Super high molecular weight polyethylene gel method for continuous producing direct spinning fine denier filament

A technology of ultra-high molecular weight and production method, which is applied in the field of continuous direct-spun fine-denier yarn production by ultra-high molecular weight polyethylene jelly method, which can solve the problems of stable increase in processing and quality, poor uniformity, etc., and achieve excellent performance and uniform quality Stable, flexible and applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

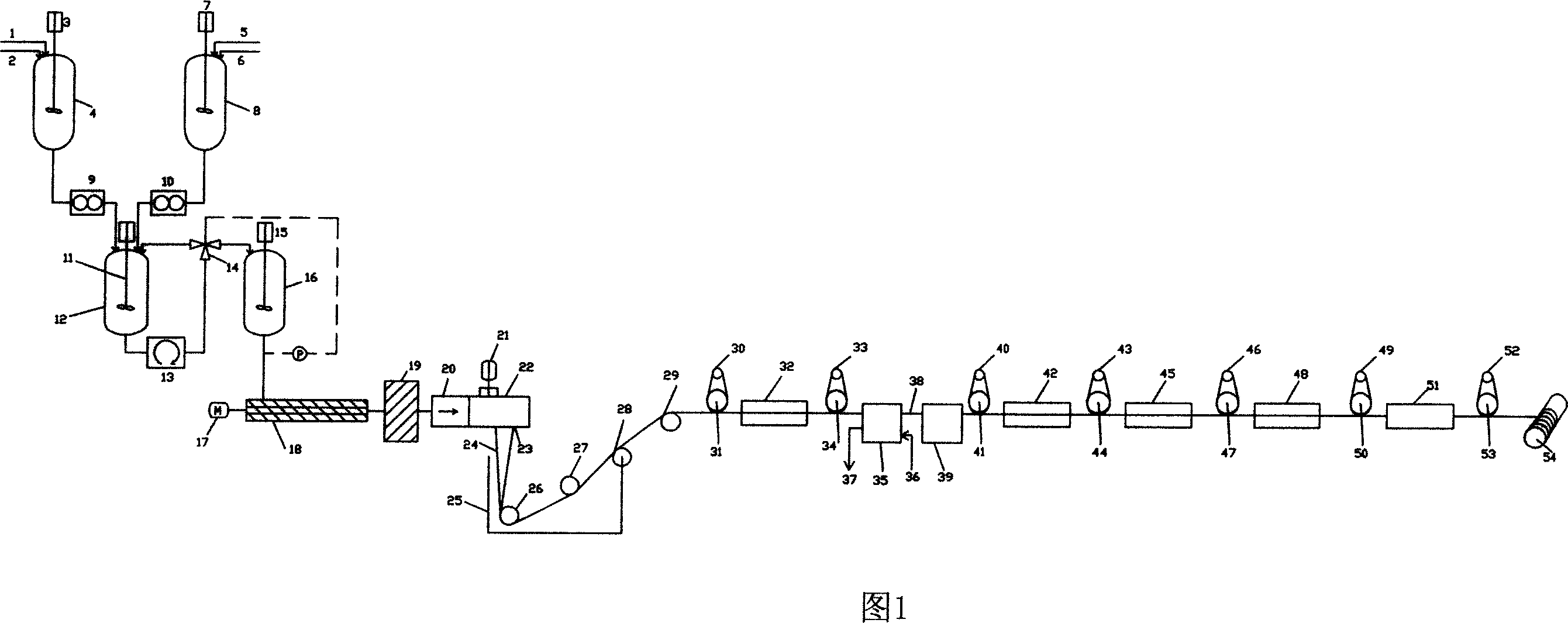

[0038] In Figure 1, the screened particle size distribution accounts for more than 90% of the total weight, and the ultra-high molecular weight polyethylene A with a viscosity-average molecular weight of 4.4 million ± 200,000 is mixed with antioxidant mixture 1 to form an ultra-high molecular weight polyethylene A. 0.2-1% of the weight ratio of high-molecular-weight polyethylene A is added, and the antioxidant mixture is compounded with triphosphite and tetraerythritol ester in a relative ratio of 30-60%; the solid content is 20-30% Add the first solvent in proportion, the first solvent 2 is paraffin oil, feed the above-mentioned raw materials into the kettle 4, heat, stir, homogenize and mix, the temperature range is 60-120°C, and the viscosity-average molecular weight of the raw materials is 4-5×10 6 , the rotating speed of the stirring blade 3 is 20~100rpm. Another kind of viscosity-average molecular weight is 4 million ± 200,000, but the ultra-high molecular weight polyeth...

Embodiment 2

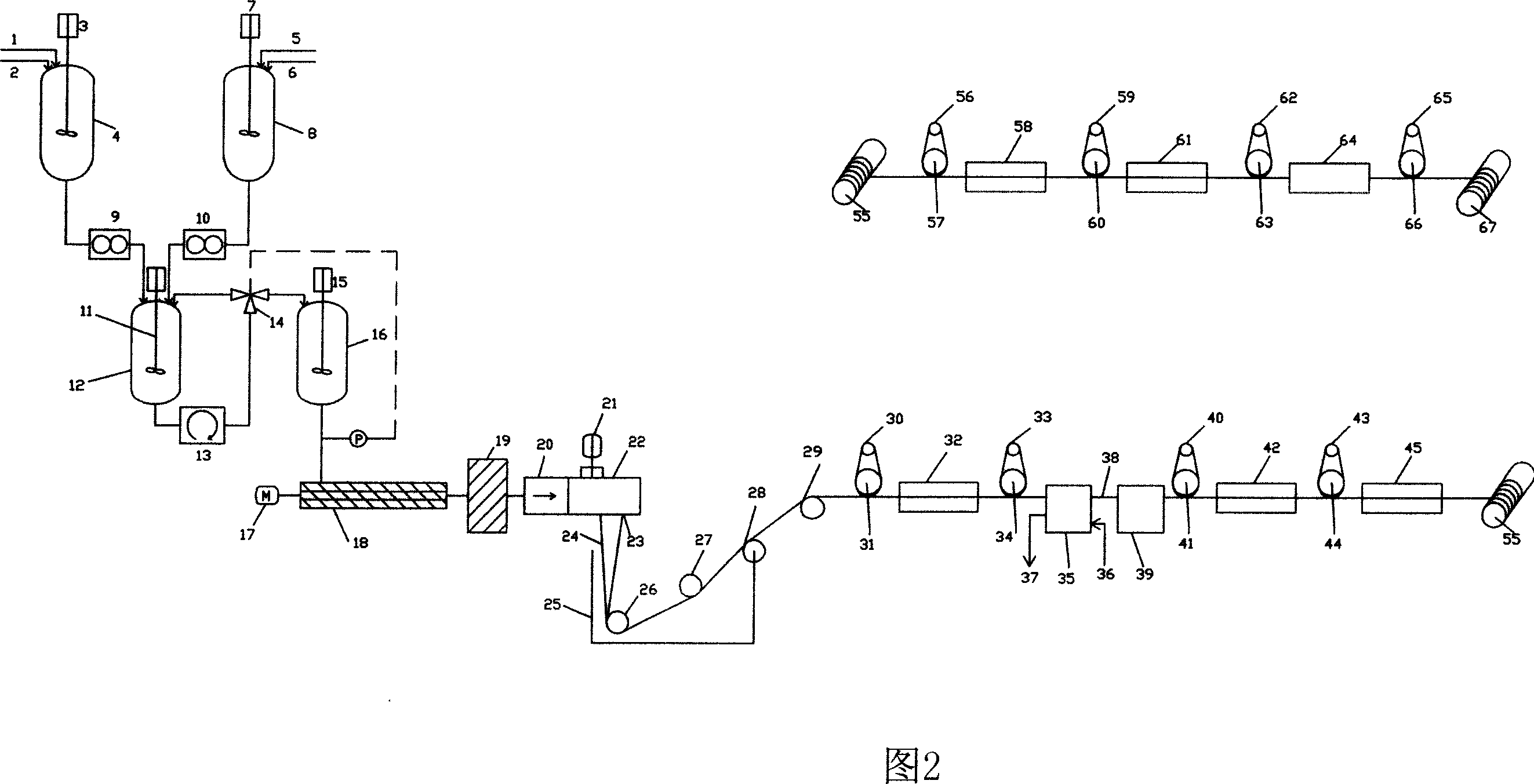

[0057] Operate by the process parameter of example 1, manufacture fiber by the process route of Fig. 2.

[0058] Using the stretching process shown in Figure 2, the dried dry rubber filaments are stretched for 40-47 steps in two stages, and then wound and formed at 55 points to become primary products.

[0059] To improve the performance of the fiber, the tow wound at 55 places can be wound and formed at 67 places through stretching and shaping links 56-66 again. Its winding speed depends on the post-drawing ratio (winding speed = total post-drawing multiple K × unwinding wire speed, according to needs, the unwinding wire speed can be 10-30 m / min, the total post-drawing The multiple can be 2-5 times).

[0060] Main process parameters:

[0061] The temperatures of 58, 61 and 64 were 140°C, 152°C, 155°C, 159°C, respectively.

[0062] Inlet velocity V 57 =20m / min, exit speed V 66 =43.9, winding speed V 67 =44.1

[0063] Average properties of finished filaments wound at 67:...

Embodiment 3

[0069] Operate by the process parameter of example 1, main process parameter:

[0070] Add ultra-high molecular weight polyethylene (viscosity average molecular weight: 4.4 million) and the first solvent (white mineral oil) in the ratio of 1:3 (w.t.%) to kettle 4 . The heating temperature is 70°C, the stirring speed is 80rpm, and the residence time is 30min.

[0071] The ultra-high molecular weight polyethylene (viscosity-average molecular weight: 4 million) and the first solvent in the kettle 8 are prepared into a solution with a concentration of 2%.

[0072] The heating temperature is 140°C, the stirring speed is 60rpm, and the residence time is 35min.

[0073] The weight ratio of metering device 9 and 10 is 4:19.

[0074] Kettle 16 was kept at a constant temperature of 90°C.

[0075] The temperature of the dissolution extrusion device 18 was 260°C.

[0076] Spinneret hole diameter 0.8mm

[0077] Carry out continuous operation according to the process in Figure 1, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com