Method for preparing acetone through low temperature gas phase dehydrogenation of water-containing isopropanol

A water-containing isopropanol, gas-phase dehydrogenation technology, applied in the field of fine chemicals, can solve the problems such as acetone has not been reported, and achieve the effect of high acetone selectivity, easy separation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

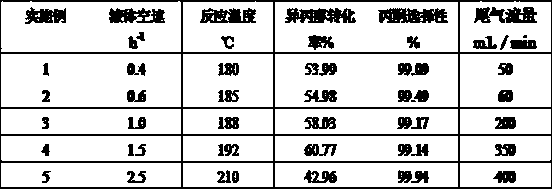

[0021] Carry out continuous dehydrogenation reaction on fixed bed device with catalyst reduction, liquid space velocity 0.4h -1 , under nitrogen flow, the system pressure is ≤0.1MPa, the tail gas flow rate is 50mL / min, the reaction temperature is 180°C, the vaporization temperature is 150°C, the vaporized material is kept at 195-200°C, the reaction product passes through the gas-liquid separator and the condenser, and the tail gas is vented to collect the reaction. liquid. The dehydrogenation solution was analyzed by gas spectrometer internal standard, and the results are shown in Table 1.

Embodiment 2

[0023] Carry out continuous dehydrogenation reaction on the fixed bed device with the catalyst reduced, the liquid space velocity is 0.6h -1 , under nitrogen flow, the system pressure is ≤0.1MPa, the tail gas flow rate is 60mL / min, the reaction temperature is 185°C, the vaporization temperature is 160°C, and the vaporized material is kept at 195-200°C. liquid. The dehydrogenation solution was analyzed by gas spectrometer internal standard, and the results are shown in Table 1.

Embodiment 3

[0025] Carry out continuous dehydrogenation reaction on the fixed bed device with the catalyst reduced, the liquid space velocity is 1.0h -1 , under nitrogen flow, the system pressure is ≤0.1MPa, the tail gas flow rate is 200mL / min, the reaction temperature is 188°C, the vaporization temperature is 170°C, the vaporized material is kept at 195-200°C, the reaction product passes through the gas-liquid separator and the condenser, and the tail gas is vented to collect the reaction liquid. The dehydrogenation solution was analyzed by gas spectrometer internal standard, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com