Method for controlling boron content of boron steel

A technology of boron content and boron steel, which is applied in the direction of improving process efficiency, can solve the problems of boron steel exceeding the control range and other problems, and achieve the effect of improving performance, saving production cost and reducing production consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

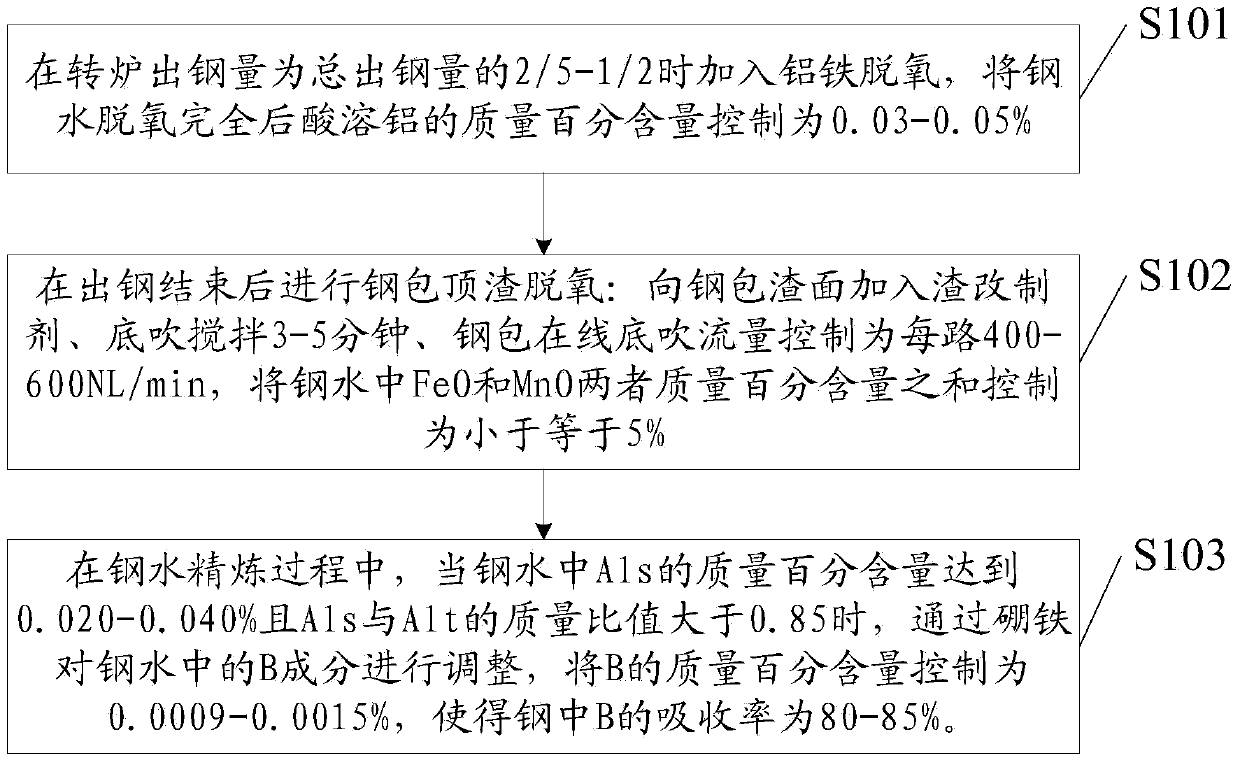

[0022] Please refer to figure 1 , the embodiment of the present application provides a method for controlling boron content in boron steel, the method comprising:

[0023] Step 101: adding aluminum-iron deoxidation when the tapping amount of the converter is 2 / 5-1 / 2 of the total tapping amount, and controlling the mass percentage of acid-soluble aluminum to 0.03-0.05% after the molten steel is completely deoxidized;

[0024] Step 102: Deoxidize the top slag of the ladle after tapping: add slag reforming agent to the slag surface of the ladle, bottom blow and stir for 3-5 minutes, control the flow rate of the ladle online bottom blow to 400-600NL / min per channel, and pour FeO in molten steel The sum of the mass percentages of MnO and MnO is controlled to be less than or equal to 5%;

[0025] Step 103: During the molten steel refining process, when the mass percentage of Als in the molten steel reaches 0.020-0.040% and the mass ratio of Als to Alt is greater than 0.85, the B co...

example 1

[0033] Example 1: Production of boron-containing SS400 using converter-CAS-OB-casting machine process:

[0034] 1) Use a slide plate to block slag to tap the steel. When tapping the steel, double bottom blowing argon gas is stirred, and the flow rate of each bottom blowing is controlled at 300NL / min. When the tapping amount is 1 / 5, add 574Kg of small-grained lime and 208Kg of fluorite;

[0035] 2) Add 1600kg of aluminum and iron when the tapping amount is 2 / 5;

[0036] 3) After tapping, add 100kg of aluminum slag balls to the slag surface, increase the bottom blowing argon to 600NL / min (each channel), turn off the bottom blowing argon after stirring for 3-5 minutes, and take molten steel samples to analyze acid-soluble aluminum Content 0.0315%;

[0037] 4) After the molten steel enters the CAS-OB refining station, first adopt dual-channel bottom blowing, the flow rate of the bottom blowing is controlled at 800NL / min in each channel, stir for 4-5 minutes, measure the temperatu...

example 2

[0042] Using converter-RH-casting machine process to produce boron-containing SAE1008:

[0043] 1) Use a slide plate to block slag and tap the steel. When tapping, double bottom blowing argon gas is stirred, and the flow rate of each bottom blowing is controlled at 350NL / min. When the tapping amount is 1 / 5, add 600Kg of small-grained lime and 198Kg of fluorite;

[0044] 2) Add 1126kg of aluminum and iron when the tapping amount is 2 / 5;

[0045] 3) After tapping, add 115kg of aluminum slag balls to the slag surface, increase the bottom blowing argon to 600NL / min (each channel), and after bottom blowing and stirring for 3-5 minutes, take a molten steel sample to analyze the acid-soluble aluminum content of 0.0348%;

[0046] 4) After the molten steel enters the RH refining station, vacuum cycle for 5 minutes, measure the temperature, take a sample of the molten steel, and at the same time take a top slag sample to analyze that the content of the component (FeO+MnO) is 2.7%;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com