Electrostatic dust collection adsorption film and production method thereof

An electrostatic dust removal and adsorption film technology, applied in the field of electrostatic dust removal adsorption film and its preparation, can solve the problems of short service life, equipment blockage and high energy consumption, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

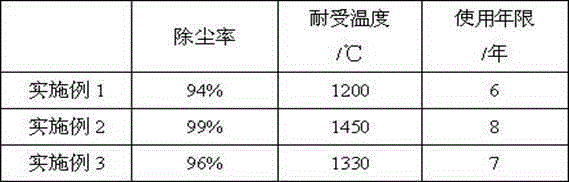

Examples

Embodiment 1

[0022] An electrostatic dust removal adsorption film, which is mainly made of the following raw materials according to the ratio of parts by mass: 8 parts of oxygen anion powder, 23 parts of polyvinyl chloride, 14 parts of polyethylene terephthalate, 12 parts of activated carbon nanoparticles, 14 parts of polycarbonate, 6 parts of dimethylformamide, 5 parts of methyl acrylate, 12 parts of polyacrylamide, and 25 parts of polyethylene glycol.

[0023] A method for preparing an electrostatic dust removal adsorption film, comprising the following steps:

[0024] (1) Dissolving the oxygen negative ion powder in polyethylene glycol, the mass concentration of the oxygen negative ion powder is 1%, to prepare the base liquid;

[0025] (2) Polyvinyl chloride, polyethylene terephthalate, activated carbon nanoparticles, polycarbonate, dimethylformamide, methyl acrylate and polyacrylamide in a mass ratio of 1:2:3:7: Add 0.5:0.2:1 into the reaction kettle, make a melt under the conditions ...

Embodiment 2

[0029] An electrostatic dust removal adsorption film, which is mainly made of the following raw materials according to the ratio of parts by mass: 21 parts of oxygen anion powder, 36 parts of polyvinyl chloride, 28 parts of polyethylene terephthalate, 29 parts of activated carbon nanoparticles, 26 parts of polycarbonate, 21 parts of dimethylformamide, 32 parts of methyl acrylate, 16 parts of polyacrylamide, and 32 parts of polyethylene glycol.

[0030] A method for preparing an electrostatic dust removal adsorption film, comprising the following steps:

[0031] (1) Dissolving the oxygen negative ion powder in polyethylene glycol, the mass concentration of the oxygen negative ion powder is 4%, to prepare the base liquid;

[0032] (2) Polyvinyl chloride, polyethylene terephthalate, activated carbon nanoparticles, polycarbonate, dimethylformamide, methyl acrylate and polyacrylamide are mixed in a mass ratio of 2:3:4:9: Add 1:2:3 into the reaction kettle, make a melt under the co...

Embodiment 3

[0036] An electrostatic dust removal adsorption film, which is mainly made of the following raw materials according to the ratio of parts by mass: 25 parts of oxygen anion powder, 40 parts of polyvinyl chloride, 35 parts of polyethylene terephthalate, 34 parts of activated carbon nanoparticles, 33 parts of polycarbonate, 27 parts of dimethylformamide, 36 parts of methyl acrylate, 22 parts of polyacrylamide, 40 parts of polyethylene glycol.

[0037] A method for preparing an electrostatic dust removal adsorption film, comprising the following steps:

[0038] (1) Dissolving the oxygen negative ion powder in polyethylene glycol, the mass concentration of the oxygen negative ion powder is 7%, to prepare the base liquid;

[0039] (2) Polyvinyl chloride, polyethylene terephthalate, activated carbon nanoparticles, polycarbonate, dimethylformamide, methyl acrylate and polyacrylamide in a mass ratio of 3:4:5:9: Add 2:2:3 into the reaction kettle, make a melt under the conditions of te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com