Feeding and conveying device of semiconductor chip sorting and testing device, and working method thereof

A technology of conveying device and testing device, which is applied in the direction of measuring device, electronic circuit test, automatic test system, etc. It can solve problems such as chip damage, lower yield rate, and unsuitability for high-end chips with precision requirements, so as to reduce production consumption and improve yield efficiency, less friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

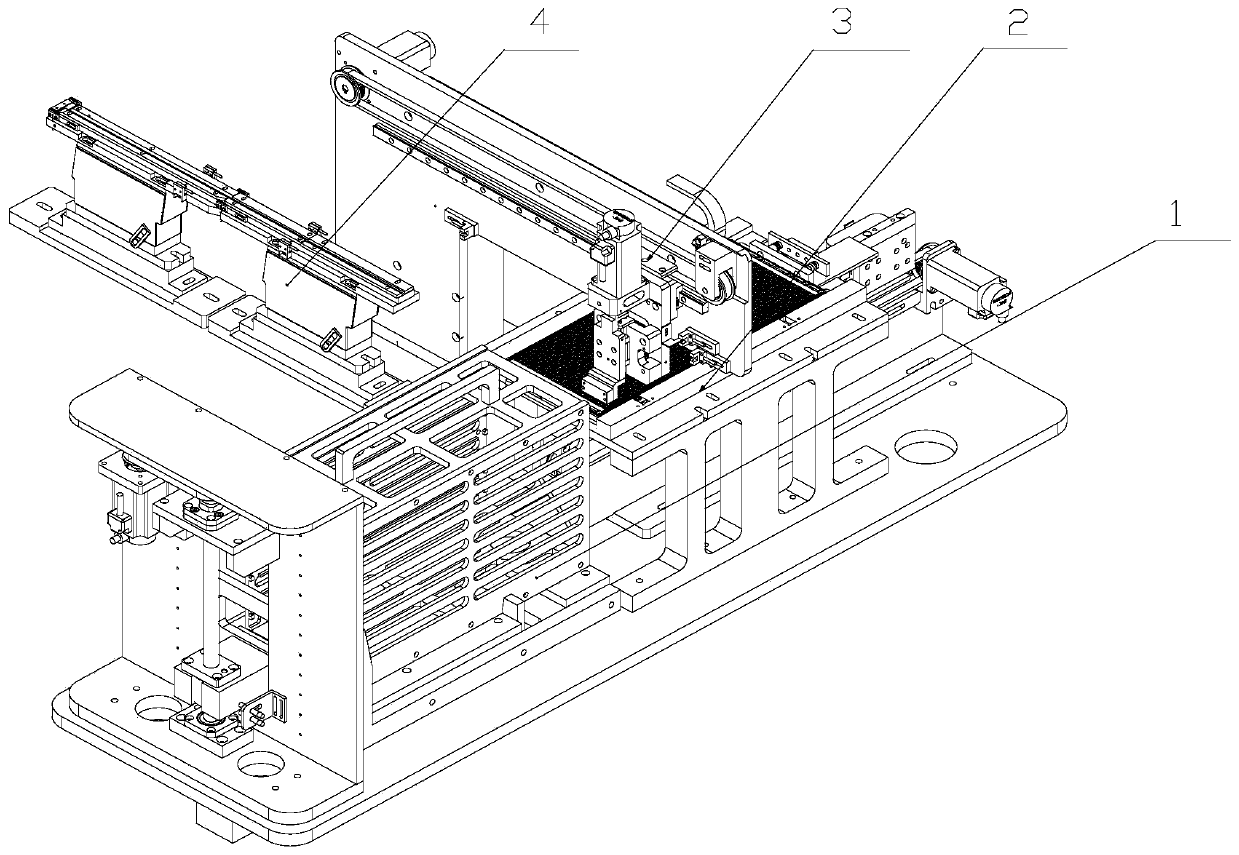

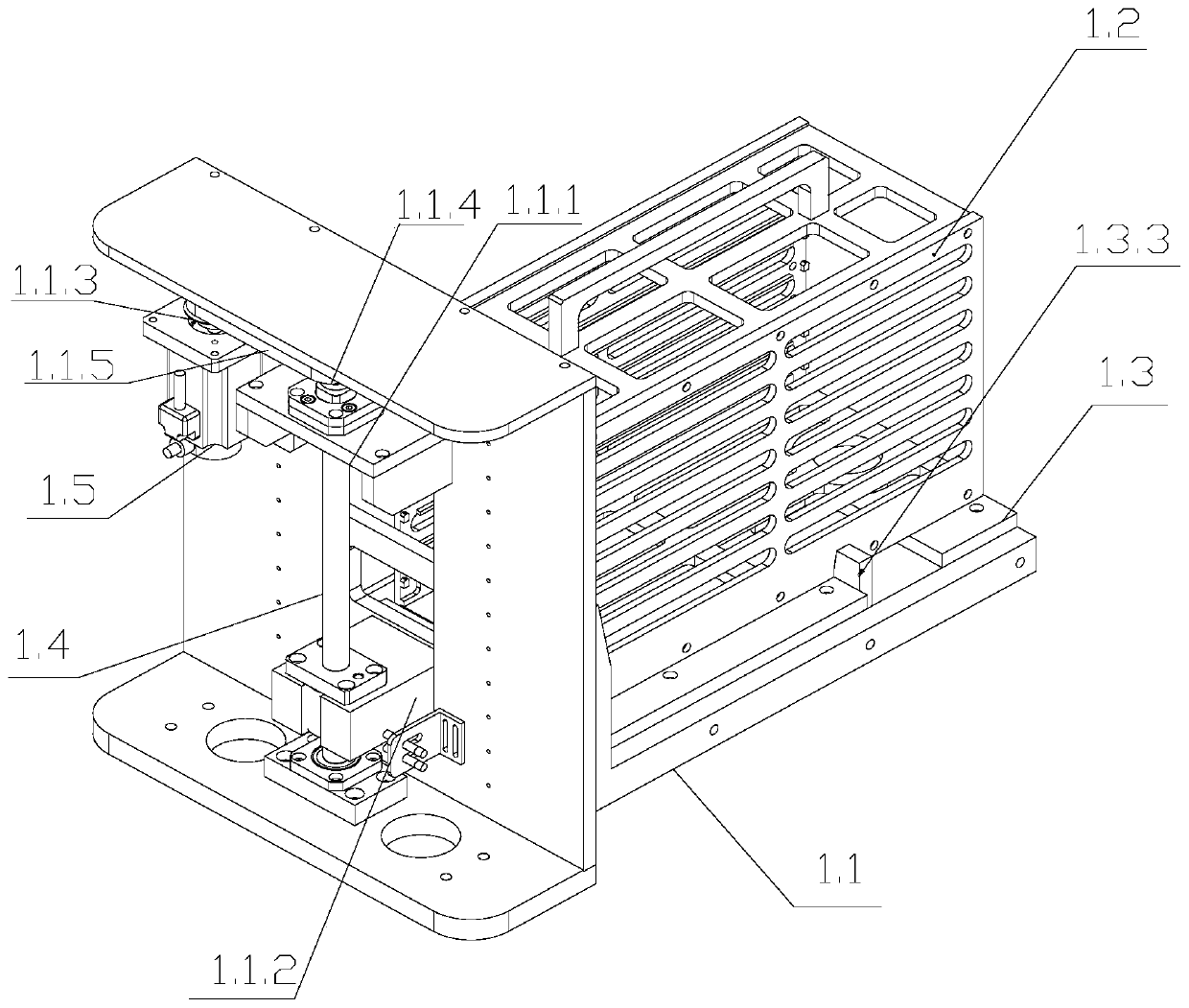

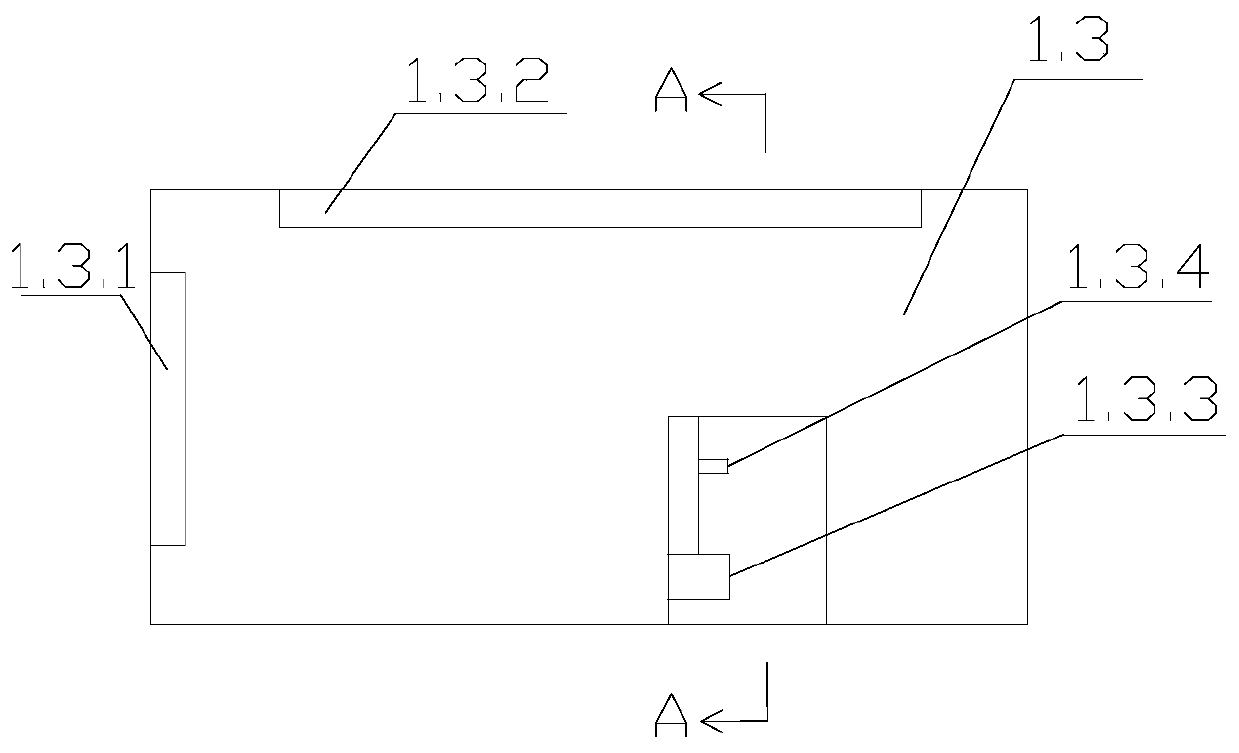

[0054] Such as Figure 1-11 Shown, a kind of feeding and conveying device of semiconductor chip sorting and testing device, comprises the tray loading and feeding device 1 that is positioned on the workbench, takes tray device 2, takes chip device 3 and chip conveying device 4, as figure 2 As shown, the feeding device includes an L-shaped support 1.1, a basket 1.2 positioned on the support 1.1 and a lifting device for the basket 1.2, and the lifting device includes a horizontally arranged basket supporting plate 1.3, a vertical The ball screw 1.4 and the servo motor 1.5 are arranged vertically, the basket support plate 1.3 is located on the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com