Patents

Literature

149results about How to "Reduce production consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

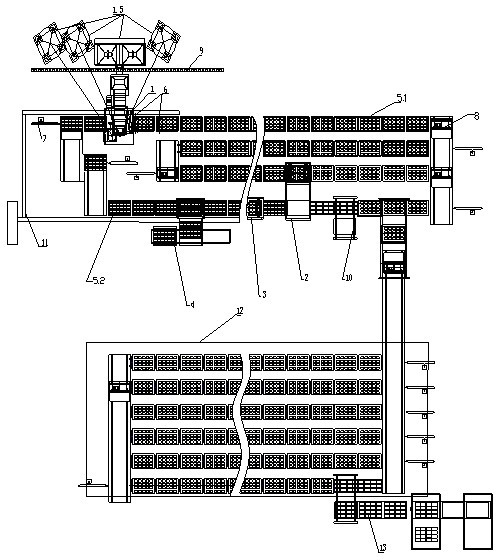

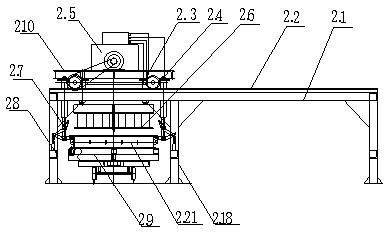

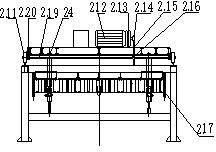

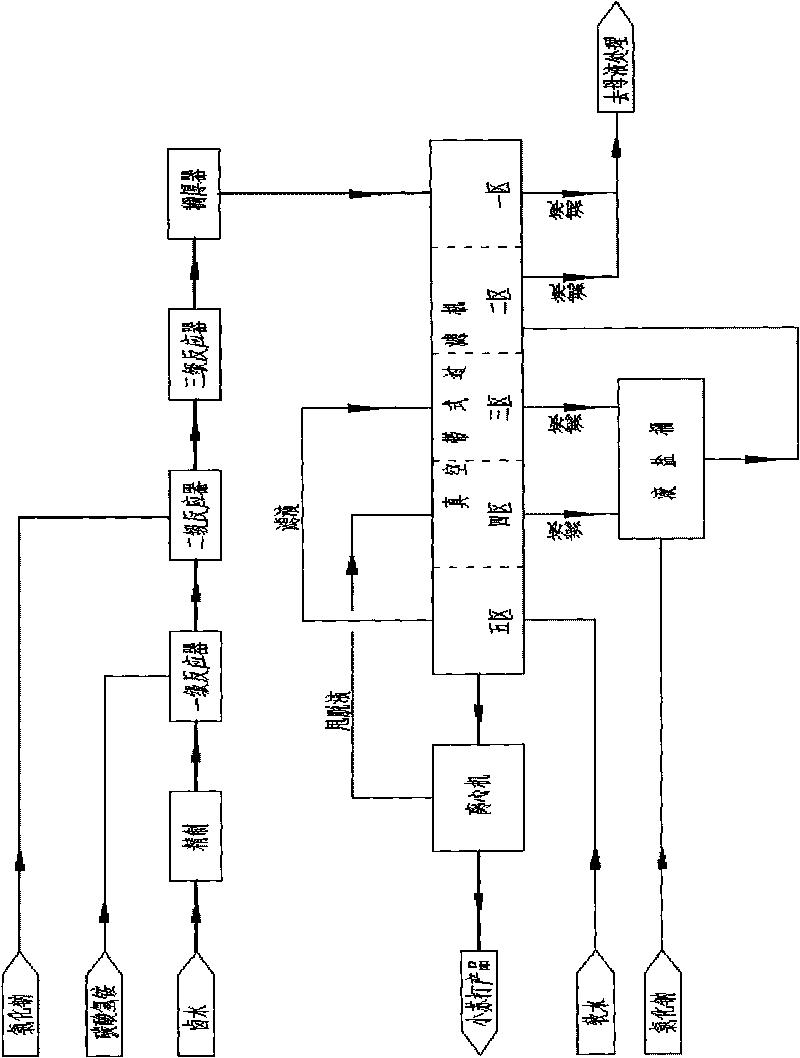

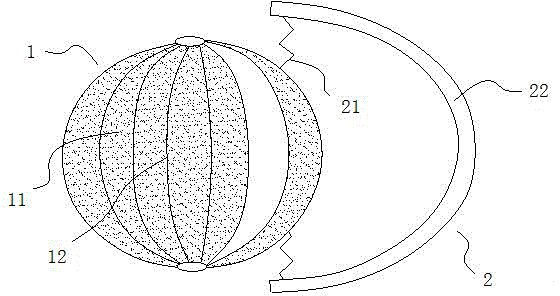

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

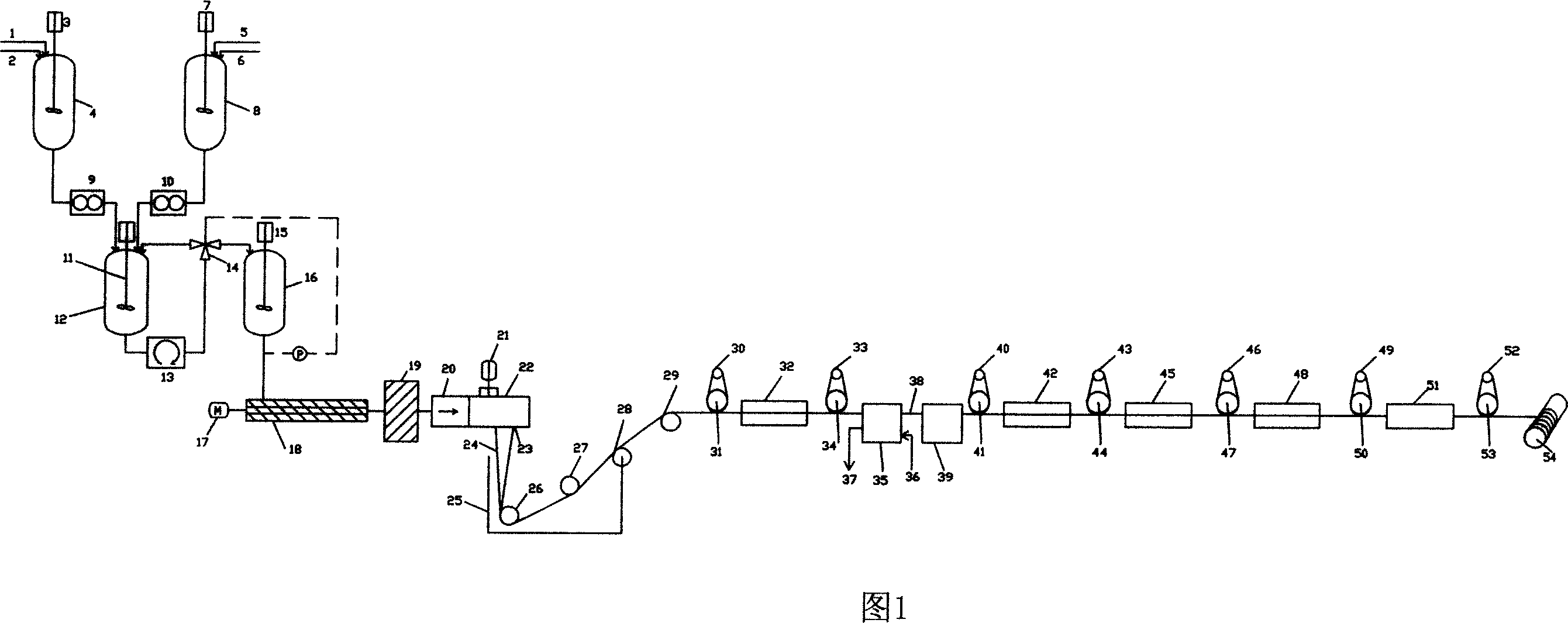

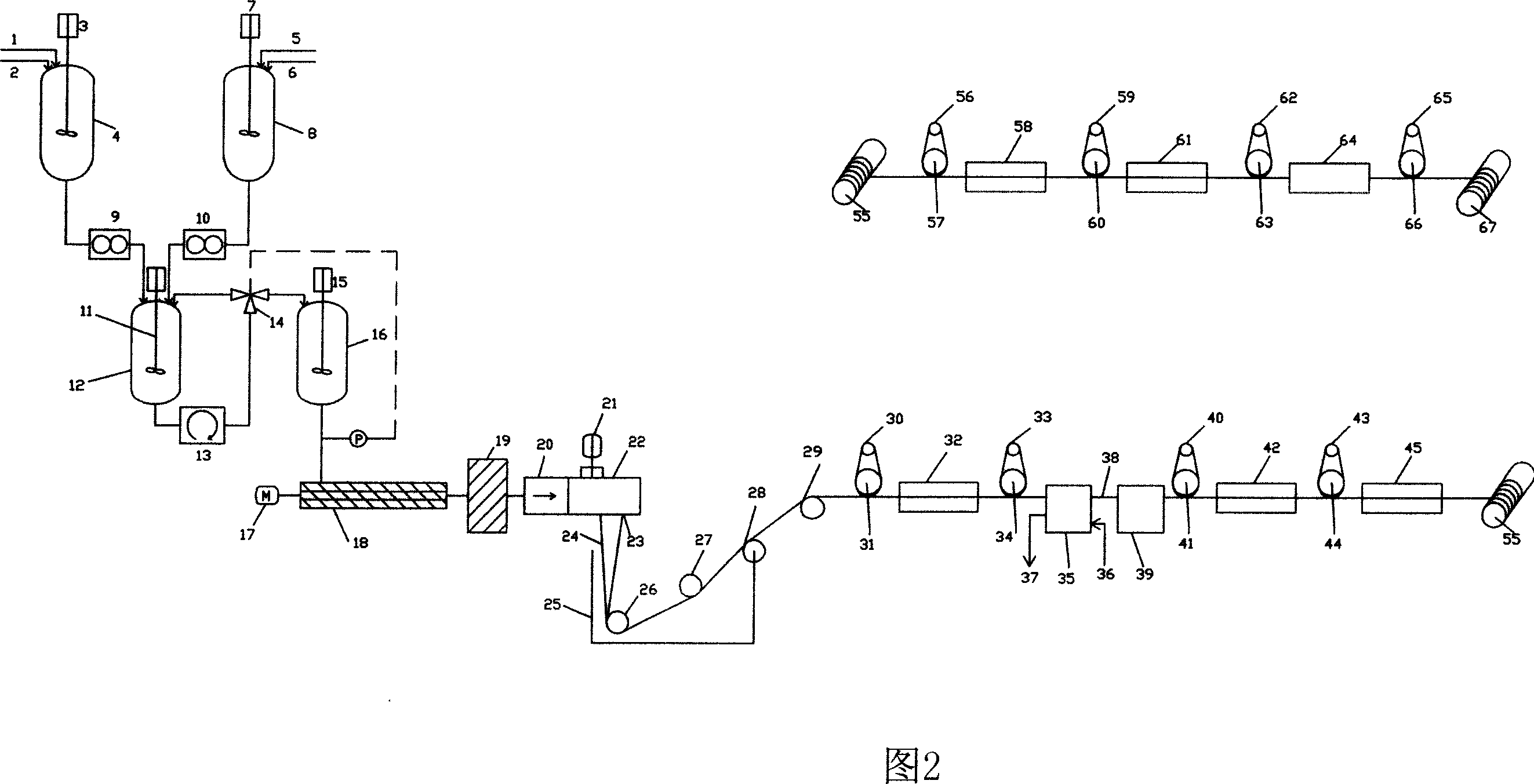

Super high molecular weight polyethylene gel method for continuous producing direct spinning fine denier filament

InactiveCN1995496AUniform and stable qualityGuaranteed accurate feedingWet spinning methodsMonocomponent polyolefin artificial filamentFiberState of art

The invention relates to a manufacturing method for continuous direct spinning fine denier yarn by uhmwpe jelly method, belonging to the spinning area and solving the problem that the single yarn or yarn beam generated by prior technology is on the high side and bad uniformity so that the difficulty for stability of manufacturing and quality of subsequent product is enhanced and the applicable range is limited. The method is provided with reasonable and compact process flow, stable process control, skillful operation and improving the quality and uniformity of product. By the method continuous stable spinning in line is realized in process parameters and the production efficiency is improved. The labor cost and intensity are lessened. Because there is less turnover link in the middle of process it is favor of decreasing producing consumption and uncontrollable factors. Under the stable running, uhmwpe fine denier yarn or yarn beam with even and stable quality, and good performance is provided.

Owner:SINOTEX INVESTMENT & DEV CO LTD

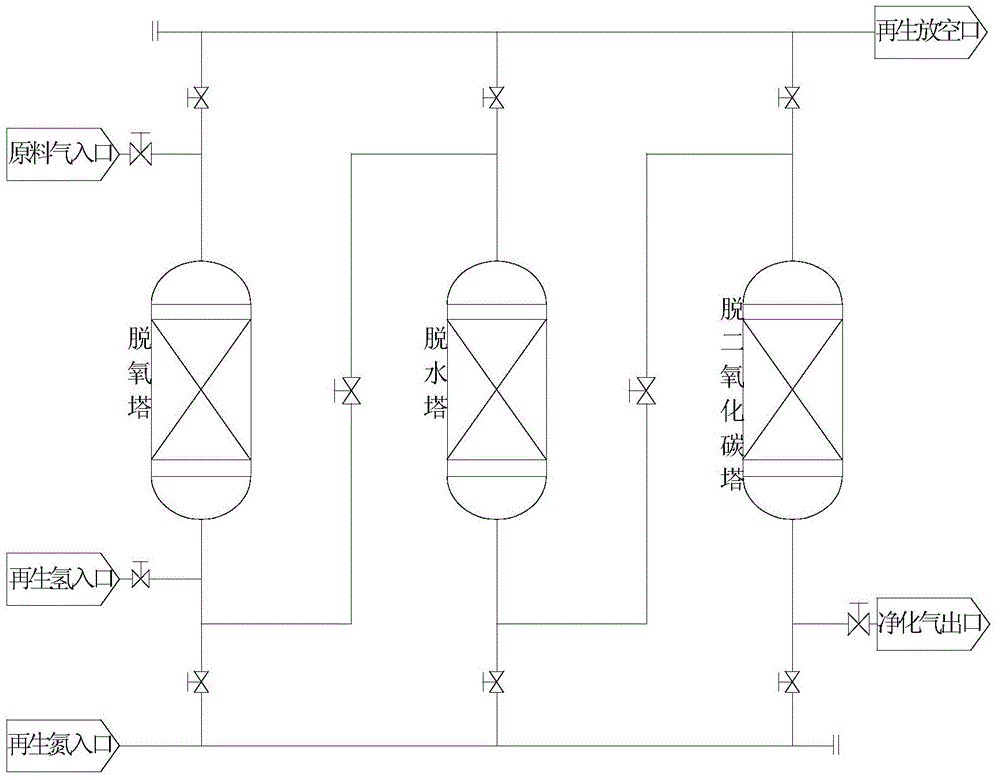

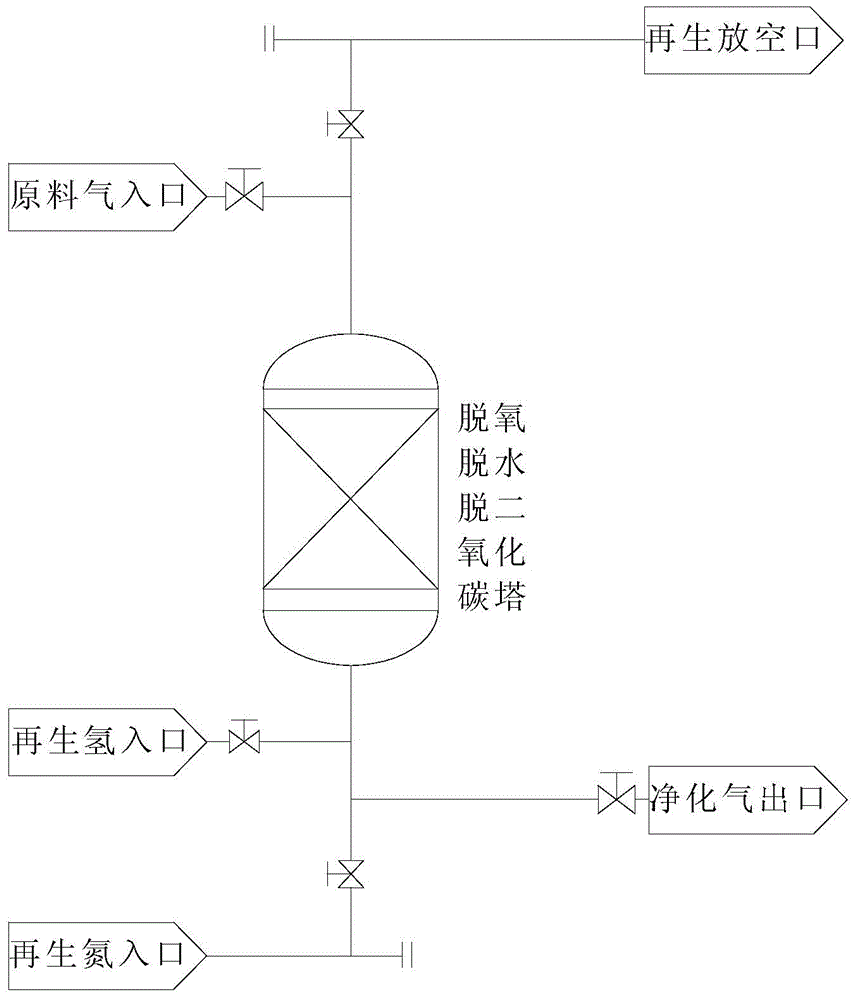

Multifunctional deoxidizer, preparation and applications thereof

InactiveCN105363406AHigh deoxygenation depthLarge capacityOther chemical processesDispersed particle separationActive componentCarbonate

The present invention relates to a multifunctional deoxidizer and a preparation method thereof, wherein the multifunctional deoxidizer comprises a suitable metal carbonate, a proper amount of an activity promoter and a proper amount of a structure support monomer. During a multifunctional deoxidizer production process, a thermal decomposition (calcination) method is used to decompose a metal carbonate to form the active component of the metal oxide deoxidizer while release carbon dioxide gas, such that a large number of uniform adsorption pore sizes having the carbon dioxide molecule size are formed in the multifunctional deoxidizer, and the pore size can deeply adsorb a lot of water and carbon dioxide. According to the present invention, the novel gas purification material is provided, the production process can be simplified, the production energy source and the materials can be saved, and the production cost and the consumption can be reduced; and the energy saving and consumption reducing industrial policy direction in the country new material and new technology application can be met.

Owner:王雅坤

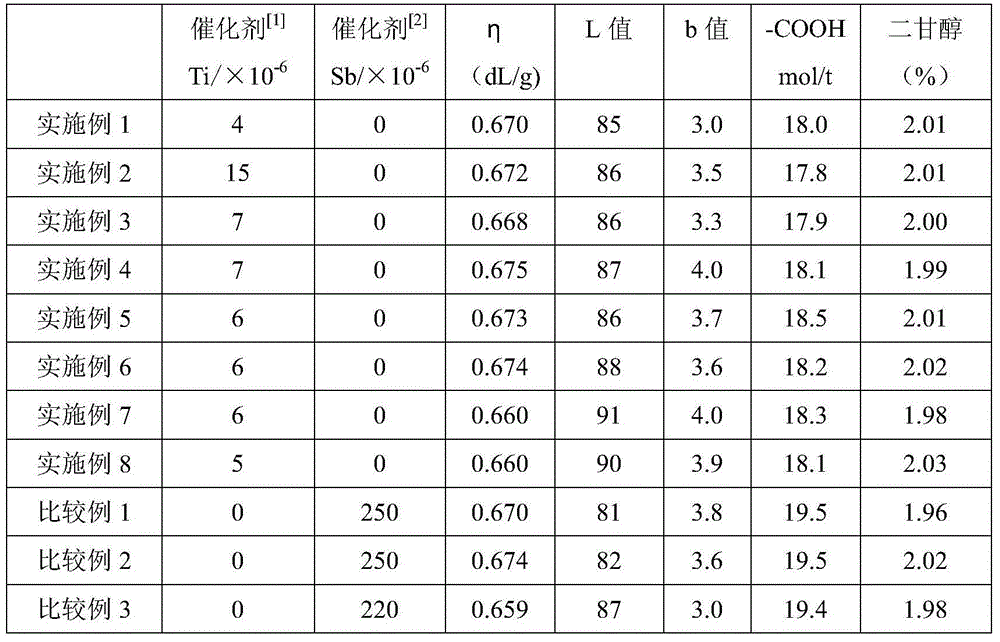

Preparation method of polyester for environment-friendly antimony-free film

The invention relates to a preparation method of polyester for an environment-friendly antimony-free film. The method comprises the following steps of (A) adopting terephthalic acid and ethylene glycol as basic raw materials to be made into slurry, adding the slurry into a reactor to have esterification reaction for 1h to 4h under the condition that the temperature is 220DEG C to 260DEG and the pressure is 0.1MPa to 0.3MPa, and obtaining an esterification product; (B) carrying out the pre-polycondensation reaction for 0.5h to 1.0h to obtain a pre-polymer under the condition that the reaction temperature is 240DEG C to 270DEG C and the pressure is gradually reduced from the absolute pressure of 101kPa to 600Pa; (C) carrying out the final polycondensation reaction for the prepolymer obtained in the step (B) for 1h to 2h to obtain a polyester product under the condition that the temperature is 270DEG C to 290DEG C and the absolute pressure is 150Pa to 50Pa. The liquid titanium catalyst and accessory ingredients of a given quantity can be added into the reaction system before or after the esterification reaction. The synthesized polyester does not contain precious metal such as antimony and is qualified in properties and suitable for producing a two-directional stretching film.

Owner:CHINA PETROLEUM & CHEM CORP

Nano self-cleaning super hydrophilic glass product production method

The production method of nano self-cleaning superhydrophilic glass prdouct includes the following steps: firstly, preparing silicone dioxide base film liquor according to the mixing formula of TEOS 2-20%, H2O 70-96% and concentrated CHl or HNO3 20-10%, then impregnating glass with the silicone dioxide base film liquor, lifting and pulling to form film, roasting; then preparing film liquor mixtureaccording to the mixing formula of titanate 2-20%, ethyl anhydride 2-10%, polybasic alcohol 3-15%, silicone dioxide 5-40%, butyl alcohol 5-10% and ethyl alcohol 28-75%, impregnating the glass with silicone dioxide base film with the above-mentioned mixture, lifting, pulling to form film, drying and roasting.

Owner:SOUTH CHINA UNIV OF TECH

Production method of embossing form packing paper

InactiveCN101205695AStrong metal textureGood flexibilityFlexible coversMechanical working/deformationSurface layerPaper production

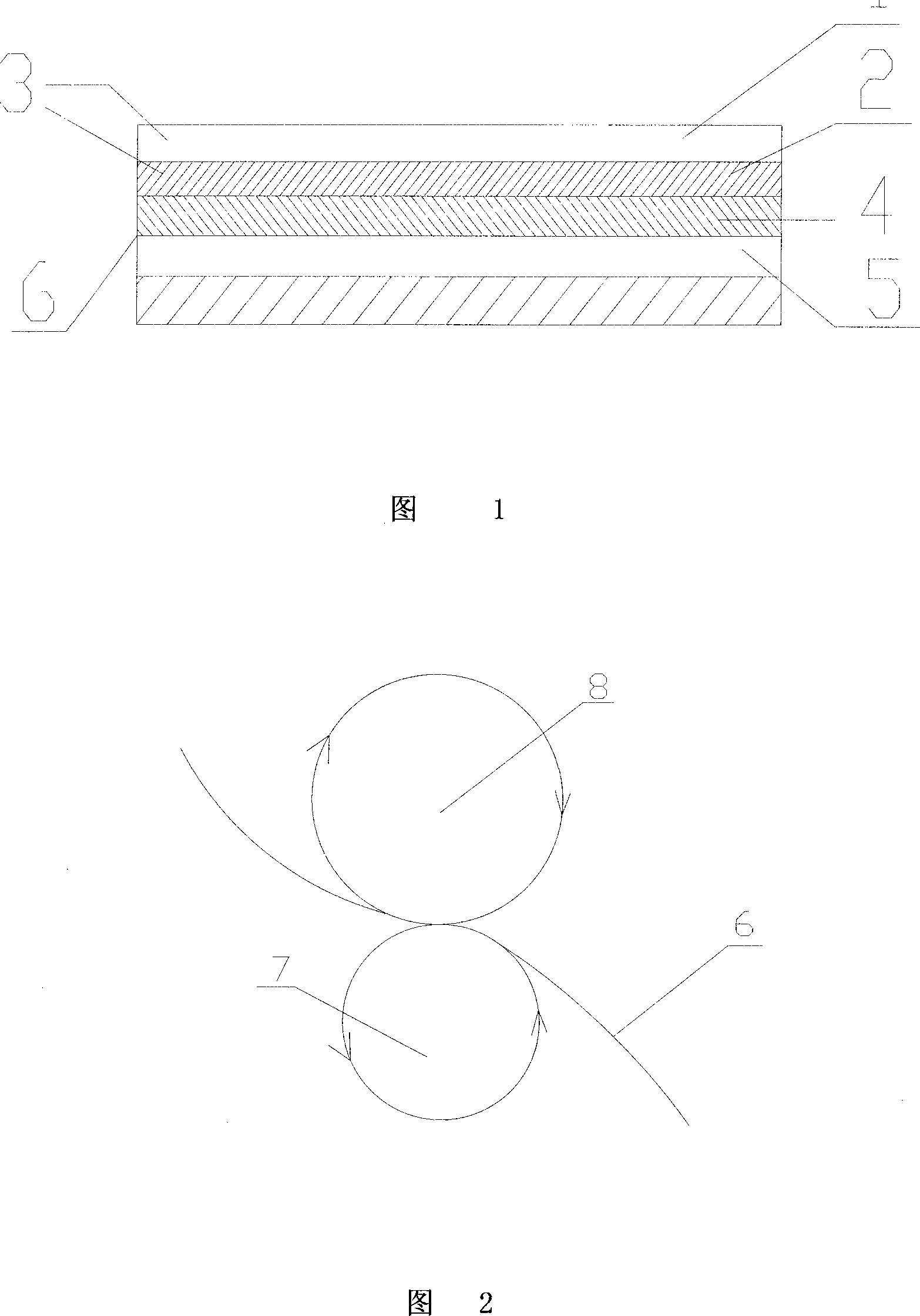

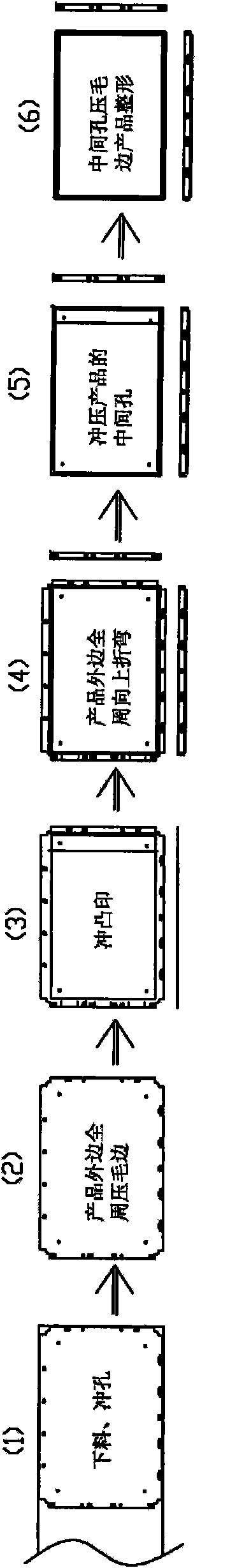

An embossing type tipping paper production method relates to the packaging material technical field. The invention comprises the following procedures that: a. coating: PET plastic light film is adopted as base material; a layer of macromolecule resin material is uniformly coated on the base material in advance; after drying and solidification, a layer of transparent surface coat with strippable performance is formed; b. mould pressing: after the coating, under the conditions of the pressure of 2Kg / cm<2> to 4Kg / cm<2>, the temperature of 160 to 180 DEG C and the speed of 35 to 45 m / min, characters or patterns on a mould pressing plate are transferred on the transparent surface coat of the PET plastic light film; a printing layer stuck on the transparent surface coat is produced to form a surface layer; c. aluminium plating; d. transferring; e. embossing: aluminum transferring paper achieved by the procedures is sleeved between a reverse rotating knaggy patterned roller and an elastic roller which are tangential. The invention has good anti-fake effect and suboptical effect and is easy to mass production.

Owner:DARE TECH

Energy-saving preparation technology of high-quality glucose powder

ActiveCN104593447AHigh purityReduce contentChemical industryFermentationLiquid glucoseGlucose-Fructose Syrup

The invention discloses an energy-saving preparation technology of high-quality glucose powder. The technology comprises the following steps: by using starch as a raw material, mixing syrup, liquefying, saccharifying, decoloring and removing impurities by an ultrafiltration membrane, removing salt by ion exchange, purifying by a simulated moving bed, collecting the cut fraction with glucose content of at least 99.5%, and then, performing membrane concentration, vacuum belt drying, cooling and grinding to obtain the finished product of the high-quality glucose powder. According to the preparation technology disclosed by the invention, preparation flows of glucose are shortened, a procedure of evaporation and concentration is replaced by membrane concentration, the steam consumption is reduced, the production cost is lowered, meanwhile, the glucose decomposition loss and production of harmful by-products caused by high temperature concentration of liquid glucose are reduced, and the product quality is improved; the glucose is purified by means of the simulated moving bed technology, so that the content of impure glucose in products is decreased, and the glucose purity is up to more than 99.5%; the glucose syrup is dried by means of vacuum belt drying, and is further ground so as to form the crystalline glucose powder, so that the production efficiency is improved.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

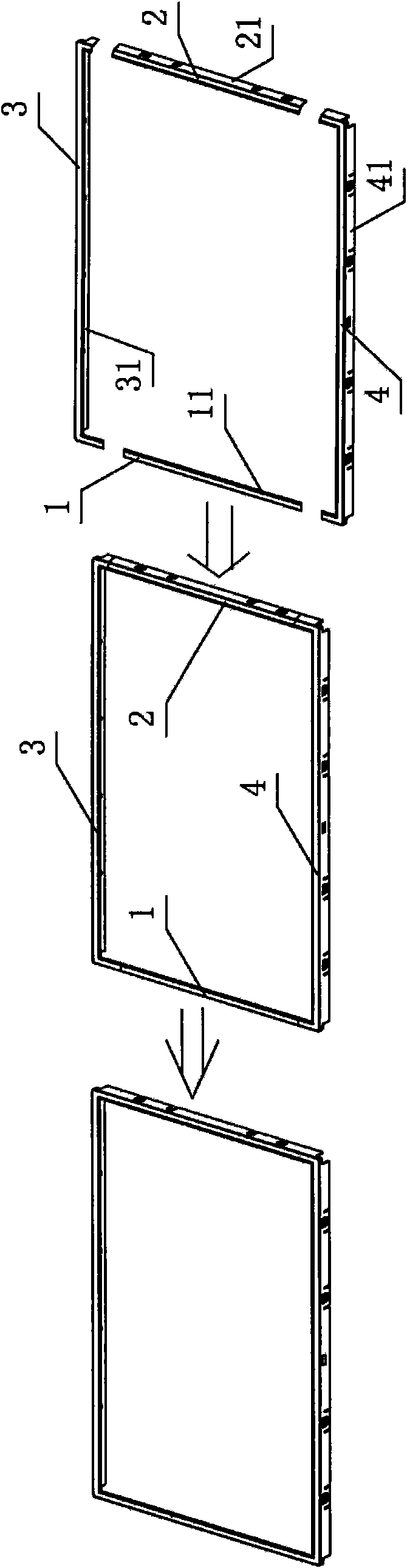

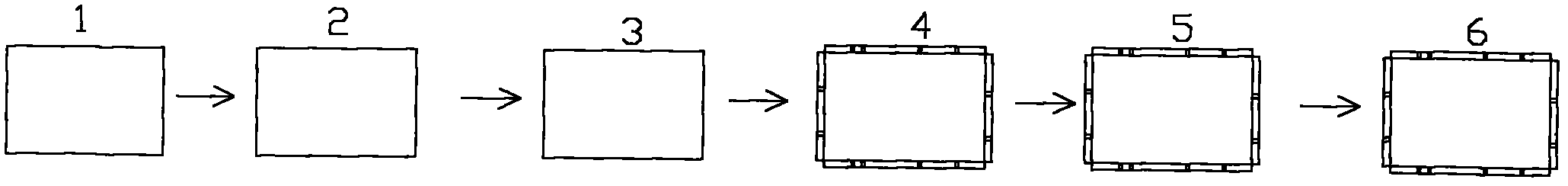

Method for manufacturing LCD panel frame and frame manufactured by using method

InactiveCN101614884AIncrease profitReduce manufacturing costNon-linear opticsEngineeringManufacturing engineering

The invention aims to disclose a method for manufacturing an LCD panel frame and a frame manufactured by using the method. The frame is formed by mutually welding a plurality of workpieces of certain shapes, and each of the workpieces is provided with ruffled edges. The manufacturing method comprises the following steps: (1) manufacturing the workpieces needed by forming the LCD panel frame by progressive tooling shaping; (2) using a mechanical hand to combine the workpieces into a rectangular frame by drawing, rotating, translating and aligning after the workpieces are shaped; and (3) connecting the workpieces mutually by welding to shape the LCD panel frame. The LCD panel frame consists of the plurality of workpieces which are compressed by progressive tooling shaping to reduce manufacturing cost and production consumption, improve material utilization and make the manufacturing method more simple, thereby achieving the aims of reducing product cost and improving production efficiency.

Owner:SHANGHAI SHILIAN TONGSHENGJIE ELECTRONICS

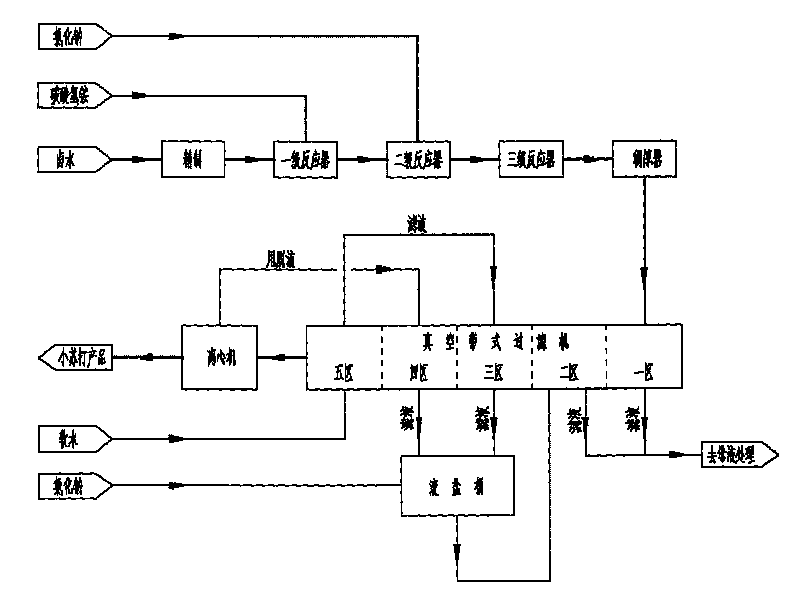

Process for producing food grade saleratus by double decomposition

The invention relates to a process for producing food grade saleratus by double decomposition. The food grade saleratus is produced through a double decomposition reaction of natural brine and ammonium bicarbonate by using the process comprising the following steps: brine refining, double decomposition reaction, thickening, filtering, centrifugal separation and drying. A three-stage reaction process is adopted for the double decomposition reaction, and a kettle type machine is used for stirring a reaction barrel; a vacuum belt type filter is used for filtration washing, and washing water can be utilized for multiple times. The food grade saleratus product has good quality, easy control of the double decomposition reaction, small washing water quantity and low production cost.

Owner:湖南裕华科技集团股份有限公司

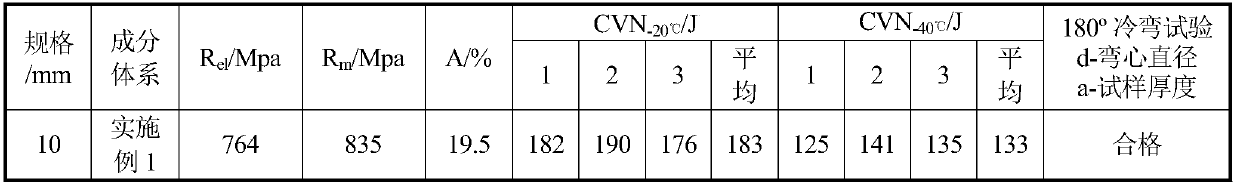

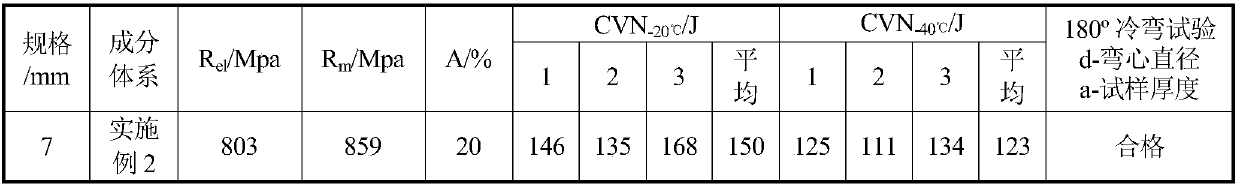

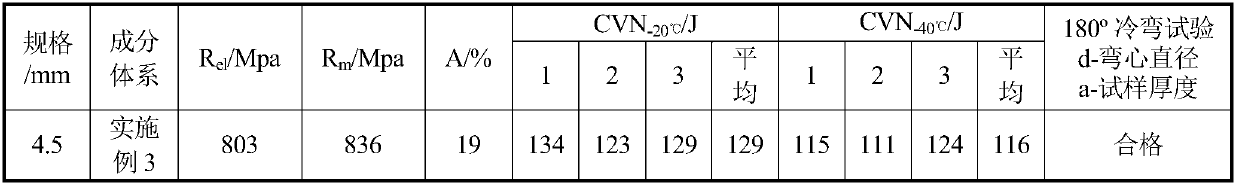

Economical high-toughness 800MPa-level automobile beam steel and production method thereof

The invention provides economical high-toughness 800MPa-level automobile beam steel. The economical high-toughness 800MPa-level automobile beam steel is prepared from the following components in percentage by weight: 0.07-0.11% of C, 1.55-1.80% of Mn, 0.05-0.20% of Si, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.020-0.040% of Nb, 0.10-0.20% of Mo, 0.03-0.06% of Al, 0.09-0.13% of Ti, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The invention further provides a production method for the economical high-toughness 800MPa-level automobile beam steel, and the production method comprises the following steps: a top and bottom re-blowing converter process, LF refining, slag continuous casting, 1780mm mill rolling, and front-sectioncooling. The automobile beam steel has high strength, high toughness and low production cost. While used as an automobile structure part, the automobile beam steel can avoid occurrence of a cracking phenomenon in use in processes such as shearing, stamping, bending and welding.

Owner:ANYANG IRON & STEEL

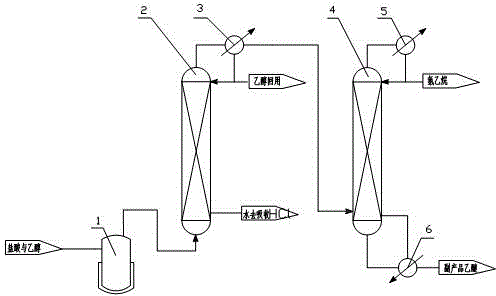

Method for preparing chloroethane from chlorination by-product hydrogen chloride

ActiveCN104311382AImprove conversion rateSpeed up the positive reactionChemical industryHalogenated hydrocarbon preparationReboilerEther

The invention discloses a method for preparing chloroethane from chlorination by-product hydrogen chloride. The method adopts a reaction rectification technology. According to the method, a reactor is connected to a first rectifying tower, water in the first rectifying tower flows out the first rectifying tower from tower bottom and then is recycled, a tower overhead fraction of the first rectifying tower goes through a first condenser, a part of ethanol is returned, a part of the ethanol is collected and then is fed into a storage tank for recycle, chloroethane and a less amount of ether mixed vapor are fed into a second rectifying tower, a tower overhead fraction of the second rectifying tower goes through a second condenser, a part of chloroethane is returned, a part of chloroethane is collected and then is fed into a storage tank for recycle, and the by-product ether is obtained by a reboiler. The method realizes timely removal of produced chloroethane and water from a system, effectively accelerates a positive reaction speed, realizes effective recovery and recycle of unreacted hydrochloric acid and ethanol, has simple processes, a high ethanol conversion rate, low production consumption and good income and realizes zero discharge.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for preparing high-quality feed-grade calcium hydrophosphate by by-product waste acid of titanium dioxide

ActiveCN102674286AImprove product qualityMeet production requirementsPhosphorus compoundsEconomic benefitsSlurry

The invention provides a method for preparing high-quality feed-grade calcium hydrophosphate by by-product waste acid of titanium dioxide, comprising the following steps of: enabling phosphorite slurry to pre-react; mixing with dilute sulphuric acid, concentrated sulfuric acid and water; and performing desulfurating, filtering, removing impurities, neutralizing, depositing and centrifugally drying on the obtained material. The method overcomes the problem that the titanium dioxide waste acid is difficult to recycle due to high impurity content; the quality of the obtained calcium hydrophosphate meets production requirement of the feed additive completely; and due to the waste produced by titanium dioxide, the method solves the pollution problem of waste sulfuric acid produced by titanium dioxide, develops new recycling path of the waste, reduces adding amount of the make-up water in the water balance of a leaching system due to low-concentration sulfuric acid, reduces water consumption for production, saves cost and improves the economic benefit.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

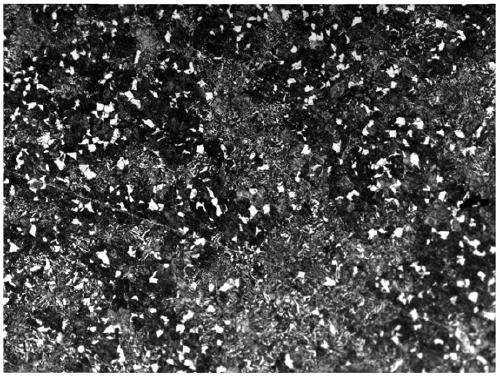

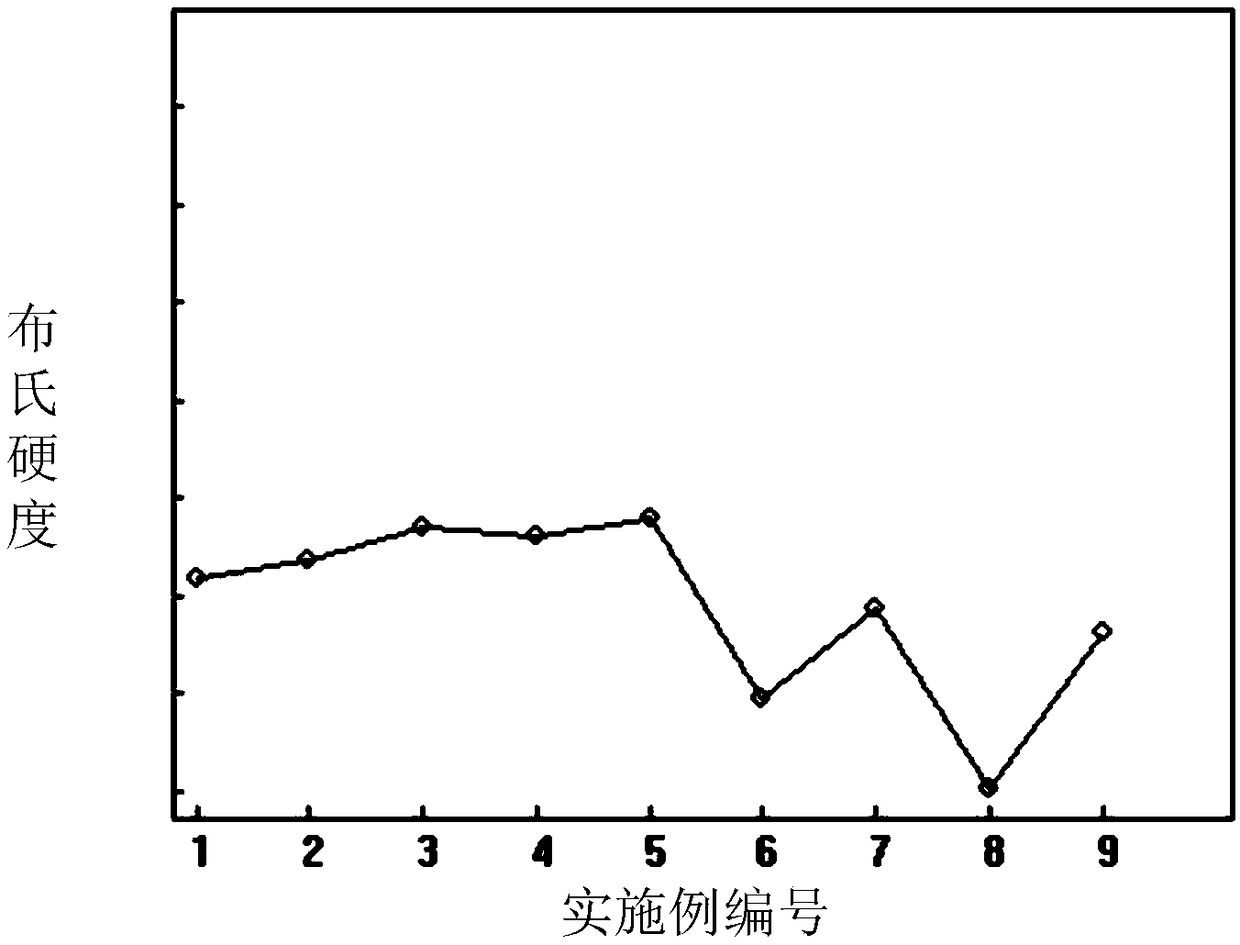

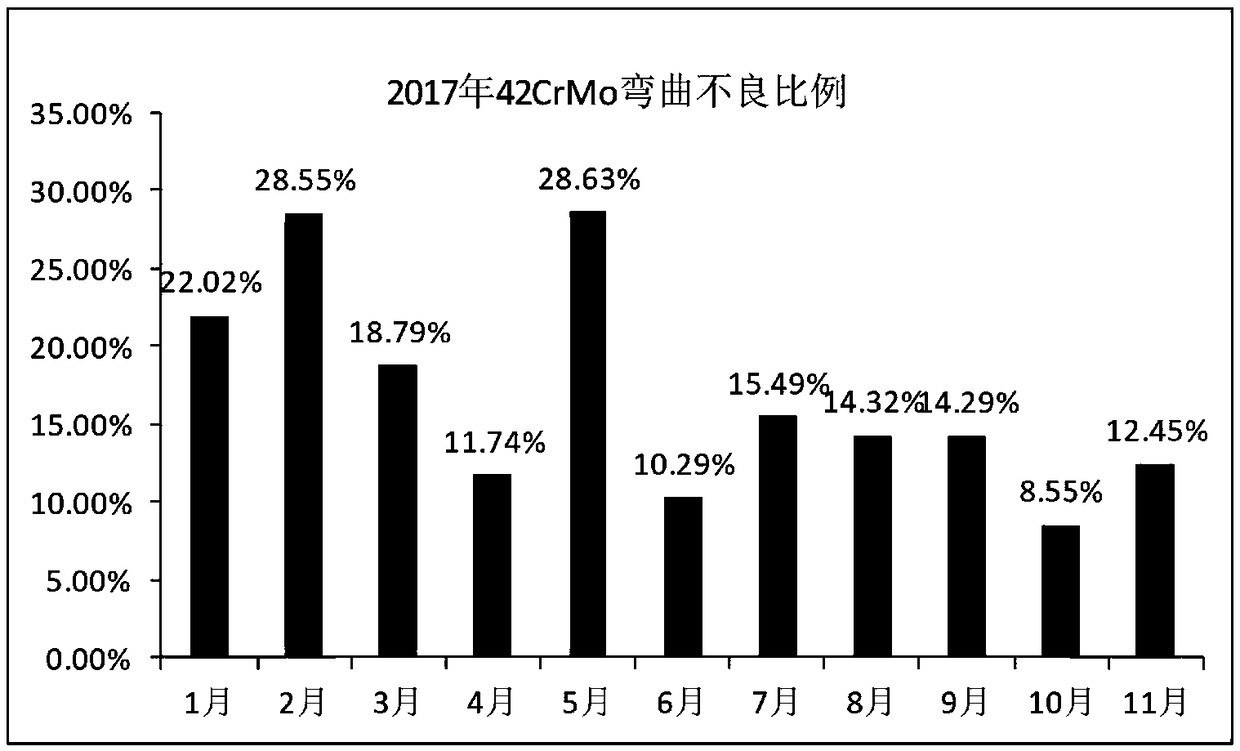

Rolling method capable of reducing hot-rolled hardness and curvature of 42CrMo

ActiveCN109013715AAvoid it happening againImprove hot rolled hardnessTemperature control deviceHardnessPearlite

The invention discloses a rolling method capable of reducing hot-rolled hardness and curvature of 42CrMo. The rolling method comprises the following steps of: (1) performing step type heating on blank; (2) rolling the blank; and (3), cooling the rolled steel. A metallographic microstructure of 42CrMo rolled by the method is ferrite, pearlite and bainite, and prevents a central area of the steel from generating a great deal of the needle-like martensite structure which is in blocky distribution, is high in strength and hardness, and is relatively poor in plasticity. The rolling method effectively improves the hot-rolled hardness of steel to be 240-300HB, and also solves the problem that curvature is worsened as a result of hardness reduction, so that the hot-rolled curvature of the steel is97.34% or higher within 0.4%. Hot-rolled direct delivery use is met, the hardness does not need to reduce by follow-up annealing, and the curvature does not need to improve by straightening. The production period is shortened, and production consumption is reduced.

Owner:NANJING IRON & STEEL CO LTD

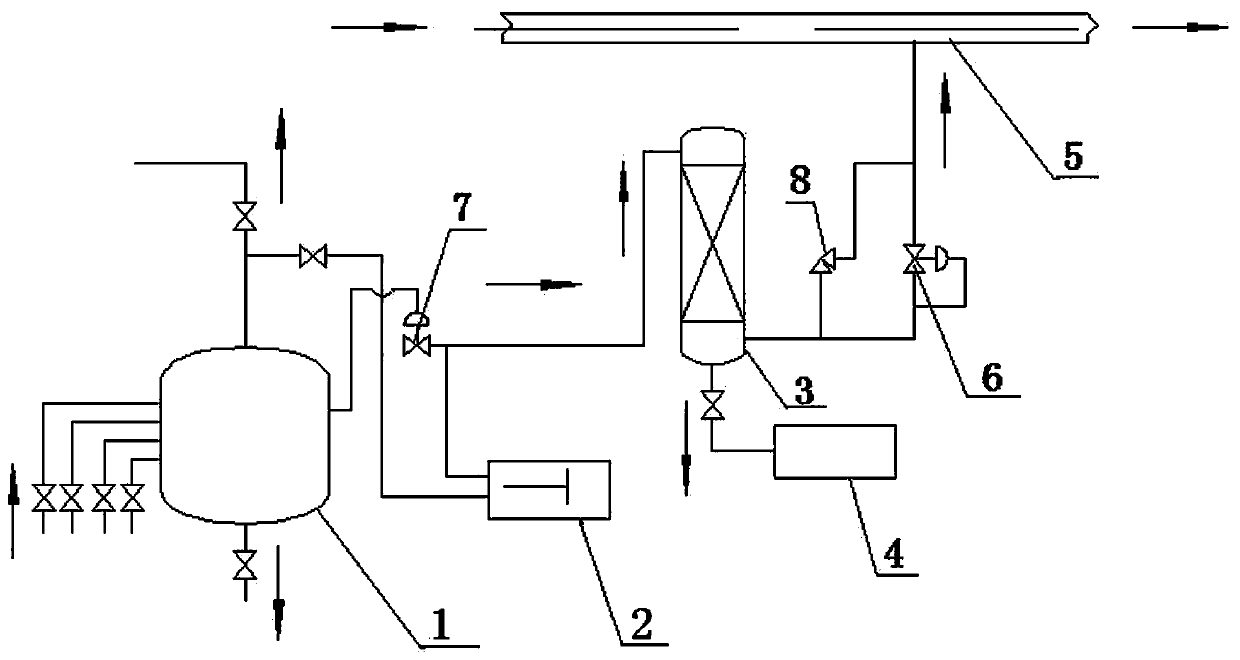

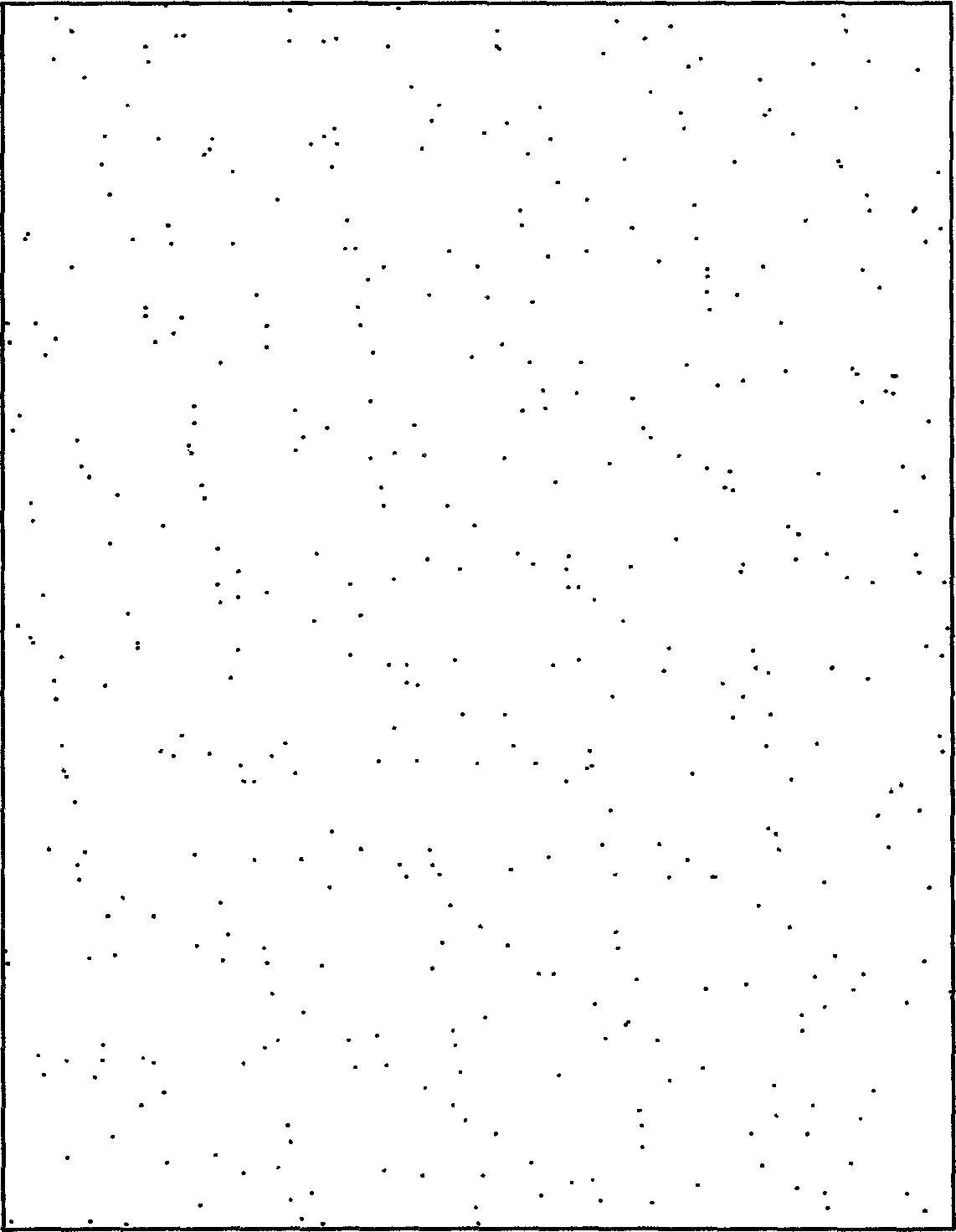

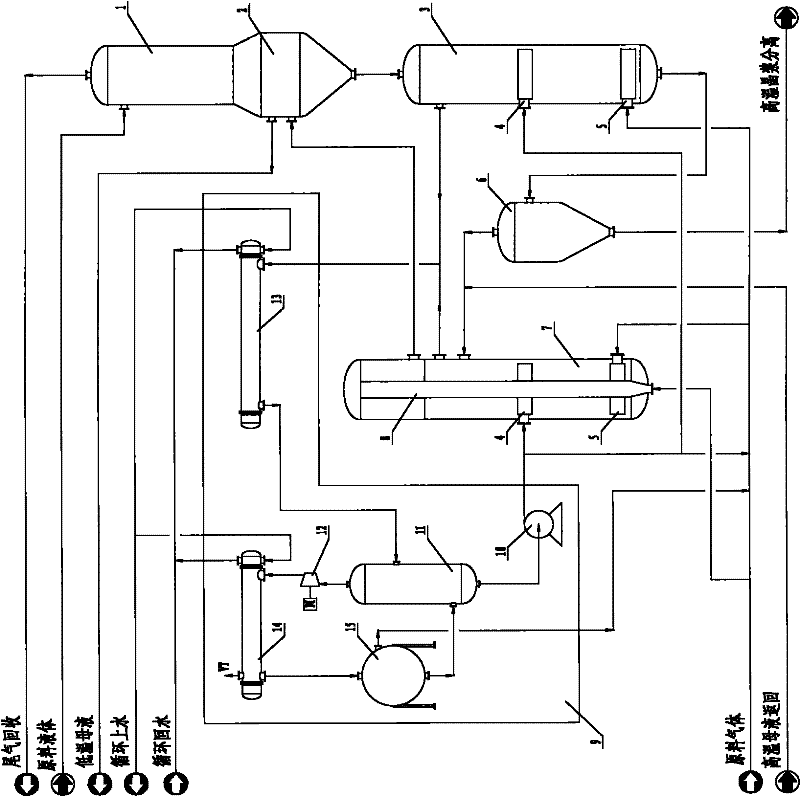

Method and device for recycling carbon disulfide from hydrogen sulfide tail gas during preparation of carbon disulfide

ActiveCN104006629AProcess conditions for completely clean productionReduce production consumptionSolidificationLiquefactionLiquid hydrogenSulfide

The invention discloses a method and device for recycling carbon disulfide from hydrogen sulfide tail gas during preparation of carbon disulfide. The method comprises the steps that the hydrogen sulfide tail gas containing carbon disulfide is introduced into a waste gas collector during preparation of carbon disulfide; the hydrogen sulfide tail gas which contains carbon disulfide and is contained in the waste gas collector is fed into a hydrogen sulfide compressor, the pressurized hydrogen sulfide tail gas containing carbon disulfide is fed into a condenser for condensation, liquid hydrogen sulfide is recycled, and gas hydrogen sulfide is conveyed into a hydrogen sulfide conveyance pipe to enter the hydrogen sulfide treatment process. The device comprises the waste gas collector, the compressor, the condenser, a carbon disulfide collector and the hydrogen sulfide conveyance pipe. According to the whole technology system, waste and sewage are not generated, so that carbon disulfide industrial production meets technological conditions of totally clean production, and production consumption is reduced to the maximum extent.

Owner:CHENGDU GRACE FIBER +1

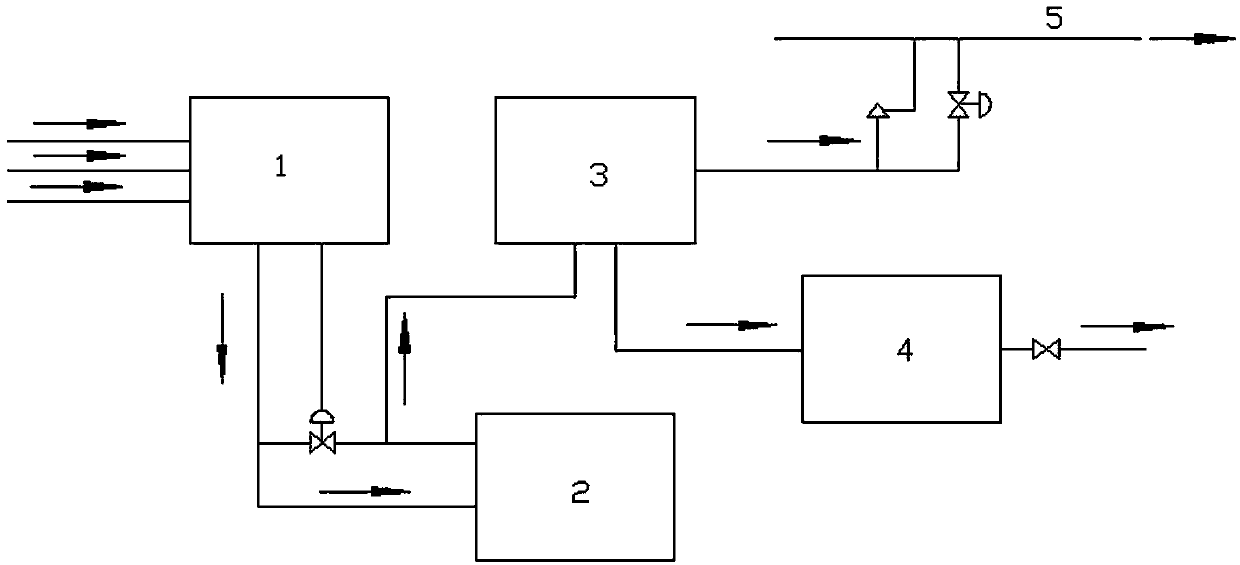

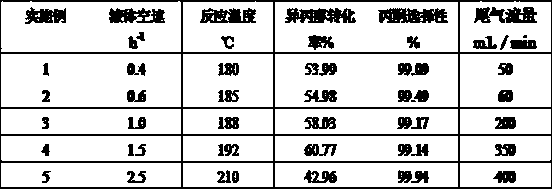

Method for preparing acetone through low temperature gas phase dehydrogenation of water-containing isopropanol

ActiveCN103772174AReduce consumptionProduction profit maximizationOrganic compound preparationPreparation by dehydrogenationPtru catalystDistillation

The invention relates to a method for preparing acetone through low temperature gas phase dehydrogenation of water-containing isopropanol, and belongs to the technical field of fine chemical industry. According to the present invention, a dehydrogenation raw material is from a production waste solution of an anti-aging agent 4010NA, a waste solution pre-treatment distillation kettle temperature is 80-90 DEG C, a gas phase temperature is 80-82 DEG C, a dehydrogenation raw material distillation rate mass percentage content is 92.86%, a copper-base catalyst is selected, a continuous dehydrogenation reaction is performed on a fixed bed, a liquid space velocity is 0.2-3.0 h<-1>, the system pressure under a nitrogen stream is less than or equal to 0.1 MPa, a tail gas flow rate is 50-400 mL / min, a reaction temperature is 160-220 DEG C, a material vaporization temperature is 150-185 DEG C, and the vaporized material is subjected to thermal insulation at a temperature of 195-220 DEG C; the waste solution can be converted into the raw material acetone for producing the anti-aging agent 4010NA so as to reduce the production consumption of the acetone; and the method has characteristics of low reaction temperature, low energy consumption, easy operation, high acetone selectivity, and easy reaction solution separation, wherein the single pass conversion rate of the isopropanol is more than 50%, and the acetone selectivity is more than 99%.

Owner:CHINA PETROLEUM & CHEM CORP +1

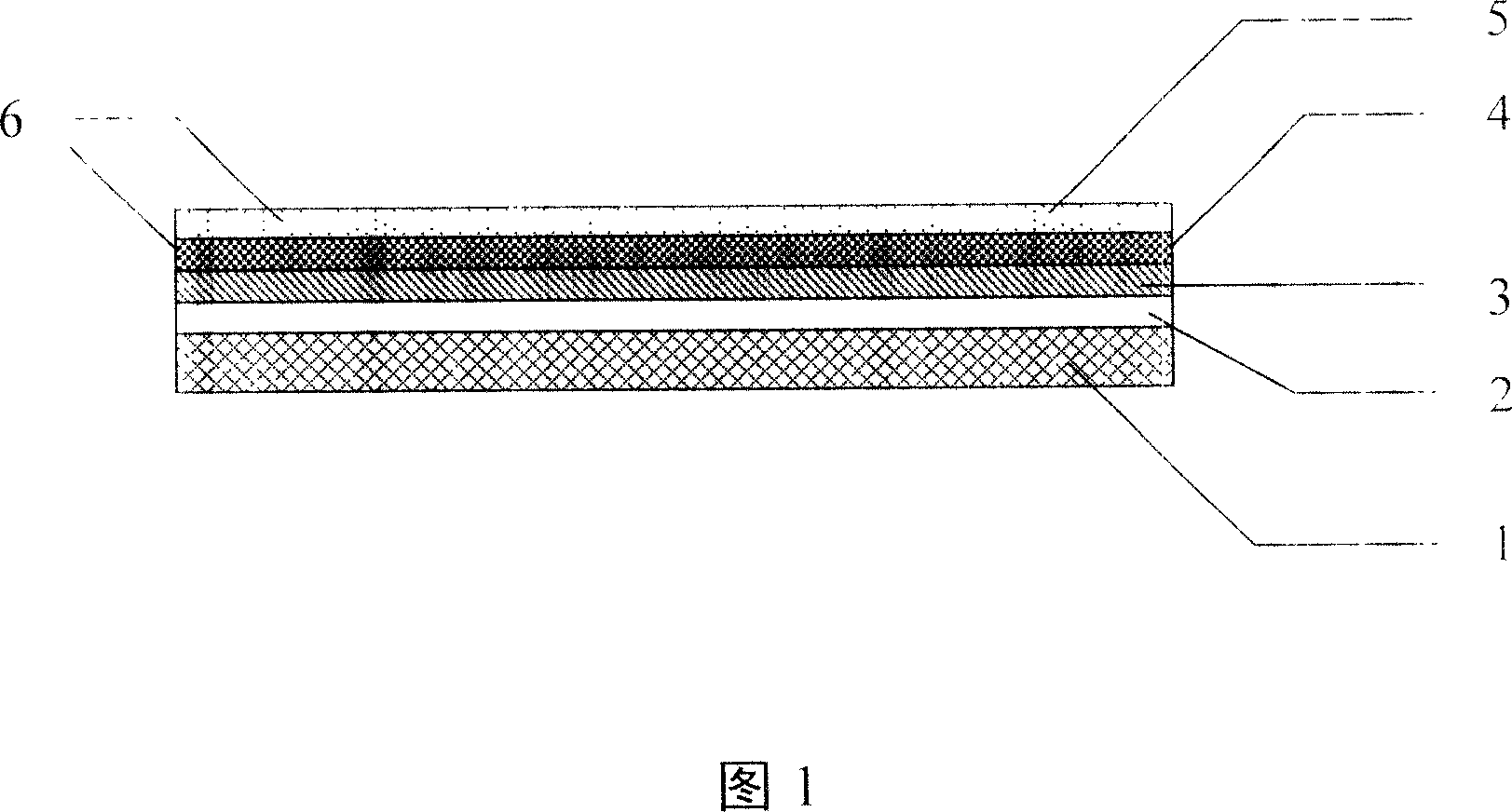

Inner-printing vacuum aluminum-coated transferring paper and its production

InactiveCN101029464AIncrease reflectionNot easy to damageSpecial paperPaper coatingAluminum coatingPolymer

An internal-printing vacuum aluminum-coated transfer paper and its production are disclosed. The transfer paper consists of substrate, adhesive coating, aluminum coating and top coating, which comprise surface coating and printing coating. Printing coating is arranged at one side of top coating adjacent to aluminum coating. The process is carried out by coating stripped resin surface coating onto polymer light film, printing character pattern, vacuum aluminum coating to form aluminum-transfer film with internal printing pattern, combining with various papers, stripping light film from paper to obtain the final product. It costs low, has excellent printing effect and no environmental pollution.

Owner:江苏省大亚铝基复合材料工程技术研究中心有限公司

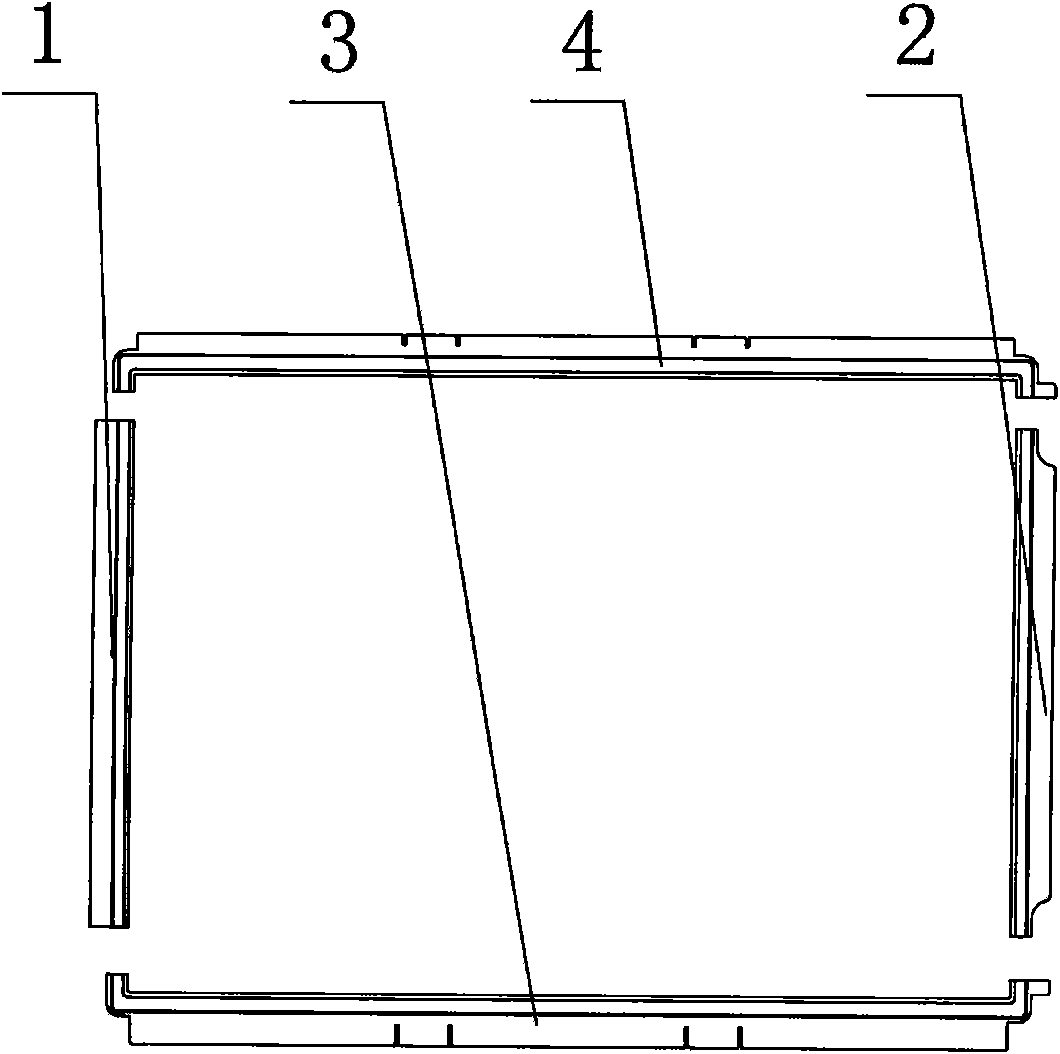

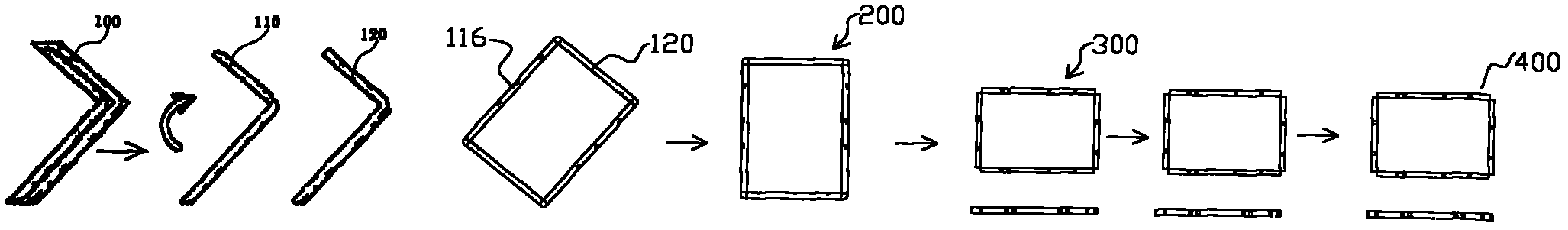

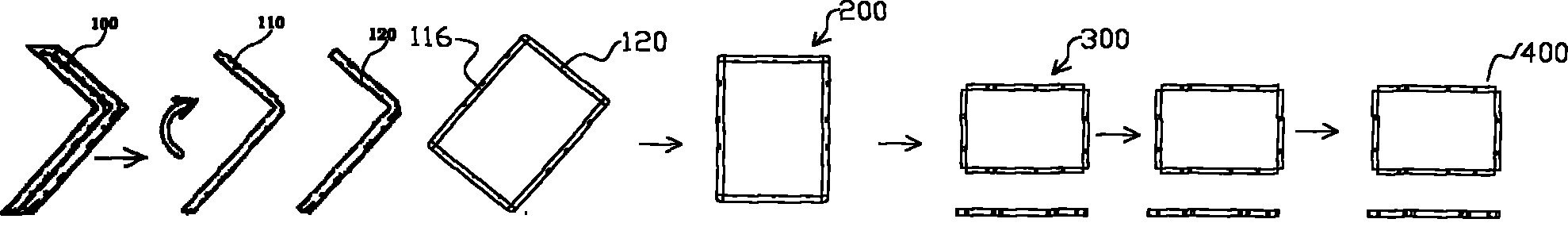

LCD panel frame and manufacturing method

InactiveCN102122088AIncrease profitReduce manufacturing costRack/frame constructionNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display (LCD) panel frame, which is formed by welding two mutually-symmetrical L-shaped strip materials. Flangings are formed on the L-shaped strip material, and holes are punched on the L-shaped strip materials. The invention also discloses a manufacturing method for the LCD panel frame. The LCD panel frame is formed by welding the two mutually-symmetrical L-shaped strip materials, wherein the L-shaped strip materials are pressed and molded by progressive tooling, so that the manufacturing cost and production consumption are reduced, the utilization rate of the materials is improved (which is over 60 percent), and the manufacturing method is simple. Therefore, the aims of reducing the cost of products and improving production efficiency are fulfilled.

Owner:通彩智能科技集团有限公司

Orange splitting technology in orange can processing

The present invention discloses an orange splitting technology in orange can processing. Firstly, orange balls are soaked in clear water, then the orange ball is hold in one hand hold, a splitting bow is hold in the other hand, and the orange is split by the splitting bow. The splitting technology of the present invention prevents fingers from squeezing orange segments; specific operation is relatively detailed, standard and comprehensive; the splitting technology is convenient for instructing and training, but most of all, can directly reduce the number of orange segments oozing juice, thereby preventing juice from oozing crossover; and the splitting technology attains split orange segments of high quality, and can, to a certain extent, improve production efficiency and product quality, and reduce raw material consumption.

Owner:ZHEJIANG TAIZHOU YIGUAN FOOD

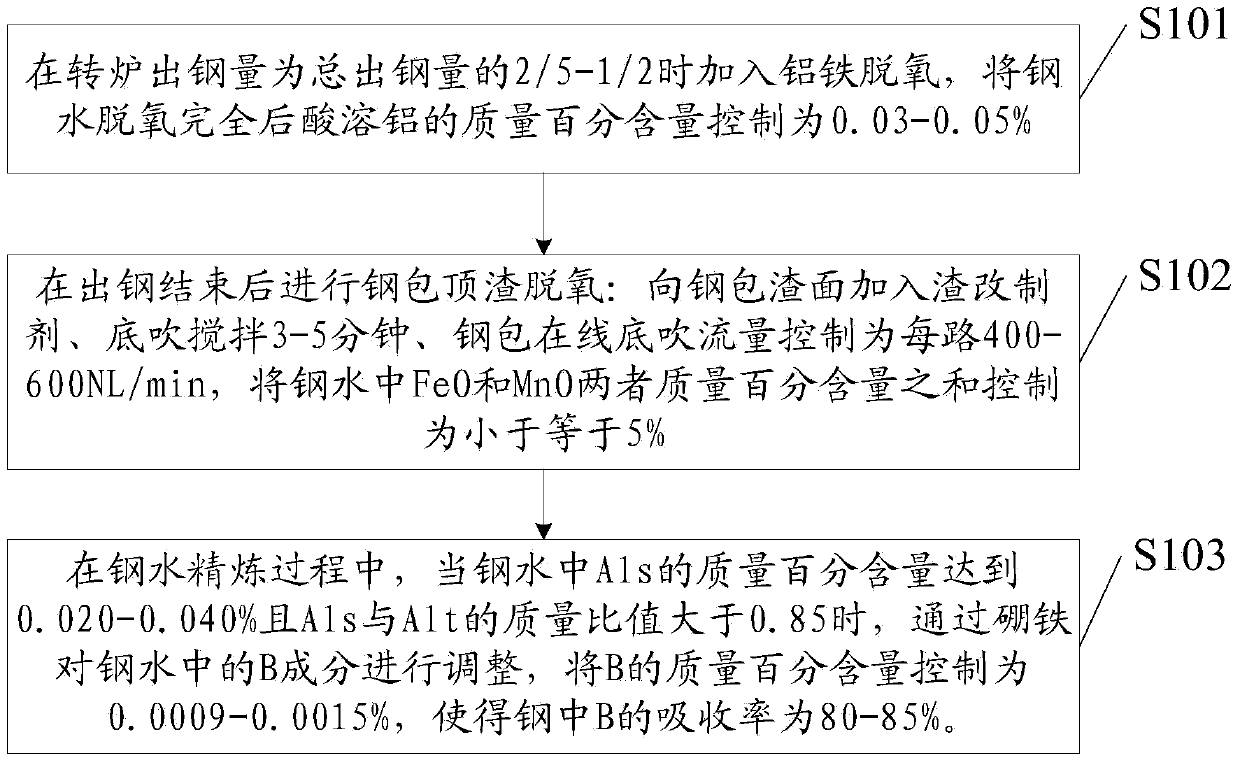

Method for controlling boron content of boron steel

The invention discloses a method for controlling the boron content of boron steel. The method includes the steps that ferro-aluminum is added for deoxygenation when the steel output of a converter ranges from two fifths to one half of the total steel output, and the mass percentage content of acid saluted aluminum is controlled to be 0.03%-0.05% after molten steel is completely deoxidized; ladle top slag is deoxidized after steel output is completed, wherein a slag modifying agent is added to the slag surface of a ladle, bottom blowing and stirring are performed for 3-5 min, the online bottom blowing flow of the ladle is controlled to range from 400 NL / min to 600 NL / min, and the sum of the mass percentage content of FeO and the mass percentage content of MnO in the molten steel is controlled to be 5% or less; and in the refining process of the molten steel, when the mass percentage content of Als in the molten steel reaches 0.020%-0.040% and the mass ratio of Als to Alt is larger than 0.85, the component B in the molten steel is adjusted through ferroboron, the mass percentage content of the component B is controlled to range from 0.0009% to 0.0015%, and the absorptivity of the component B in the steel is made to range from 80% to 85%. According to the technical scheme, the technical problem that the boron content of boron steel is beyond the control range in the prior art is solved, and performance of boron steel is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Method for producing crystalline sorbitol from starch

InactiveCN105154477AHigh yieldEasy to produceSugar derivativesChemical industryProcess engineeringSorbitol

The invention discloses a method for producing crystalline sorbitol from starch, which comprises the following steps: starch size mixing, liquification, saccharification, impurity removal, deacidification and desalting, nanofiltration purification, membrane concentration, concentration by evaporation, hydrogenation, settling and decolorization, continuous ion membrane desalting and concentration, and after-treatment. The method disclosed by the invention has the advantages of high production efficiency, short technical process, low production cost, low energy consumption, energy saving and water saving. The prepared crystalline sorbitol product has high purity, and can satisfy the requirements for application in the fields of food, Vc and other industries.

Owner:CHENGDU LIANJIE MEMBRANE TECH

Method of inhibiting acid regurgitation caused by plasticizer

InactiveCN101020763AReduce lossesControl acid refluxCarboxylic acid esters separation/purificationSodium bicarbonateCalcium bicarbonate

The present invention is method of inhibiting acid regurgitation caused by plasticizer, and belongs to the field of phthalic ester plasticizer technology. The phthalic ester plasticizer is prepared with phthalic anhydride and alcohol through reaction under the catalysis of sulfuric acid, and features that before decompressing dealcoholization, alkali powder of sodium carbonate, sodium bicarbonate, calcium bicarbonate or calcium carbonate in 50-100 ppm of coarse ester is added. The present invention can control acid regurgitation caused by plasticizer effectively.

Owner:山东宏信化工股份有限公司

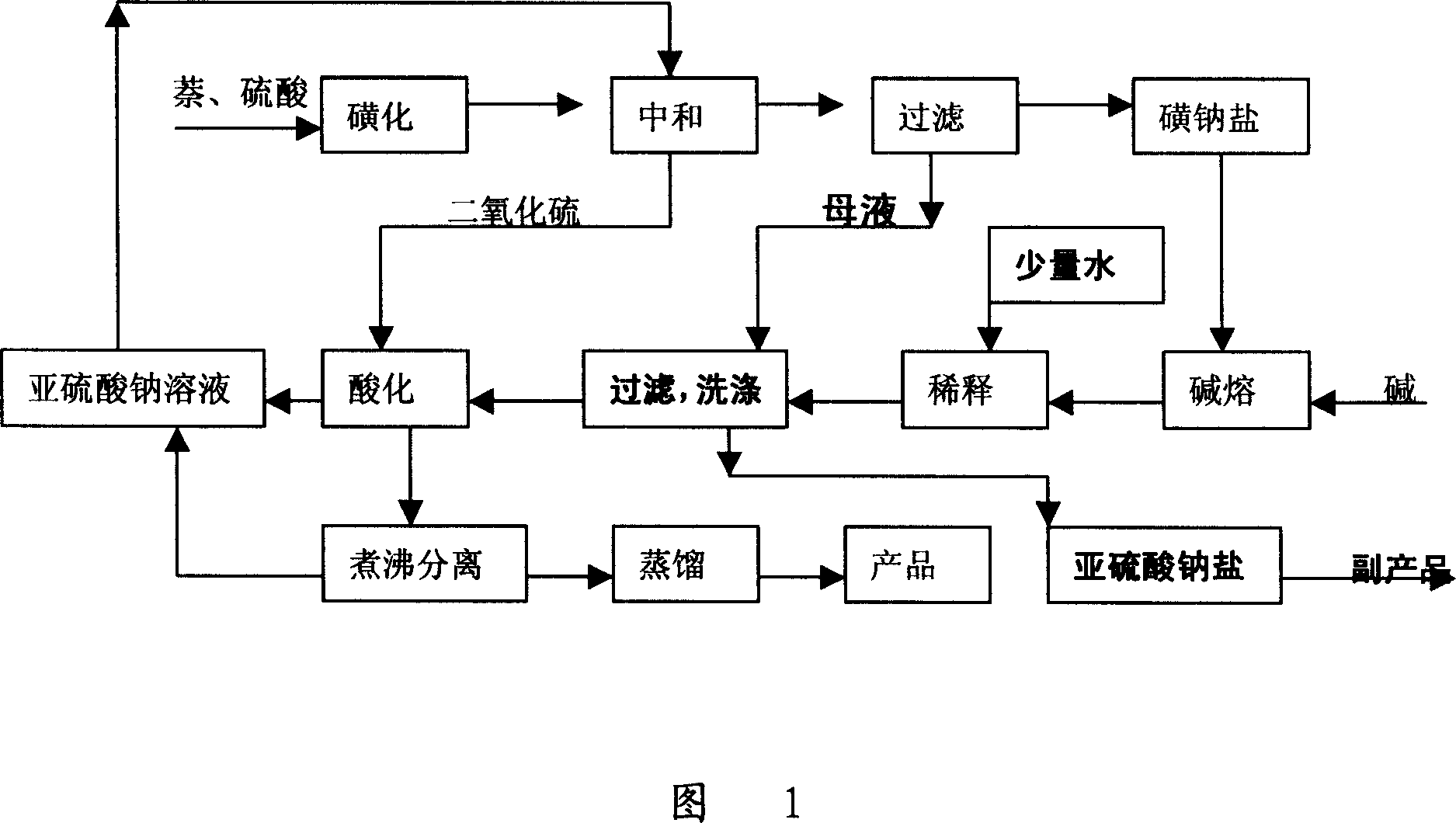

Method for circulated utilization of mother liquor of alpho-naphthol, beta-naphthol ethyl naphthol production

InactiveCN1994932AEmission reductionEfficient use ofOrganic chemistryOrganic compound preparationSulfite saltWastewater

The invention discloses a new circulating utilizing method of mother liquid in the methyl naphthol and beta-naphthol manufacturing course, which comprises the following steps: adding little water in the dilute stove before putting alkali fusing material; making solid sodium sulfite display flow crystal pattern; transmitting into filter autoclave; filtering; separating mother liquid through sulfonated sodium salt; transmitting into filter autoclave; washing; filtering; combining filtrate; transmitting into acidifying segment; entering subsequent course; obtaining the product; recycling the sodium sulfite to manufacture naphthol.

Owner:江苏华达化工集团有限公司

Lime slaking process for alumina production

The present invention relates to alumina producing technology, and is especially lime slaking process for producing alumina through Bayer process with diaspore type bauxite as material. The present invention features that lime is slaked with low concentration solution of Al2O3<80 g / L and SiO2<0.8 g / L. The lime slaking process can raise activity of lime, raise SiO2 saturation coefficient of red mud leaching calcium silica slag, lower the mineral consumption and alkali consumption in alumina production, low production cost, lower red mud discarding rate and raise apparatus capacity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Production method of aromatic vinegar

InactiveCN103333775AKeep the flavorFormulation ScienceVinegar preparationFood flavorEnergy conservation

The invention discloses a production method of aromatic vinegar, which comprises the steps that sticky rice is placed in a steeping pool; clean water is added; the sticky rice is steeped for 15-24h, and then bailed out and drained off; and the aromatic vinegar is prepared by undecanted wine making, fermented grain making and vinegar drenching. The aromatic vinegar is scientific, reasonable and novel in formula, rich in nutrition, convenient to eat, simple and easy in production technology method, high in product nutrition strengthening efficiency, low in production consumption, and low in cost, can allow common table vinegar to be subjected to nutrition strengthening, still keeps the original flavor of the table vinegar, does not require very complicated equipment, and saves energy sources.

Owner:ZHENJIANG DANHE VINEGAR

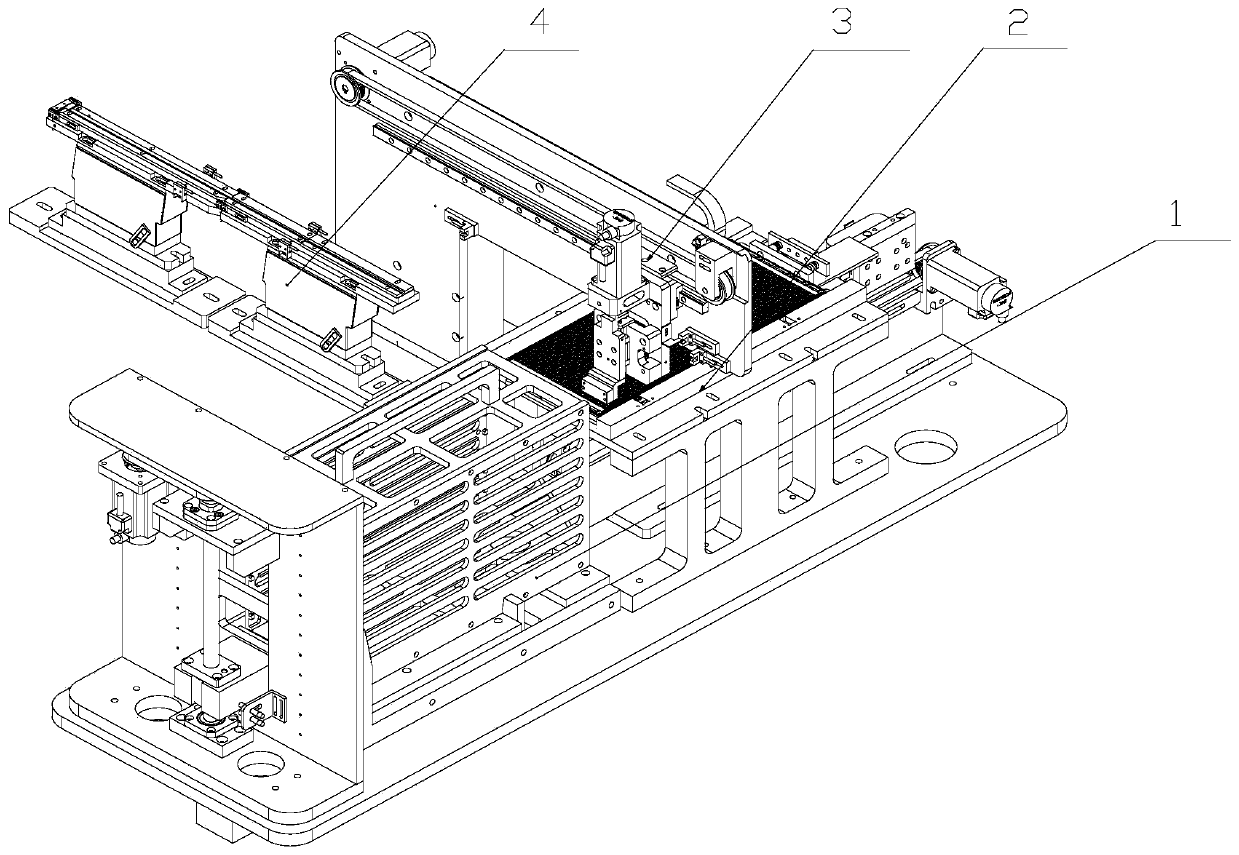

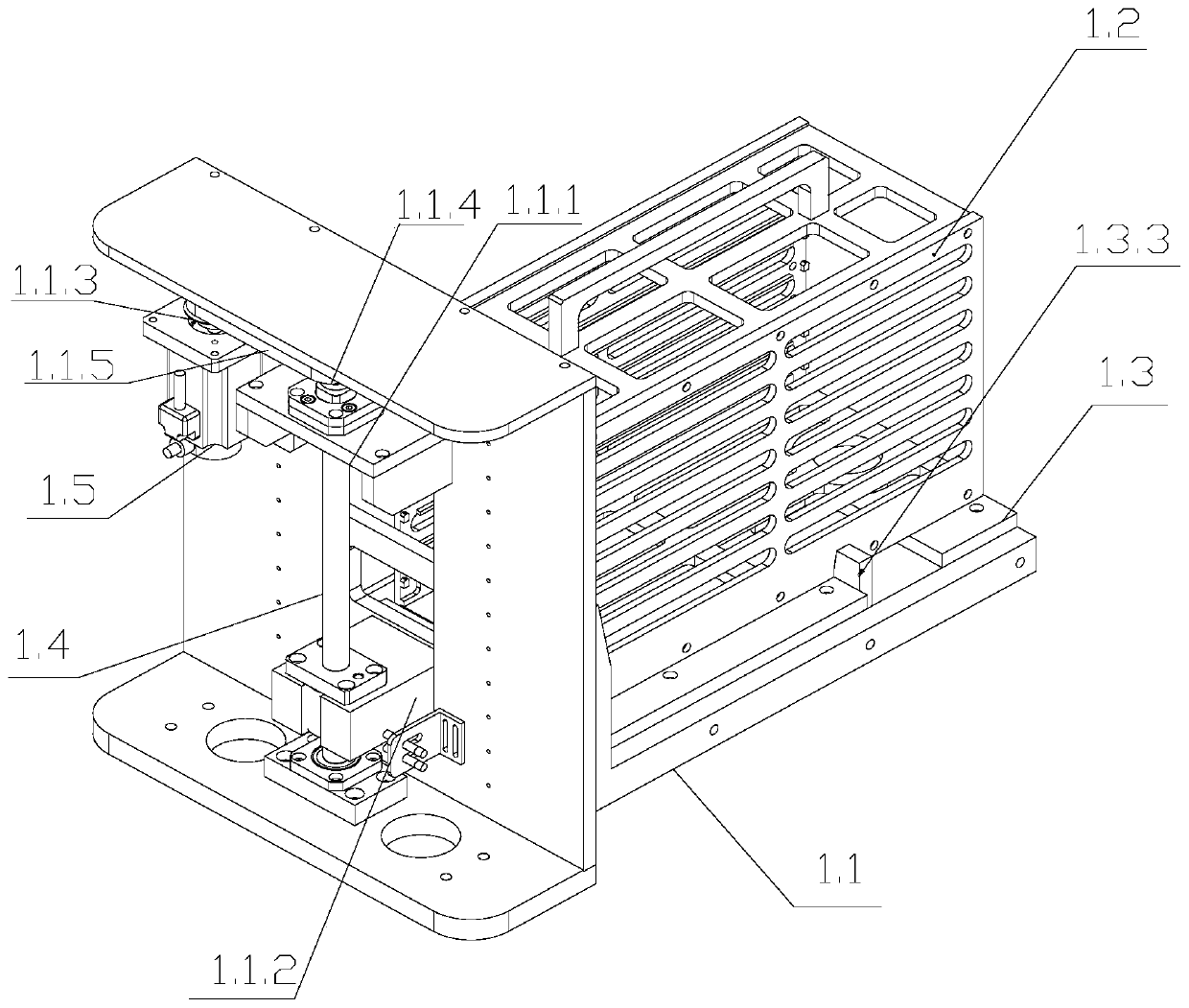

Feeding and conveying device of semiconductor chip sorting and testing device, and working method thereof

PendingCN110646724AImprove yield rateReduce collisionSortingAutomated test systemsSemiconductor chipProcess engineering

The invention provides a feeding and conveying device of a semiconductor chip sorting and testing device, which generates no damage to the chip and has a high automation degree, and a working method thereof. The feeding and conveying device comprises a tray feeding device located on a worktable, a tray taking device, a chip taking device and a chip conveying device, the tray feeding device is responsible for raising a tray to a suitable position to enable the tray taking device to take out the tray, the tray taking device is responsible for taking out trays in a lifting basket one by one for enabling the chip taking device to take out chips, the chip taking device is responsible for taking out the chips in the trays and conveying the chips into the chip conveying device, and the chip conveying device is responsible for conveying the chips to a detection station. The chips in the feeding and conveying device provided by the invention are subjected to less collision and friction, the yield of the chips is greatly improved, and the production consumption is reduced, so that the production cost is reduced.

Owner:扬州泽旭电子科技有限责任公司

Method for producing L-histidine

ActiveCN101125831AReduce technical difficultyReduce manufacturing costOrganic chemistryActivated carbonHydrolysate

The invention discloses an L-histidine production method, the mixed amino-acid mother liquor that is acquired through a protein hydrolysis method is separated by secondary strong acid cationic resin column, neutralized by hydrochloric acid, decolorized by activated carbon, exchanged by strong alkali cationic resin column and crystallized, thus acquiring the product. The optical rotation of product acquired by the invention is as much as (Alpha)D20+12.1 degree-+12.8 degree, and the content is as much as 99.8-101.5 percent which even meets and exceeds the national standard of AJI97, and the product yield is as high as 1.2kg / m3 hydrolysate.

Owner:湖北新生源生物工程有限公司

Reinforced wood floorboard with decorative surface made of filling materials and method for producing same

InactiveCN1970966AReasonable production processSimple processLamination ancillary operationsLaminationFilling materialsFlax fiber

The invention relates to a strengthened wood floor with decorating and filling material and the manufacturing method. It comprises wear-resistance layer, decorating layer, base material layer and balance layer. Gold onion powder and / or noctilucent powder and / or flax fiber is used as decorating material to fill in wear-resistance layer and / or decorating layer so as to form the decorating face. The manufacturing method comprises wear-resistance paper dipping, decorating paper dipping, balance paper dipping and hot-pressed compound so on. The invention with a novel method improves the conventional technology. The technology of filling decorating material is applied for fabricating decorating image, which is not simulated by prior computer technology entirely. Compared with prior the craft production with printed image, it is provided with easy and rational technology, high production ratio, low cost, elegant image and strong stereoscopic sense so on. It is especially applied in fabricating the strengthened wood floor with plot image decorating face.

Owner:圣象实业(江苏)有限公司

Crystallization method through gas-liquid biphasic reaction and apparatus thereof

ActiveCN102188940AHigh purityReduce production consumptionCrystallization separationAlkali metal carbonates shape formationChemical reactionControl system

A crystallization method through gas-liquid biphasic reaction is disclosed. Liquid materials react with gas phase materials to produce solid phase crystals. The method includes the following steps that: in a low temperature crystallizer, liquid materials and gas phase materials are subjected to chemical reactions so as to realize generation and growth of crystal nucleuses, wherein the chemical reaction process is a biphasic continuous reaction process that comprises a chemical reaction process of which the liquid materials are continuous phase and the gas phase materials are dispersed phase and a chemical reaction process of which the gas phase materials are continuous phase and the liquid materials are dispersed phase; then in a high temperature crystallizer, a reaction process of using a liquid phase as a continuous phase and a gas phase as a dispersed phase on the crystal nucleuses is performed so as to crystallize and make the crystal nucleuses become bigger; a high temperature crystal plasma separator is used to obtain solid phase crystallized products. The crystal nucleuses can be automatically returned in a crystal nucleus system so that formation and quantity of the crystal nucleuses can be controlled. The grown crystals are taken out in a high temperature area of an apparatus and the crystal nucleuses are formed in a low temperature area of the apparatus. The processes of generation and growth of the crystal nucleuses are performed in different containers of a gas-liquid biphasic response apparatus provided in the invention.

Owner:武奋超

Waterborne ceramic digital spray-painting ink and a preparing method thereof

InactiveCN106905769AReduce manufacturing costReduce production consumptionInksGlycerolSurface tension

The objective of the invention is to provide waterborne ceramic digital spray-painting ink and a preparing method thereof to overcome defects of present waterborne ceramic digital spray-painting ink. To achieve the objective, the provided ink is prepared by mixing water, glycerol, propylene glycol, glycol, polyethylene glycol, n-butanol, a dispersant, a coupling agent, a surfactant, a defoamer, an anti-settling agent, a sterilizing agent and pigment. The water, the glycerol, the propylene glycol, the glycol, the polyethylene glycol, the n-butanol, the dispersant, the coupling agent, the surfactant, the defoamer, the anti-settling agent, the sterilizing agent and the pigment are fully mixed according to a ratio, the mixture is ground by a sand mill for 5 h at a speed of 2000 r / min until the granularity is about 150-350 nm, viscosity and surface tension of the product are tested, and the ink is obtained when the viscosity and surface tension are qualified.

Owner:QINGDAO AGRI UNIV

Reinforced brake band made of carbon fiber covering yarns and preparing method of reinforced brake band

The invention discloses a carbon fiber core-spun yarn reinforced brake belt, which comprises a carbon fiber core-spun yarn braided belt and a mixed rubber compound containing carbon fiber attached thereto. The innovative use of carbon fiber, and the production process is simple, and the prepared brake band has excellent performance and effect, which meets the national quality standard and international environmental protection requirements. The brake band prepared by the method of the present invention uses natural renewable fibers, the natural fiber is environmentally friendly and biodegradable, and the carbon fiber core-spun yarn reinforced brake band of the present invention significantly improves the stretching of the brake band Strength and modulus of elasticity, with excellent mechanical properties. After more than 20,000 times of braking tests, the change of front and rear braking torque does not exceed 1.5N.m, and there is no abnormal braking sound.

Owner:DONGTAI HUAYANG GLASS FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com