Inner-printing vacuum aluminum-coated transferring paper and its production

A technology of vacuum aluminum plating and production method, which is applied in the direction of paper, papermaking, paper coating, etc., which can solve the problems of labor and time-consuming, high cost, and difficulty in mass production, and achieve reduced production costs, high production efficiency, and bright colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

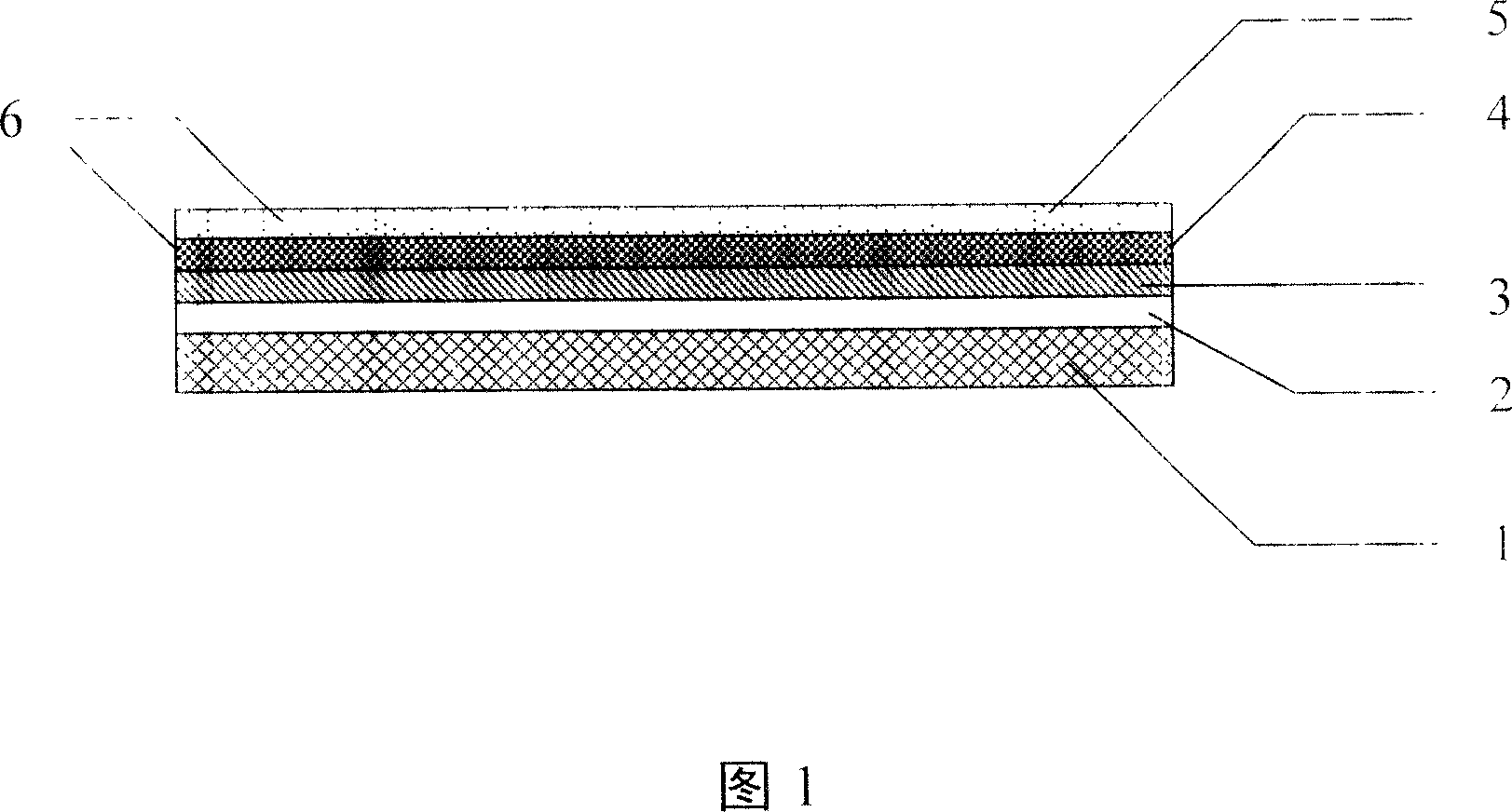

[0015] This embodiment produces the internal printing type vacuum aluminized transfer paper as shown in the accompanying drawing, and the specific steps are as follows:

[0016] a. Coating: Use uncorona-treated polymer PET or OPP plastic light film as the base material. On the base material, use coating equipment to coat a layer of polymer resin material evenly and appropriately, such as cellulose Resin or other resins, after being dried and solidified, form a layer of transparent surface coating 5 with peelable properties, the thickness of which is 0.5 μm to 1.5 μm;

[0017] b. Printing: use coating printing equipment to print characters or patterns on the surface of the coated transparent surface coating 5 to produce a printing layer 4 pasted on the transparent surface coating 5 to form a surface layer 6;

[0018] c. Aluminum plating: on the surface of the surface layer 6 printed with the printing layer 4, apply the vacuum aluminum plating technology to carry out aluminum pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com