LCD panel frame and manufacturing method

A manufacturing method and frame technology, applied in the direction of manufacturing tools, rack/frame structures, instruments, etc., can solve problems such as affecting product cost and low material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

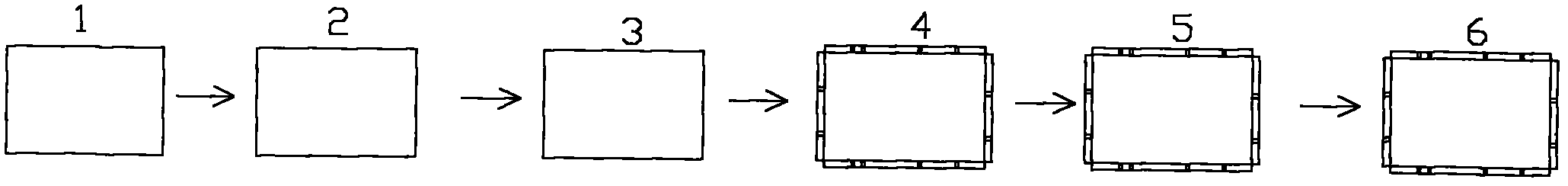

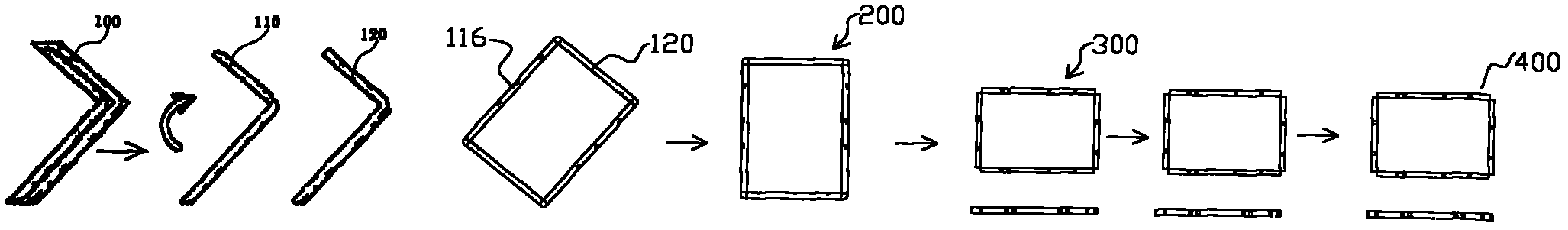

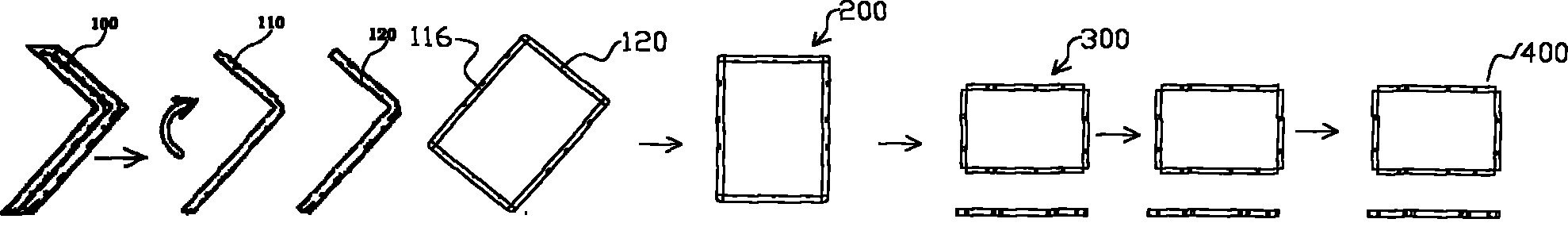

[0020] Such as figure 2 Shown, a kind of manufacturing method of LCD panel frame, it comprises the steps:

[0021] Step (1): forming an L-shaped strip 100 constituting the frame of the LCD panel by progressive tooling, and the L-shaped strip is punched with holes;

[0022] Step (2): The L-shaped strip 100 in step (1) is pulled apart by the manipulator, one of the L-shaped strips is rotated 120 to 180°, translated, and aligned to combine the two L-shaped strips 110, 120 into one Unwelded rectangular frame 200;

[0023] Step (3): butt-welding the two L-shaped strips 110 and 120 of the unwelded rectangular frame in step (2) to form a welded rectangular frame 200;

[0024] Step (4): Bending the four sides of the rectangular frame 200 welded in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com