Orange splitting technology in orange can processing

A technology of splitting and orange, applied in the field of orange splitting process, can solve the problems of increased production consumption of raw materials, slipping of fingers crossed in juice, affecting the progress of split orange slices, etc. Avoid the effect of sticking orange chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

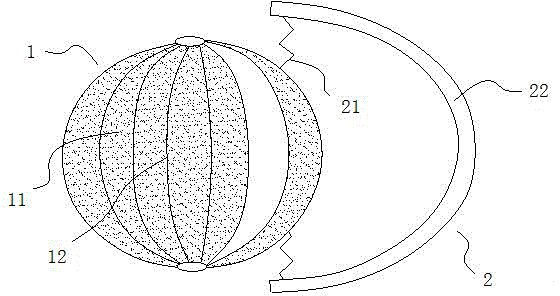

[0016] Such as figure 1 Shown, a kind of orange parting technology in canned orange processing, it mainly comprises the following several steps:

[0017] (1) Soak the orange balls 1 in clear water: put the orange balls 1 in a stainless steel plate after peeling, generally place 70-80 orange balls 1 in each plate, then add clear water to soak until the orange balls 1 are completely covered to increase the amount of orange balls. The degree of lubricity between the slices 11 prevents the orange slices 11 from sticking together after being split, and simultaneously leaves a part of space in the stainless steel dish to place the split orange slices 11.

[0018] (2) Hold the orange ball 1 in one hand: generally use the left hand, keep the palm facing the orange heart, open the five fingers and gently hold the orange ball 1, the whole orange ball 1 is slightly inclined downward, so that the hand can It is consistent with the direction of the slit 12 of the orange slice 11.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com