Preparation method of polyester for environment-friendly antimony-free film

An environmentally friendly, polyester technology, which is applied in the field of polyester film preparation using liquid titanium catalysts and a certain amount of additives, can solve the problem of inability to use titanium catalysts, unstable process conditions and parameters, and unqualified performance. problem, to achieve the effect of improved performance, simple modulation method, and improved L value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

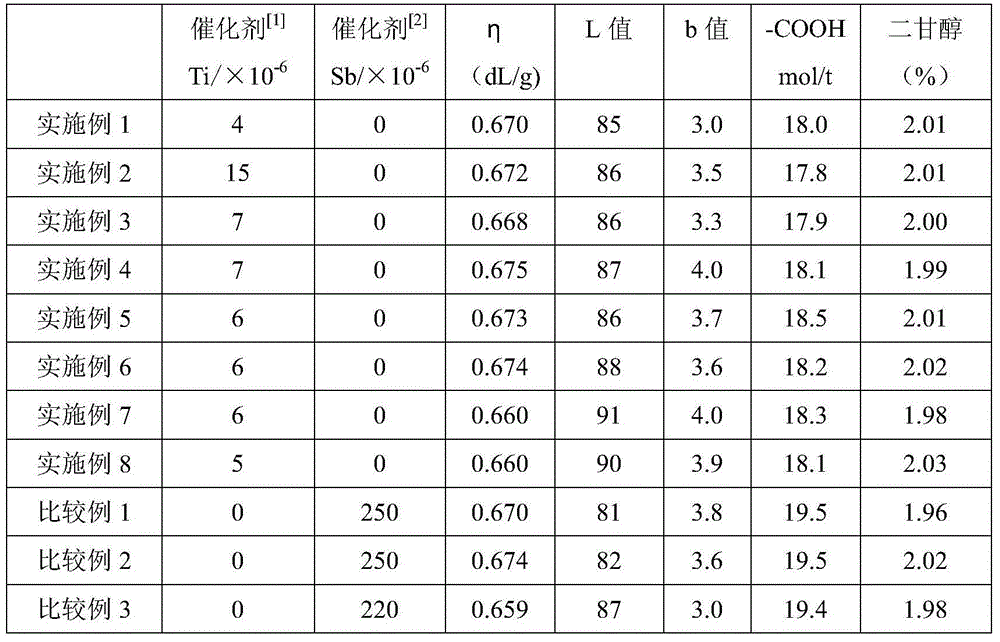

Examples

Embodiment 1

[0039] (A) A 2L stainless steel reactor was used to synthesize PET slices for membranes. Mix 500g terephthalic acid (PTA) and 260g ethylene glycol (EG) evenly, add liquid titanium catalyst TY-1, 4×10 -6 (Based on the content of the atomic mass of titanium in the total weight of the polyester produced) It can also be based on the output of theoretical products or the input amount of raw materials. The esterification reaction was carried out at 220°C under a pressure of 0.1 MPa, and the reaction time was 4 hours;

[0040] (B) After the end of the esterification reaction, start vacuuming for pre-condensation reaction, the reaction temperature is 240°C, the reaction pressure is an absolute pressure of 101kPa and gradually decreases to 600Pa, and the reaction time is 0.5 hours

[0041] (C) The final polycondensation reaction was carried out at 270°C and a pressure of 50 Pa. After 120 minutes of reaction time, polyester chips with an intrinsic viscosity of 0.670, an L value of 85, an...

Embodiment 2

[0043] (A) A 2L stainless steel reactor was used to synthesize PET slices for membranes. Mix 500g PTA and 260g EG evenly, add titanium catalyst TY-1, 15×10 -6 (Based on the content of titanium atomic mass in the total weight of the polyester produced), no other additives are added. The esterification reaction was carried out at 270°C under a pressure of 0.3 MPa, and the reaction time was 1 hour;

[0044] (B) After the esterification reaction is finished, start vacuuming to carry out the pre-condensation reaction, the reaction temperature is 270 ° C, the reaction pressure is an absolute pressure of 101kPa and gradually drops to 600Pa, and the time is 1 hour;

[0045] (C) The final polycondensation reaction was carried out at 280°C and a pressure of 100 Pa. After a reaction time of 60 minutes, polyester chips with an intrinsic viscosity of 0.672, an L value of 86, and a b value of 3.5 were obtained.

Embodiment 3

[0047] (A) A 2L stainless steel reactor was used to synthesize PET slices for membranes. Mix 500g of PTA and 260g of EG evenly, carry out esterification reaction at 250°C and a pressure of 0.2MPa, and the reaction time is 2.5 hours;

[0048] (B) After the esterification reaction, add titanium catalyst 7×10 -6 (Based on the content of the titanium atomic mass in the total weight of the polyester produced), add the auxiliary agent silicon dioxide 3000×10 -6 , Magnesium acetate 3000×10 -6 , (according to the content in the total weight of the polyester produced), after stirring evenly, start vacuuming to carry out the pre-condensation reaction, the pre-condensation reaction temperature is 270 ° C, the reaction pressure is an absolute pressure of 101kPa gradually reduced to 600Pa, time for 45 minutes;

[0049] (C) The final polycondensation reaction was carried out at 275°C and a pressure of 70 Pa. After a reaction time of 105 minutes, polyester chips with an intrinsic viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com