Crystallization method through gas-liquid biphasic reaction and apparatus thereof

A gas-phase reaction and liquid-phase reaction technology, applied in the chemical method, crystallization separation, and separation method of reacting liquid and gas medium, etc., can solve the problems of prolonging the crystal growth period, unsatisfactory crystal particle size, slow crystal growth, etc. Achieve the effect of inhibiting the generation of crystal nuclei, improving the crystallization effect, and improving the basic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with examples.

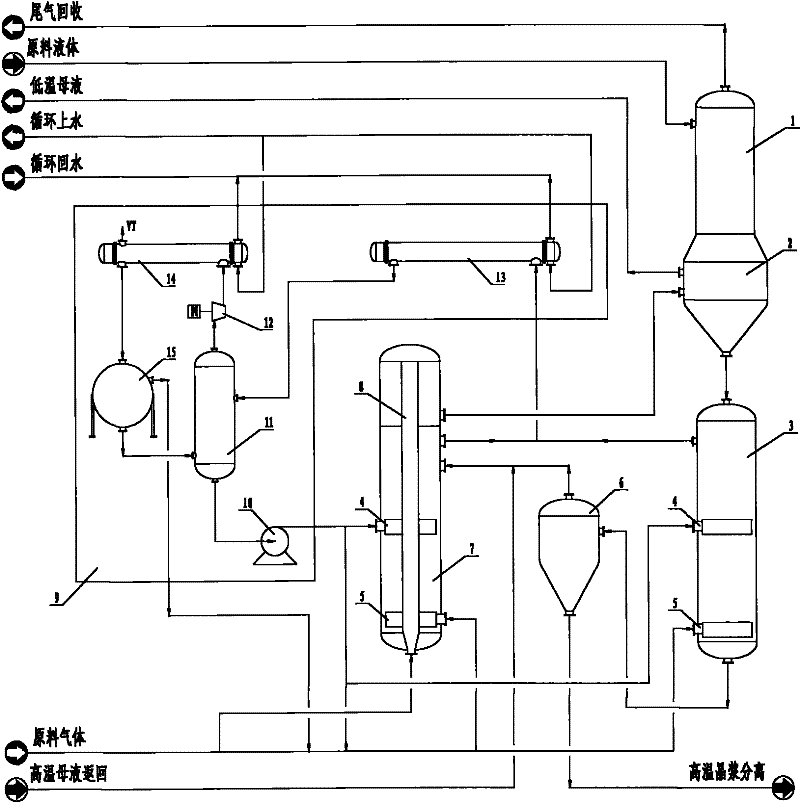

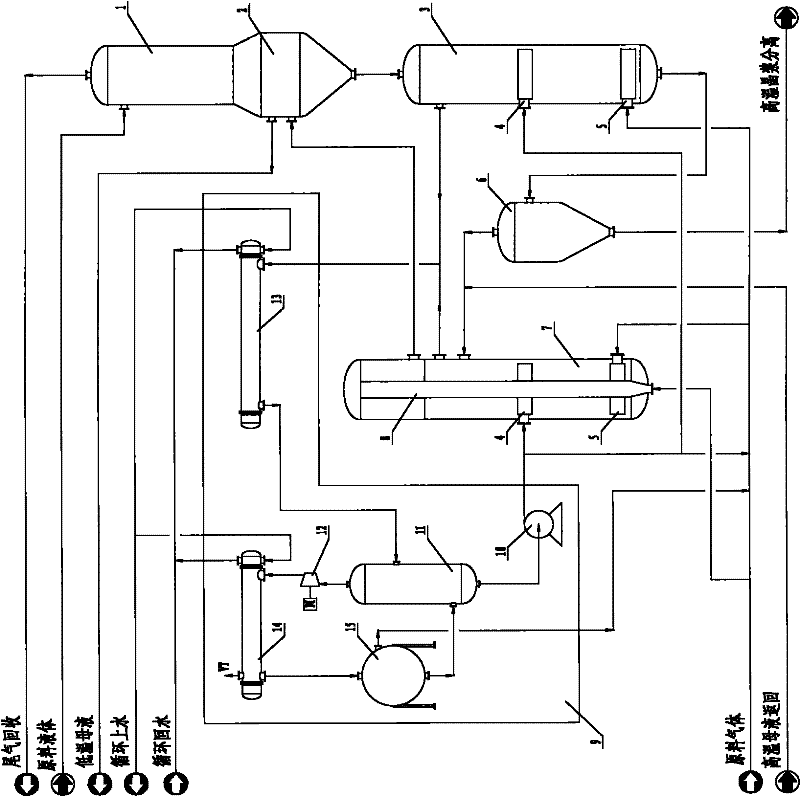

[0043] Such as figure 1 Shown is the two-phase reaction crystallization device used in the carbonation reaction and crystallization process of the soda ash industrial production process in the present invention. The raw materials used are: the liquid phase substance is ammonia brine, and the gas phase substance is CO 2 , The two-phase reaction process is:

[0044] NaCl+NH 3 +CO 2 +H 2 O→NaHCO 3 ↓+NH 4 Cl

[0045] The reaction produces crystals, heavy alkali NaHCO 3 . The following is the crystalline heavy alkali NaHCO when the soda ash is produced by the soda ash method 3 The production process of is a specific embodiment, and the production method and production device of the present invention are described in detail.

[0046] The gas-liquid two-phase reaction crystallizer includes a low-temperature crystal slurry separator 2, a high-temperature reaction crystallizer 3, a high-temperature cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com