Method for manufacturing LCD panel frame and frame manufactured by using method

A manufacturing method and frame technology, applied in optics, instruments, nonlinear optics, etc., can solve problems affecting product cost and low material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

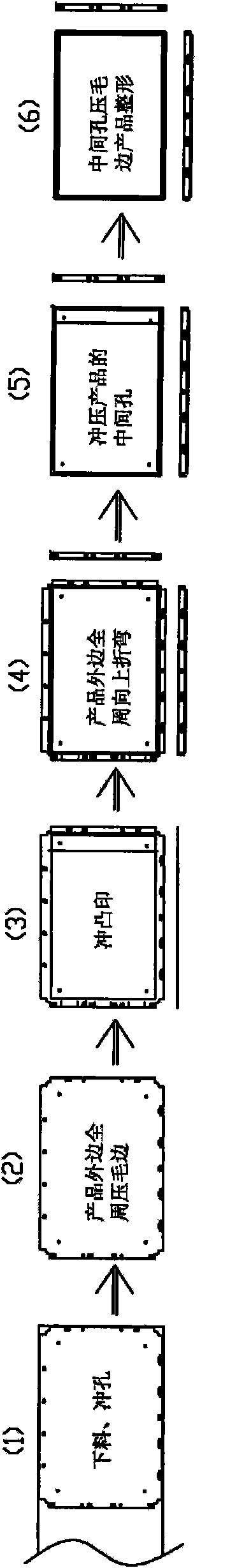

Method used

Image

Examples

Embodiment Construction

[0029] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

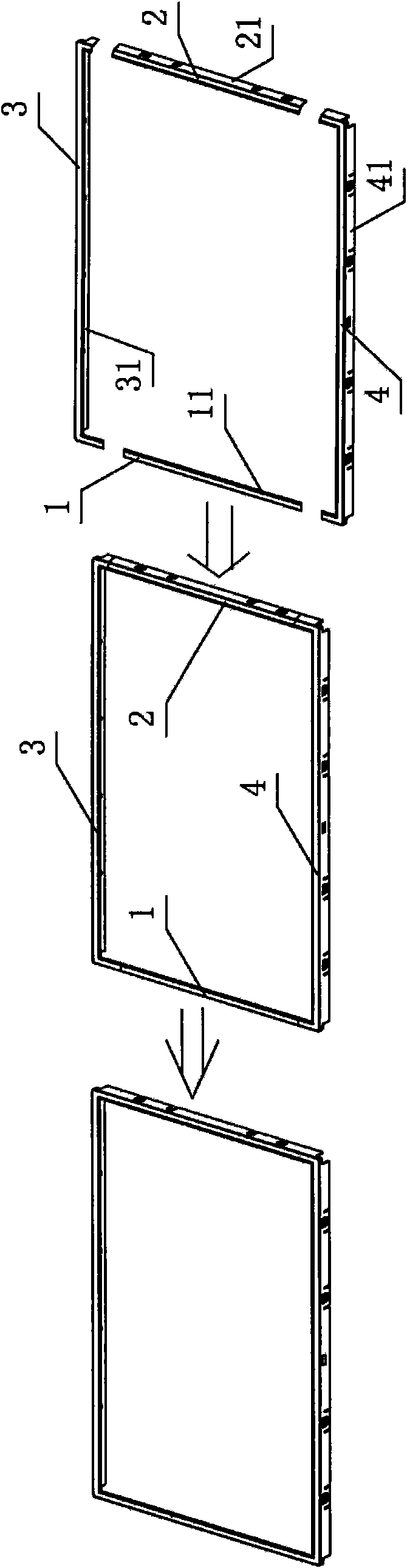

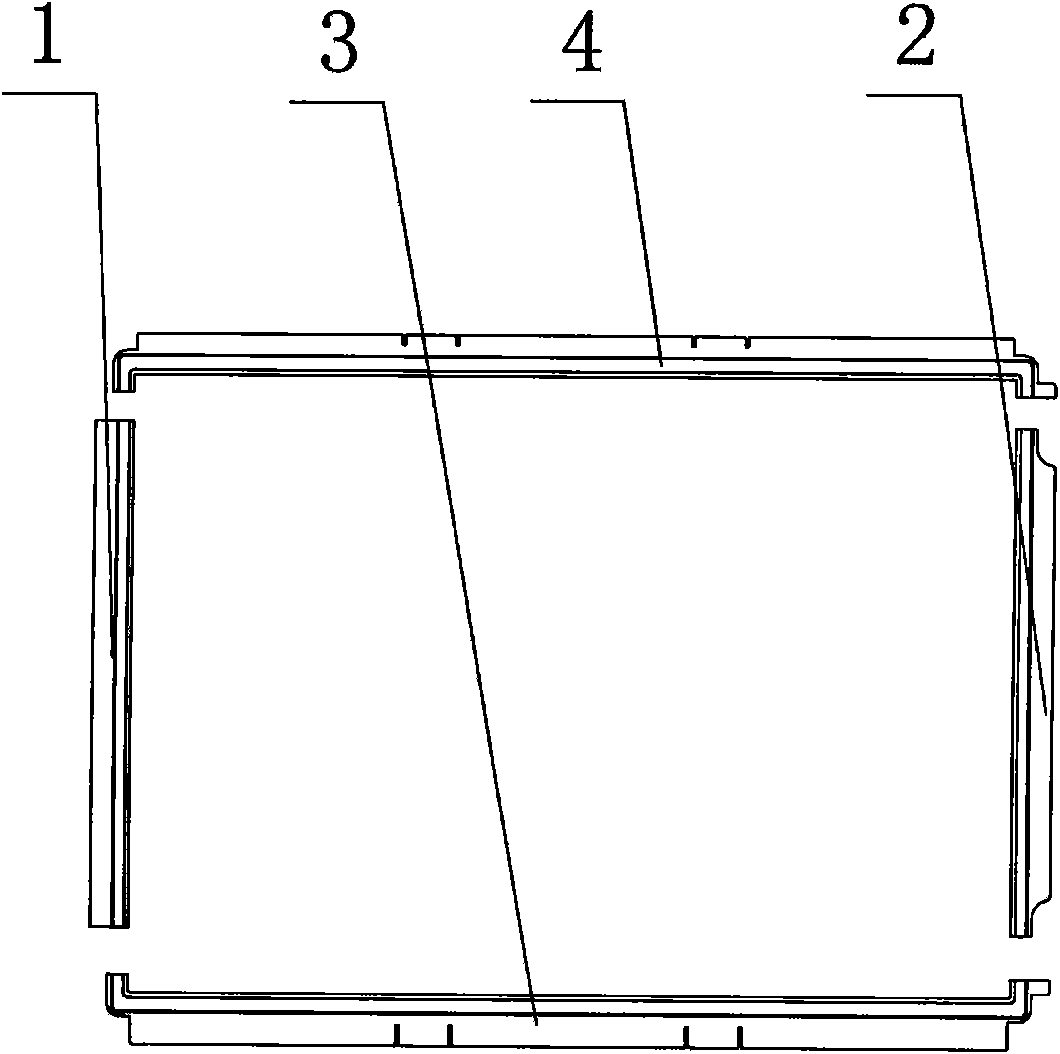

[0030] like figure 2 As shown, an LCD panel frame is composed of workpiece 1, workpiece 2, workpiece 3 and workpiece 4, and workpiece 1, workpiece 2, workpiece 3 and workpiece 4 are welded to each other, and the welded seam is L-shaped, Workpiece 1, Workpiece 2, Workpiece 3 and Workpiece 4 are combined together to form a rectangular LCD panel frame. Folding edges 11, 21, 31 and 41 are respectively provided on Workpiece 1, Workpiece 2, Workpiece 3 and Workpiece 4.

[0031] like Figure 3a As shown, in one embodiment of the present invention, workpiece 1 and workpiece 2 are two linear workpieces, workpiece 3 and workpiece 4 are two U-shaped workpieces, workpiece 1 and workpiece 2 are placed opposite to each other, and workpiece 3 and workpiece 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com