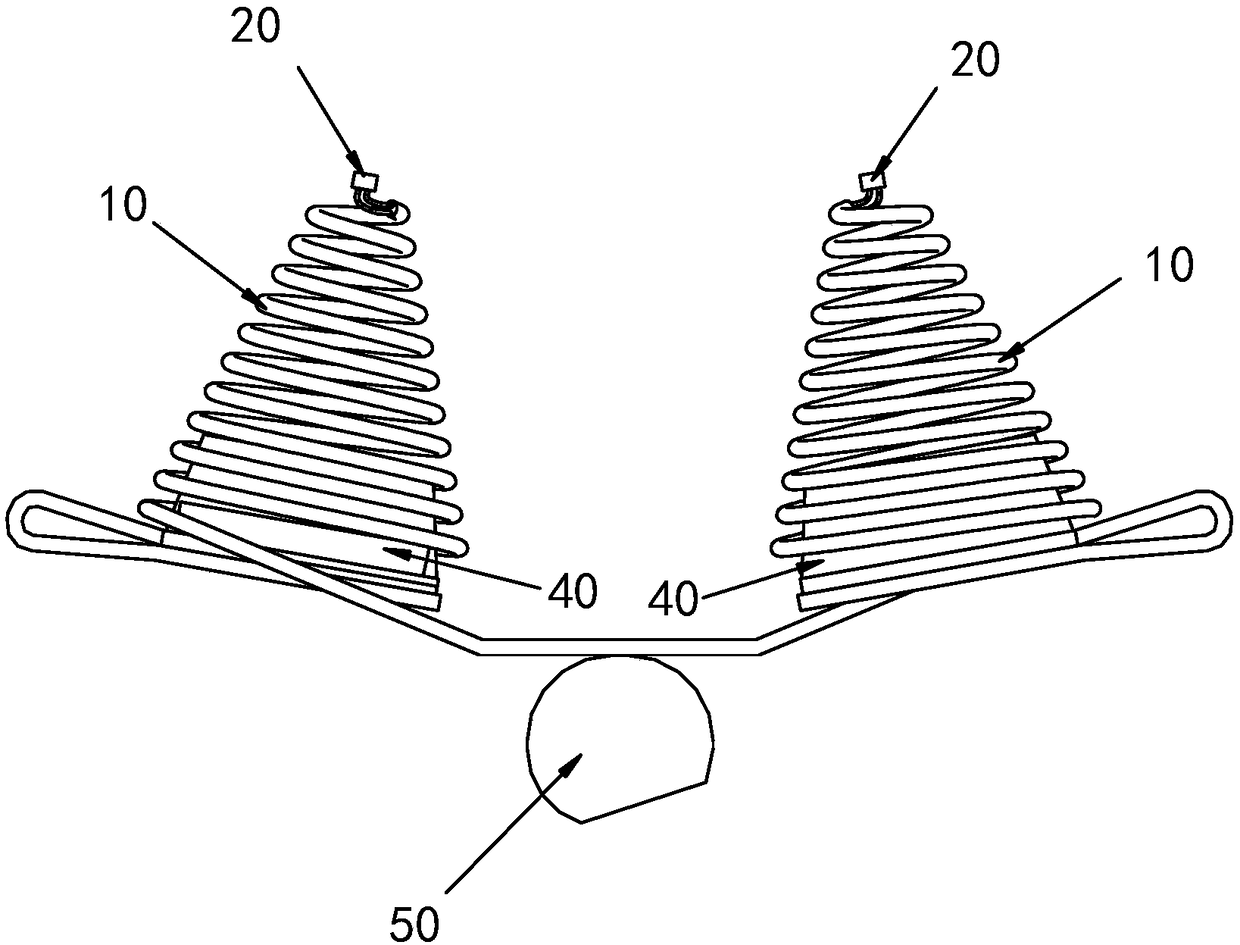

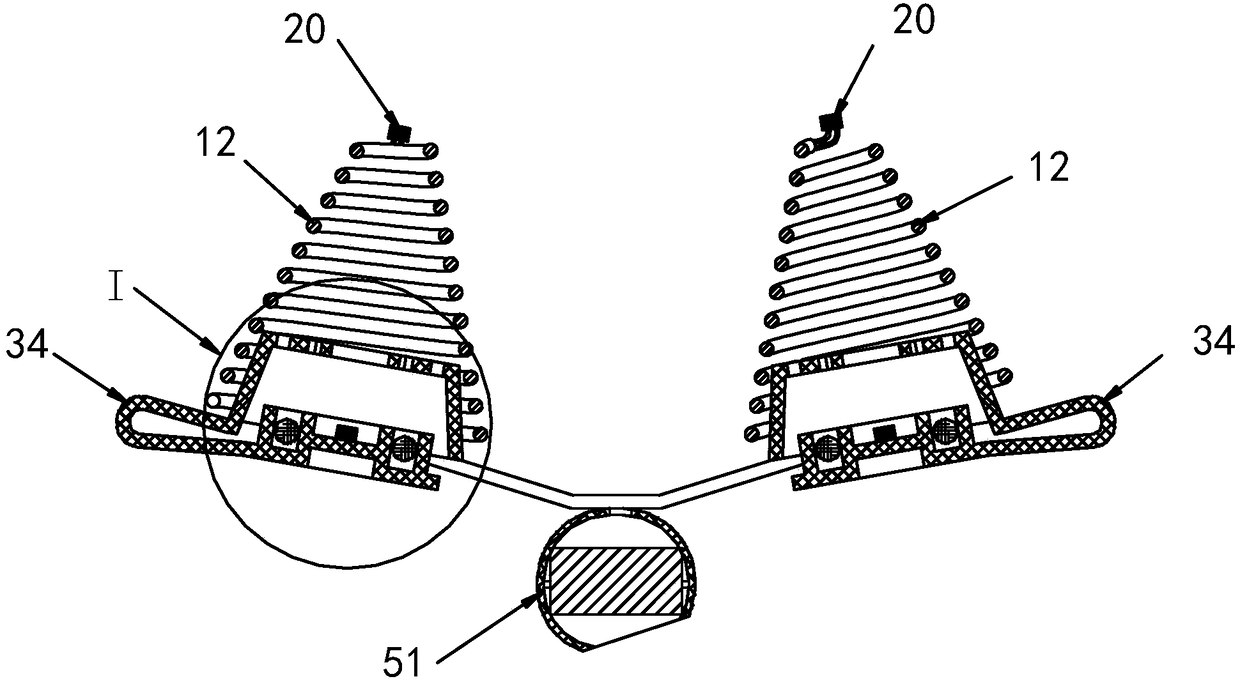

Multifunctional nose aerate instrument

InactiveCN108404280ALow gas resistanceWill not cause blockageSurgeryMedical devicesNasal cavityNostril

The invention discloses a multifunctional nose aerate instrument. The multifunctional nose aerate instrument comprises a conical spiral spring, an internal LED and a power supply device, wherein the small-caliber end of the conical spiral spring can be inserted into the nostril of a patient, and the conical spiral spring is spirally wound by a spring wire, an electric heating wire and a first conducting wire are arranged in the spring wire; the inner LED is arranged at the small-caliber end of the conical spiral spring; the power supply device is connected with the internal LED and the electric heating wire through the first conducting wire. According to the multifunctional nose aerate instrument provided by the invention, a small special matching spring tension force of the conical spiralspring is utilized to slightly expand the nostril to increase the airway ventilation efficiency of 5 percent to 25 percent, the gas resistance of the conical spiral spring is small and will not causeblockage, The conical spiral spring has the advantages of simple structure and convenient operation. At the same time, the multifunctional nose aerate instrument is used for irradiating the interiorof the nasal cavity with the internal LED, and is favorable for treating rhinitis.

Owner:谢昆宏

Automobile fee information checking system without parking

InactiveCN1691070AWill not cause blockageGuaranteed reliabilityTicket-issuing apparatusPaymentHand held

Motor vehicle payment information non-stop audit system comprises 1. Hand-held audit machine; 2. Payment center management computer; 3. Audit machine in inspect vehicle; and 4. Management center computer. When using, set machine carried by vehicle in the vehicle; set audit machine in inspect vehicle to inside of inspect vehicle; hand-held audit machine is held by audit operational staff and can be mobile operation. The system can use radio engineering to take wireless inquire for information of motor vehicle regulated payment on the condition vehicle is non-stop; for the has paid, auto register and release, for the did not pay or out of effective data, auto register and give alarm, and hold up vehicle and give punishment if necessary; audit staff need not to stand up side of road for long, they can also stay in house side road or car, which then releases greatly the workload and labor strength; the checked vehicle needs not to decelerate, can not bring traffic block; the audit speed is more quick, and the regulated payment can be paid in time.

Owner:颜斌

Movable vehicle body assembly and guardrail cleaning vehicle

ActiveCN102828481AOccupy lessPractical washing car efficiencyRoad cleaningAutomotive engineeringIndependent suspension

The invention discloses a movable vehicle body assembly for a guardrail cleaning vehicle. The longitudinal middle part of the guardrail cleaning vehicle is provided with a guardrail passing space, wherein the movable vehicle body assembly comprises a movable vehicle body part (7) and wheels which are installed on the movable vehicle body part (7) through independent suspensions, and mounting structures which can install the movable vehicle body part (7) in a rotating or lifting manner on a fixed vehicle body part (10) of the guardrail cleaning vehicle is arranged on the movable vehicle body part (7). In addition, the invention further provides the guardrail cleaning vehicle. According to the movable vehicle body assembly and the guardrail cleaning vehicle, the movable vehicle body part can move in a manner relative to the fixed vehicle body part to change the height position, accordingly, convenience is provided for the guardrail cleaning vehicle to cross a guardrail, the guardrail cleaning vehicle can be changed from a conventional side cleaning mode into a middle guardrail crossing cleaning mode, and accordingly, the traffic jam is conveniently relieved.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Peanut oil filtering device for edible oil processing

InactiveCN113440924AReduce oil contentWill not cause blockageFatty-oils/fats refiningFiltration circuitsProcess engineeringEdible oil

The invention relates to the technical field of peanut oil production, in particular to a peanut oil filtering device for edible oil processing, which comprises a shell, a filtering mechanism is rotatably mounted on the inner side of the shell through a driving mechanism, and the filtering mechanism comprises a filtering disc in a circular truncated cone shape and a filtering ring fixedly mounted on the edge of the filtering disc; according to the oil filtering device, oil can be filtered for three times, the filtering effect is effectively improved, impurities are cleaned in the filtering process, the structure of a filtering part is not blocked, compared with a traditional filtering device, the filtering part does not need to be cleaned and replaced regularly, the impurities can be collected in a centralized mode, the oil content in the collected impurities is extremely low. The discharging position is concentrated, workers do not need to watch all the time, and convenience is brought.

Owner:湖南金珠油脂有限公司

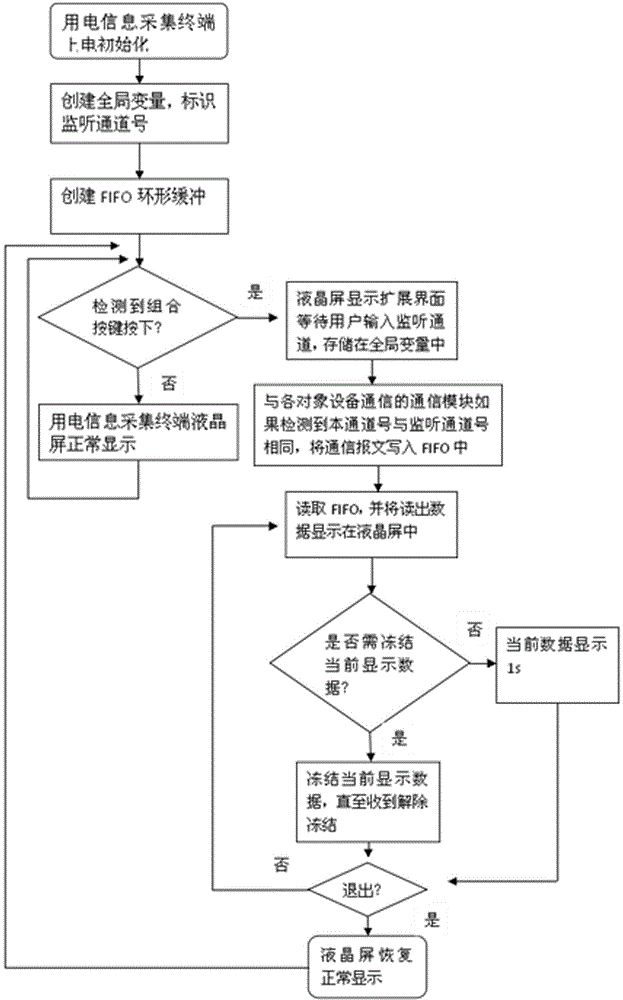

Power utilization information acquisition terminal communication message local real-time monitoring method

ActiveCN104868593AEasy to judgeCommunication Security ImpactCircuit arrangementsLiquid-crystal displayComputer module

The invention relates to the field of an intelligent grid power utilization information acquisition system, and particularly relates to a power utilization information acquisition terminal communication message local real-time monitoring method. According to the invention, specification display on a liquid crystal display screen can be turned off temporarily through using keys on the liquid crystal display screen of an acquisition terminal in a combined mode, the liquid crystal display screen is guided and switched into an expansion interface, a monitoring channel number is selected, and the channel number is monitored by using a global variable identifier established at the beginning, so that each communication module judges whether being monitored or not when the acquisition terminal is communicated with each device, thereby being convenient for storing communication messages of the monitored channel to a circular buffer, and then displaying task calling and the communication messages by the liquid crystal display screen. The method provided by the invention does not need additional computers or communication cables, does not result into congestion, can display the communication message of the required channel effectively in real time, and is convenient for checking communication faults.

Owner:INTEGRATED ELECTRONICS SYST LAB

Candle filter element

PendingCN108079638AReduce contact areaSpeed up the flowStationary filtering element filtersEngineeringCandle

The invention relates to a candle filter element which comprises an upper end cover, a lower end cove, a center pipe, a filter element framework, less than three filter frames and a filter fabric. A liquid inlet hole is formed in the center pipe and positioned at the bottom of the center pipe, a lower connector and the lower end cover are mounted at the bottom of the center pipe, the lower connector is positioned below the liquid inlet hole, the bottom of the center pipe is plugged by the lower connector, the upper connecting pipe and the upper end cover are mounted at the top of the center pipe, the upper connecting pipe is communicated with the center pipe, the filter element framework is provided with a circular pipe and sleeves the center pipe, filter frames uniformly surround the outer circumferential surface of the filter element framework, gaps are formed among the filter frames, liquid passing holes are formed in the filter frames and parallel to the axis of the filter elementframework, the filter fabric sleeve the filter frames, two ends of the filter fabric are fixed on the upper cover and the lower end cover through hoops, the filter frames are communicated with the upper end cover and the lower cover, and the lower end cover is communicated with the liquid inlet hole. The filter element is good in filtering effect, low in cost and wide in application range.

Owner:YNT PETROCHEM MACHINERY EQUIP

Essence with pearlescent appearance and preparation method thereof

InactiveCN110420127AGood moisturizing effectWill not cause blockageCosmetic preparationsToilet preparationsCuticleCholesterol

The invention discloses essence with pearlescent appearance and a preparation method thereof. The composition is composed of the following components in percentage by weight: 0.05%-0.2% of fatty acid,0.01%-0.1% of water-soluble ceramide, 0.01%-0.08% of cholesterol, 0.05%-0.3% of hydrogenated lecithin, 0.1%-0.5% of a thickener, 3%-5% of ethanol, 10%-30% of polyol, 0.3%-0.8% of a cosolvent, 0.01%-0.15% of potassium hydroxide, 0.01%-0.05% of citric acid, 0.0001%-0.0005% of a water-soluble pigment, 0.005%-0.05% of essence, 0.1%-0.5% of an antibacterial agent and the balance deionized water. Underthe condition that mica pearl powder is not added, essence crystals with the pearlescent effect are obtained by compounding the fatty acid and the potassium hydroxide. The fatty acid, the ceramide and the cholesterol which are added into the essence are main components of skin cuticle intercellular lipid, and have an excellent moisturizing effect on skin; and meanwhile, pearl powder is not contained, and the safety problems of pore blockage or skin pricking and the like cannot be caused.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com