Patents

Literature

187results about How to "Uniform and stable quality" patented technology

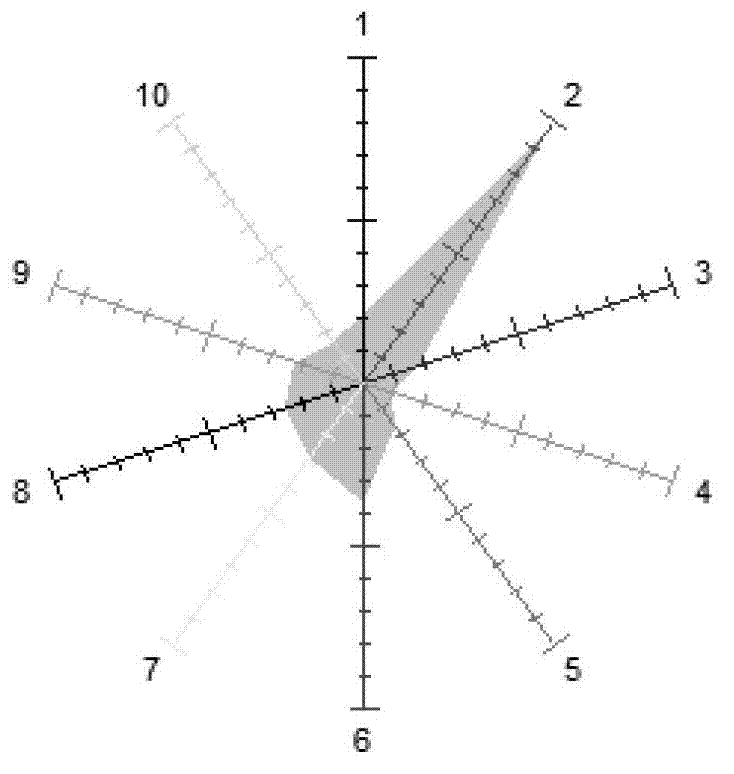

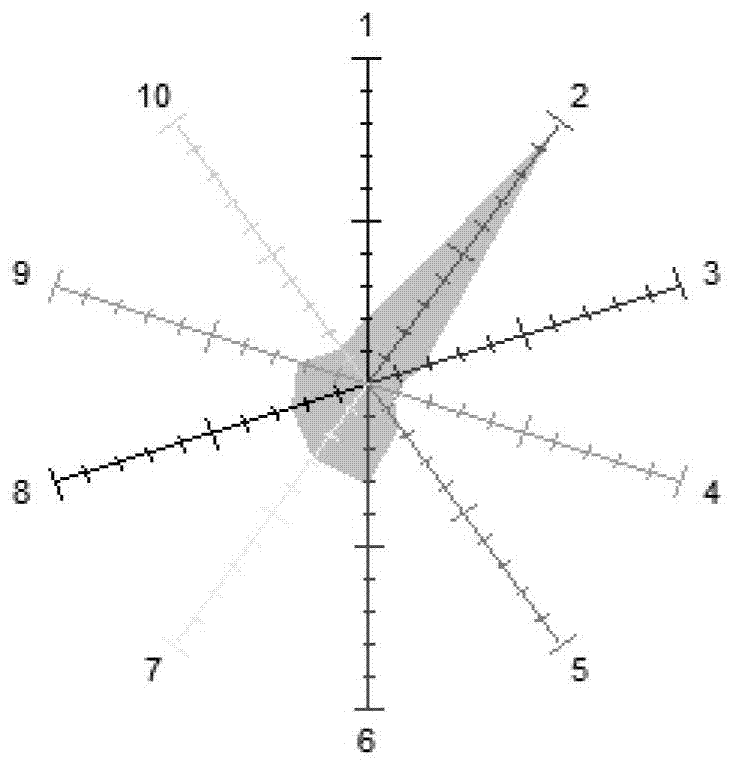

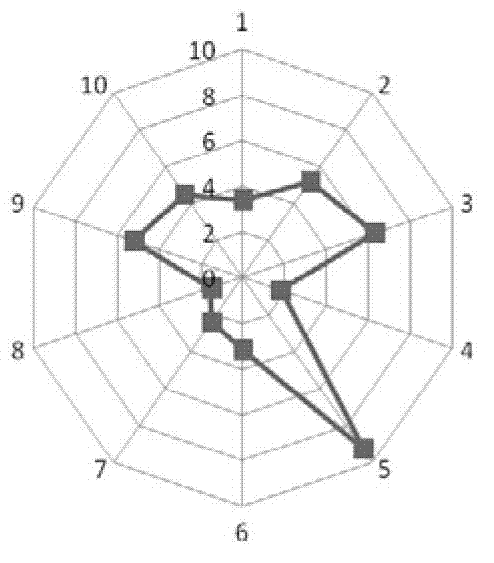

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

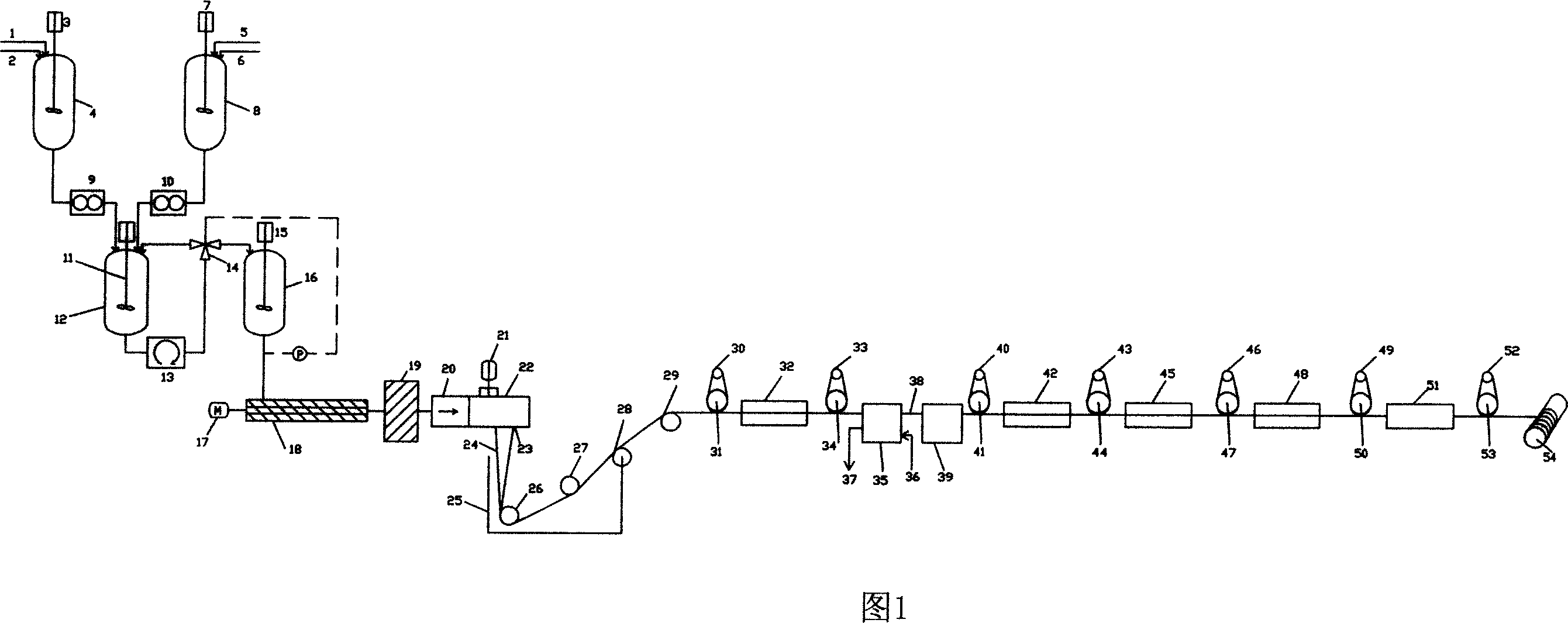

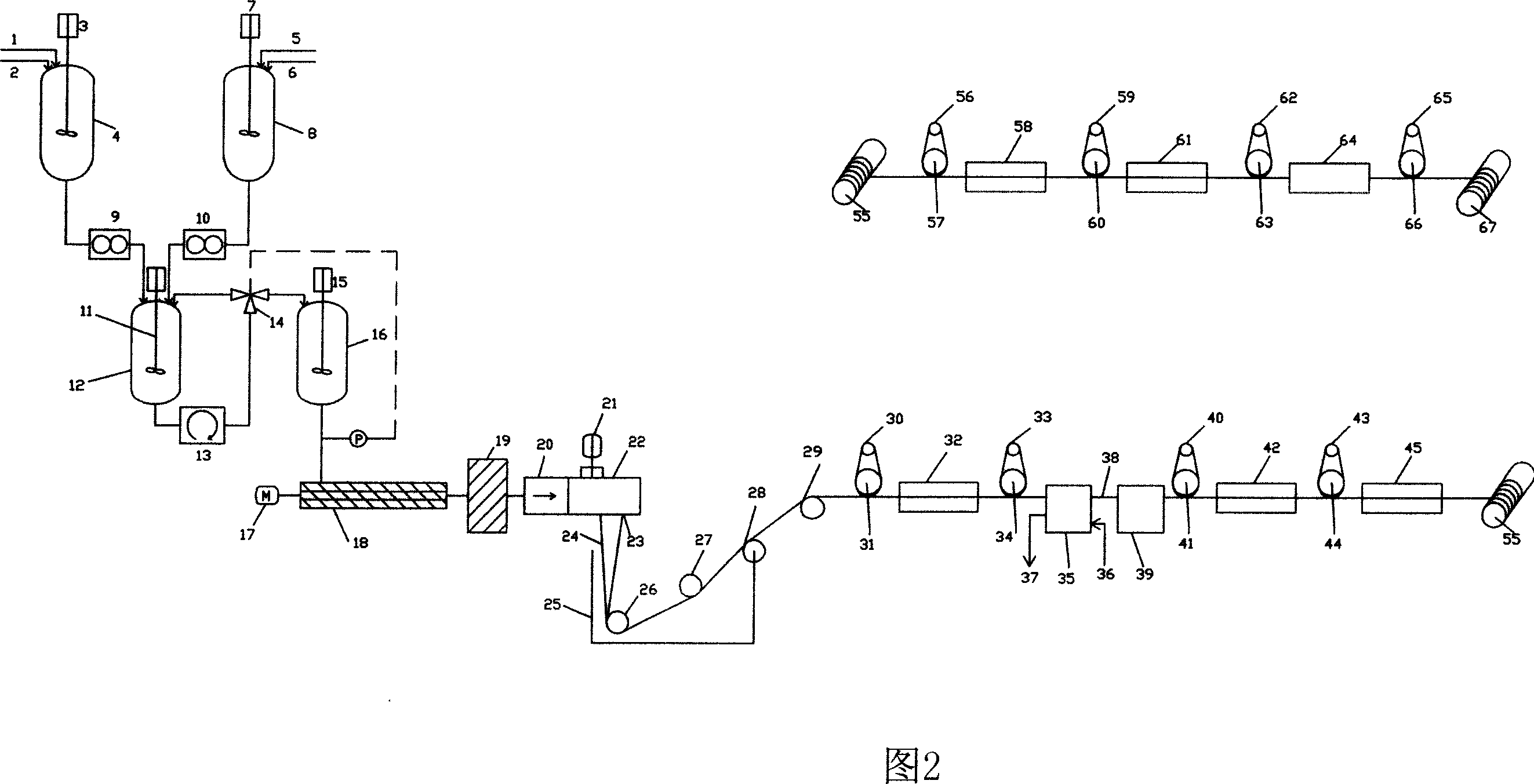

Super high molecular weight polyethylene gel method for continuous producing direct spinning fine denier filament

InactiveCN1995496AUniform and stable qualityGuaranteed accurate feedingWet spinning methodsMonocomponent polyolefin artificial filamentFiberState of art

The invention relates to a manufacturing method for continuous direct spinning fine denier yarn by uhmwpe jelly method, belonging to the spinning area and solving the problem that the single yarn or yarn beam generated by prior technology is on the high side and bad uniformity so that the difficulty for stability of manufacturing and quality of subsequent product is enhanced and the applicable range is limited. The method is provided with reasonable and compact process flow, stable process control, skillful operation and improving the quality and uniformity of product. By the method continuous stable spinning in line is realized in process parameters and the production efficiency is improved. The labor cost and intensity are lessened. Because there is less turnover link in the middle of process it is favor of decreasing producing consumption and uncontrollable factors. Under the stable running, uhmwpe fine denier yarn or yarn beam with even and stable quality, and good performance is provided.

Owner:SINOTEX INVESTMENT & DEV CO LTD

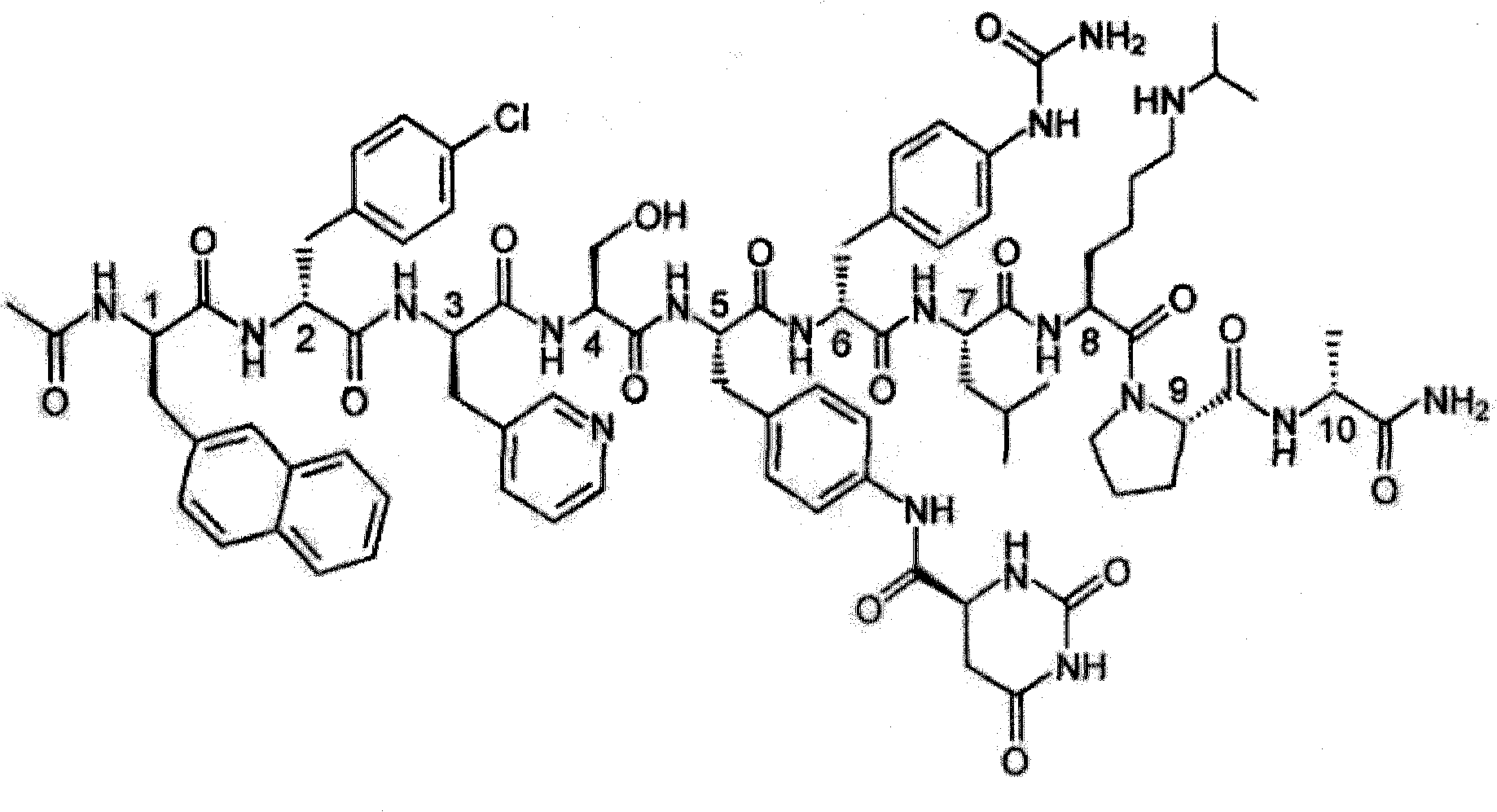

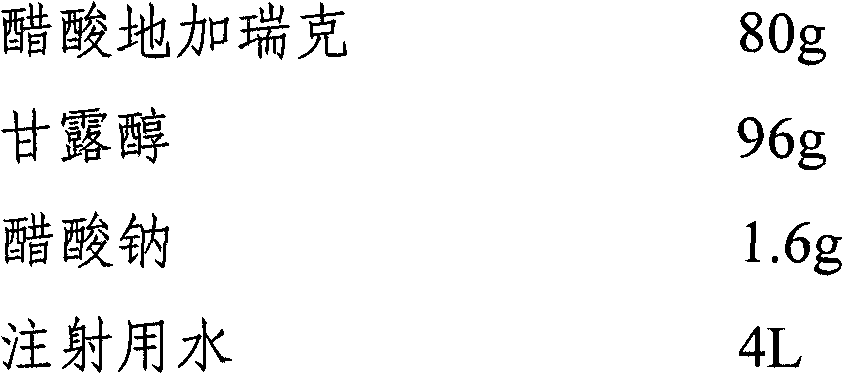

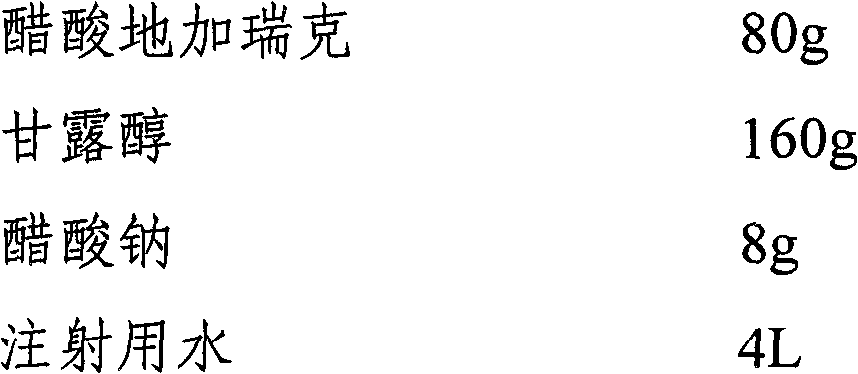

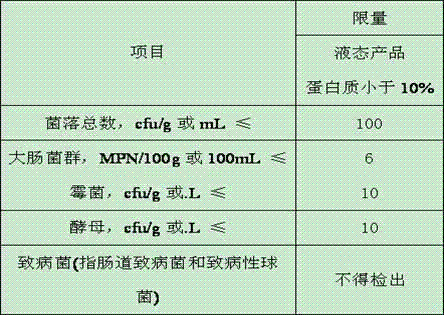

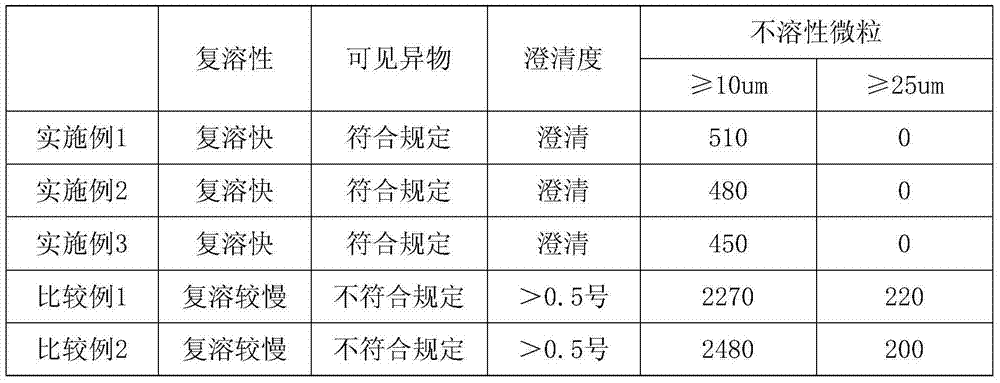

Degarelix acetate lyophilized powder injection and preparation method thereof

ActiveCN102204889AReduce contentUniform and stable qualityPowder deliveryPeptide/protein ingredientsChemistryMoisture

The invention provides a degarelix acetate lyophilized powder injection, which consists of degarelix acetate, mannitol and sodium acetate in the mass ratio of 1:(1.2-2):(0.02-0.1). The lyophilized powder injection is obtained by performing freeze drying on the degarelix acetate, the mannitol and the sodium acetate serving as main medicaments. In the preparation process, the stability and safety of a preparation are ensured strictly. The prepared degarelix acetate lyophilized powder injection has the advantages of low content of relevant substances, uniform and stable mass, complete moisture drying, stability in transportation, storage and using processes, convenience for clinical application, high stability and high biological activity, and the like. The preparation method adopted by the invention is simple and effective, has high repeatability and low production cost, and is easy for industrial production.

Owner:蚌埠丰原涂山制药有限公司

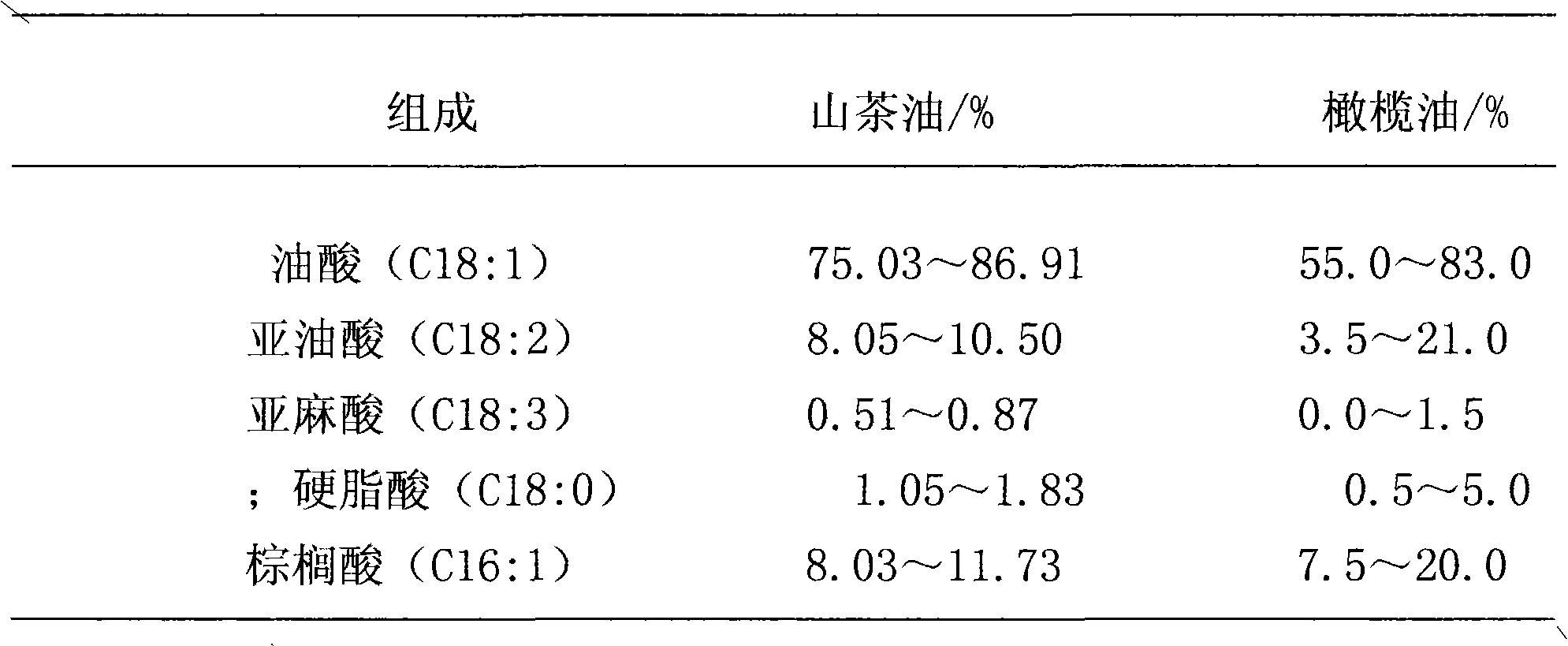

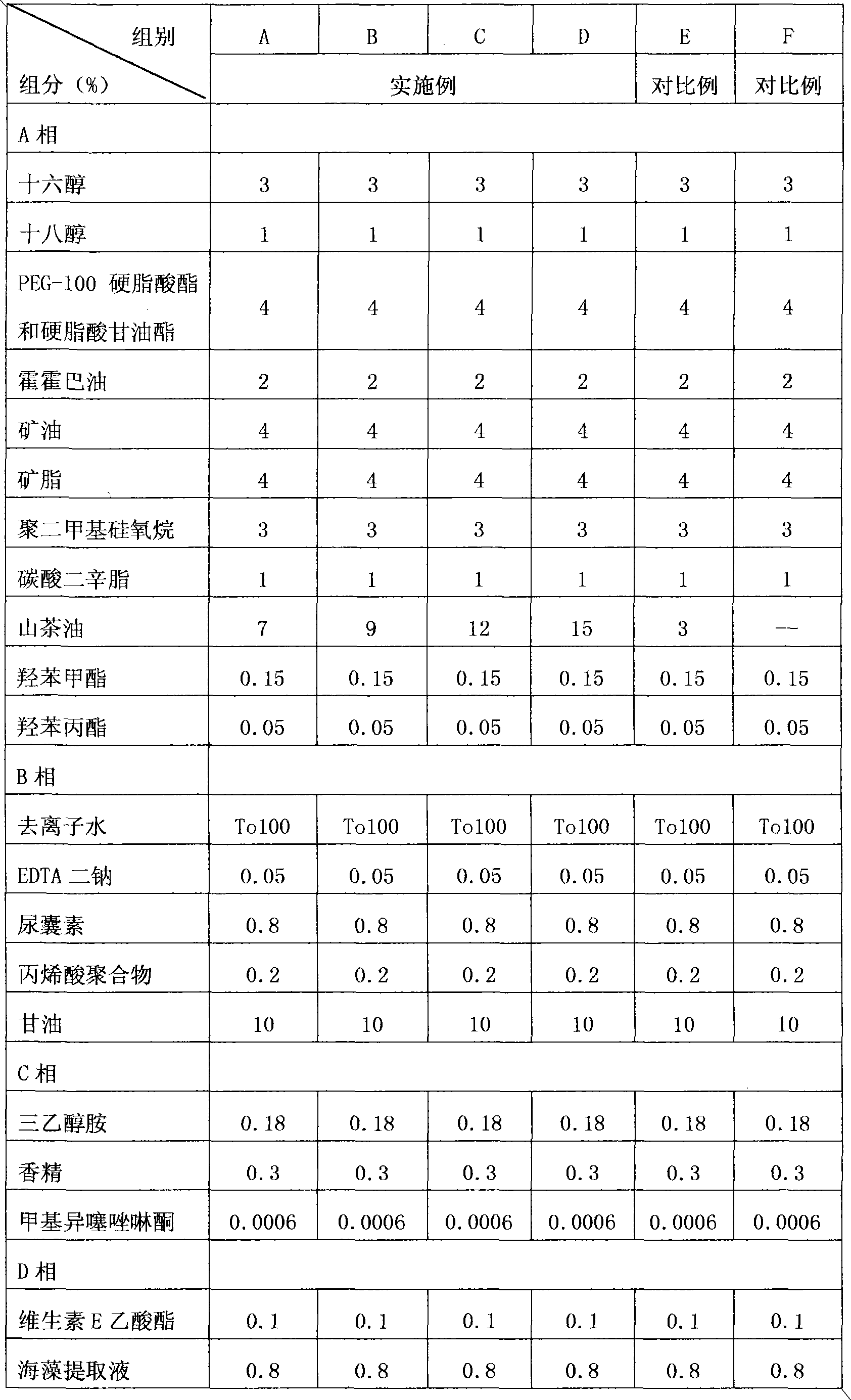

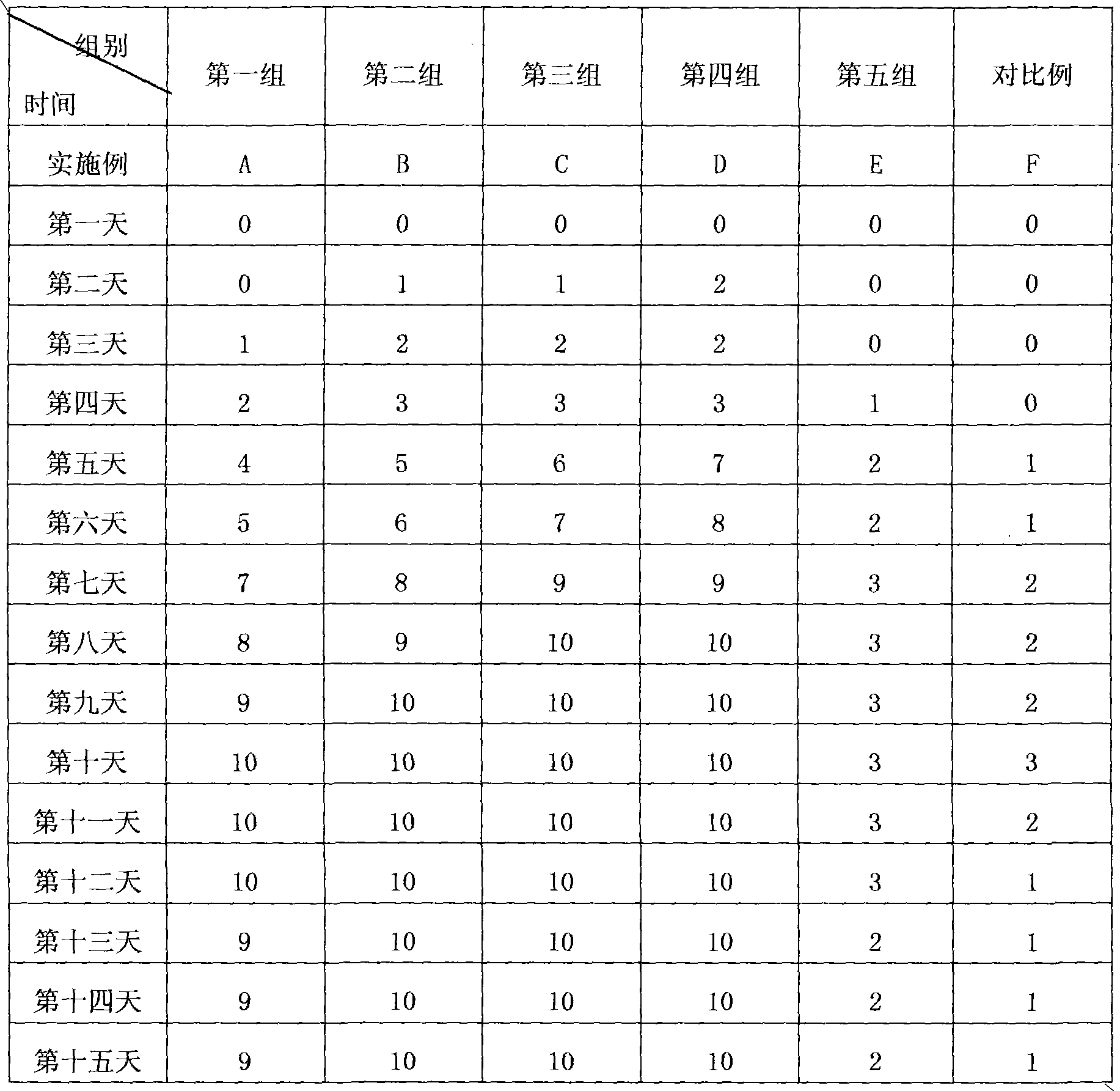

Preparation method of tea oil anti-cracking cream composition and product thereof

ActiveCN101889966AWell mixedUniform and stable qualityCosmetic preparationsToilet preparationsCracking skinPhase composition

The invention discloses a preparation method of a tea oil anti-cracking cream composition. The method is characterized by comprising the following steps: (1) weighing raw materials according to the formula and weight percentage; (2) preparing an A-phase composition; (3) preparing a B-phase composition; (4) preparing a C-phase composition; (5) preparing a D-phase composition; (6) slowly adding the B-phase composition into the A-phase composition while stirring, stirring for 2-5 minutes, and homogenizing for 5 minutes, wherein the stirring speed is controlled at 15-25 r / m, the homogenizing speed is 1400-2600 r / m, and the homogenizing temperature is controlled at 80-90 DEG C; (7) after homogenizing, stirring for 5-10 minutes again, cooling to 50-55 DEG C, adding the C-phase composition; (8) and adding the D-phase composition while cooling to 40-45 DEG C, continuing to stir, and discharging while cooling to 35-38 DEG C, thereby obtaining the tea oil anti-cracking cream composition. The invention also discloses a tea oil anti-cracking cream composition prepared by the method. The method has stable process; and the product can prevent the skin from cracking from dryness, and has obvious function of renovating cracked skin.

Owner:GUANGDONG KINGKEY FINE CHEM CO LTD

Quantitative marinating method of leisure meat product

InactiveCN102871137AImprove water retentionImprove the uniformity and stability of qualityFood preparationLivestockSmoke

The invention discloses a quantitative marinating method of a leisure meat product. The method comprises the following steps: mixing meat product raw materials and flavorings in proportion, rolling and rubbing, then performing cooking and smoke curing to complete the marinating of the leisure meat product. Compared with traditional marinating methods, the method proportions the raw materials and auxiliary materials quantitatively, has a high spice utilization rate, and has a spice using amount being 10%-30% than that of the traditional methods; the method has no boiling loss; the product yield is improved by 5%-8%; the product quality is consistent; the energy consumption is reduced, and the energy power consumption is only 40%-50% than that of the traditional methods; no waste bittern is discharged, and thus no environmental pollution is caused. The method is suitable for the production of sauce-marinated leisure meat products by cutting raw materials of livestock and poultry fresh (frozen) meat such as duck necks, chicken wings, chicken necks, meat pieces, and the like, and is a novel marinating seasoning method. The method is low in production cost, high in production efficiency, and can realize continuous and industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for quickly producing Pu-Er ripe tea

ActiveCN101703122AReduce adverse effectsAvoid pollutionPre-extraction tea treatmentCore temperatureGreen tea

The invention discloses a method for quickly producing Pu-Er ripe tea, which comprises the following steps: moistening crude green tea with clear water, wrapping the moistened crude green tea with a cloth bag, placing the wrapped crude green tea in a basket and fermenting the crude green tea in the basket for 15 to 25 days at the temperature of 25 to 40 DEG C under the condition that relative humidity is 40 to 80 percent; turning a fermented tea pile for 4 to 6 times during the fermentation, starting replenishing water from the turning for the third time in a way that the water replenished for each time is 20 to 80 percent of the weight of the crude green tea and controlling the core temperature of the fermented tea pile to be below 59 DEG C; and after the fermentation, drying the fermented tea pile to obtain the Pu-Er ripe tea. Compared with the conventional method, the method has the characteristics of easily-controlled production process, clean production environment, no pollution of products, 40 to 60 percent-reduced processing time, stable tea quality, reduced production cost, relatively higher efficiency, normative production process and the like, and realizes the large-scale and normative production of the Pu-Er ripe tea.

Owner:云南和本茶业有限公司

Alloy material for crusher hammerhead and preparation method thereof

The invention relates to an alloy material for a crusher hammerhead, which contains the following chemical elements in percentage by mass: 0.2-0.4% of carbon, 0.7-0.9% of silicon, 3.2-3.5% of manganese, 3.6-3.8% of chromium, 1.7-1.9% of molybdenum, 0.2-0.5% of titanium, 0.02-0.04% of Sb, 0.01-0.02% of Lu, 0.02-0.03% of Ga, at most 0.05% of S, at most 0.05% of P and the balance of iron. By using the low-carbon steel as the main material, the material has favorable toughness; the material contains the Sb, Lu, Ga and many other alloy elements, so that the alloy has high hardness, high wear resistance and high hot strength; and the material is suitable for a medium-size crusher and used for crushing ores with moderate hardness, the service life can be prolonged by 1 time or so as compared with high-chromium cast iron, and the cost is lower. When the refining agent is used for casting production, no pores can be generated on the casting surface, and the included oxide content is obviously lowered.

Owner:MAANSHAN HENGYI MACHINERY MFG

Functional drink with function of relieving visual fatigue and preparation method thereof

InactiveCN104256817AReduce extraction timeImprove extraction efficiencyTea substituesFood ingredient functionsLuteinSugar

The invention provides a functional drink with a function of relieving visual fatigue and a preparation method thereof, belonging to the technical field of functional drinks. The functional drink with the function of relieving the visual fatigue is prepared from five raw materials of lutein, medlar, chrysanthemum, white granulated sugar and citric acid, wherein the lutein is extracted from marigold; the functional drink is prepared by adopting a series of steps of pretreating raw materials, extracting, blending and the like. The functional drink prepared by adopting the preparation method is safe and reliable in raw materials; meanwhile, no caffeine, preservative and artificial color are added, and the functional drink has functions of improving the eyesight and relieving the visual fatigue.

Owner:河南福森药业有限公司

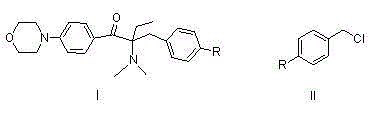

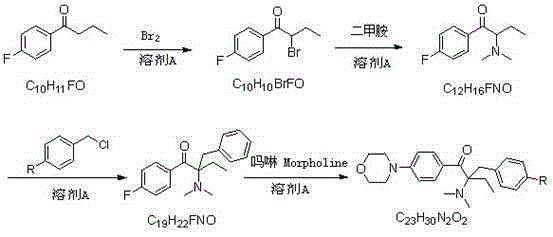

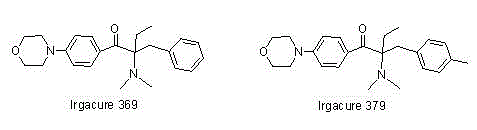

Alpha-amino acetophenone photoinitiator preparation method

ActiveCN105384707AReduce the number of separationsReduces chances of cross-contaminationOrganic chemistryPhotoinitiatorAcetophenone

The present invention relates to an alpha-amino acetophenone photoinitiator preparation method, particularly to a preparation method of 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butanone and 2-(4-methylbenzyl)-2-dimethylamino-1-(4-morpholinophenyl)butanone. According to the present invention, 1-p-fluorophenyl-1-butanone is adopted as the raw material, and only the safe and cheap solvent is used in the whole method to conveniently prepare 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butanone and 2-(4-methylbenzyl)-2-dimethylamino-1-(4-morpholinophenyl)butanone; and the method has characteristics of cheap and readily available raw materials, high yield, no requirement of intermediate purification, and continuous reaction without solvent replacement, and is the preparation method with characteristics of low cost, environmental protection and easy operation and suitable for industrialization.

Owner:SHANDONG JIURI CHEM TECH CO LTD

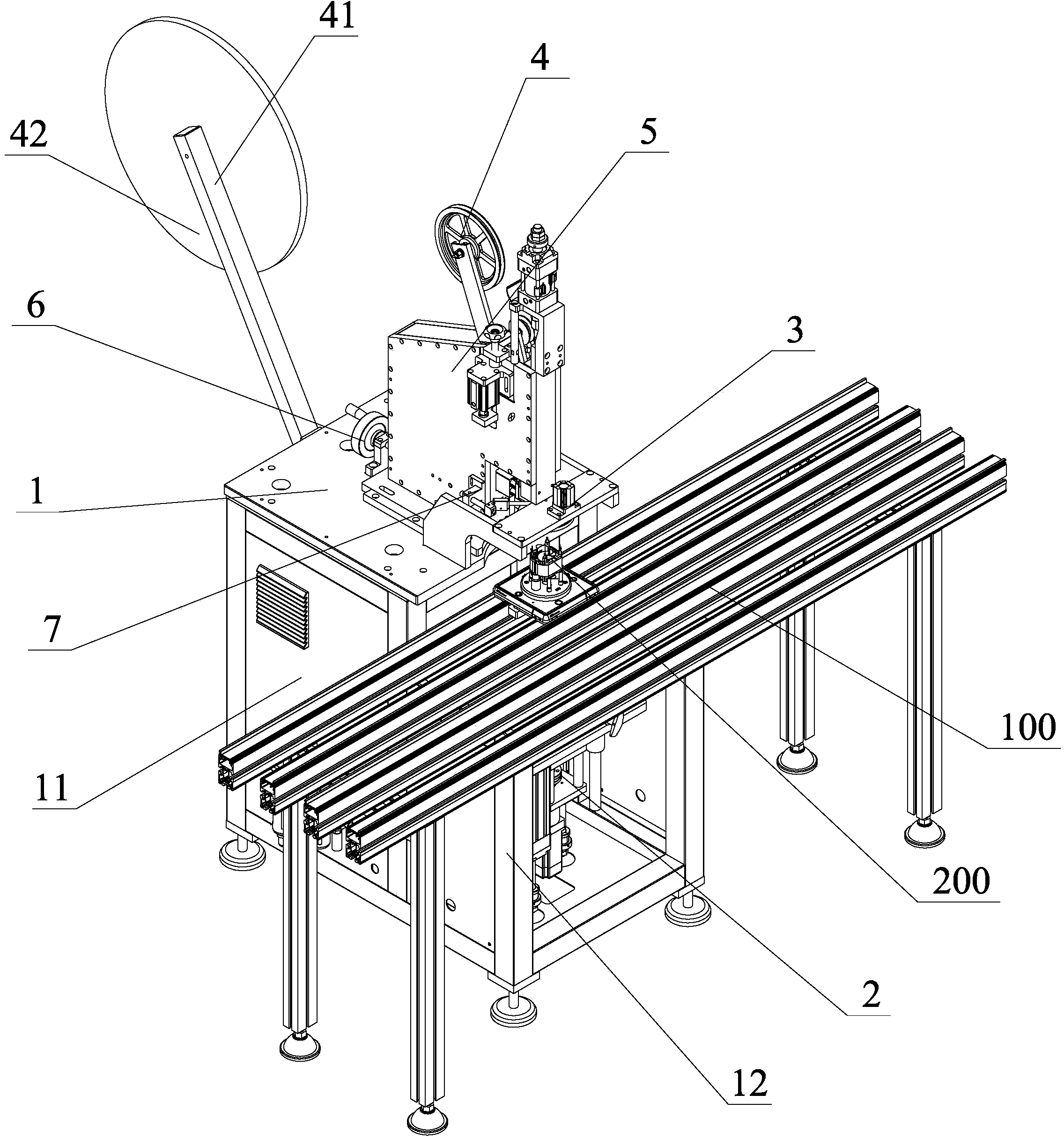

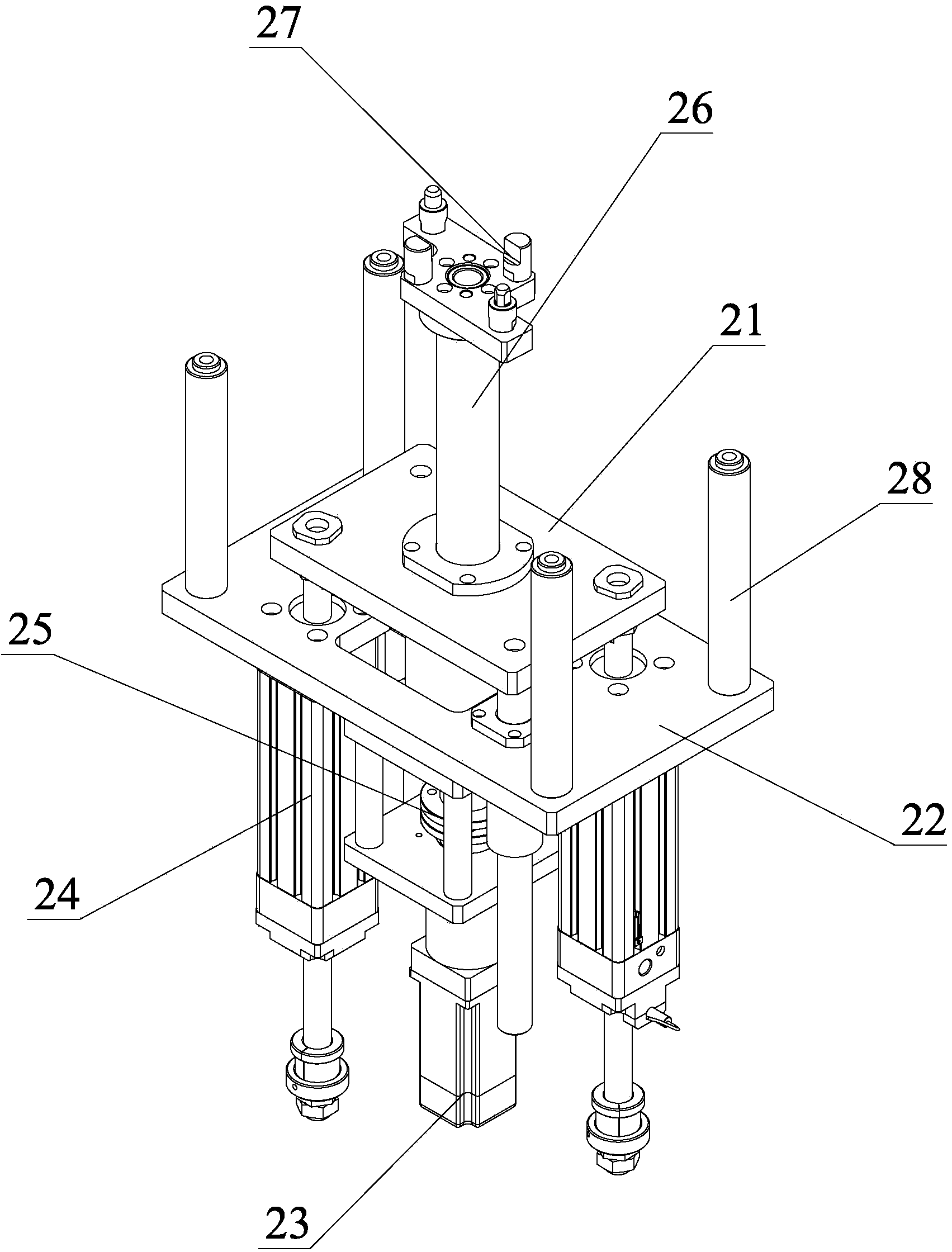

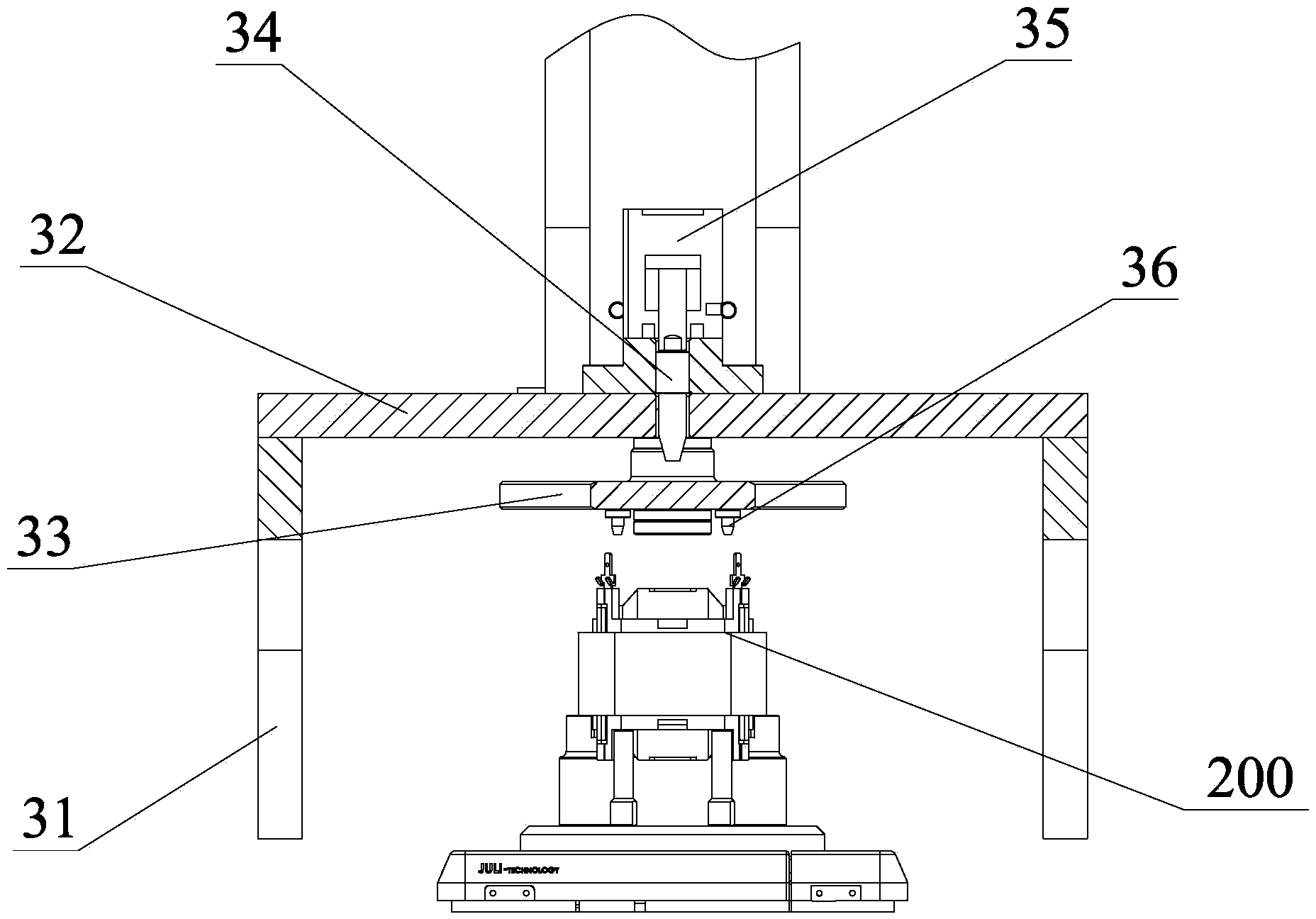

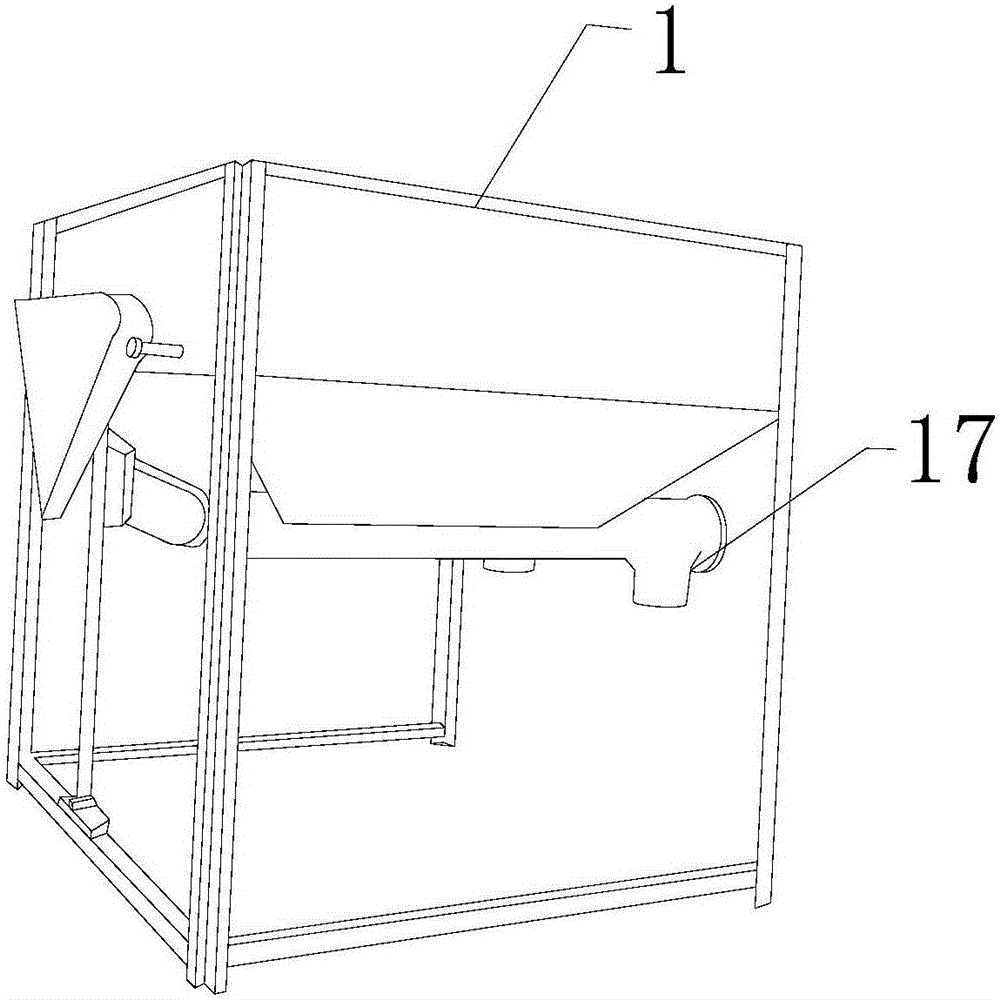

Automatic terminal insertion device of stators

ActiveCN104167882ANo manual operationSave human effortManufacturing stator/rotor bodiesAssembly lineInsertion procedure

The invention provides an automatic terminal insertion device of stators. The automatic terminal insertion device comprises a rack platen assembly, a jacking feeding assembly, a positioning rotating assembly, a terminal channel assembly, a head section assembly and a terminal insertion position adjusting assembly. The jacking feeding assembly is used for jacking the stators on an assembly line upwards to terminal insertion stations; the positioning rotating assembly is used for rotating the stators; the terminal channel assembly is used for providing a terminal feeding channel; the head section assembly comprises a head section frame plate, a terminal feeding mechanism, a terminal cutting mechanism and a terminal insertion mechanism. The head section assembly is further provided with a terminal detection device used for detecting whether terminals are inserted correctly or not, and the head section assembly is installed on the rack platen assembly through the terminal insertion position adjusting assembly. An automatic terminal insertion procedure is added on a stator conveying assembly line, and the automatic terminal insertion device can adapt to terminals and stators of various specifications; in this way, the device does not need replacing, and device resources are saved; besides, no human intervention exists in the whole process, automatic insertion and automatic detection are achieved, and output quality is stable and uniform.

Owner:巨力敖轩科技(浙江)有限公司

Highly-wear-resistant alloy steel material used for pump trucks and preparation method of the alloy steel material

The invention discloses a highly-wear-resistant alloy steel material used for pump trucks. The alloy steel material comprises following chemical elements by weight: 0.2-0.4% of carbon, 1.4-1.7% of silicon, 4.2-4.4% of manganese, 1.7-2.1% of chromium, 0.4-0.7% of molybdenum, 0.1-0.3% of aluminum, 0.3-0.5% of boron, 0.5-0.8% of titanium, 0.04-0.07% of La, S not more than 0.04% and P not more than 0.04%, with the balance being iron. The alloy steel has high hardness, good wear resistance, high toughness, good plasticity, good corrosion resistance and long service lifetime, and is suitable for working in highly-wearing environments such as pump truck tank bodies, delivery pipes, and the like. A portion of waste iron is used as a raw material of the alloy steel material and a secondary refining process is performed so that the quality of the alloy steel material is stable and uniform. A refining agent provided by the invention is used for casting production and is capable of increasing the rate of finished products, reducing the porosity degree in castings by 1-2 degrees, avoiding air hole generation on casting surfaces and reducing significantly oxide inclusion which is about at the 2 level.

Owner:TONGLING JINGWEI FLUID SCI & TECH

High-temperature resistant and wear-resistant alloy steel lining plate material and preparation method thereof

The invention discloses a high-temperature resistant and wear-resistant alloy steel lining plate material which comprises the following chemical elements in percentage by mass: 0.2-0.4% of carbon, 0.2-0.4% of silicon, 3.5-3.7% of manganese, 0.7-0.9% of chromium, 0.8-1.1% of molybdenum, 1.2-1.4% of vanadium, 0.1-0.15% of lanthanum, 0.04-0.07% of Nb, less than or equal to 0.04% of S, less than or equal to 0.04% of P and the balance of iron. In the lining plate provided by the invention, the alloy steel obtained by adding the elements such as lanthanum, molybdenum and niobium into low-carbon steel has the advantages of high hardness, high strength, good wear resistance, high-temperature resistance, good toughness, good plasticity, corrosion resistance and high cost performance. In the lining plate material disclosed by the invention, the waste iron is partially used as the raw material, secondary refining is performed, the thermal treatment temperature after casting is reasonably controlled, the raw material is fed in batches, and the comprehensive mechanical properties are improved. A refining agent is applied to the casting production; and in a casting, the porosity is reduced by 1-2 degrees, and the oxide inclusion is at about level 2.

Owner:CHUZHOU UNIV

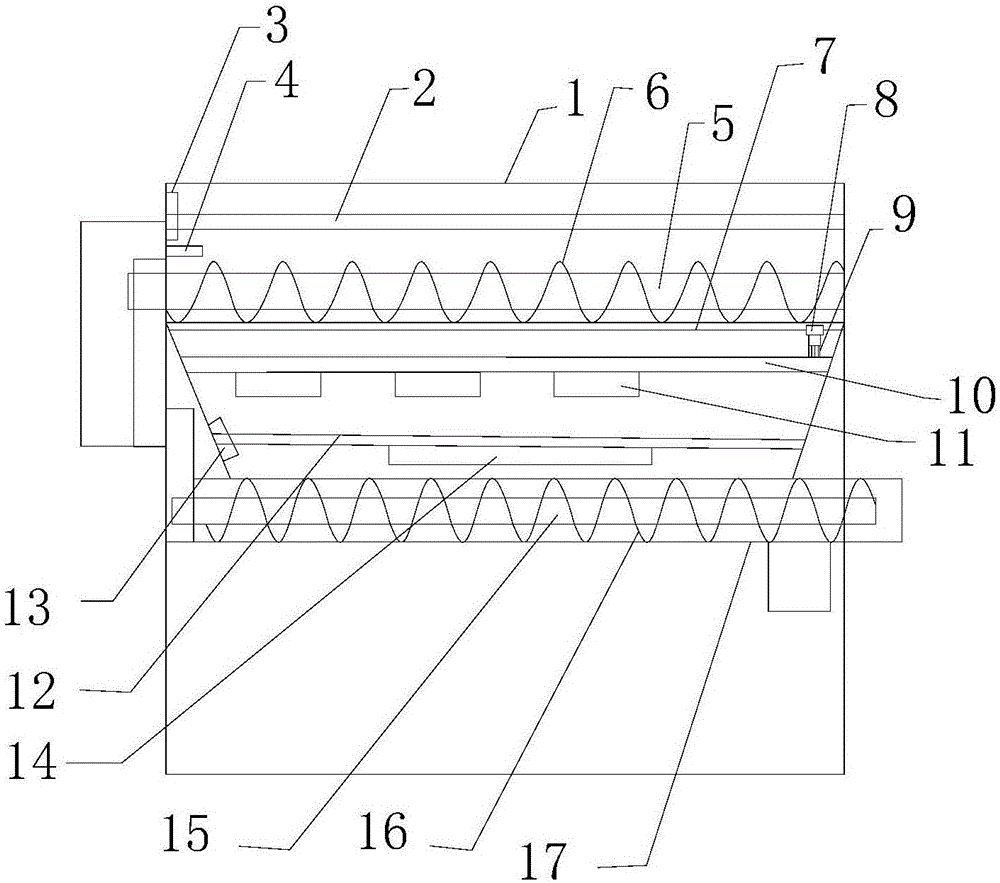

Organic fertilizer packaging silo

ActiveCN106043755AUniform and stable packaging qualityEasy to operateSievingConveyorsGastric tube feedingAgricultural engineering

The invention discloses an organic fertilizer packaging silo. The organic fertilizer packaging silo comprises a sorting silo, first feeding baffles, a first angle adjuster, a sensing electric eye, first feeding shafts, first feeding paddles, cleaning guide tracks, a cleaning sliding block, a screen cleaning brush, a sorting screen, sorting oscillators, a second feeding baffle, a second angle adjuster, a weight sensor, a second feeding shaft, a second feeding paddle and feeding tubes. By the organic fertilizer packaging silo, conveying and packaging of organic fertilizers can be monitored and adjusted in real time, the packaging quality of the organic fertilizers is ensured to be uniform and stable, and at the same time, conveyance of the organic fertilizers can be planned automatically. The organic fertilizer packaging silo is convenient to operate, high in degree of automation and high in production efficiency.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

Pump super-wear-resistant high-hardness alloy steel material and preparation method thereof

ActiveCN103667944AHigh hardnessImprove wear resistanceProcess efficiency improvementPorosityWear resistant

The invention relates to a pump super-wear-resistant high-hardness alloy steel material which comprises the following chemical element compositions in percentage by mass: 2.2-2.4% of carbon, 0.3-0.4% of silicon, 1.7-1.9% of manganese, 3.4-3.6% of chromium, 5.7-6.2% of tungsten, 0.7-0.9% of vanadium, 2.1-2.3% of molybdenum, 0.5-0.7% of cobalt, 0.2-0.3% of titanium, 1.3-1.5% of magnesium, 0.6-0.8% of aluminum, 0.5-0.7% of boron, 0.04-0.06% of niobium, 0.1-0.15% of gadolinium, less than or equal to 0.04% of S, less than or equal to 0.04% of P, and the balance of iron. Elements of tungsten, boron and the like are added in the pump super-wear-resistant high-hardness alloy steel material on the basis of high-carbon steel, so that the hardness and wear resistance of the alloy can be enhanced, and the thermal strength performance and toughness of the alloy can be increased by using elements of vanadium, niobium and the like; the porosity of castings can be reduced by one to two degrees through a refining agent, and the oxide inclusion is at about 2 level. The alloy steel is applicable to components of impellers, conveying pipelines, valves and the like of a pump.

Owner:ANHUI RONGDA VALVE

Alloy steel hammerhead material for small-size crusher and preparation method thereof

The invention relates to an alloy steel hammerhead material for a small-size crusher, which contains the following chemical elements in percentage by mass: 0.2-0.4% of carbon, 0.8-1.0% of silicon, 2.1-2.3% of manganese, 5.2-5.5% of chromium, 0.8-1.1% of molybdenum, 0.2-0.3% of vanadium, 2.6-2.8% of titanium, 0.15-0.25% of V, 0.08-0.12% of Te, 0.5-0.7% of Zr, at most 0.05% of S, at most 0.05% of P and the balance of iron. By using medium-manganese low-carbon steel as the main material, the material has favorable toughness; the material contains the Zr, V, chromium, molybdenum and many other alloy elements, and thus, has the characteristics of higher strength, excellent high temperature resistance and excellent corrosion resistance; and the material is suitable for small-size working conditions with non-severe impact, and the service life is 2-3 times longer than that of common low alloy steel. When the refining agent is used for casting production, the porosity in the casting is lowered by 1-2 degrees, and the oxide inclusions are lowered by 2 levels or so.

Owner:MAANSHAN HENGYI MACHINERY MFG

High-magnesium aluminum alloy material for wheel hubs and preparation method thereof

InactiveCN103774007AQuality improvementHigh magnesium aluminum alloy has light weightPorosityManganese

The invention relates to a high-magnesium aluminum alloy material for wheel hubs, which contains the following chemical components in percentage by mass: 12-15% of magnesium, 3.2-3.5% of silicon, 0.2-0.5% of calcium, 0.12-0.17% of molybdenum, 0.1-0.15% of copper, 0.04-0.06% of manganese, 0.2-0.25% of titanium, 0.04-0.06% of nickel, 0.12-0.15% of strontium, 0.12-0.16% of Ta and the balance of aluminum. The high-magnesium aluminum alloy has the characteristics of light weight and corrosion resistance; and the titanium, strontium, nickel and other elements are added to refine the crystal grain and enhance the strength and wear resistance of the alloy, so that the alloy quality is more stable and uniform. When being used for manufacturing wheel hubs, the aluminum alloy has the advantages of favorable casting and forging property, favorable thermal conductivity, light weight and fuel cost saving. When the refining agent is used for casting production, the porosity in the casting can be lowered by 1-2 degrees, the oxide inclusion content is Grade 2 or so, and the yield is high.

Owner:MAANSHAN HENGYI MACHINERY MFG

Wear-resistant alloy steel material for valve bodies and preparation method thereof

The invention relates to a wear-resistant alloy steel material for valve bodies, which contains the following chemical elements in percentage by mass: 1.2-1.5% of carbon, 2.2-2.5% of silicon, 0.4-0.5% of manganese, 1.6-1.8% of chromium, 0.6-0.8% of copper, 1.2-1.4% of vanadium, 0.12-0.15% of boron, 0.15-0.20% of titanium, 0.1-0.15% of strontium, at most 0.030% of S, at most 0.030% of P and the balance of iron. By using the combination of the chromium, manganese, titanium and many other raw materials, the formed alloy steel has the characteristics of high strength, high hardness, favorable wear resistance and favorable corrosion resistance. Part of scrap iron is used as the raw material, and secondary refining is performed, so that the product quality is more stable and uniform. By adding the refining agent, the porosity is lowered by 1-2 degrees, and the oxide inclusions are lowered by 2 levels or so. The alloy steel is suitable for manufacturing valve bodies and is corrosion-resistant, and the service life is obviously prolonged.

Owner:张超

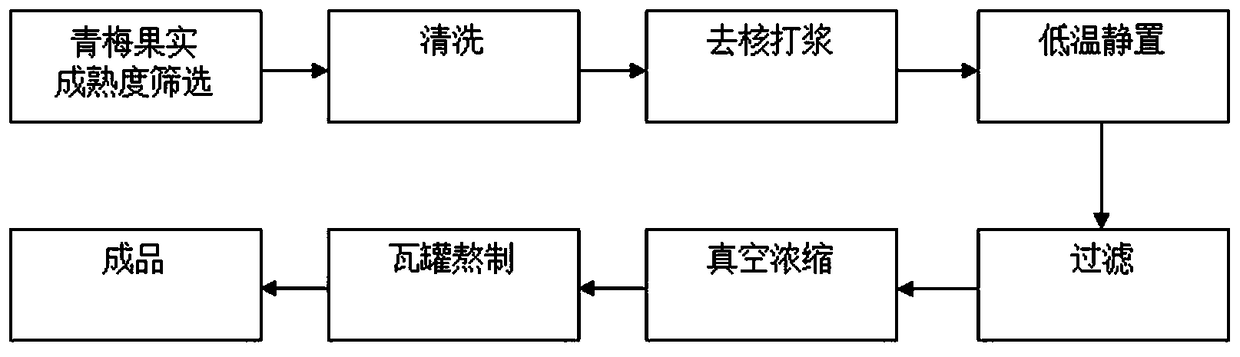

Preparation method of green plum essence

InactiveCN108936658AEffectively retain organic acidsRetained organic acidNatural extract food ingredientsFood ingredient as mouthfeel improving agentSugarFood flavor

The invention relates to a preparation method of a green plum essence. The preparation method comprises the following steps of (1) screening green plum fruits as a raw material according to maturity;(2) performing washing; (3) performing kernel removing and pulping; (4) performing low-temperature standing; (5) performing filtering; (6) performing vacuum concentration; and (7) performing decoctingwith a crock. According to the preparation method disclosed by the invention, the maturity of the raw material is strictly controlled, so that the situation that the quality of the green plum fruitsis unified and stable is guaranteed; besides, the problems that conventional high-temperature decocting is long in time consumption, and the effective components of the green plums are damaged are solved; and through determining the sugar acidity of the raw material, a preparation method of combining vacuum concentration with decocting with the crock is utilized, so that the time consumption is low, the energy can be saved, and the prepared green plum essence is thorough in reservation of effective components, good in quality and good in flavor.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST +1

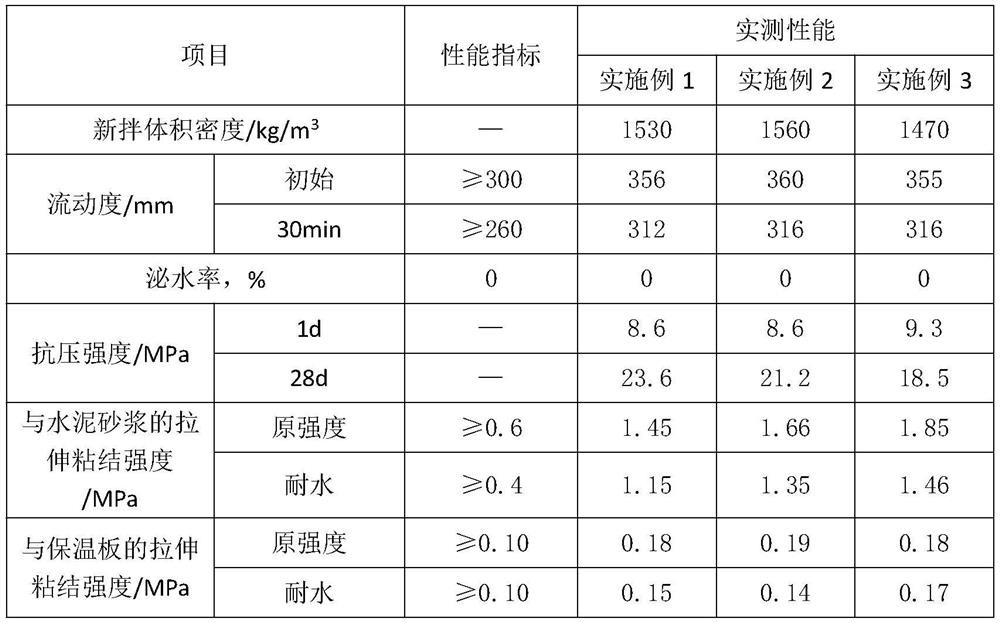

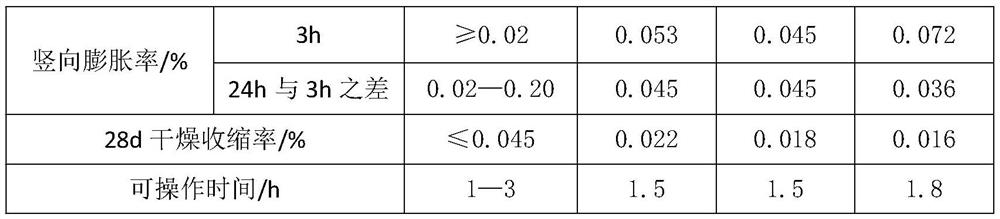

Lightweight grouting material for repairing hollowing of wall thermal insulation system and preparation method

InactiveCN112341124AImprove volume stabilityGood empty drum repair and compact effectAluminateCellulose

The invention belongs to the technical field of building materials, and provides a lightweight grouting material for repairing hollowing of a wall insulation system and a preparation method. The lightweight grouting material comprises a ternary cementing material, an auxiliary cementing material, latex powder, cellulose ether, a water reducing agent, an air entraining agent, an antifoaming agent,a water repellent, an expanding agent, lightweight aggregate and quartz sand, wherein the ternary cementing material is formed by mixing Portland cement, sulphoaluminate cement and gypsum, and the auxiliary cementing material is a mixture of titanium slag micro-powder and fly ash. The lightweight grouting material is simple to prepare and convenient to use, and has the advantages of easiness in grouting, good hollowing repairing effect, controllable setting time and operable time, small volume density, no segregation or layering, quicker early strength development, higher strength, high bonding strength with a matrix, no shrinkage cracking problem and the like; the grouting material is suitable for hollowing repair projects of various wall exterior and wall interior thermal insulation systems, and other grouting repair projects with low requirements on compressive strength and high requirements on adhesive properties.

Owner:TONGJI UNIV

Process of preparing calcium carbonate by air bubble film method and application thereof

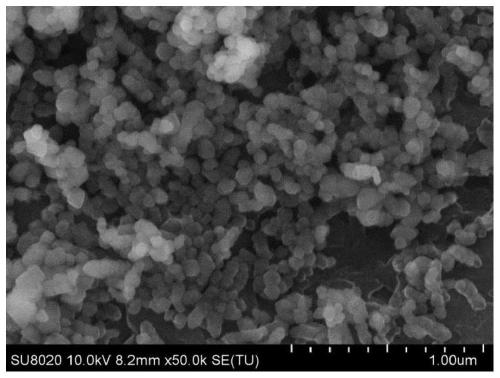

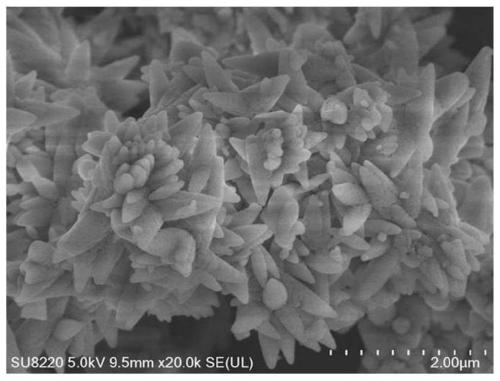

ActiveCN109824076AIncrease chance of contactIncrease reaction rateCalcium/strontium/barium carbonatesMaterial nanotechnologyDispersityCalcium hydroxide

The invention discloses a process of preparing calcium carbonate by an air bubble film method and application thereof and belongs to the technical field of preparation of inorganic nonmetal calcium carbonate powders. The process herein comprises carbonization and surface treatment; refined calcium hydroxide slurry is quickly carbonized in an air bubble film quick carbonizing reactor; a slurry fromthe reaction is subjected to suitable surface treatment as required; the treated slurry is filtered, drying is carried out before crushing, and screening is performed to obtain calcium carbonate powder uniform in particle size. The process herein has no need for adding a crystal form control agent; the crystal morphology is controllable; the finished product has uniform particle size and good dispersity; the process is simple and feasible and has low production cost; the prepared calcium carbonate powder is applicable to the industries of plastics, rubber, papermaking, foods, medicine, and cosmetics, and has good economic and social benefits.

Owner:GUANGXI UNIV +1

Wear-resistant high-manganese steel liner plate material and preparation method thereof

ActiveCN103667945AHigh hardnessImprove wear resistanceProcess efficiency improvementPorosityWear resistant

A wear-resistant high-manganese steel liner plate material comprises the following chemical elements by mass percent: 1.2 to 1.4 of carbon, 1.3 to 1.5 of silicon, 9.2 to 10.4 of manganese, 1.1 to 1.3 of titanium, 0.9 to 1.3 of chromium, 0.02 to 0.04 of molybdenum, 0.1 to 0.2 of aluminum, 0.02 to 0.04 of lanthanum, 0.04 to 0.07 of neodymium, less than or equal to 0.04 of S, less than or equal to 0.04 of P and the balance of iron. The alloy steel, prepared by adding lanthanum, neodymium, titanium and other elements into the alloy steel based on the high-carbon manganese steel, has the advantages of high hardness, excellent wear resistance, good toughness and good plasticity. The performance of the alloy steel is more superior to that of the ordinary high-manganese steel and suitable for liner plate material with large wear. The porosity of the casting pieces can be reduced by 1-2 degrees, no pores are generated on the surface of casting pieces and oxide inclusions are significantly reduced to about 2-level when the refining agent is used in casting.

Owner:MAANSHAN YIFENG INDAL GROUP

Corrosion-resistant, wear-resistant and high-temperature-resistant alloy steel material for pump valve and preparation method thereof

The invention relates to a corrosion-resistant, wear-resistant and high-temperature-resistant alloy steel material for a pump valve. The material comprises the following chemical elements in percentage by weight: 0.3-0.5% of carbon, 0.5-0.8% of silicon, 8.2-8.4% of manganese, 4.4-4.6% of chromium, 1.9-2.1% of molybdenum, 5.1-5.3% of nickel, 0.8-1.0% of niobium, 2.2-2.4% of magnesium, 4-5% of zinc, 0.02-0.04% of boron, 3.2-3.4% of titanium, 0.5-0.8% of Be and the balance of ferrum and inevitable impurities. On the basis of low carbon steel, elements such as manganese, boron and magnesium are added, so that the formed alloy steel has extremely good characteristics of corrosion resistance, wear resistance, acid resistance and high hardness. A refining agent is used for foundry practice. The pore degree is reduced by 1-2 degrees, and oxide inclusion is in about level II. According to the alloy steel for the pump valve, the service life is more than doubled compared with that of a common stainless steel acid proof pump.

Owner:张超

Rare-earth wear-resistant stainless steel lining board material and preparation method thereof

The invention relates to a rare-earth wear-resistant stainless steel lining board material which contains the following chemical components in percentage by mass: 0.2-0.4% of carbon, 0.3-0.4% of silicon, 3.2-3.4% of manganese, 3.5-3.8% of chromium, 0.03-0.04% of nickel, 0.12-0.25% of molybdenum, 0.04-0.07% of vanadium, 0.01-0.03% of lanthanum, 0.04-0.07% of Sc, at most 0.04% of S, at most 0.04% of P and the balance of iron. The lanthanum, scandium and other elements are added on the basis of medium / low-carbon steel, so the obtained alloy steel has the advantages of high hardness, excellent wear resistance, favorable toughness, favorable plasticity and corrosion resistance; and compared with the low-carbon high-alloy steel, the alloy steel provided by the invention has lower cost. Part of scrap iron is used as the raw material, so that the alloy quality is more stable and uniform, thereby enhancing the comprehensive mechanical properties. When the refining agent is used for casting production, the yield is obviously enhanced.

Owner:MAANSHAN YIFENG INDAL GROUP

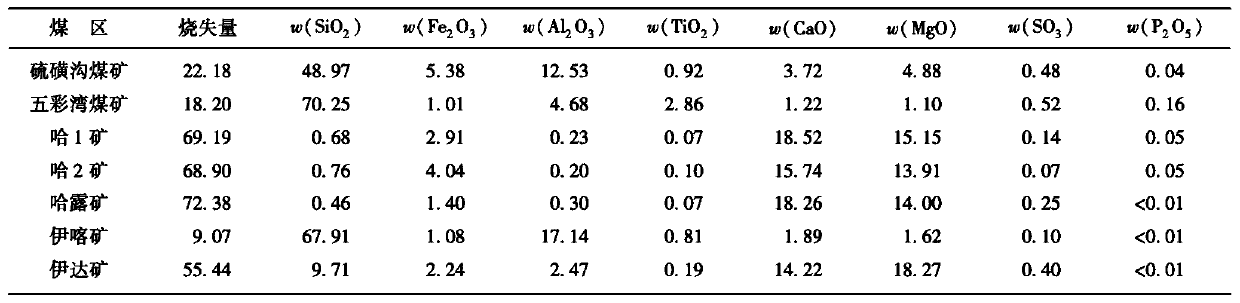

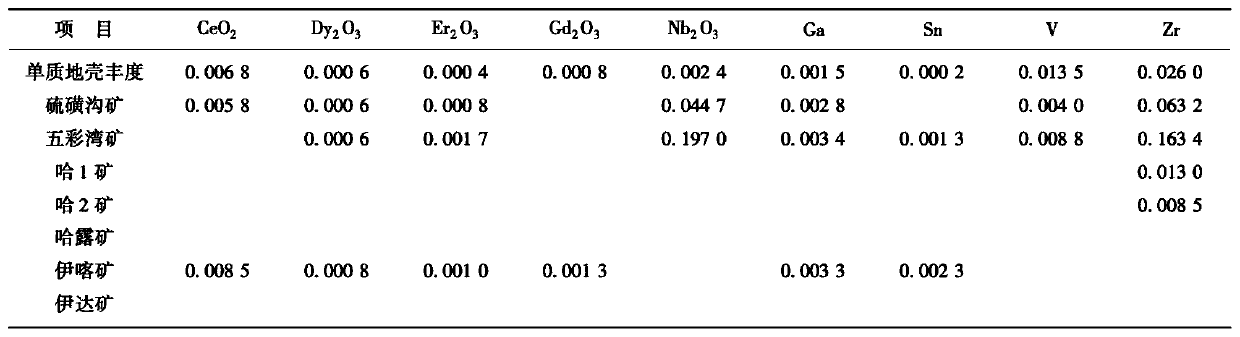

Dry anti-seepage material and preparation method thereof

The invention belongs to the field of anti-seepage materials, and specifically relates to a dry anti-seepage material. The dry anti-seepage material comprises the following components in parts by weight: 60 to 80 parts of coal gangue, 8 to 15 parts of andalusite and 15 to 23 parts of a binder, wherein the coal gangue is originated from the coal gangue in the area of Xinjiang in China. Meanwhile, the invention also discloses a preparation method for the dry anti-seepage material. Compared with a traditional dry anti-seepage material, the dry anti-seepage material provided by the invention is ananti-seepage material produced by modifying and processing a local main raw material capable of being utilized by a local enterprise in Xinjiang in terms of a process, so the production cost of the enterprise is greatly reduced, and the dry anti-seepage material provided by the invention is surely accepted by the market.

Owner:新疆天山建材集团耐火材料有限责任公司

Rare earth alloy steel material used for valves and preparation method of the material

The invention discloses a rare earth alloy steel material used for valves. The rare earth alloy steel material comprises following chemical elements by weight: 0.2-0.4% of carbon, 0.3-0.45% of silicon, 3.2-3.4% of manganese, 0.9-1.2% of chromium, 0.5-0.7% of molybdenum, 0.1-0.25% of vanadium, 0.02-0.04% of lanthanum, 0.02-0.04% of cerium, 0.12-0.24% of copper, 0.04-0.07% of Tm, S not more than 0.04% and P not more than 0.04%, with the balance being iron. An alloy produced has characteristics of high strength, compact resistance, wear resistance and high hot strength by utilization of the molybdenum, the vanadium, the vanadium, the rare earth elements, etc., and by adding the raw materials in batches and reasonably controlling the thermal treatment temperature after casting. The rare earth alloy steel material is suitable for valves, pipes and impellers of pumps operated at high temperature. A refining agent provided by the invention is used for casting production and is capable of increasing the rate of finished products. In particular, the porosity degree in castings is reduced by 1-2 degrees and oxide inclusion is at about the 2 level.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Antimony-containing highly-wear-resistant alloy steel material used for pump valves and preparation method of the alloy steel material

The invention discloses an antimony-containing highly-wear-resistant alloy steel material used for pump valves. The alloy steel material comprises following chemical elements by weight: 0.3-0.45% of carbon, 0.7-0.85% of silicon, 1.1-1.4% of manganese, 2.7-2.9% of chromium, 0.3-0.5% of boron, 0.12-0.15% of cerium, 0.5-0.8% of As, 0.02-0.04% of Sb, S not less than 0.04% and P not less than 0.04%, with the balance being iron. By adoption of combination of the antimony, the boron, the cerium, and other elements, the alloy steel obtained has high hardness, good wear resistance, good toughness and good corrosion resistance, is suitable for working in highly-wearing environments, such as pump truck tank bodies, delivery pipes, bearings, pump shafts, and the like, and has service lifetime two times longer than a common material. A portion of waste iron is used as a raw material of the alloy steel material and a secondary refining process is performed so that the quality of the alloy steel material is stable and uniform. A refining agent provided by the invention is used for casting production. The porosity degree in castings is reduced by 1-2 degrees. Oxide inclusion is at about the 2 level.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Texturing technology for transparent conducting film as top electrode of thin film solar cell

ActiveCN102306682AMeet the requirementsImprove surface uniformityFinal product manufactureSemiconductor devicesAutomatic controlTransparent conducting film

The invention discloses a texturing technology for a transparent conducting film as a top electrode of a thin film solar cell. The technology successively comprises the following operational steps: immersing, cleaning and drying. According to the immersing, the cleaning and the drying steps, an automatic control method is employed to carry out automatic and continuous immersing, etching and texturing. A solution for etching of a transparent conducting film is composed of oxalic acid, hydrochloric acid, a surface active stabilizer and deionized water as well as particularly comprises, by weight: 0.1% to 1.5% of the oxalic acid; 0.3% to 2.5% of the hydrochloric acid; 0.01% to 0.5% of the surface active stabilizer; and the balance being the deionized water. According to the invention, an etching solution that is prepared autonomously and an integrated matching of various technologies including an automatic up-and-down feeding technology, an automatic temperature adjusting technology, an automatic immersing technology, an automatic cleaning technology, an automatic drying technology and an automatic monitoring and control technology and the like are utilized, so that industrially automatic and continuous immersing and etching production of the transparent conducting film that is needed by the thin film solar cell is realized.

Owner:江苏汇景薄膜科技有限公司

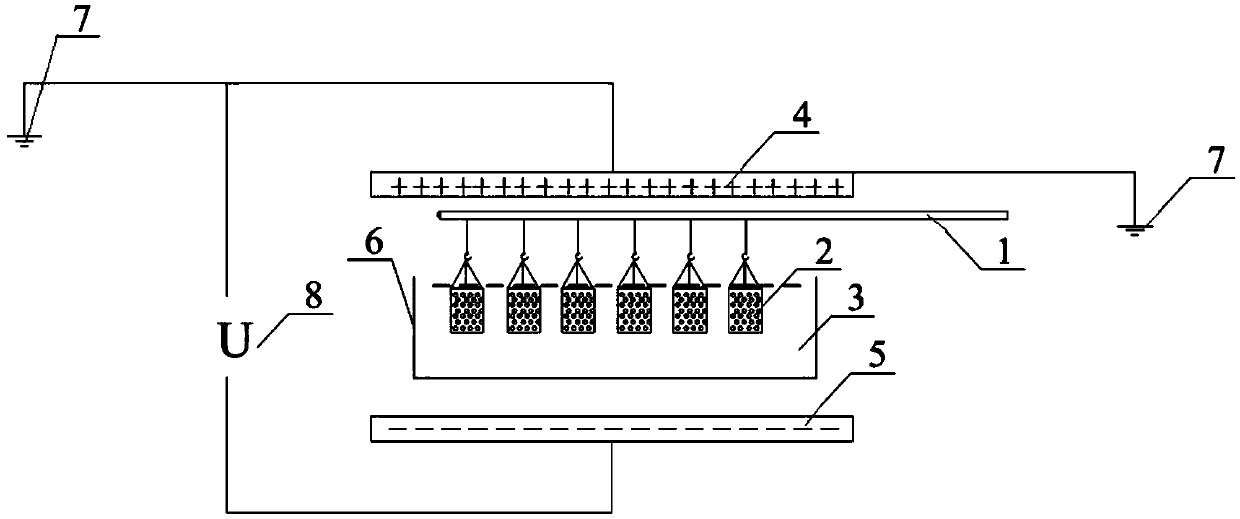

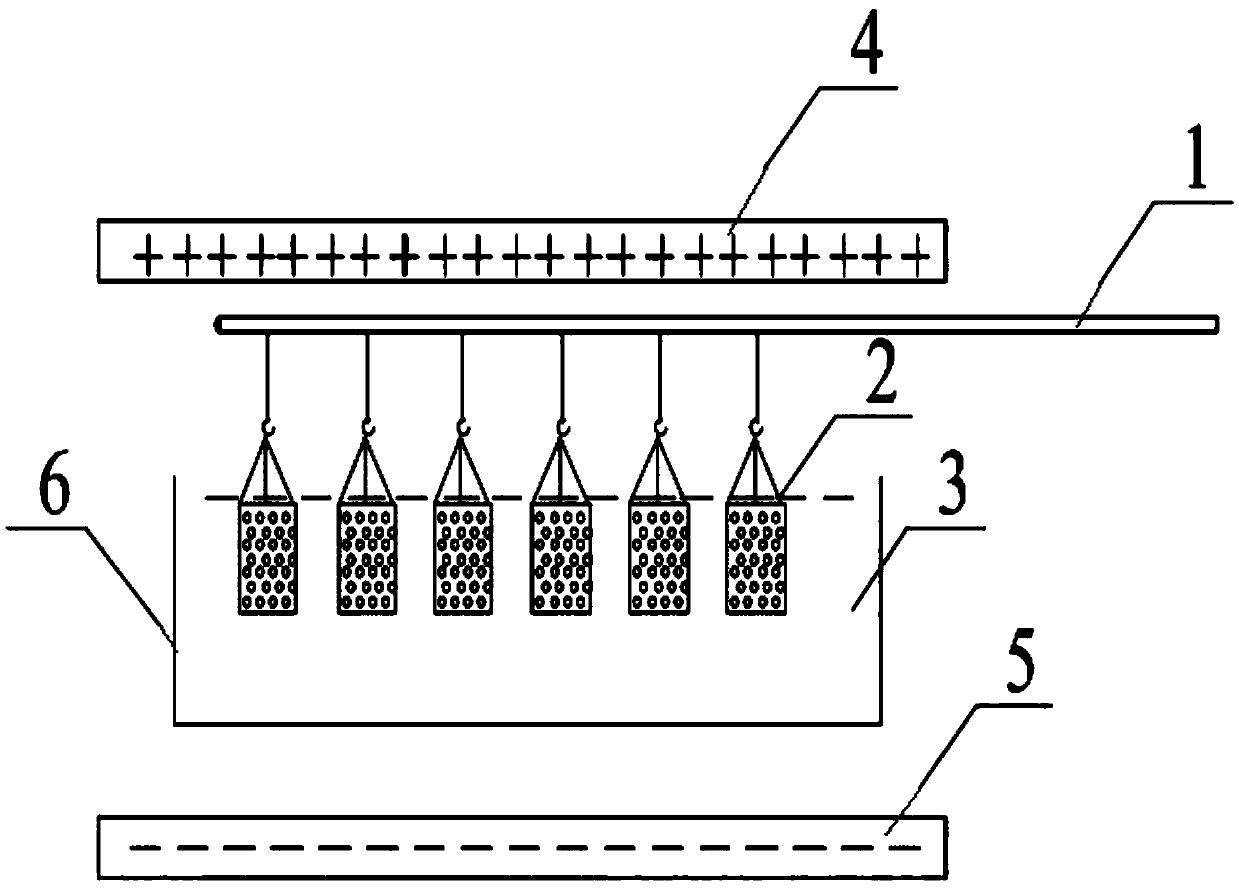

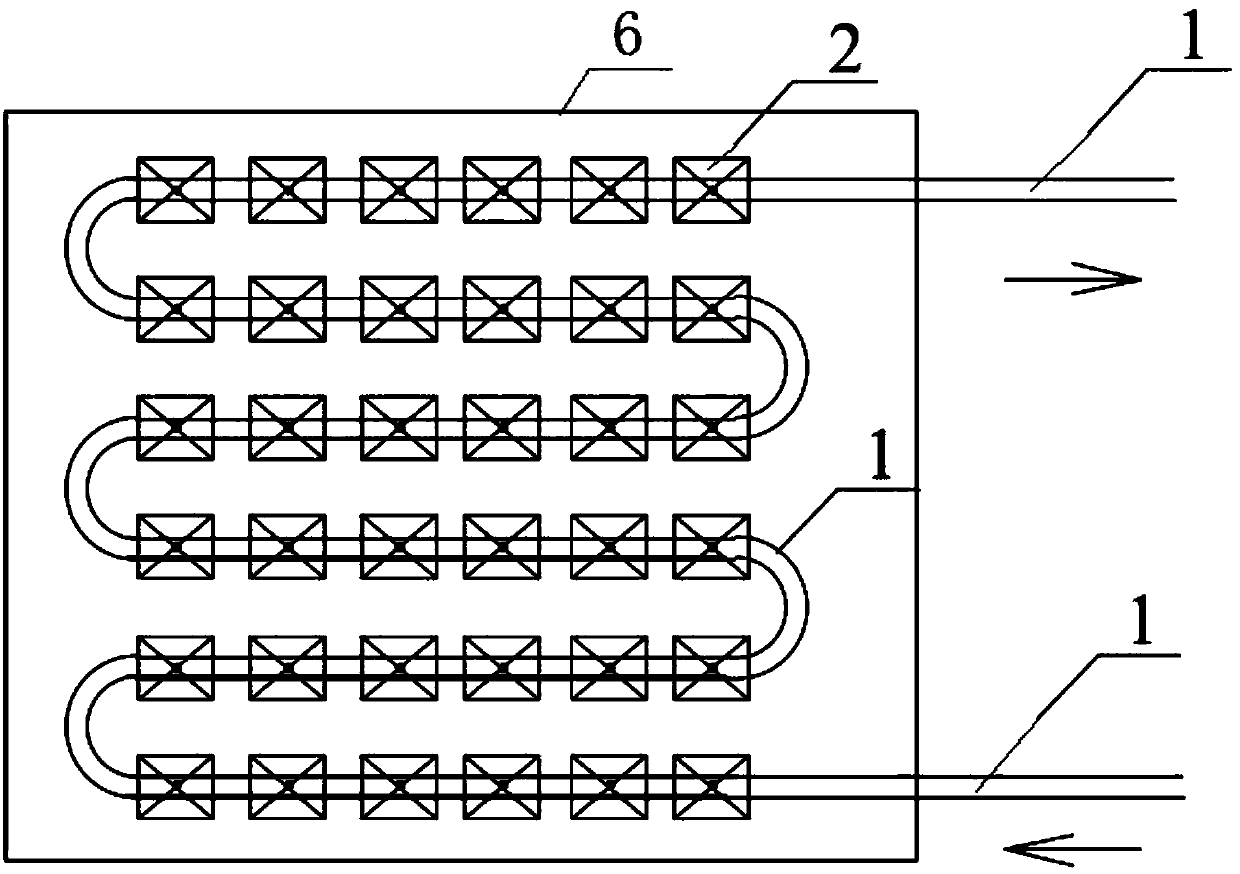

Rapid reformed egg manufacturing system and method using medium-high voltage electric field

The invention relates to a rapid reformed egg manufacturing system and method using a medium-high voltage electric field. The system comprises an overhead rail delivering system, a medium-high voltageelectric field pickling system, and a washing system. Eggs to be processed is introduced into the system from the input end of the overhead rail delivering system; the output end of the overhead raildelivering system is connected to the input end of the washing system; the medium-high voltage electric field pickling system is arranged between the overhead rail delivering system and the washing system; the overhead rail delivering system can drive the eggs to go through the medium-high voltage electric field pickling system; eggs are pickled in the medium-high voltage electric field picklingsystem after the eggs enter the medium-high voltage electric field pickling system; and the washing system can wash and dry pickled eggs. The structure is simple, the operation is convenient, automation is easy to realize; the system can be applied to production lines in a factory, the efficiency is high, energy is saved, environment is protected, industrial production is easy to realize, and thesystem can be applied to large scale production of reformed eggs.

Owner:TIANJIN UNIV OF SCI & TECH

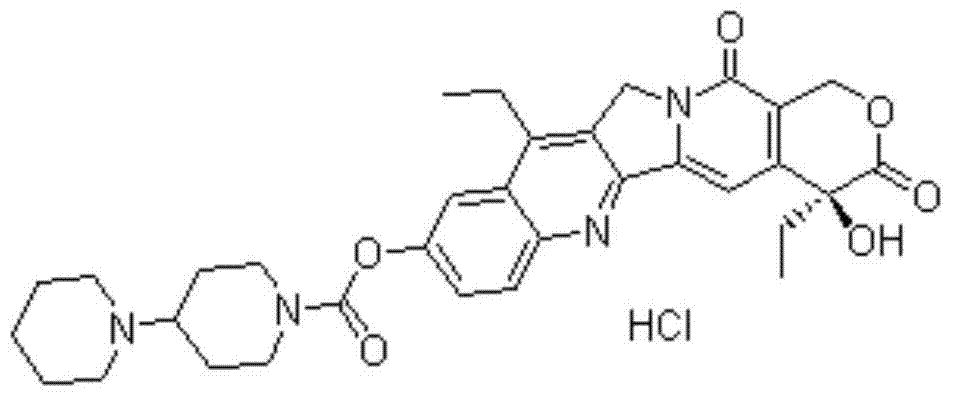

Irinotecan hydrochloride pharmaceutical composition and preparation method thereof

InactiveCN103655491AImprove reconstitution performanceUniform and stable qualityOrganic active ingredientsPowder deliveryChemistryIrinotecan Hydrochloride

The invention discloses irinotecan hydrochloride pharmaceutical composition and a preparation method thereof. The composition contains irinotecan hydrochloride and mannitol. The preparation method comprises the following steps: 1), preparation is performed: ambroxol hydrochloride and mannitol are placed into a preparation tank in a weight ratio of 1:(1-20), water for injection is added, and the mixture is stirred until complete dissolution and uniform mixing are achieved; 2), sterile filtration, subpackaging and half stoppering are performed; and 3), vacuum freeze drying is performed to obtain a product. The composition and the preparation method have the advantages that the formula is simple, the technology is advanced, the quality is uniform and stable, moisture drying is thorough, and the redissolution performance is better.

Owner:BEIJING KEYUAN CHUANGXIN TECH

Wear-resisting alloy steel for mine breaking hammer and preparation method of wear-resisting alloy steel

The invention discloses a wear-resisting alloy steel for a mine breaking hammer and a preparation method of the wear-resisting alloy steel. The wear-resisting alloy steel comprises the following chemical element components in percentage by mass: 2.2-2.4% of carbon, 1.9-2.1% of silicon, 3.0-3.2% of manganese, 9.2-9.7% of chromium, 4.1-4.3% of molybdenum, 0.4-0.5% of Al, 0.05-0.09% of Dy, not larger than 0.05% of S, not larger than 0.05% of P and the balance of Fe. According to the wear-resisting alloy steel, such elements as Cr, Mo, Al and Dy are added on the basis of high-carbon steel, a part of scrap iron is used as a raw material, secondary refining is carried out, the raw materials are fed in batches and the heat treatment temperature after casting is reasonably controlled, so that the alloy has high original hardness and wear resistance and has certain toughness, impact resistance and good corrosion resistance at the same time; the quality of the alloy is stable and uniform. The wear-resisting alloy steel disclosed by the invention is suitable for working conditions of non-severe impact and hard materials, and the service life of the wear-resisting alloy steel is about 2 times longer than that of common high-manganese steel. A refining agent disclosed by the invention is applied to casting production to obviously improve the yield.

Owner:MAANSHAN HENGYI MACHINERY MFG

Red-hardness high alloy steel material for pump valves and preparation method thereof

A red-hardness high alloy steel material for pump valves comprises the following chemical element components by mass percent: 0.2-0.4% of carbon, 0.6-0.9% of silicon, 1.7-1.9% of manganese, 2.1-2.4% of molybdenum,1.6-1.8% of chromium, 0.02-0.04% of vanadium, 0.02-0.05% of nickel, 0.1-0.15% of niobium, 0.04-0.06% of Ta, not more than 0.04% of S, not more than 0.04% of P, and the balance of iron. The alloy steel of the invention not only has high hardness and good red hardness, but also has good toughness and good wear resistance. The method of the invention partly adopts scrap iron as a raw material; secondary refining is performed; and the comprehensive mechanical properties are improved. The alloy steel of the invention is suitable for high-wear rate parts used at high temperature, such as pump shafts, pipelines, valves and the like. The method of the invention adopts a refining agent in the casting production, which significantly improves the yield, especially reduces the degree of porosity in casting by 1-2 degrees, and controls the oxide inclusion level at about grade two.

Owner:TONGLING SIDE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com