Economical high-toughness 800MPa-level automobile beam steel and production method thereof

A technology of automobile girder steel and production method, which is applied in the direction of manufacturing converters, etc., can solve problems such as unfavorable application and promotion, increase production cost, reduce product cost performance and market competitiveness, increase descaling effect, avoid hemp pits, The effect of saving production consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

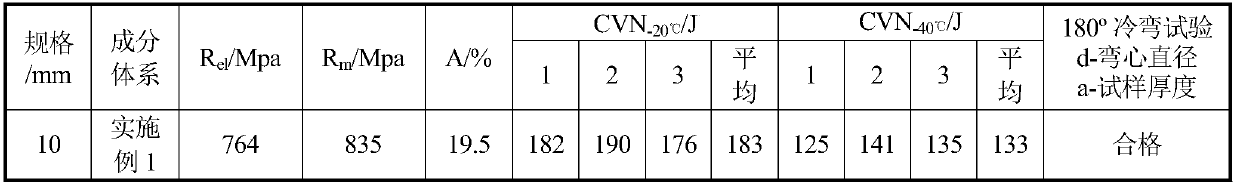

Embodiment 1

[0027] In this embodiment, the process of the 1780 production line of our company to produce a product specification of 10mm thick and 800MPa grade automobile frame steel is taken as an example to further illustrate the present invention. The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.08%, Si: 0.10%, Mn: 1.73%, P: 0.010%, S: 0.006%, Mo: 0.135%, Nb: 0.025%, Ti : 0.13%, N: 0.002%, Al: 0.035%, and the balance is Fe and unavoidable impurities.

[0028] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, LF refining, slab continuous casting, 1780mm rolling mill rolling, and front-stage cooling.

[0029] Among them, the continuous casting slab is heated in a furnace within 24 hours. The temperature of the heating furnace is 1260 ° C, the heating time is 140 min, and the finishing temperature of the rough rolling is 1030 ° C. The rough rolling p...

Embodiment 2

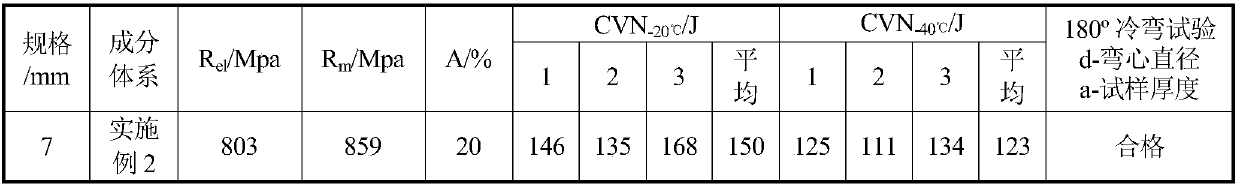

[0035] In this embodiment, the process of producing 7mm thick and 800MPa grade automobile frame steel by the company's 1780 production line is taken as an example to further illustrate the present invention. The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.07%, Si: 0.14%, Mn: 1.68%, P: 0.011%, S: 0.002%, Mo: 0.131%, Nb: 0.038%, Ti : 0.13%, N: 0.004%, Al: 0.045%, the balance is Fe and unavoidable impurities.

[0036] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, LF refining, slab continuous casting, 1780mm rolling mill rolling, and front-stage cooling.

[0037] Among them, the continuous casting slab is heated in a furnace within 24 hours. The temperature of the heating furnace is 1260 ° C, the heating time is 140 min, and the finishing temperature of rough rolling is 1060 ° C. The rough rolling process is 3 passes, and rough descaling i...

Embodiment 3

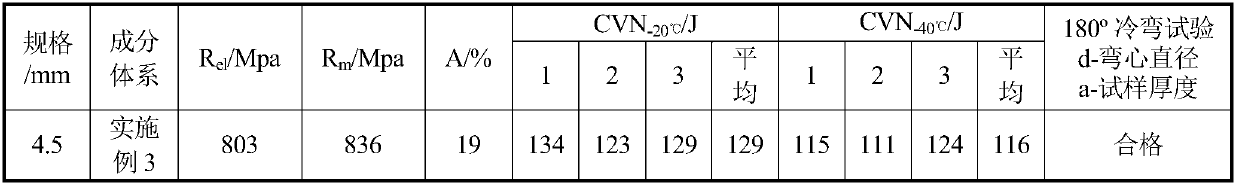

[0043] In this embodiment, the process of producing 4.5mm thick and 800MPa grade automobile frame steel by the company's 1780 production line is taken as an example to further illustrate the present invention. The automobile frame steel of this embodiment is proportioned according to the following weight percentages: C: 0.07%, Si: 0.16%, Mn: 1.65%, P: 0.011%, S: 0.002%, Mo: 0.131%, Nb: 0.030%, Ti : 0.10%, N: 0.004%, Al: 0.043%, and the balance is Fe and unavoidable impurities.

[0044] The production process route of the automobile frame steel in this embodiment includes top-bottom combined blowing converter, LF refining, slab continuous casting, 1780mm rolling mill rolling, and front-stage cooling.

[0045] Among them, the continuous casting slab is heated in a furnace within 24 hours. The temperature of the heating furnace is 1260°C, the heating time is 140min, and the finishing temperature of the rough rolling is 1065°C. The rough rolling process is 3 passes, and rough desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com